Implementation

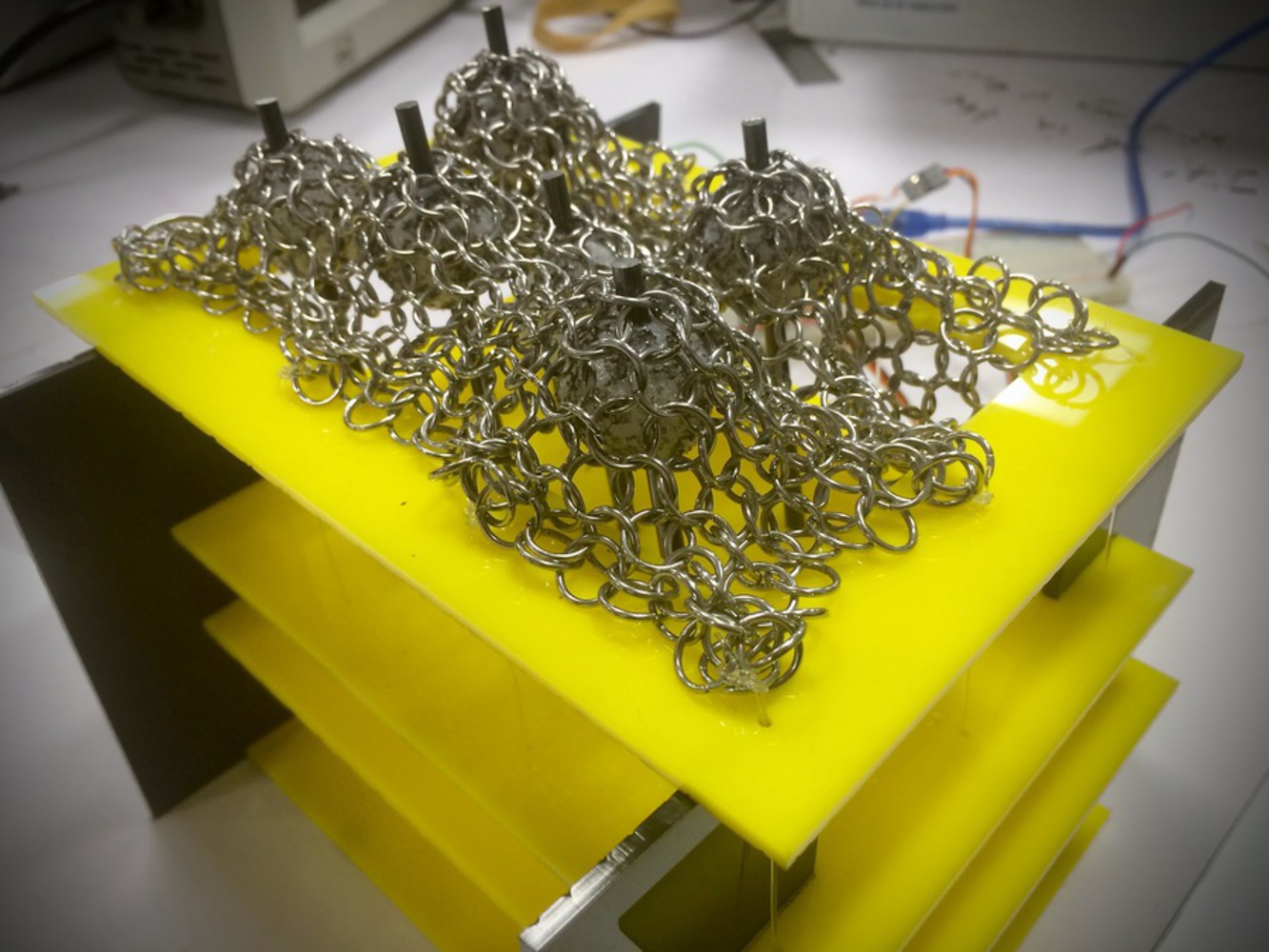

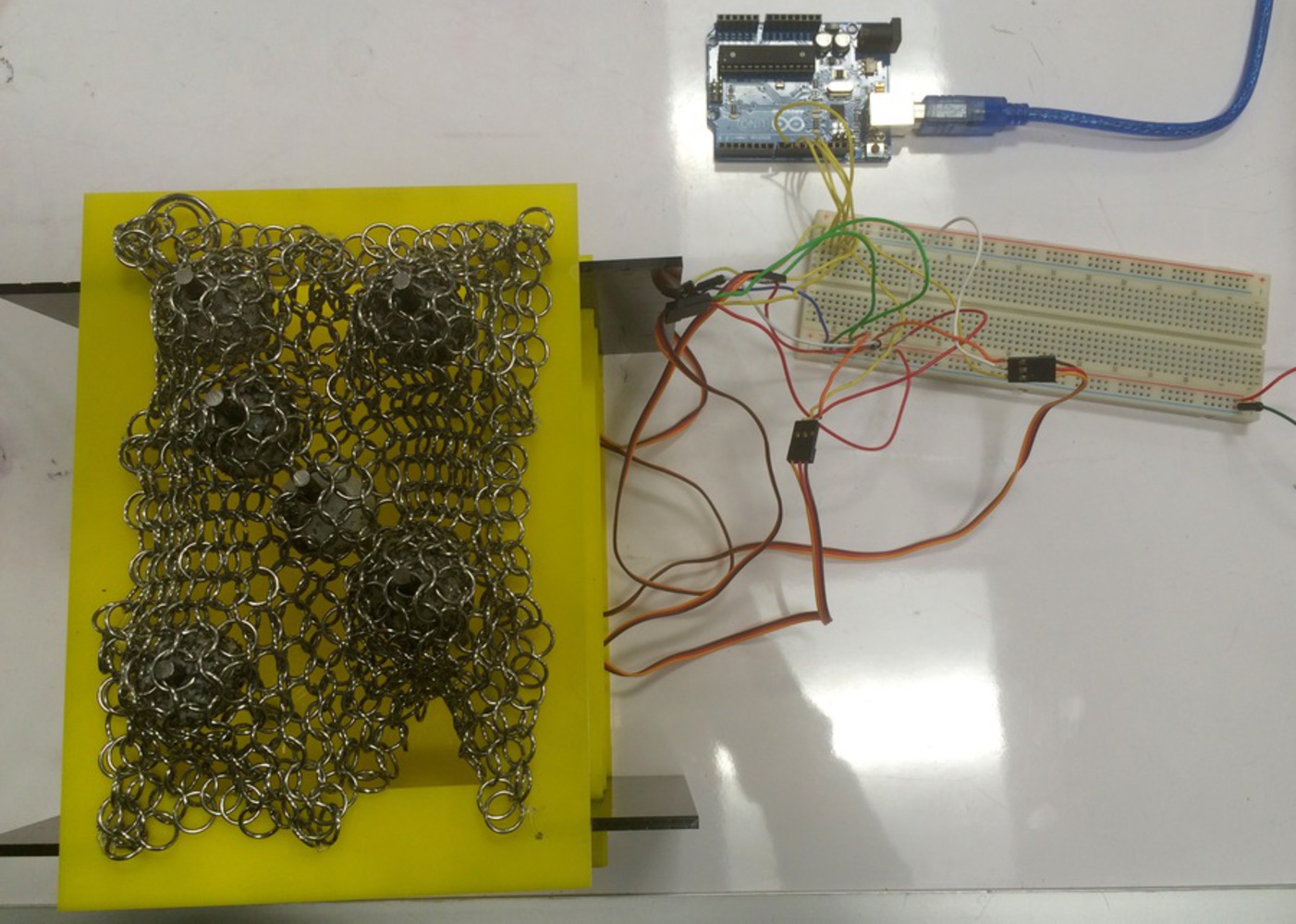

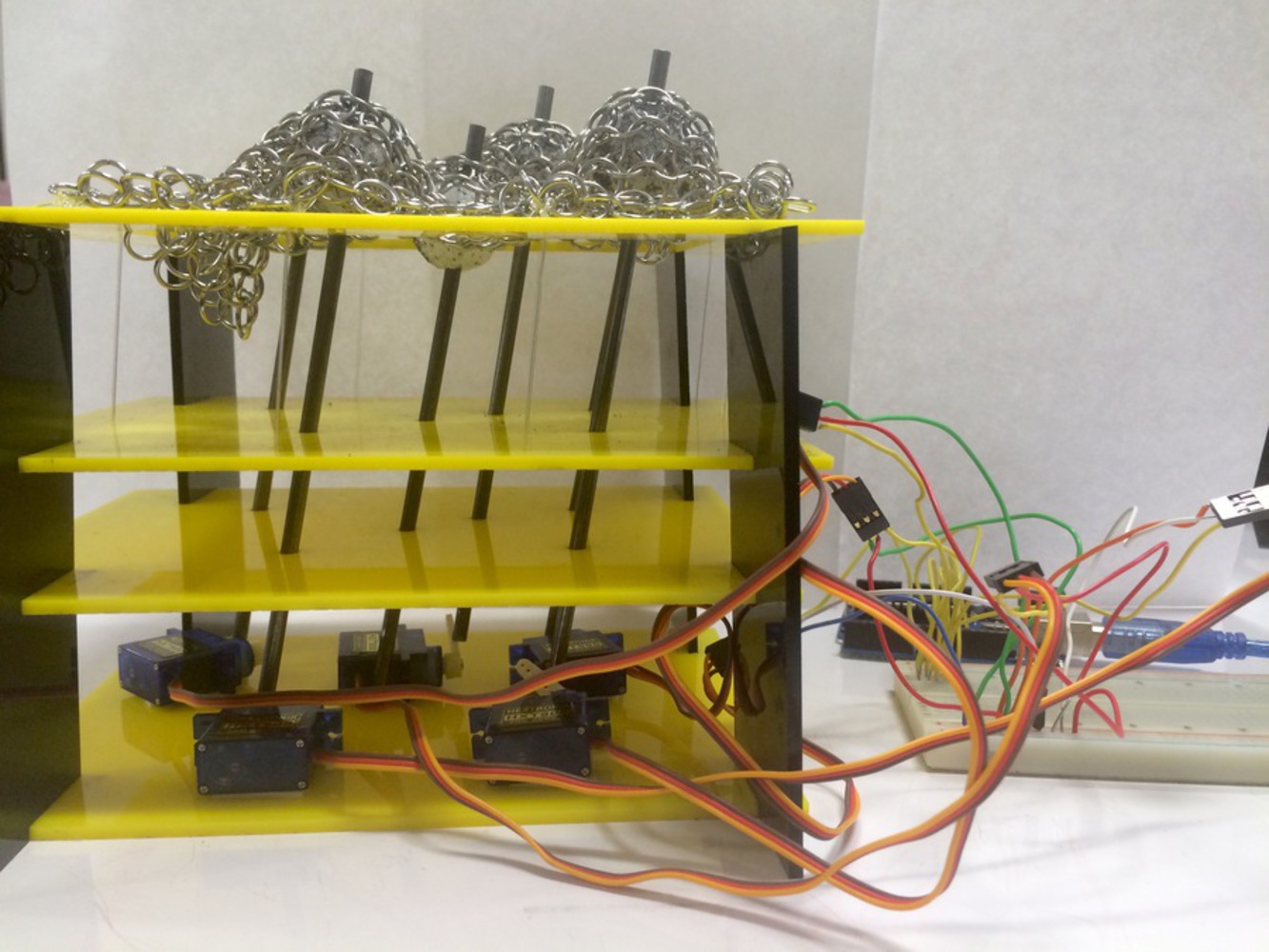

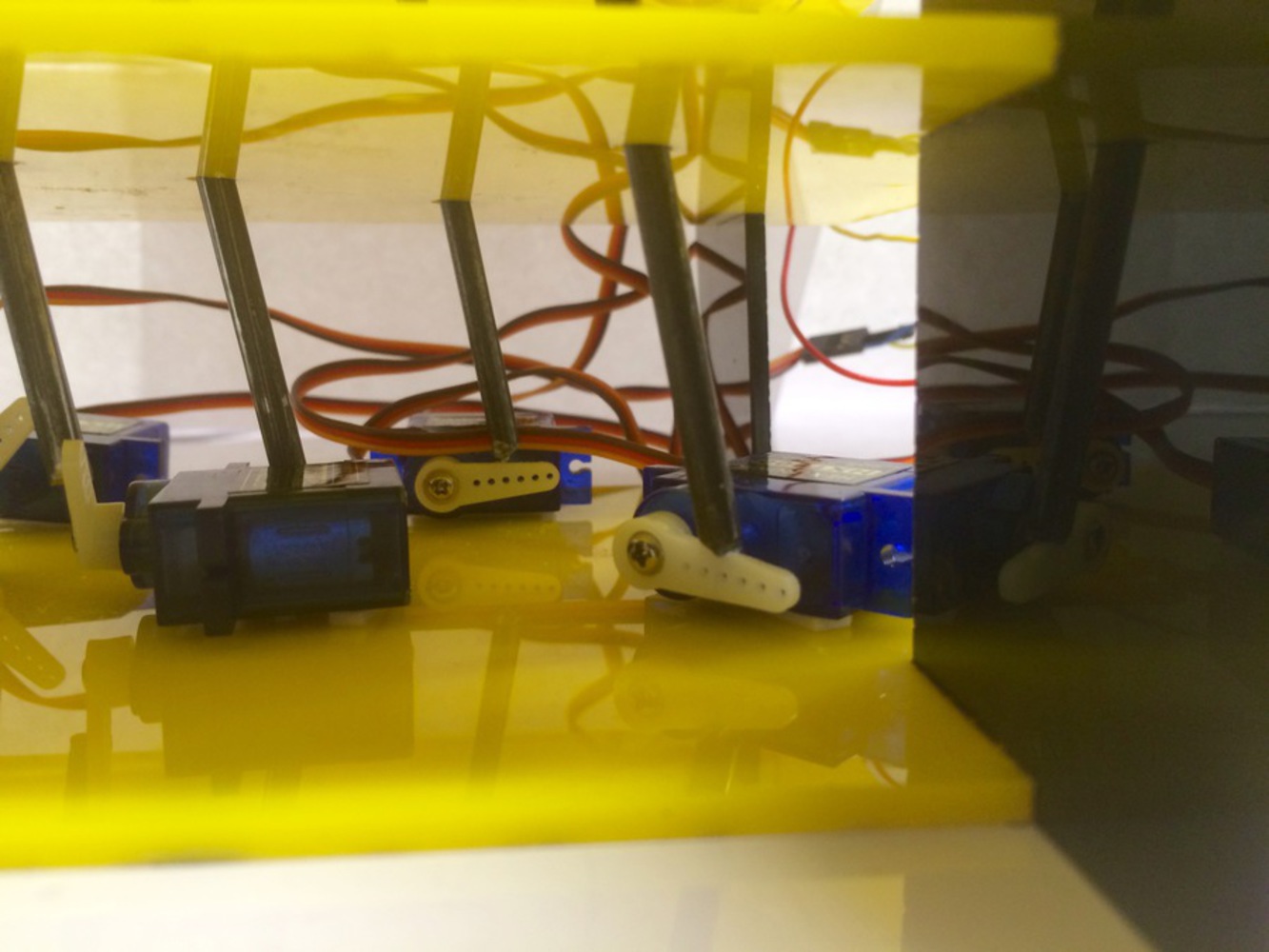

We started with chainmail because of it’s beauty and potential to become a facade. Facades generally allow interaction between the user and one side of the piece. This metal chainmail accompanied by piano wire and foam balls decorated to look metallic provided the “machine” of our project. This “machine” is the kinetic aspect of our project with servos acting as the actuator. As you can see the raw form of the wire to servo connection below, this reinforces the idea that mechanized systems are generally not glued together but rather an intelligent form of material friction.

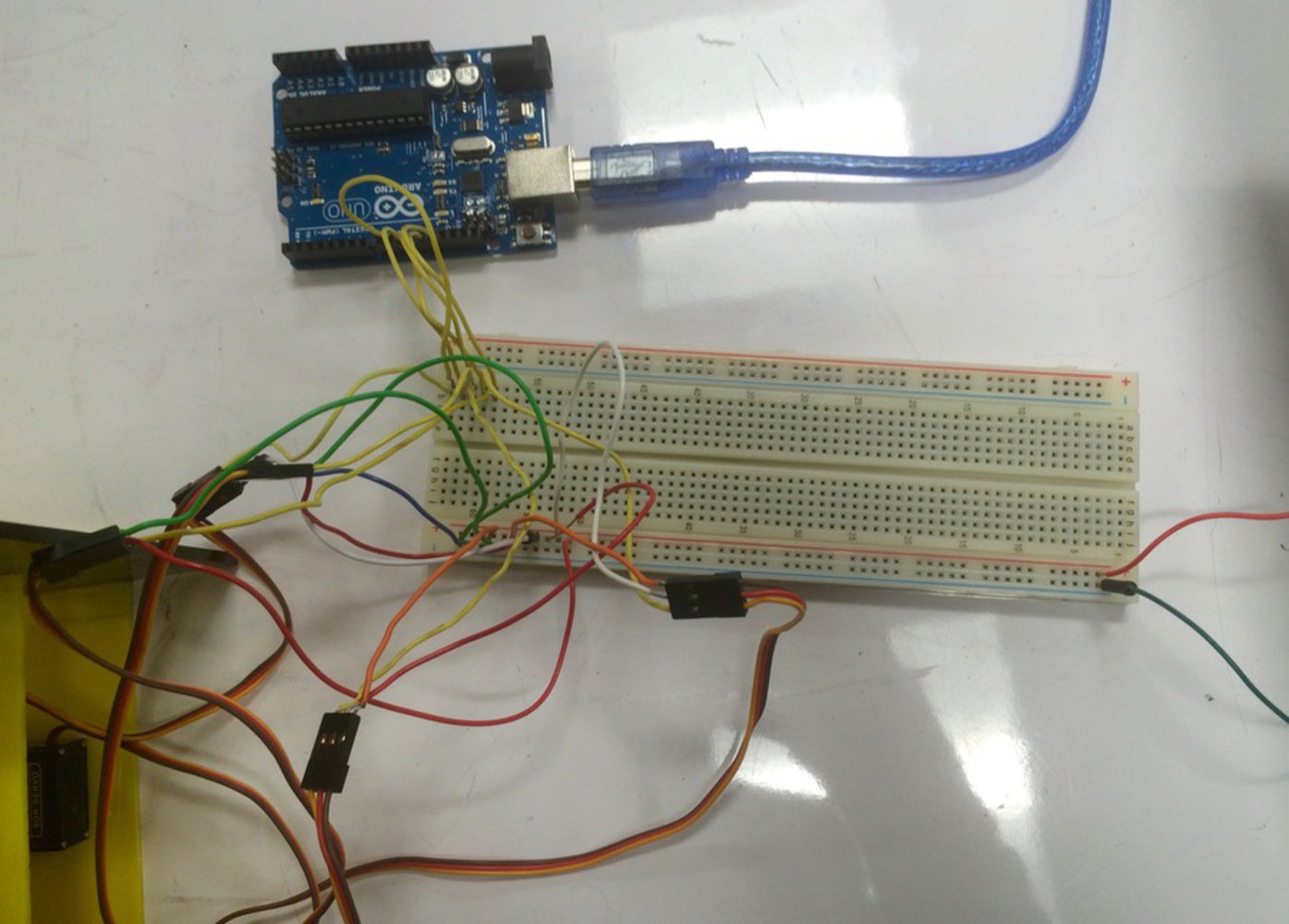

More specifically, the machine’s layers and supports were designed using CAD and lasercut. The layers were attached to the supports using Acrylic Glue and the piano wire was held in place by acrylic and foam balls. The chainmail was placed over the piano wire and secured using a string called “stretch magic”. The servos were secured using mounting tape and the piano wire rested on the servo arms. The piano wire and servo were not attached using a bonding agent, instead they rely on friction to hold them in place, while allowing freedom of motion at the joint when the servos as moving. The servos were controlled using an Arduino Uno to create the organic feeling to the inorganic machine, as shown in the video below. The Arduino code also contains other functions to give the machine other feelings (not demonstrated).