Intention

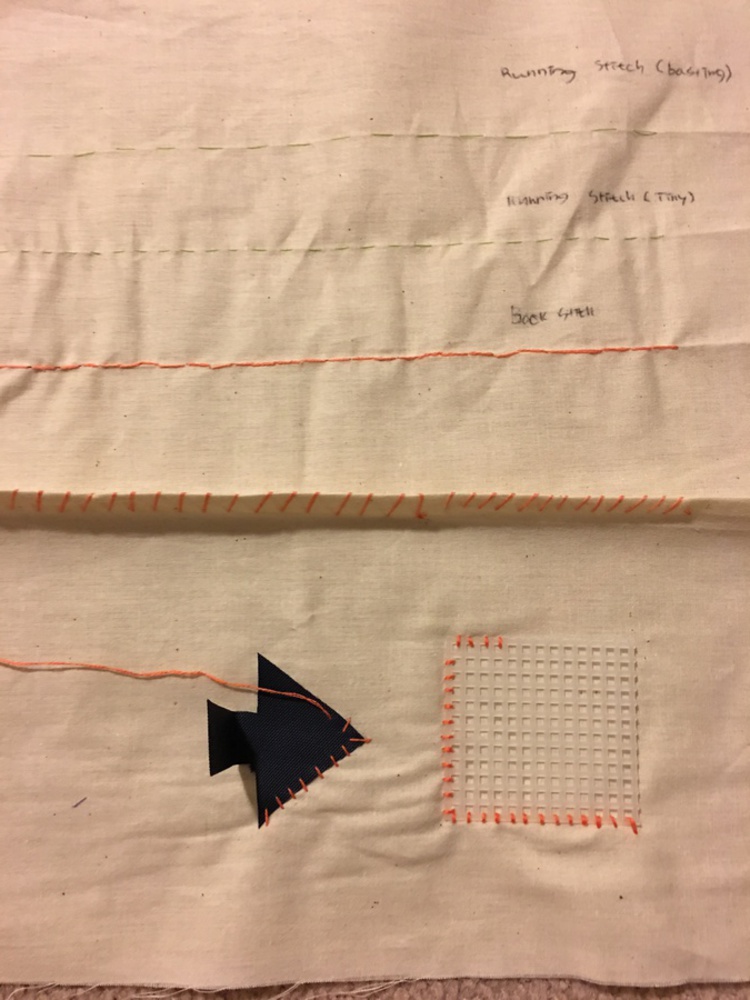

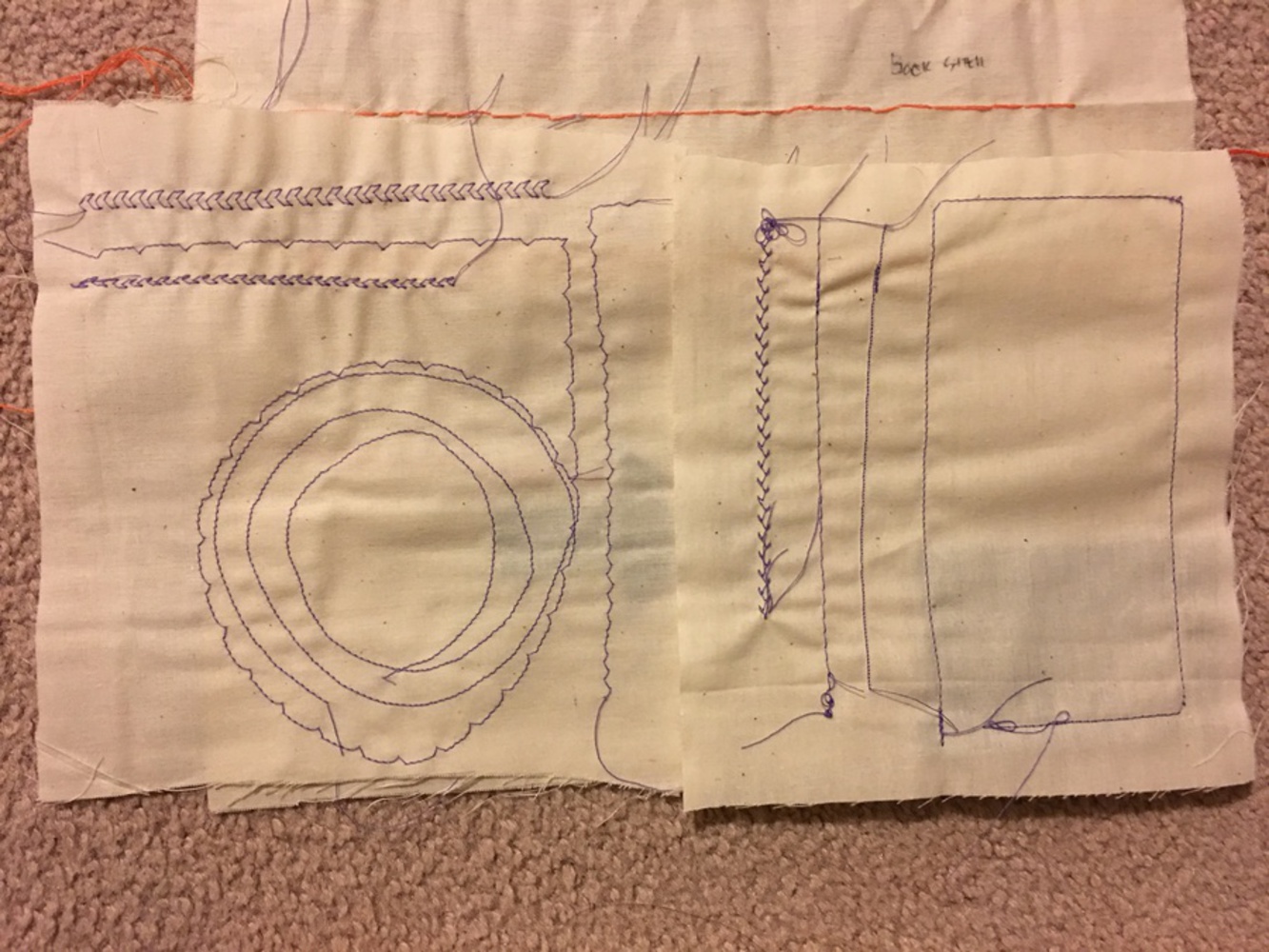

From what I have learnt from Soft Fabrication course, I'd like to make a jacket correcting users' poor postures. Sedentary lifestyle and increasing use of computer accelerate this type of harmful behaviors which cause pain around neck and back. I have also experienced such pains offten as a design professional or a student.

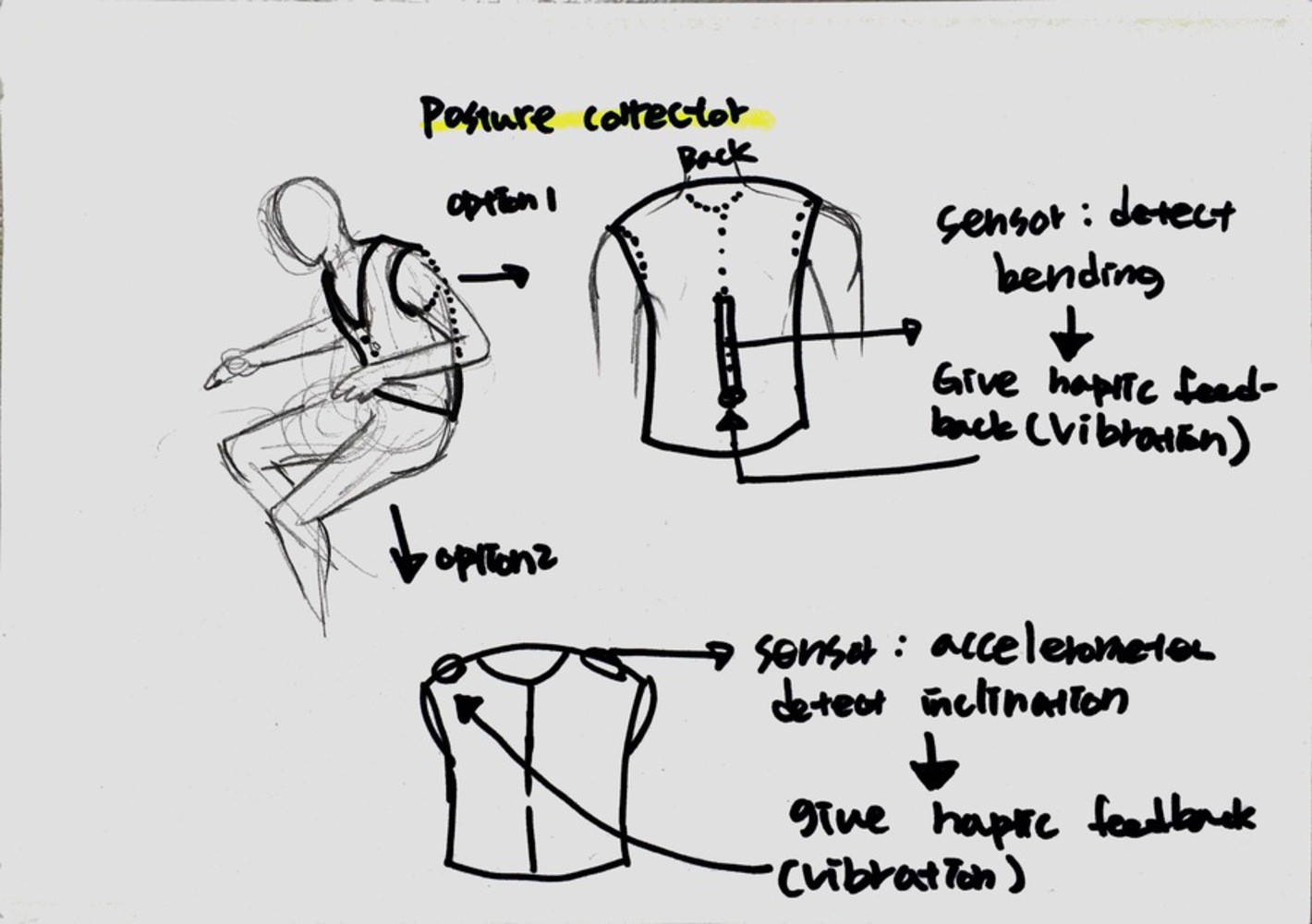

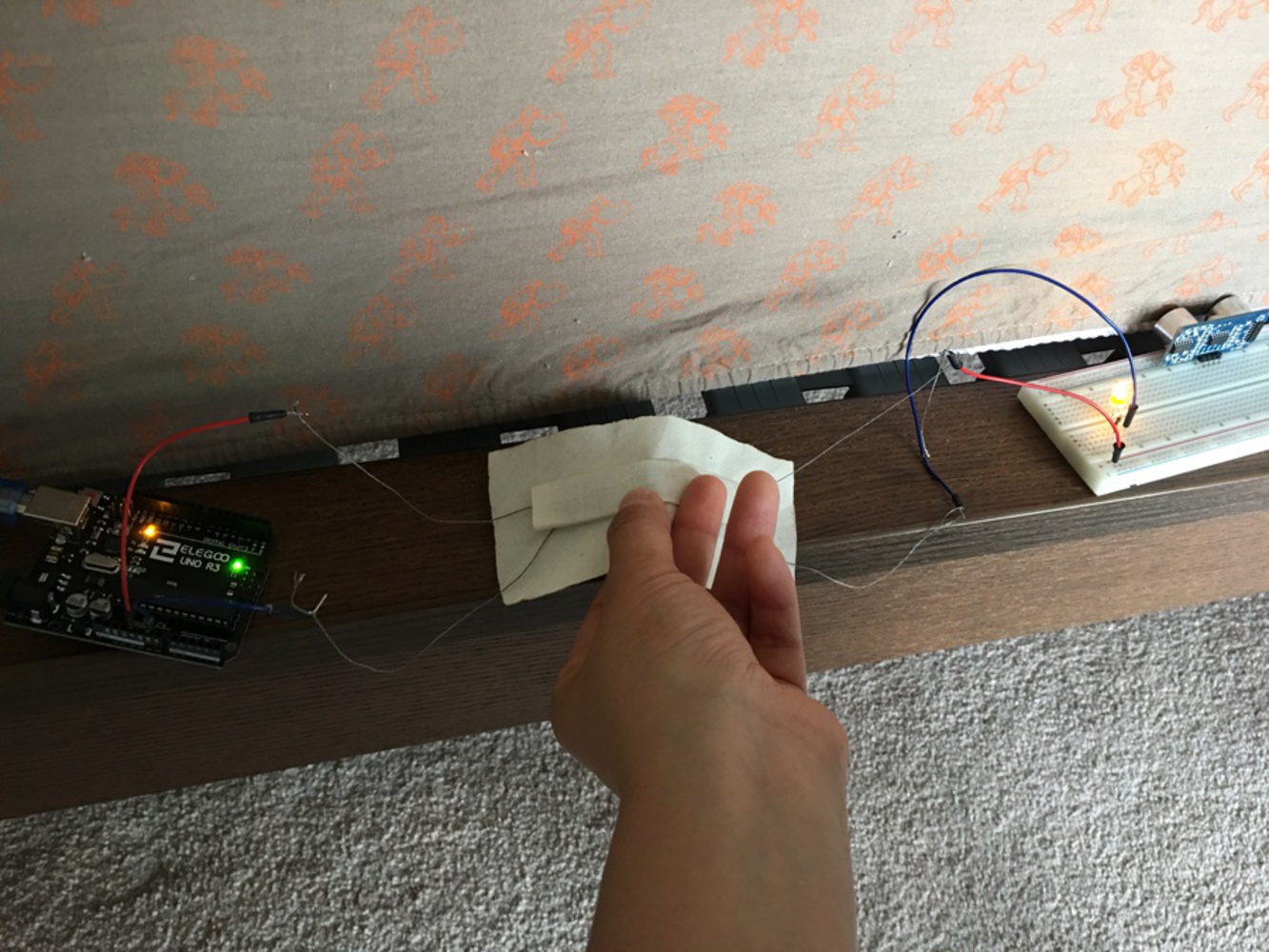

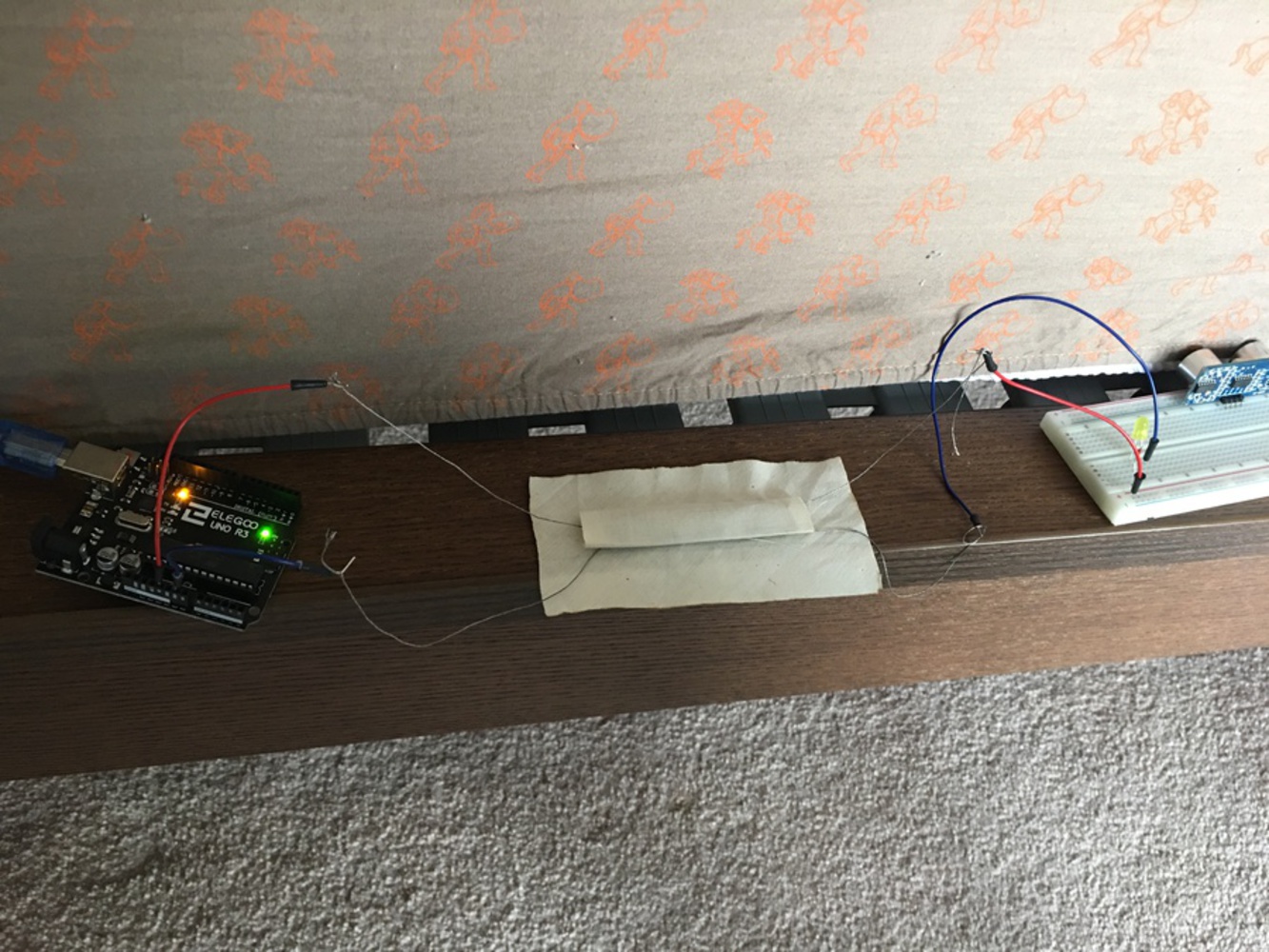

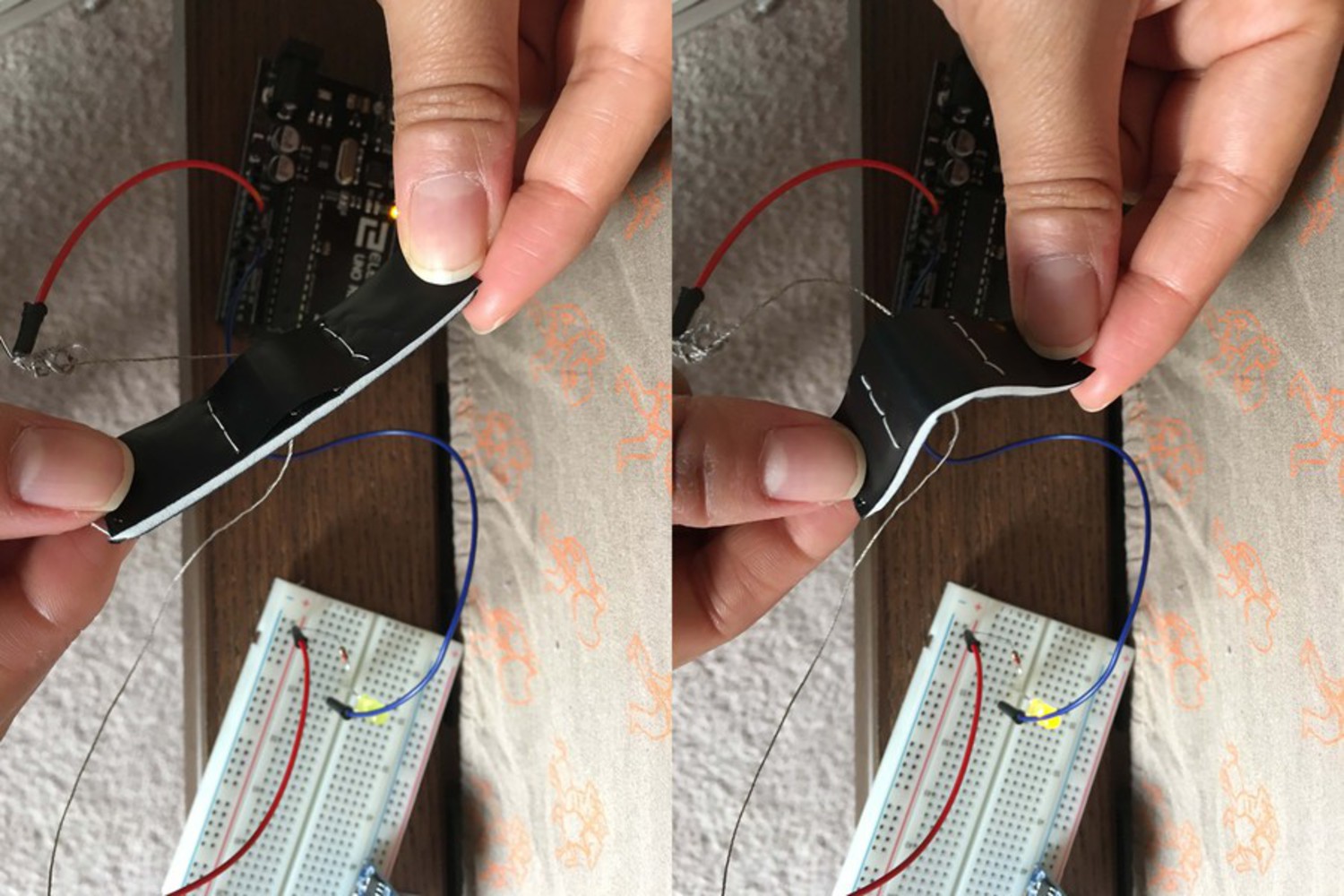

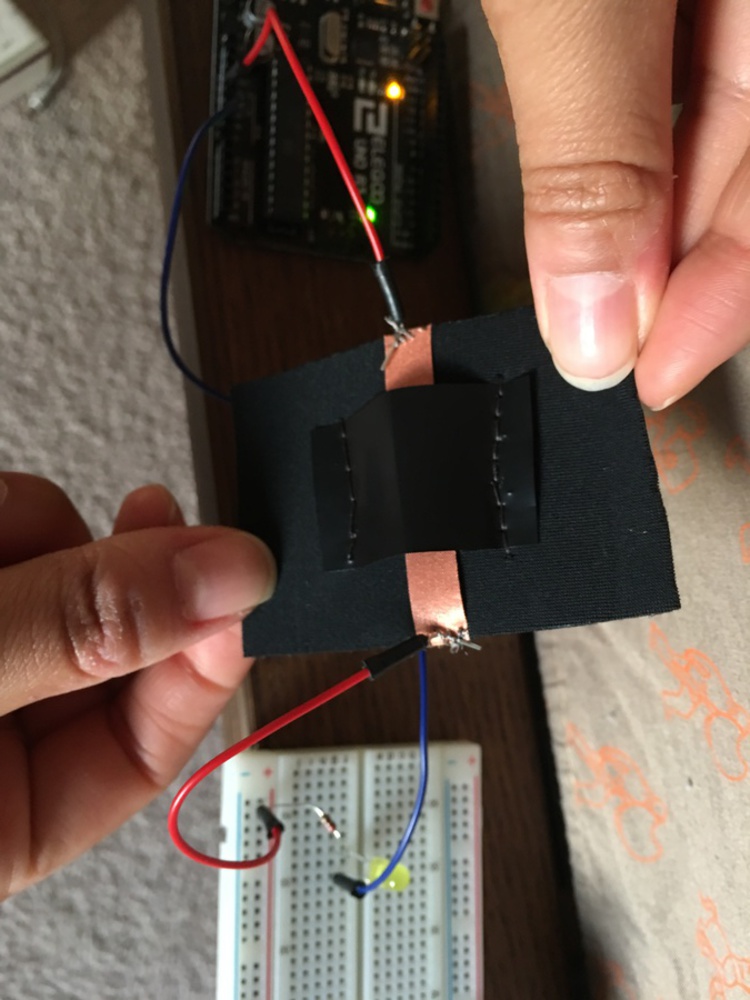

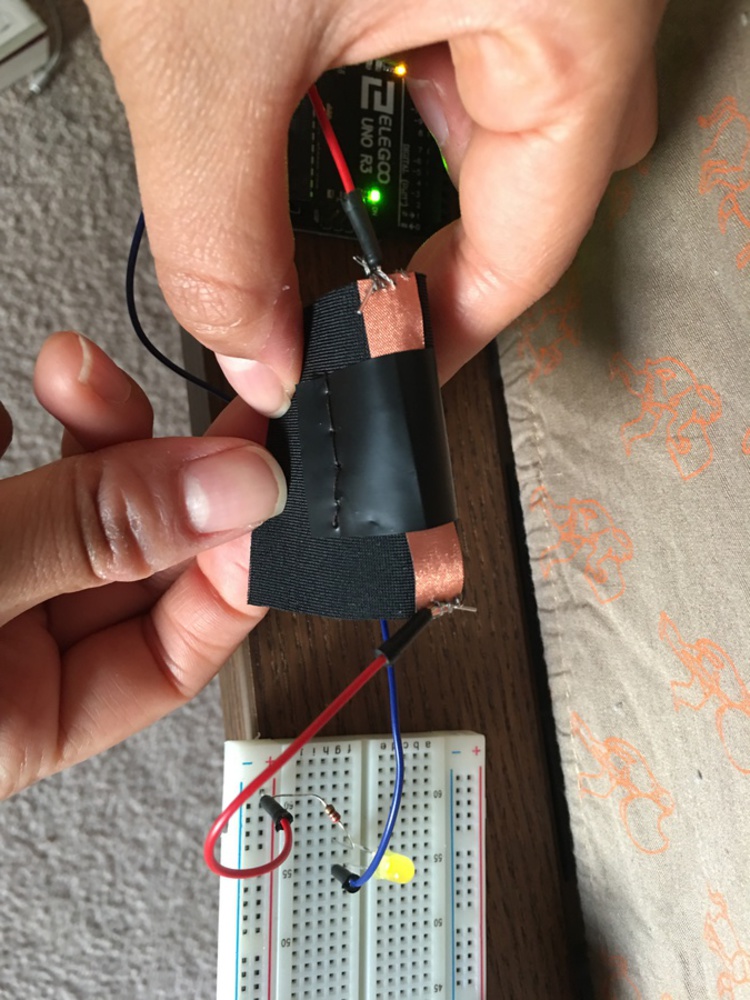

The jacket would give a haptic feedback(vibration) when a user leans forward more than a given threshhold. As the first step to achieve the project, I created some prototypes of bend sensors; the option 1 of the sketch below.