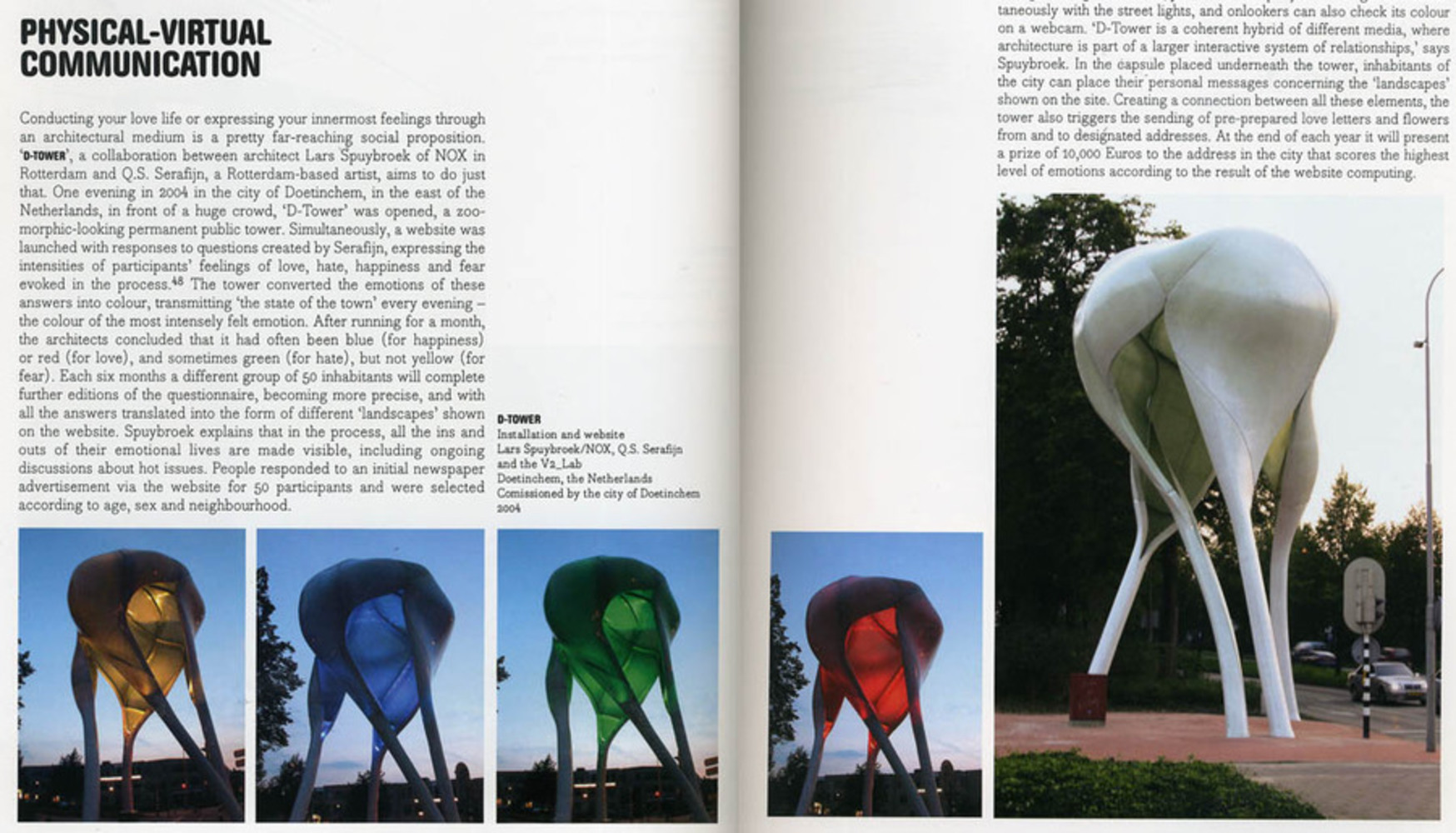

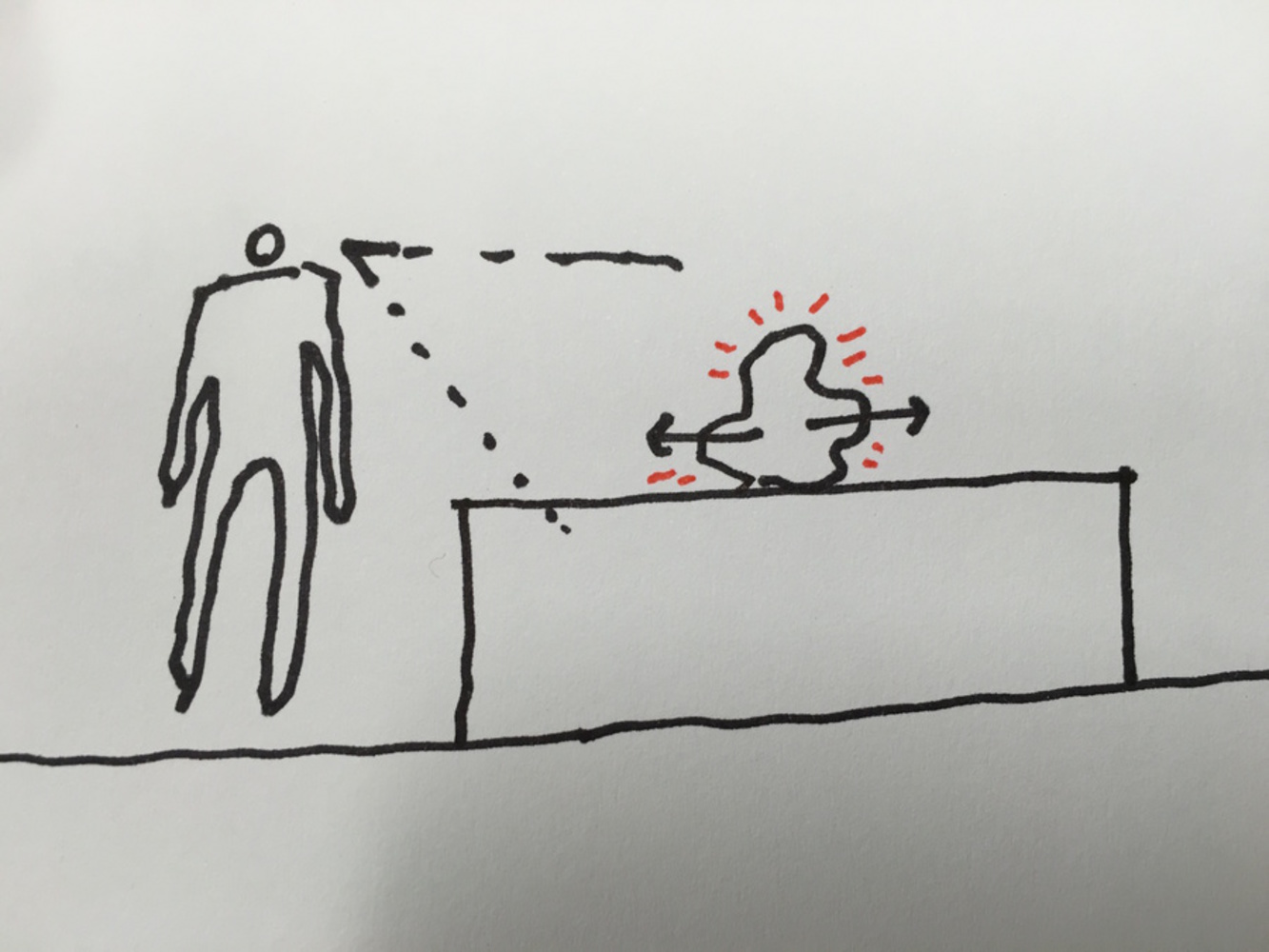

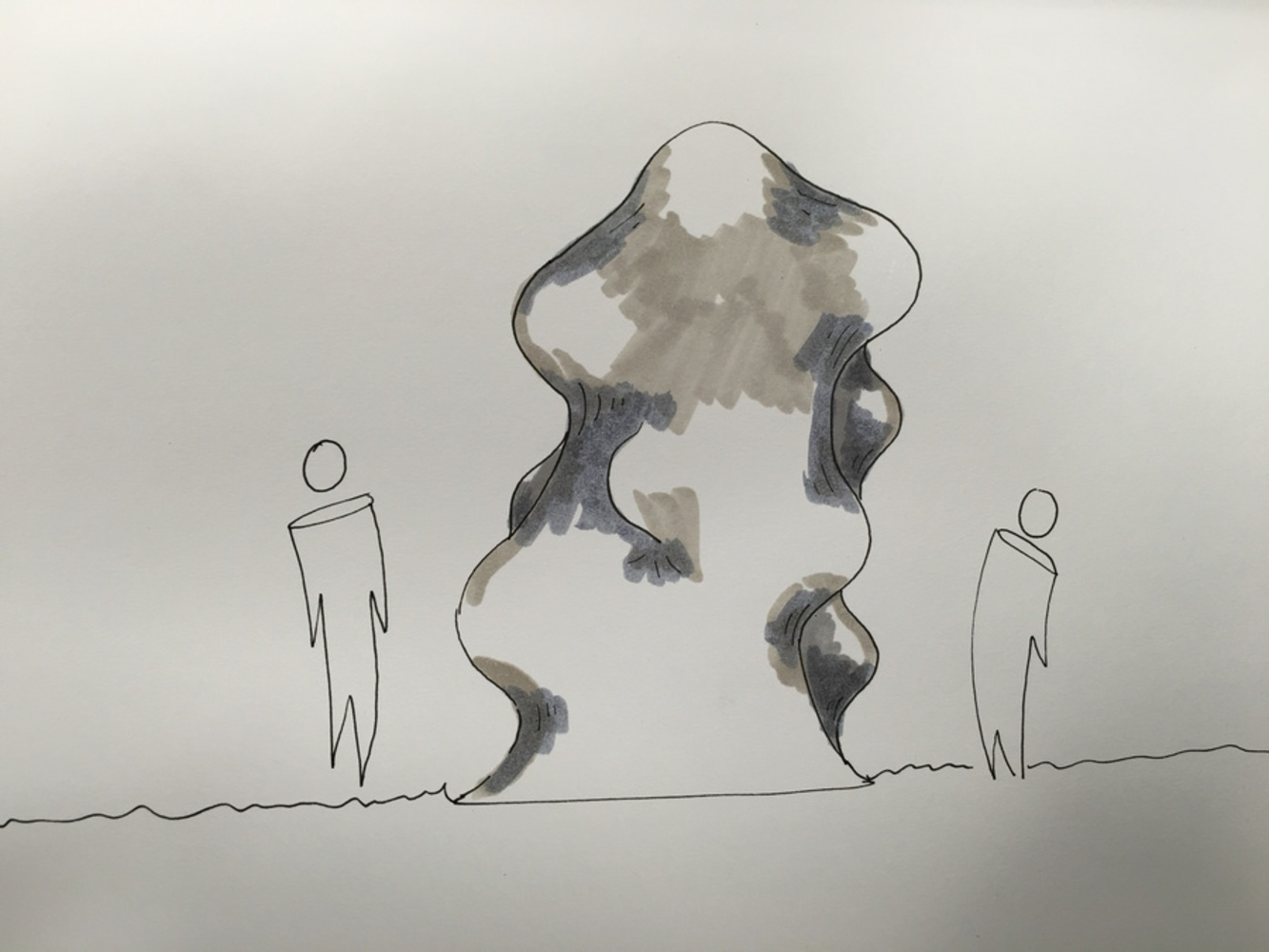

The Beating Blob mimics the muscular beating of the human heart. The sculptural arms inside The Beating Blob move faster as more people enter the Carnegie Mellon University fitness facilities.

Outcome

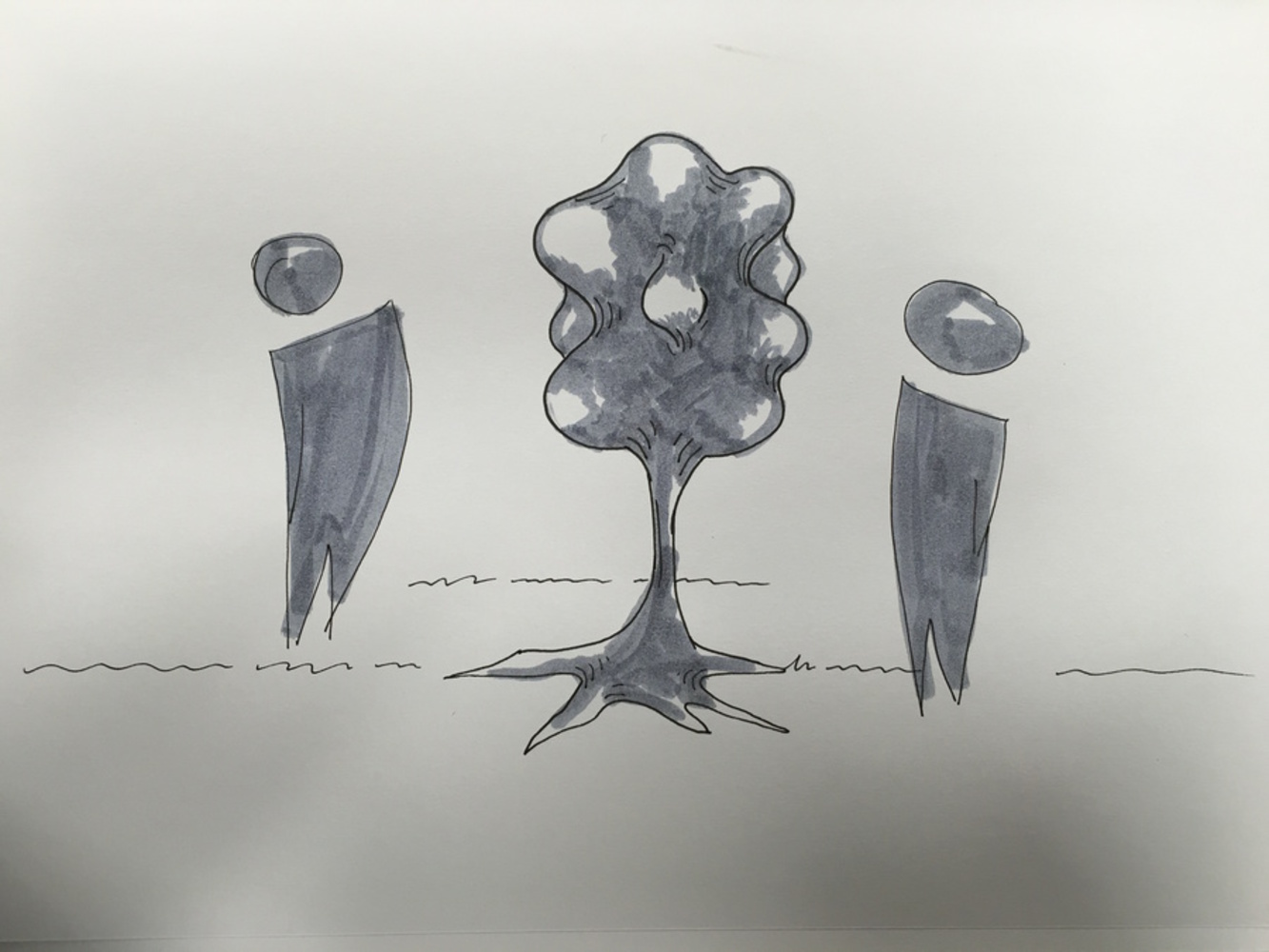

Designed to mimic the pulsing, flexing, and stretching of a muscle, The Beating Blob mimics the physical activity of the people in the space it represents. Rather than use light, sound, text, or other outputs to represent the number of people using the fitness facilities, we chose muscular-like movement as the most appropriate method of showing passersby how many people are using the gym.

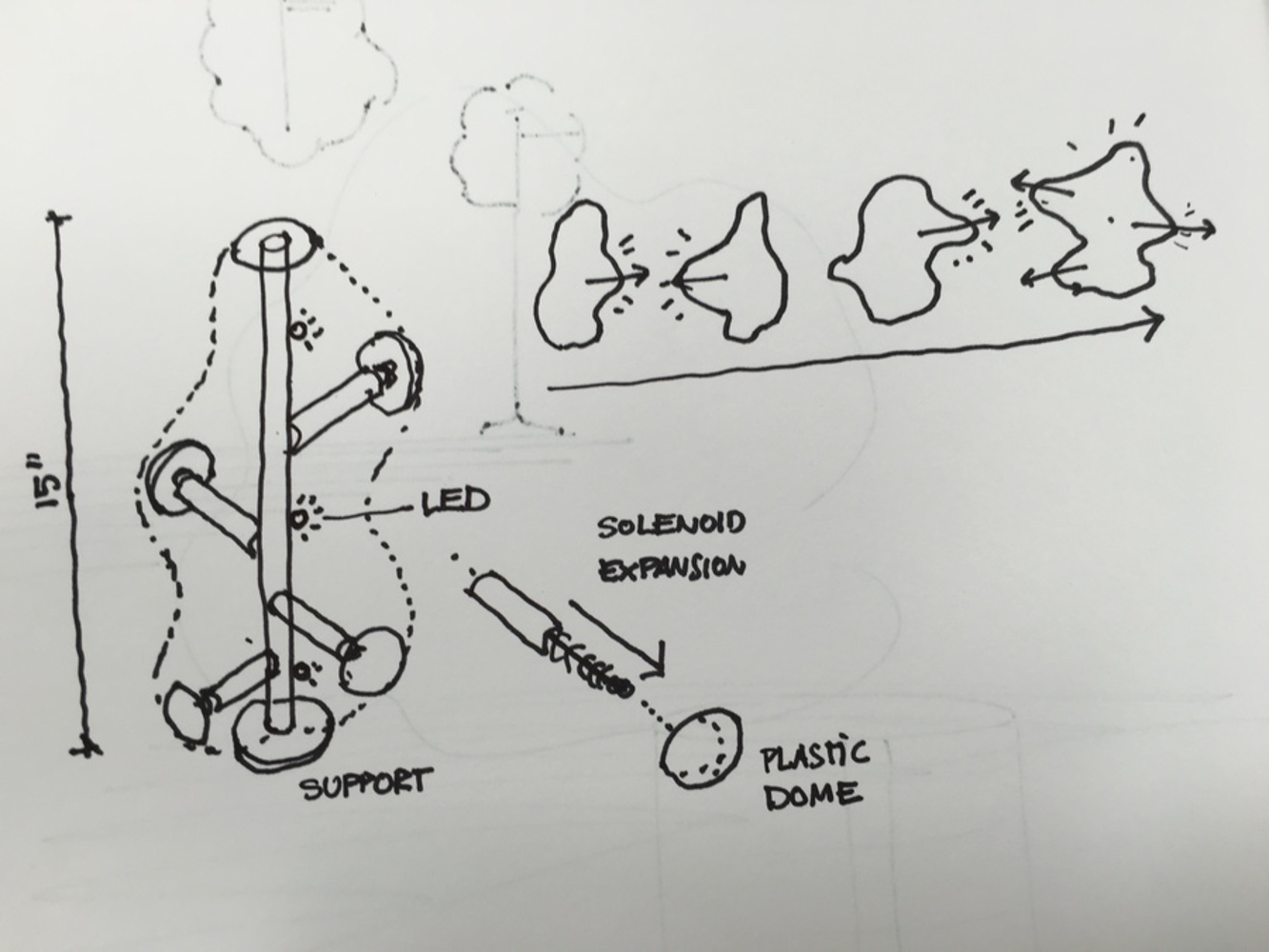

Early on we decided our peripheral display would have a beating and pulsing movement, but we were unsure of what form we wanted it to take. We considered a display that could stand on a table or take the form of a ceiling lamp or even be affixed as a series of moving tiles on the outside of a building.

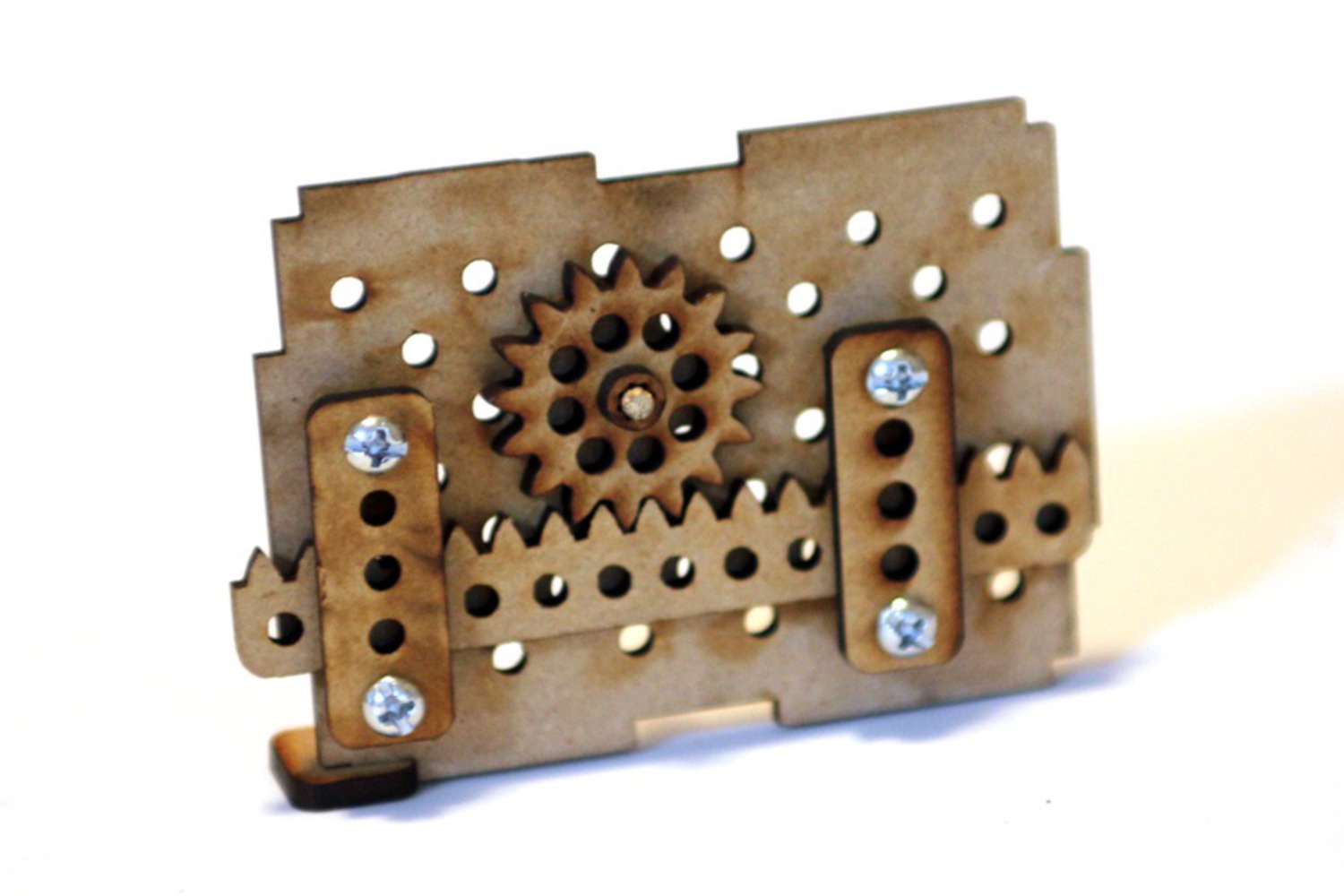

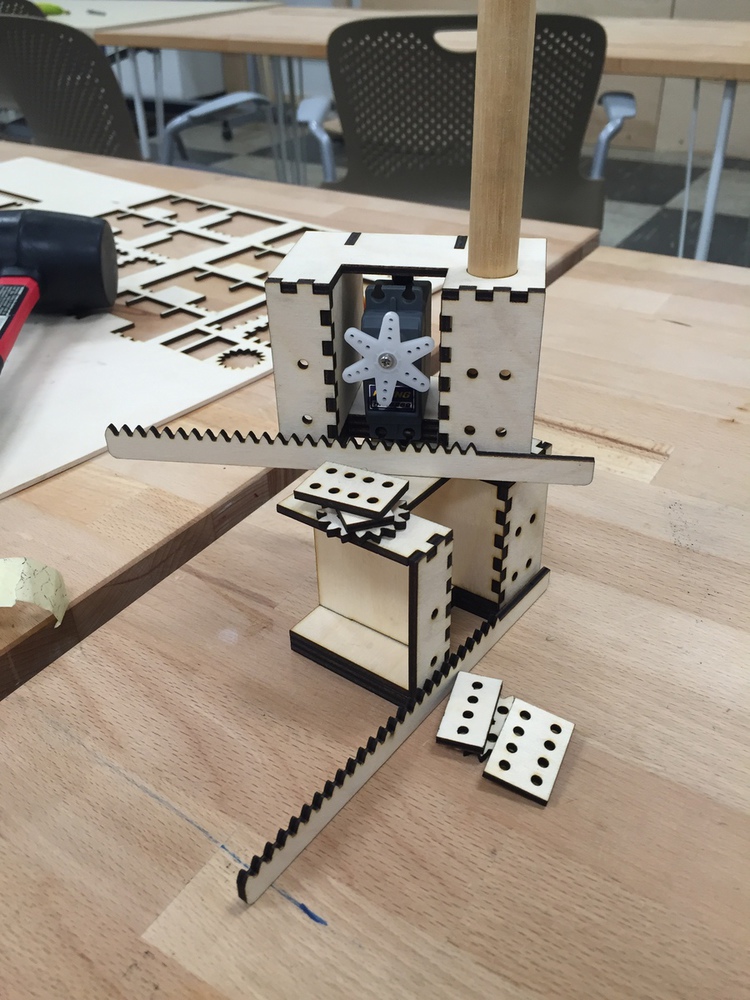

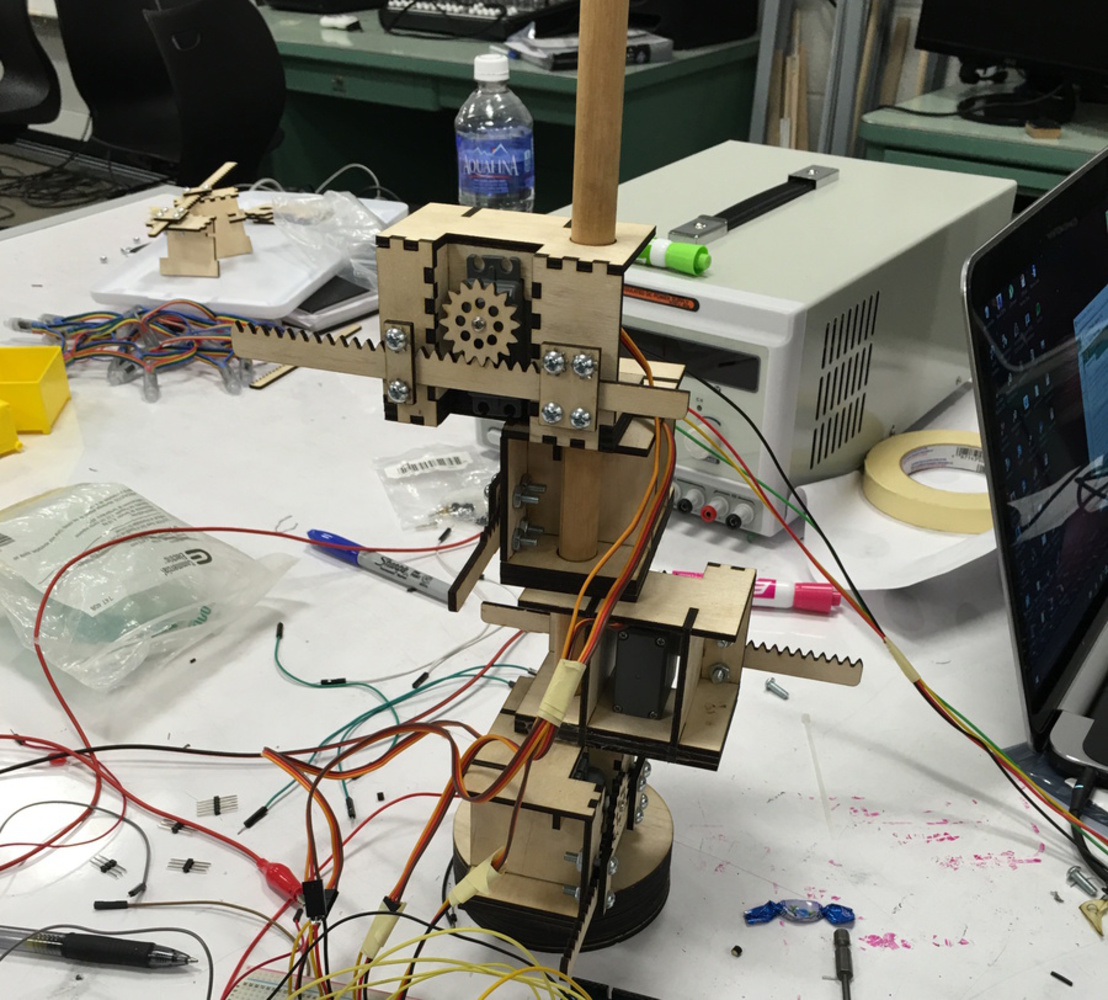

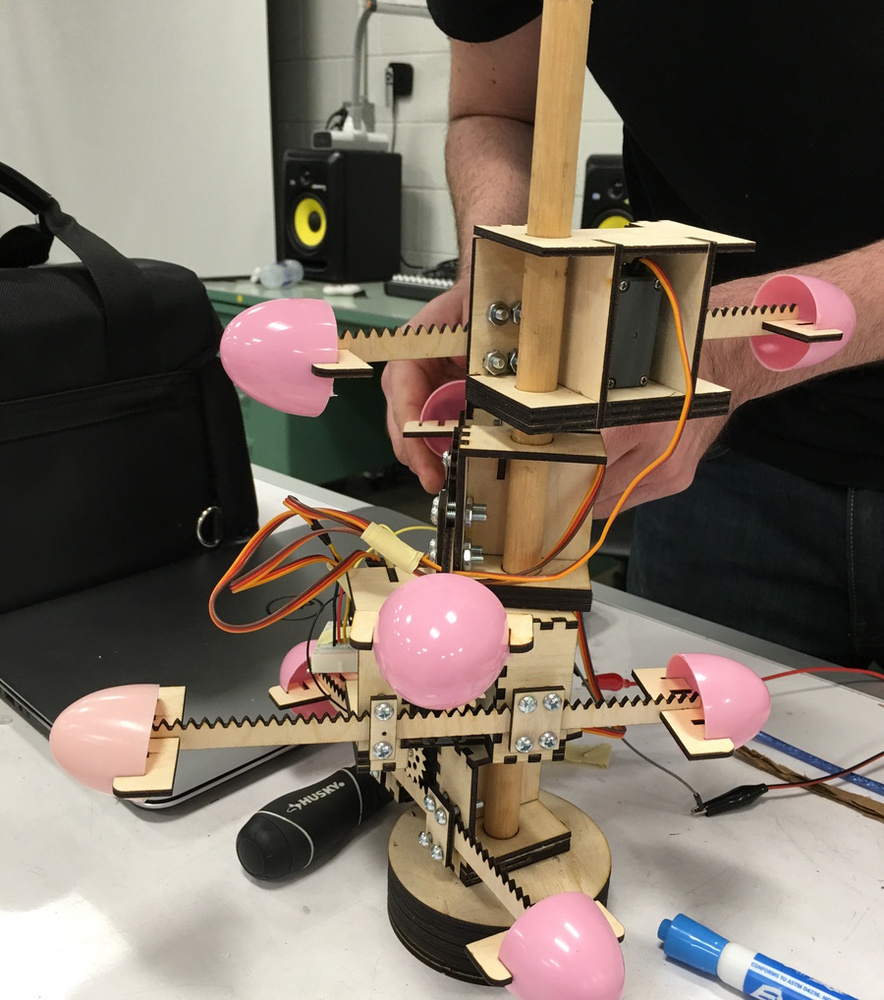

We first considered solenoids as the driver of our sculpture's movement. We quickly learned solenoids only allow control of the length of time between pulses, not the speed. We then considered using servo motors with customized pieces for translating movement of the servo into linear motion. We gained inspiration from the Automino modular construction kit (pictured above).

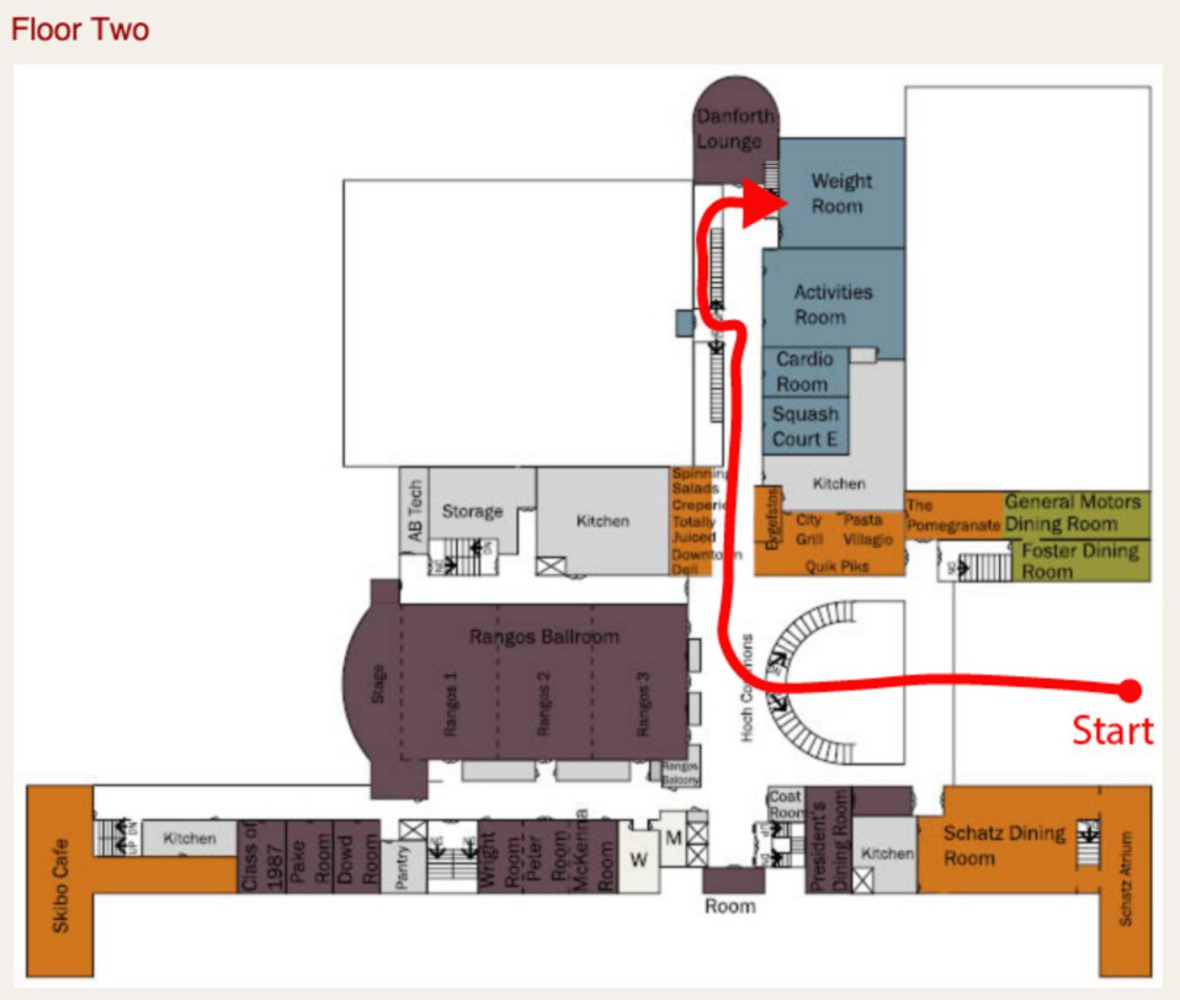

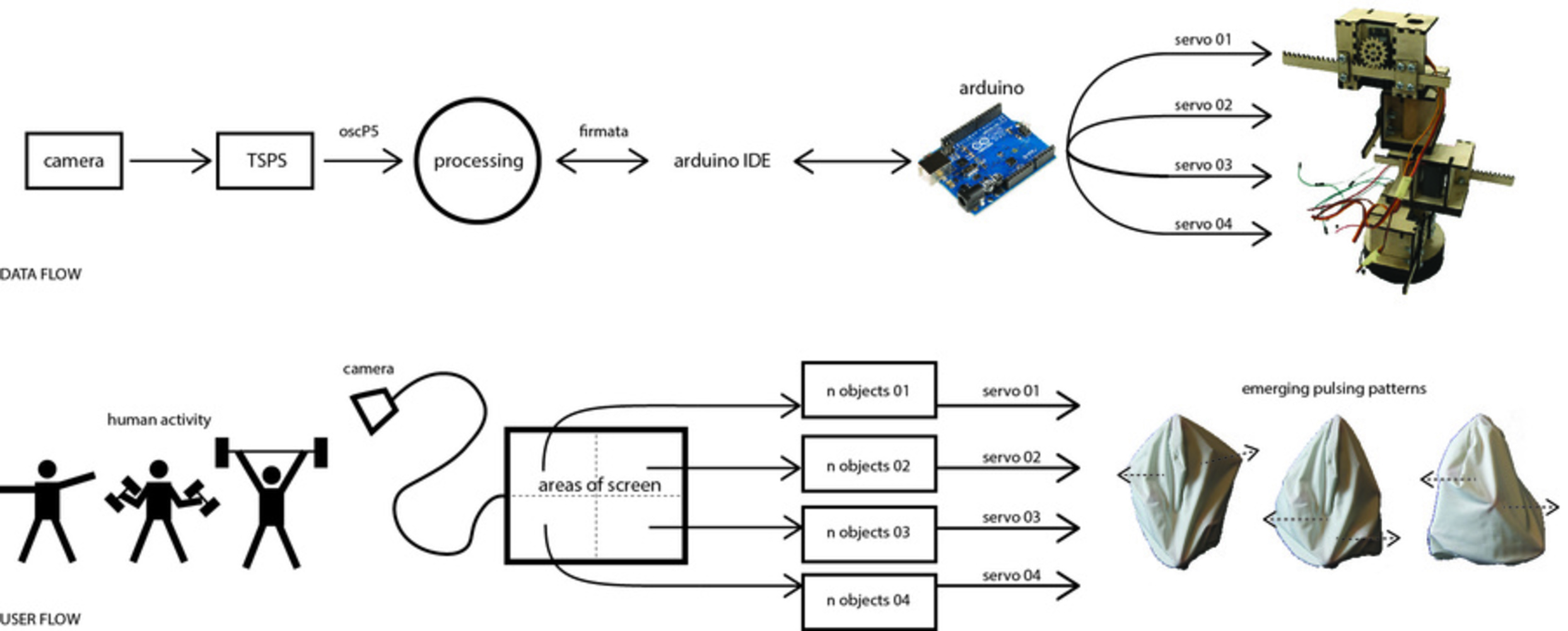

The data used by the sculpture is captured by a camera within the fitness facilities. We used a program called openTSPS to extract the number of people in each area of the gym. The areas of the gym were broken up into four quadrants, each quadrant mapping to an arm of the sculpture. We then wrote a program in Processing to translate the number of people in a specific quadrant into the speed of a the respective arm. As the number of people in a given area increases, the speed of the arm also increases.

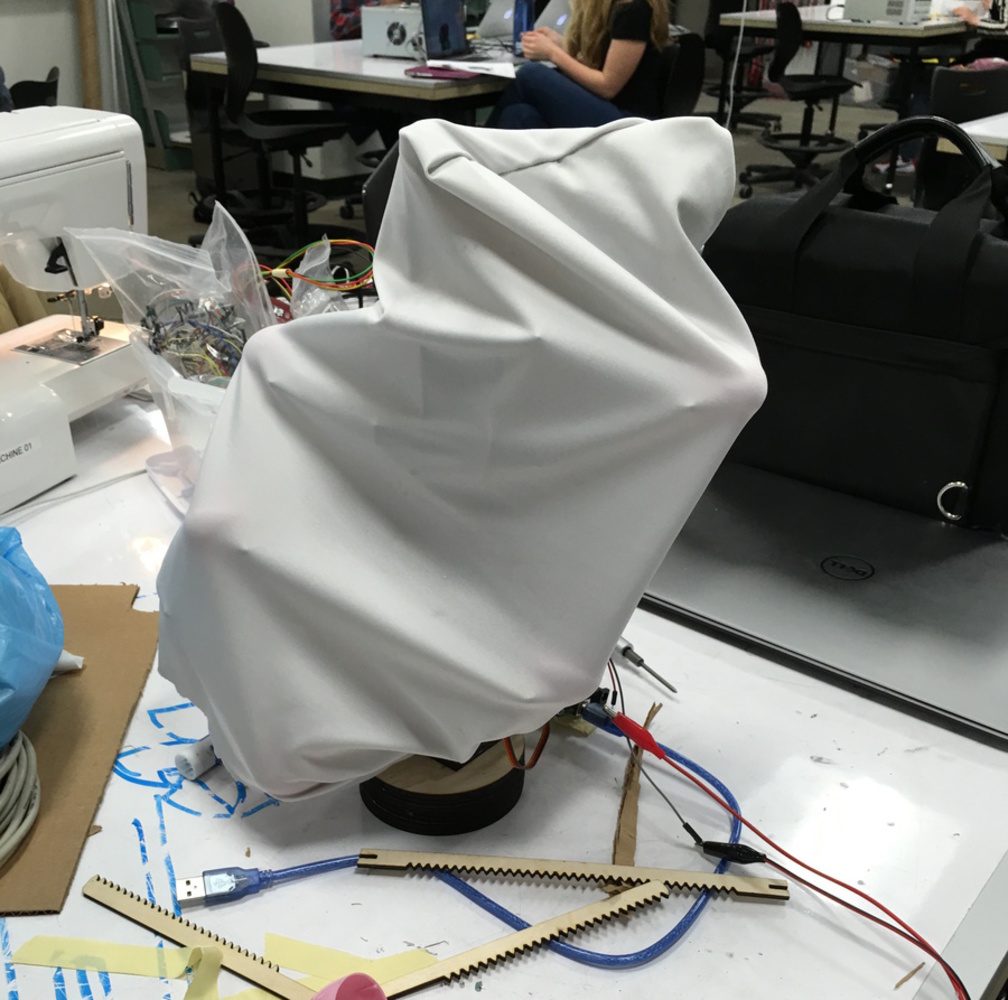

The final prototype needed some kind of cover to complete the appearance of a blob. Our intention was to have a very tight material that wrapped around the entire sculpture. We imagined a latex-like covering that wrapped around the sculpture like an air-tight, semi-transparent skin. We purchased a lycra fabric at a local reuse store and found that the lycra was too strong for the servo motors to push the arms through. The servos were not powerful enough to move the arms. We therefore had to make the lycra cover fairly loose. In further iterations, we would focus on transforming the bag-like covering into a tightly wrapped, flexible skin.

You can upload files of up to 20MB using this form.