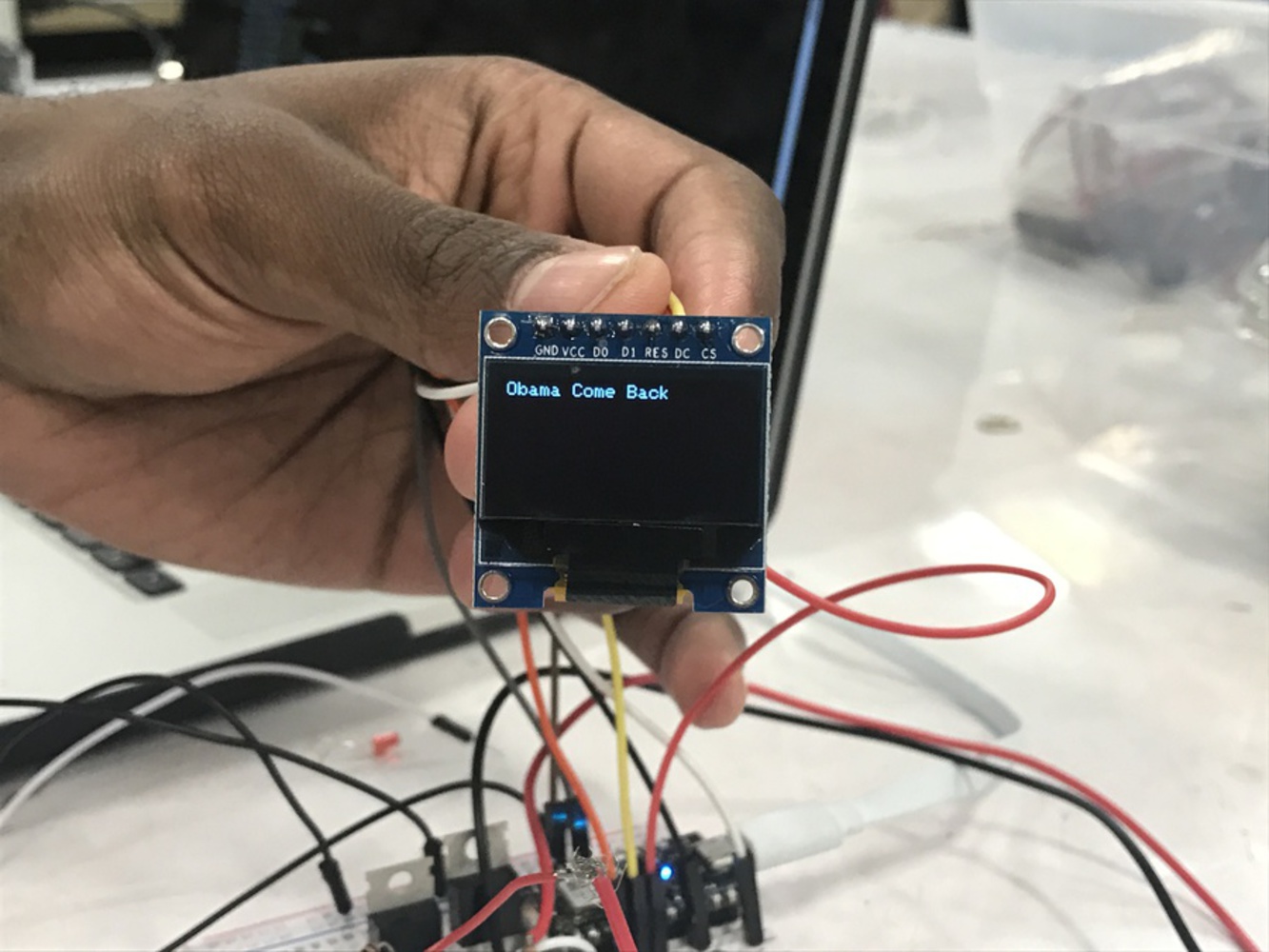

Intention

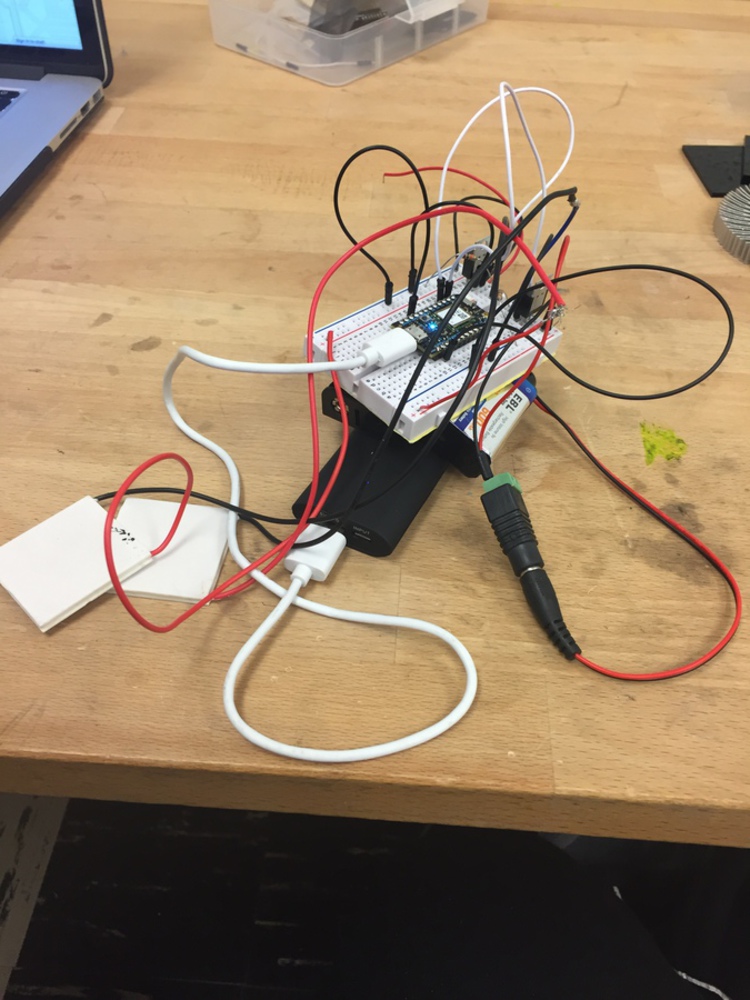

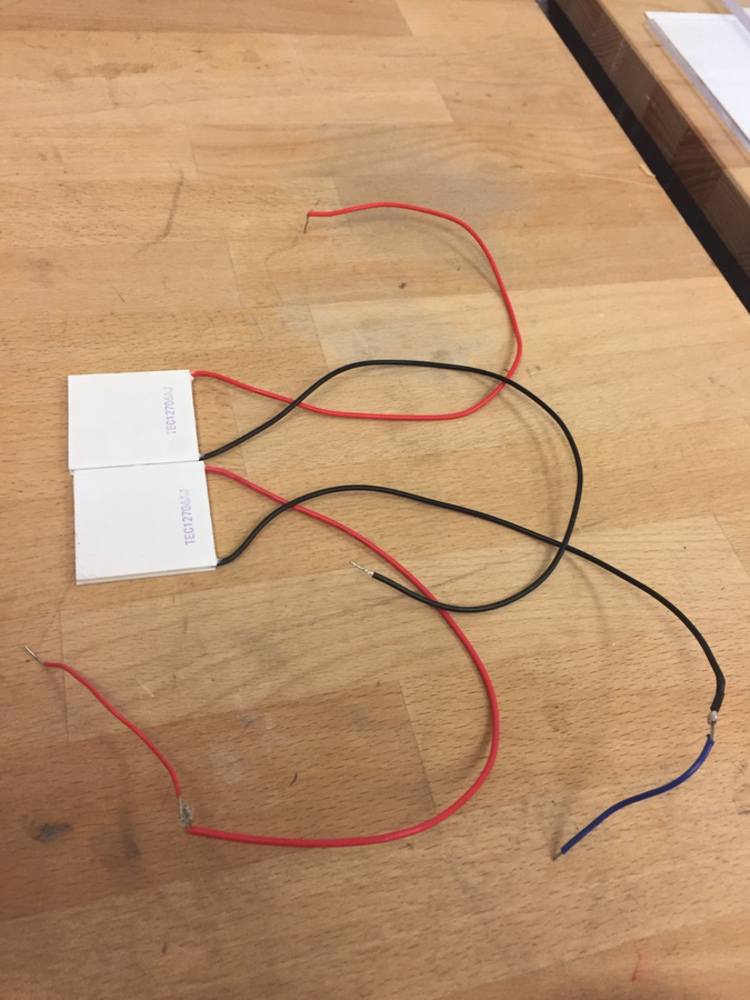

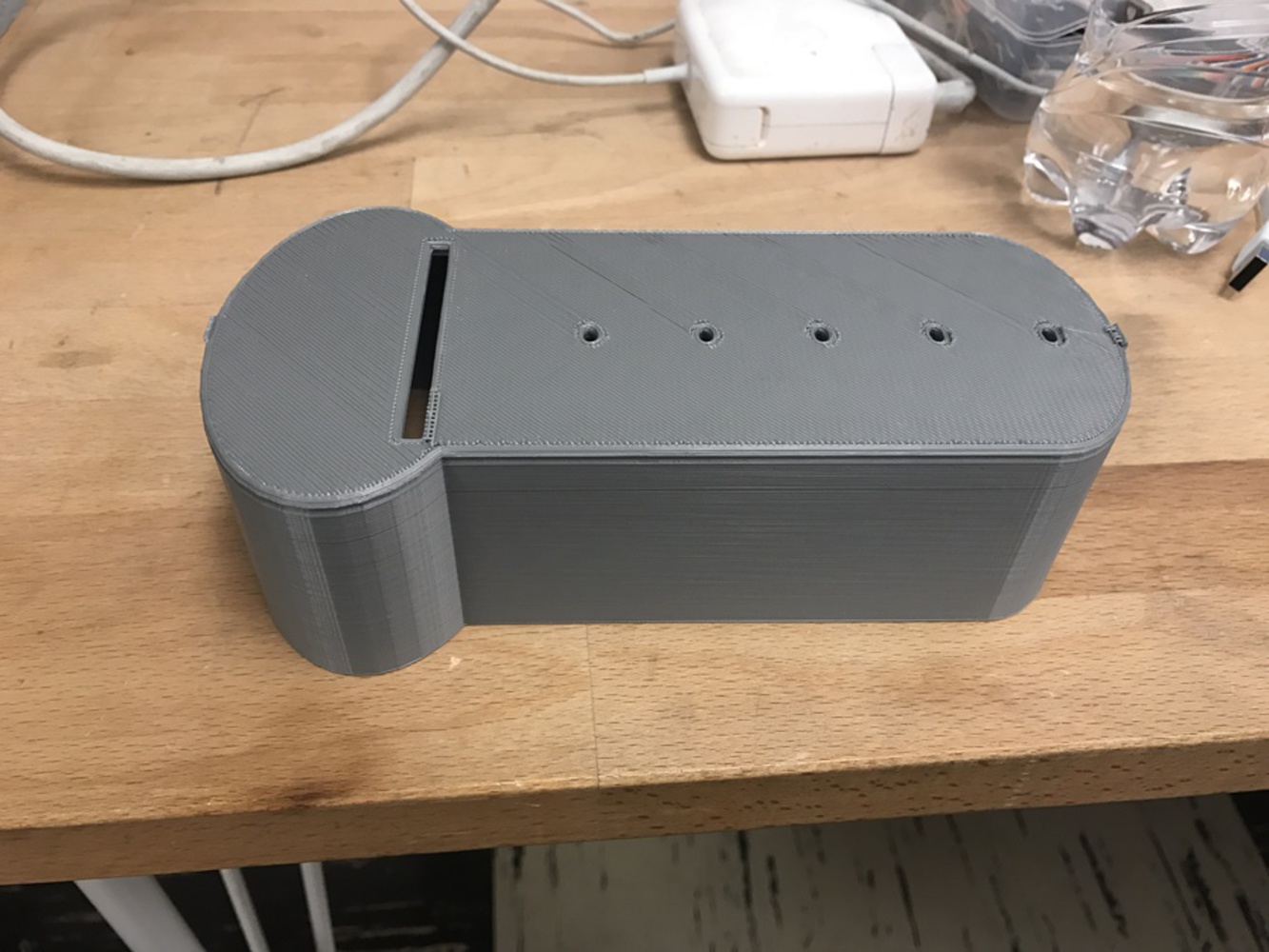

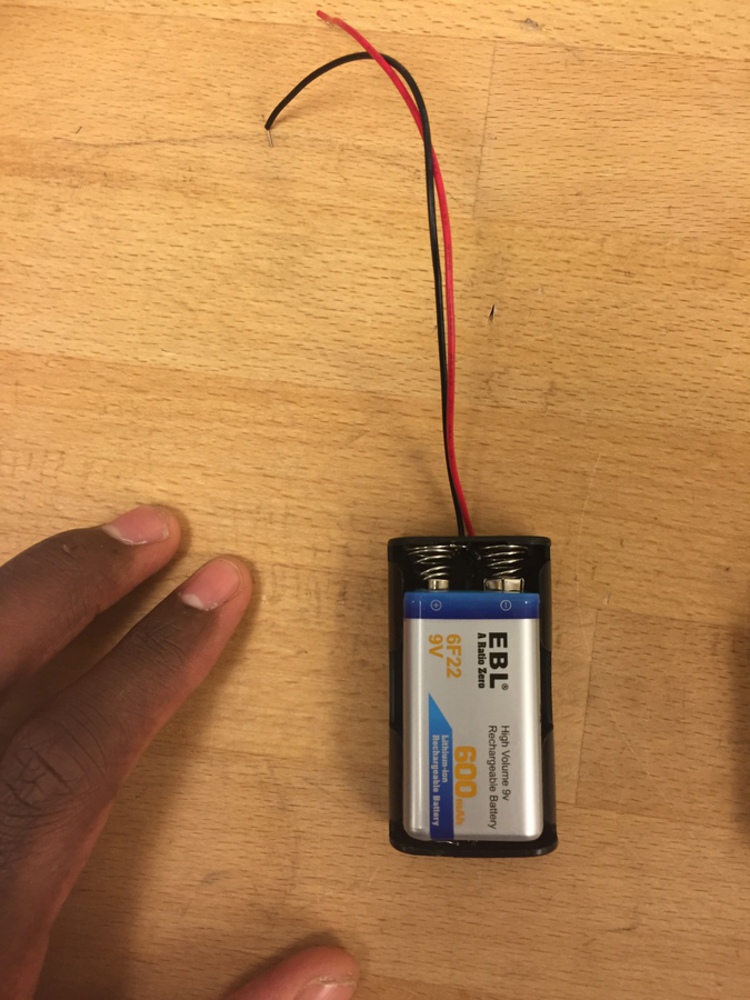

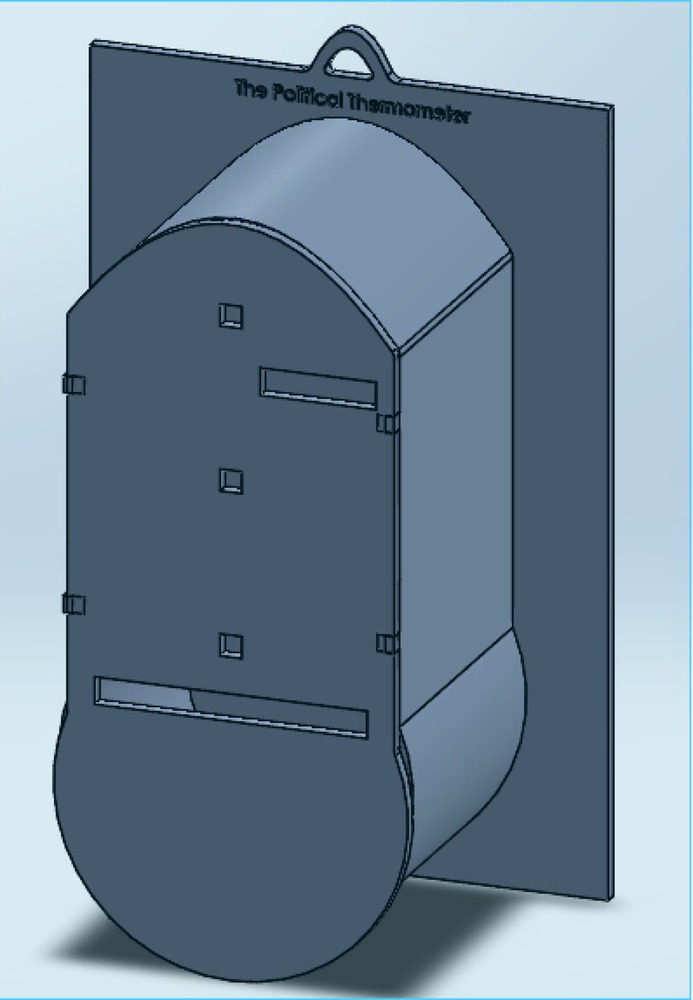

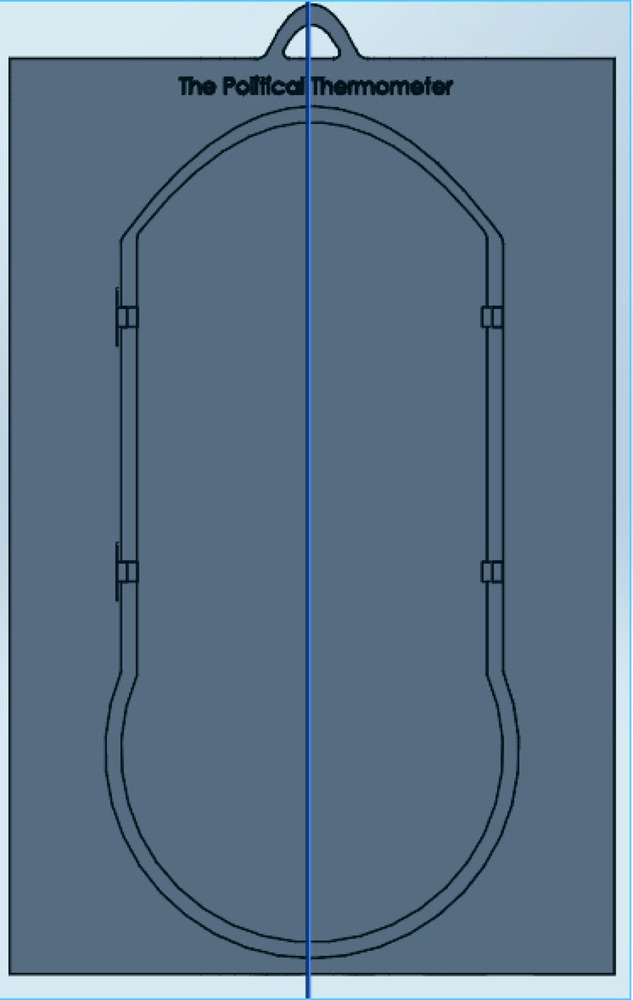

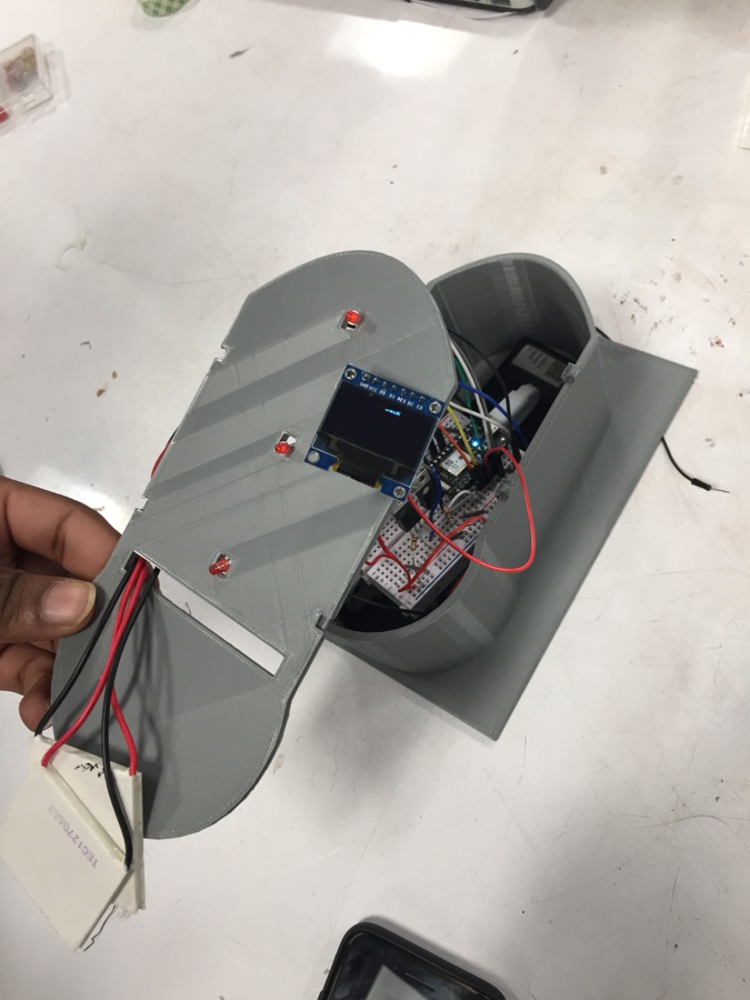

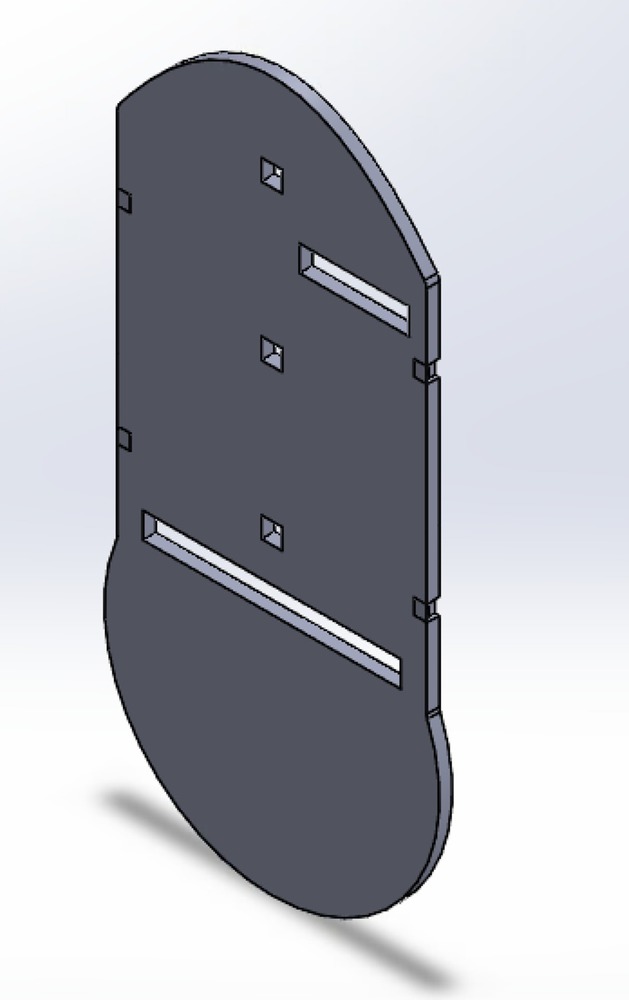

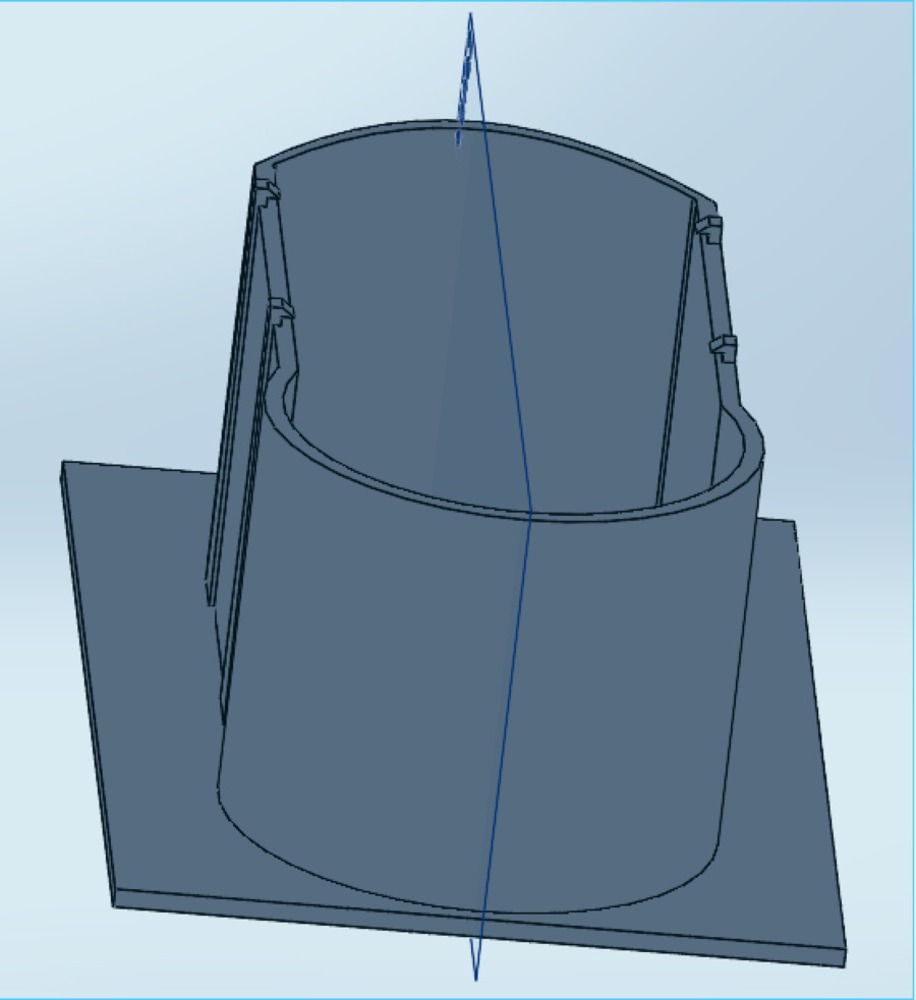

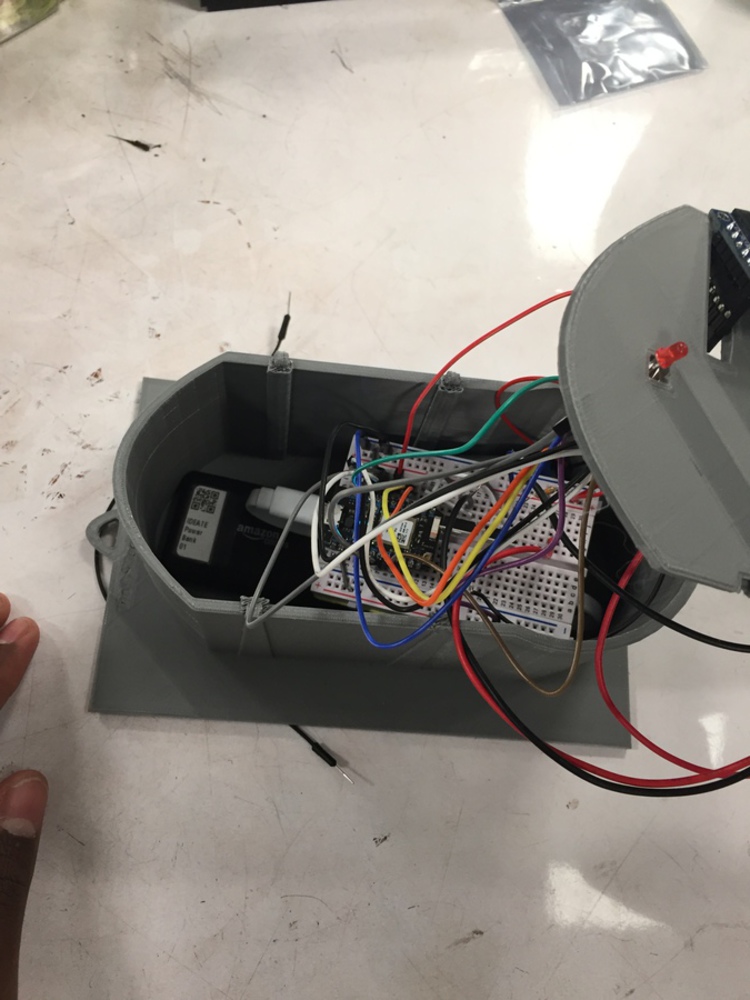

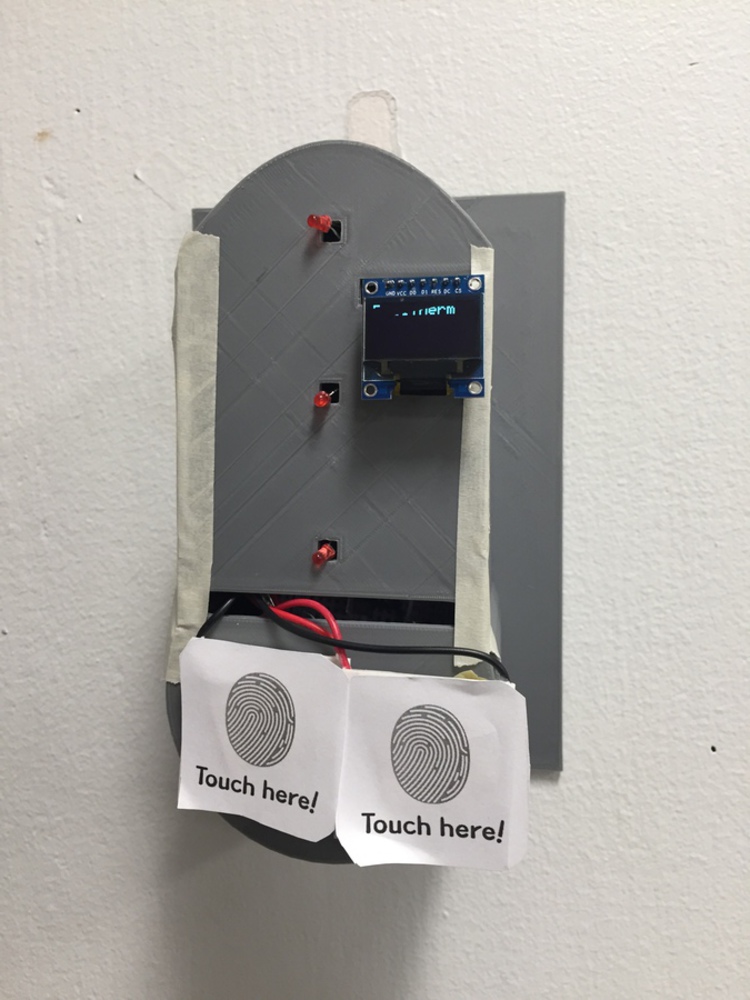

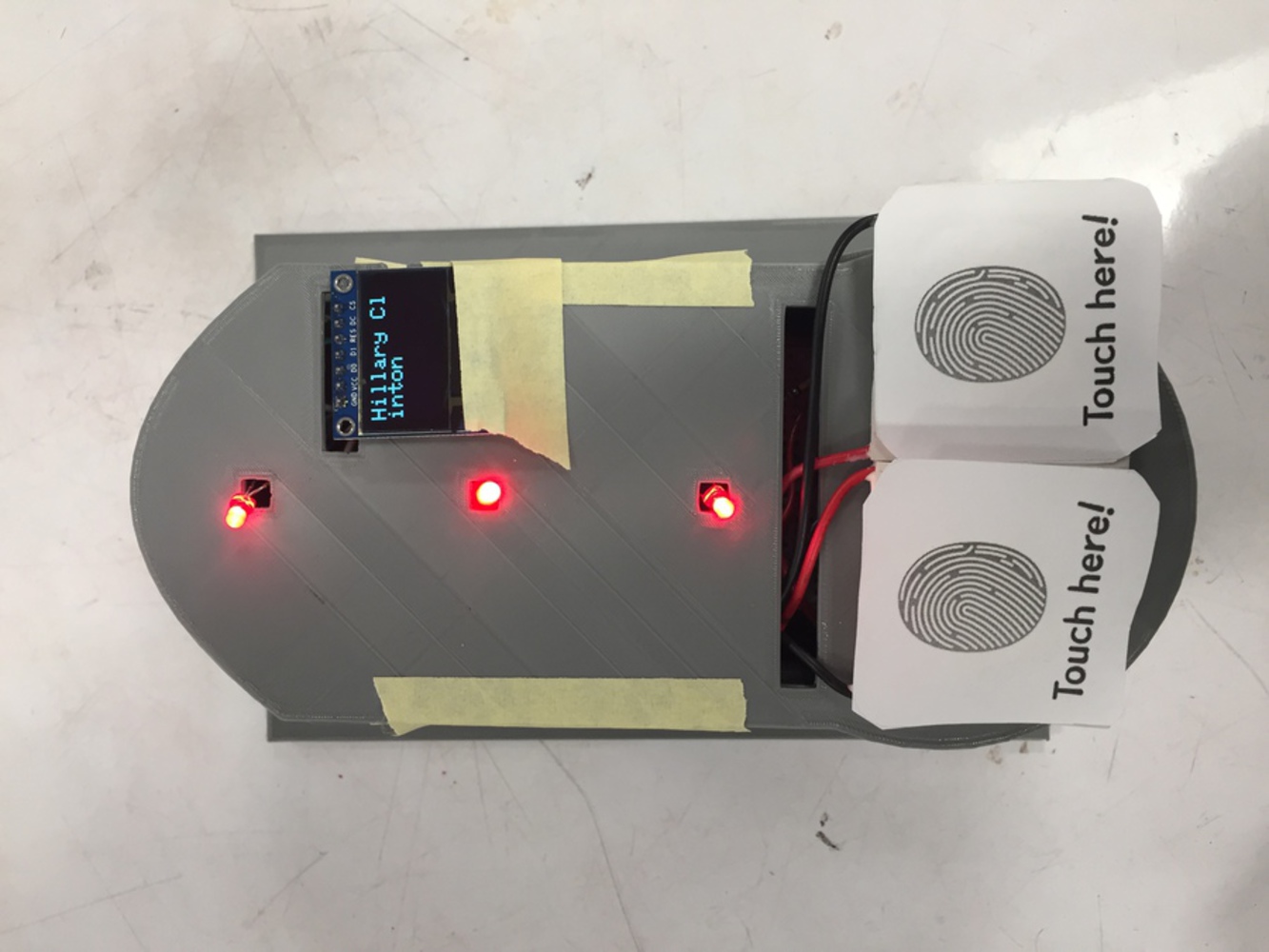

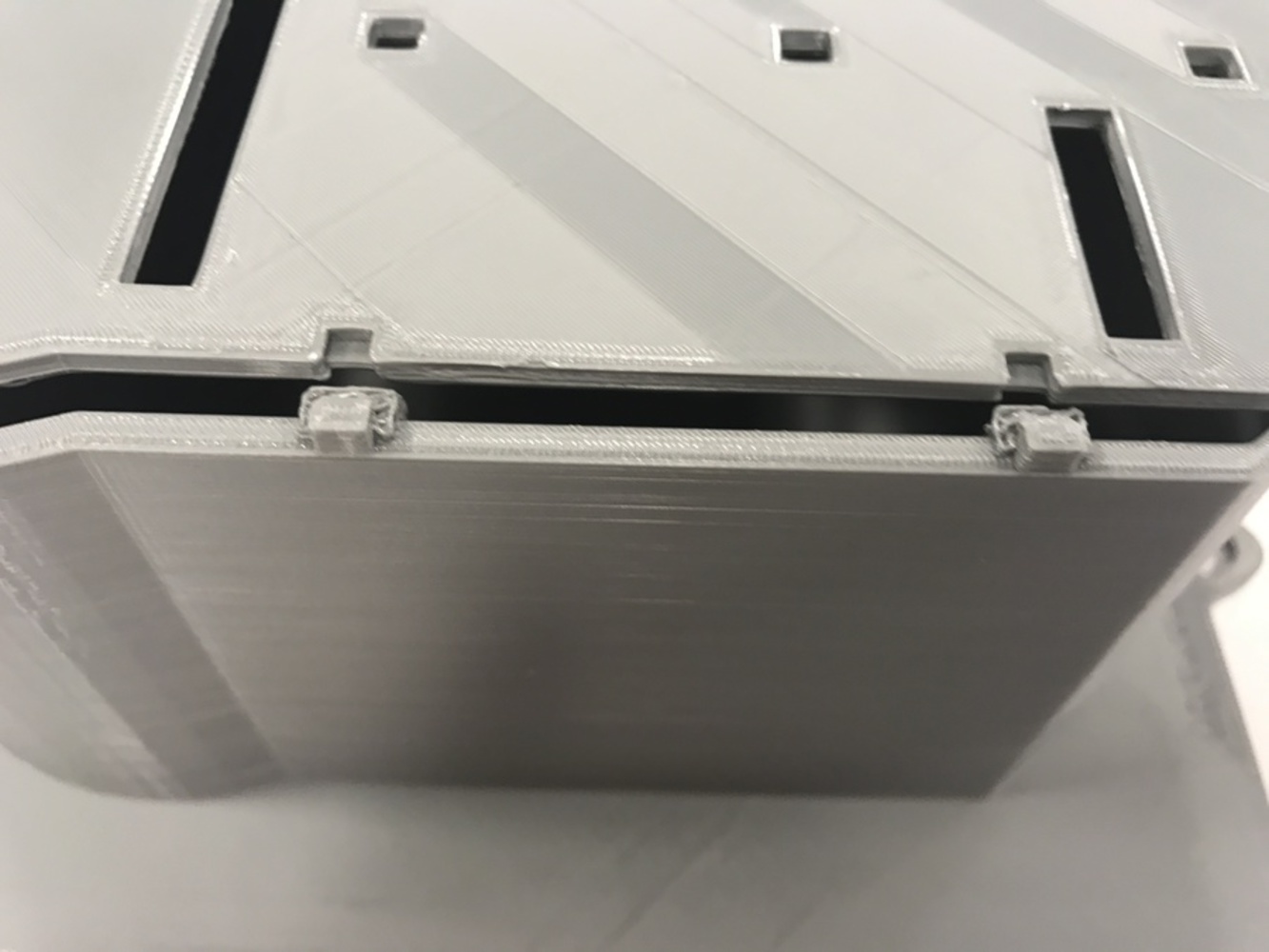

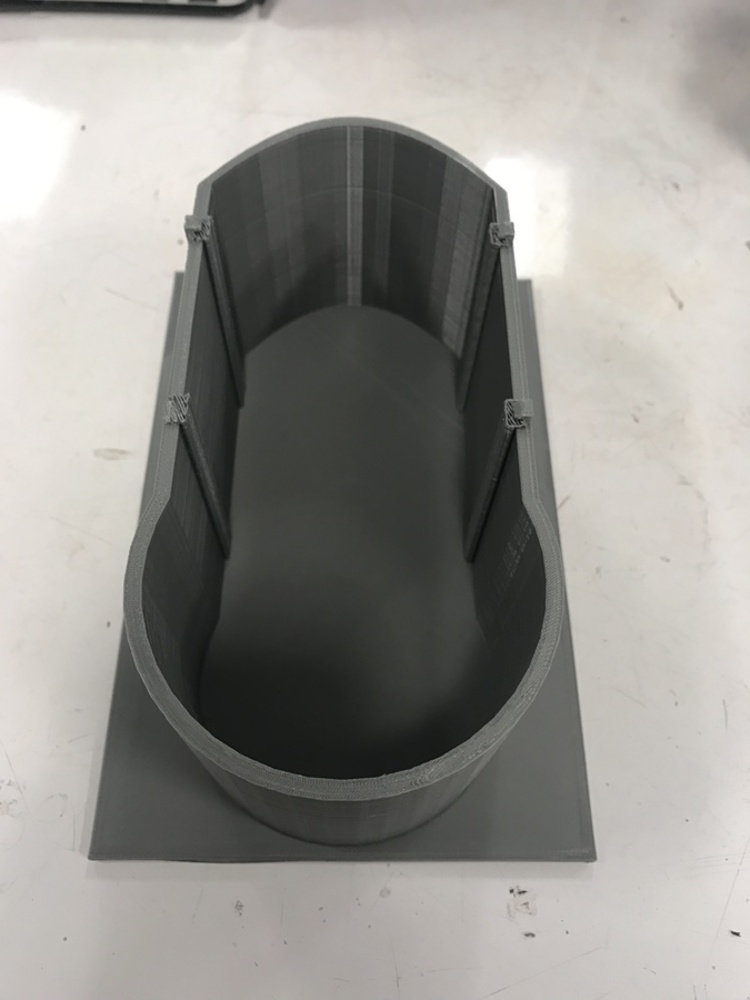

When we set out to create PoliTherm we wanted a way to express the current partisan political climate that was more than visual. By adding the temperature aspect to the project we aimed to allow people to literally feel the effect of their words. Originally, we aimed to create a wearable but found that there were too many electronics to allow the user to fit comfortably on the wearer. As such, we moved to a design that allowed the PoliTherm to hold space similar to a clock, a peripheral that fades into the background but is readable at a glance, while at the same time drawing attention with the "touch here!" signs.