Fabrication

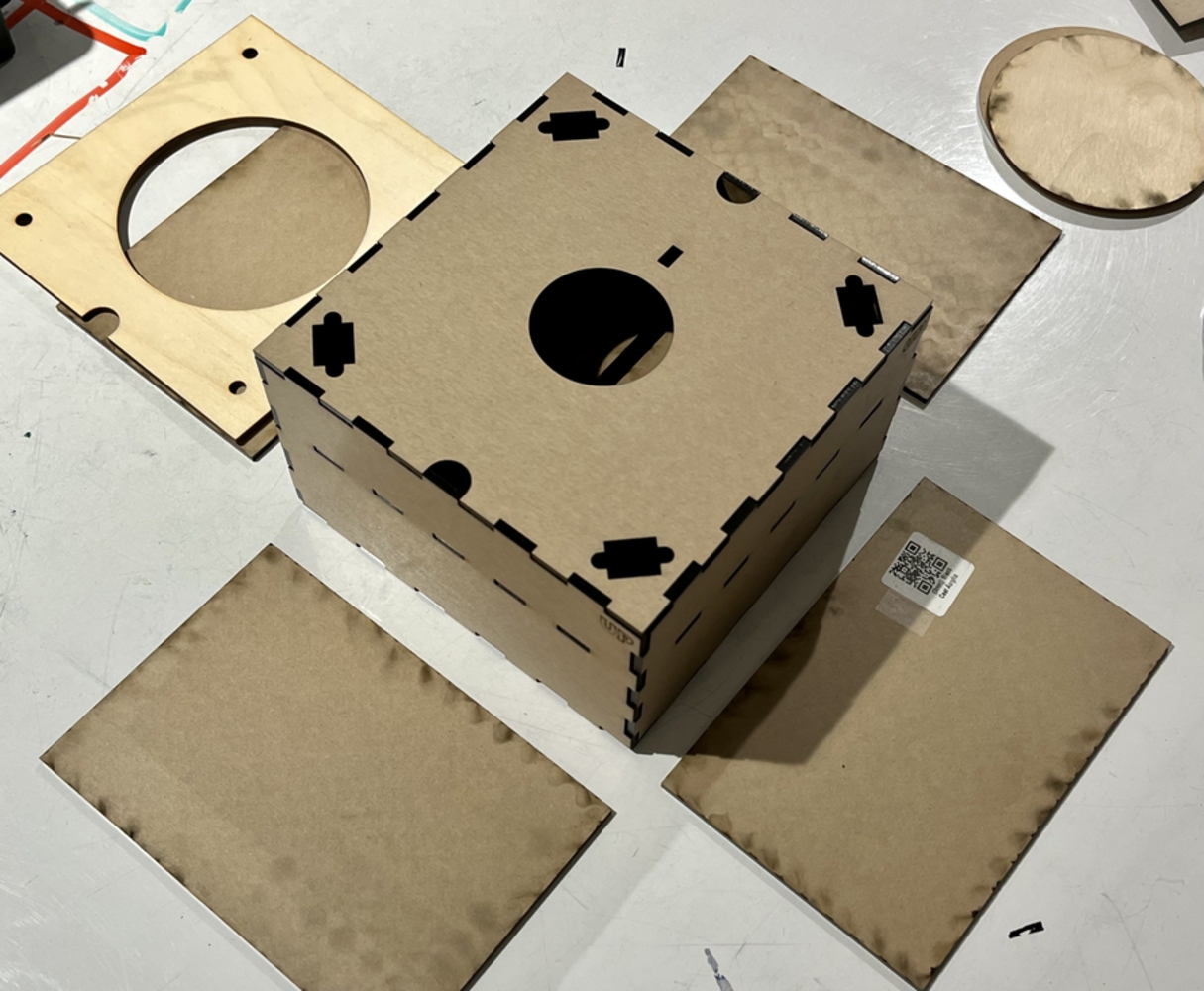

Assembly of the device is primarily composed of two parts: (1) the Primary housing of the lamp was constructed using laser-cut panels of plexiglass, while (2) the user interface is built with plywood panels to maintain the overall generic appearance and form.

Laser cutting serves as the primary method of fabrication for custom shapes and joinery of plexi glass panels, allowing rapid prototyping combined with a preliminary polished appearance of the project.

Technical Resources:

- Adafruit Arduino Code Library: Adafruit Industries · GitHub

- CMU IDEATE 3D Printing - SkyLab : 3D Printers – IDeATe Resources (cmu.edu)

- Non-Delay Coding Tutorial: Simple Delays, non Blocking & timer free

Bill of Materials:

- Micro Controller (Arduino Uno R3) (1ct)

- 16Bulbs LED light ring (1ct)

- LED light strip (1ft)

- Servo Motor (Amazon brand) (1ct)

- Proximity Sensor (Adafruit ANCL4730) (1ct)

- LCD Screen (Adafruit ST7789) (1ct)

- High-power LED light with heatsink (1ct)

- 3mmPlexiglass panel (1 sheet)

- 6mm Plywood panel (1 sheet)

Annotated Final Product:

content

Content Rating

Is this a good/useful/informative piece of content to include in the project? Have your say!

You must login before you can post a comment. .