Process

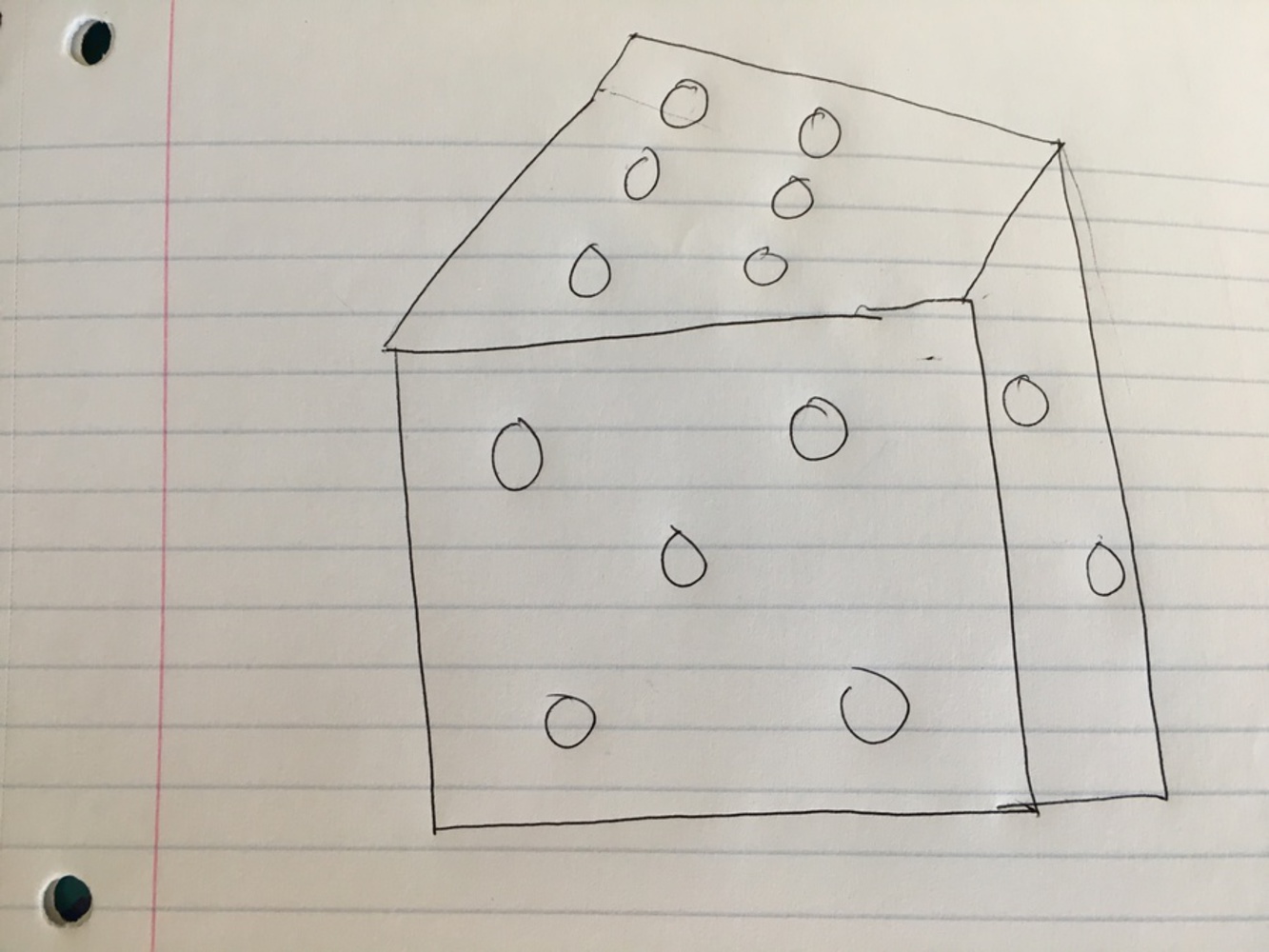

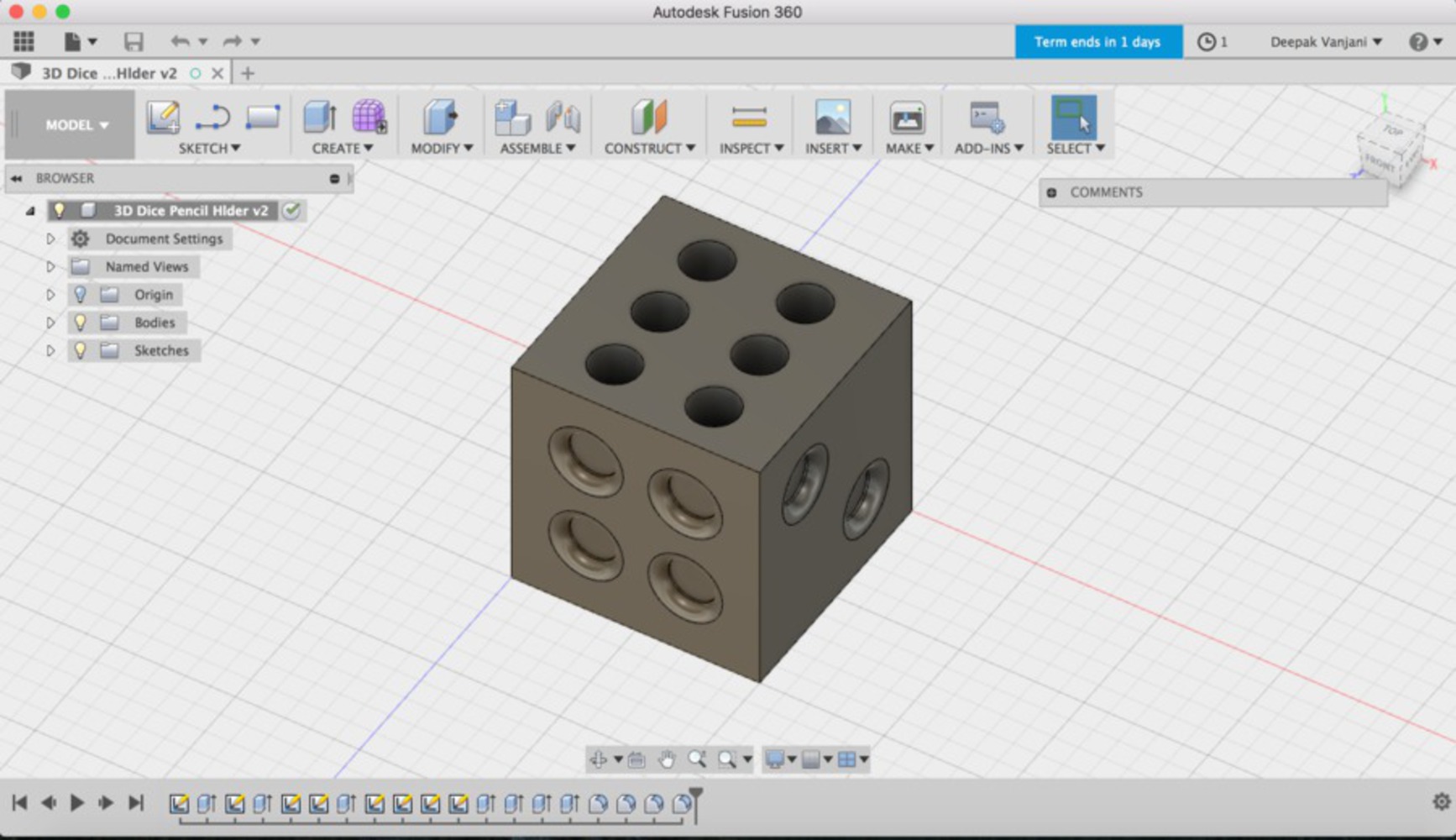

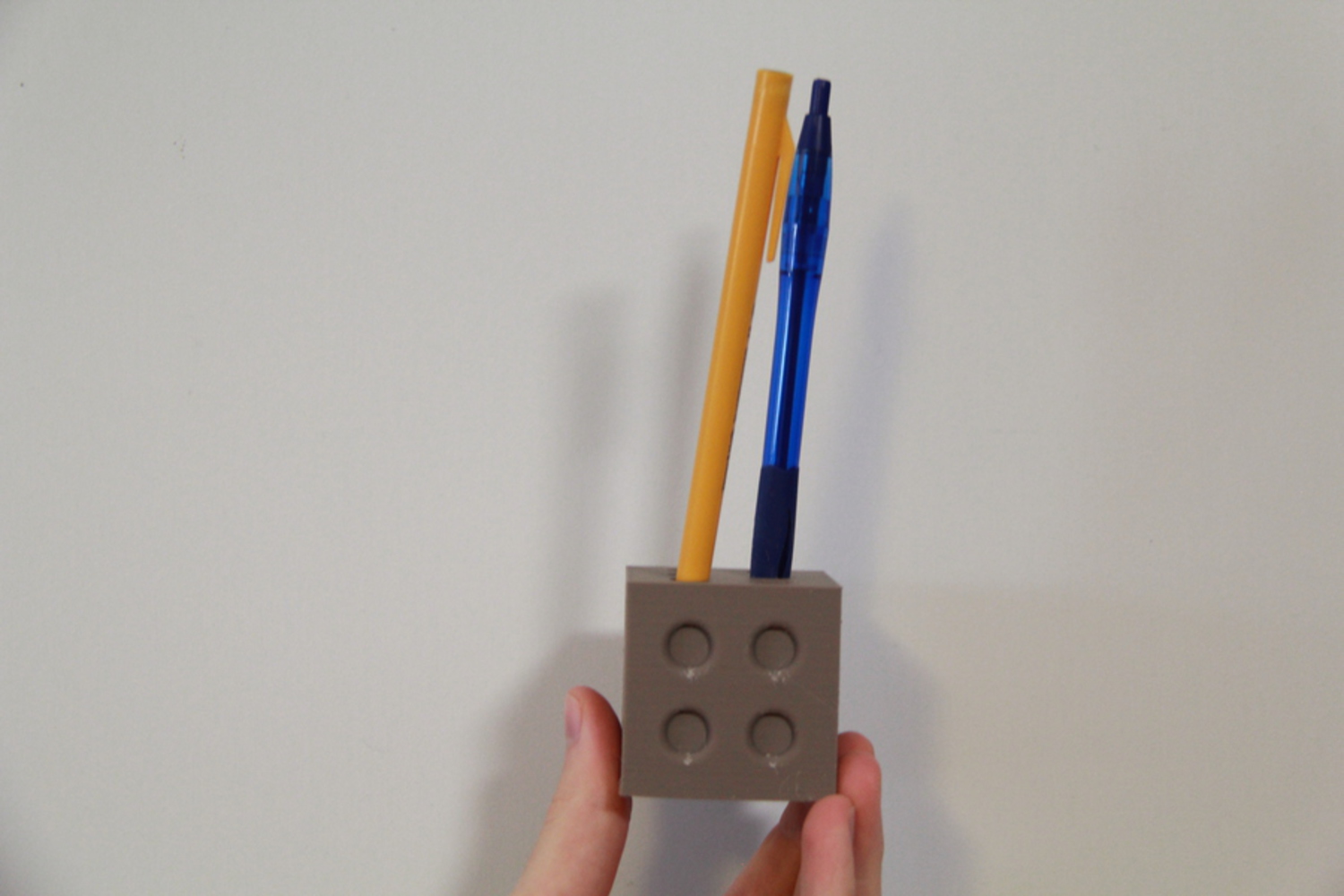

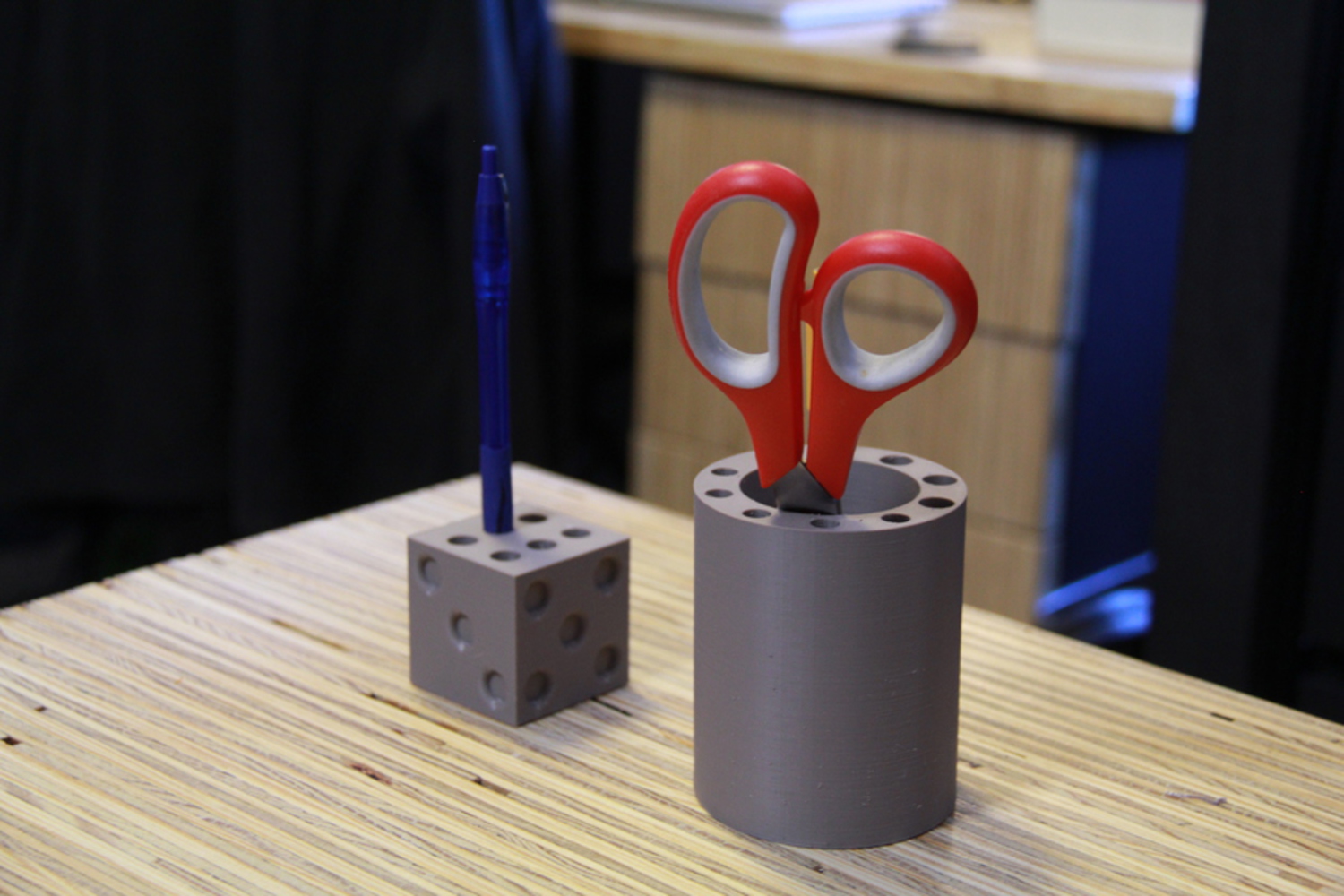

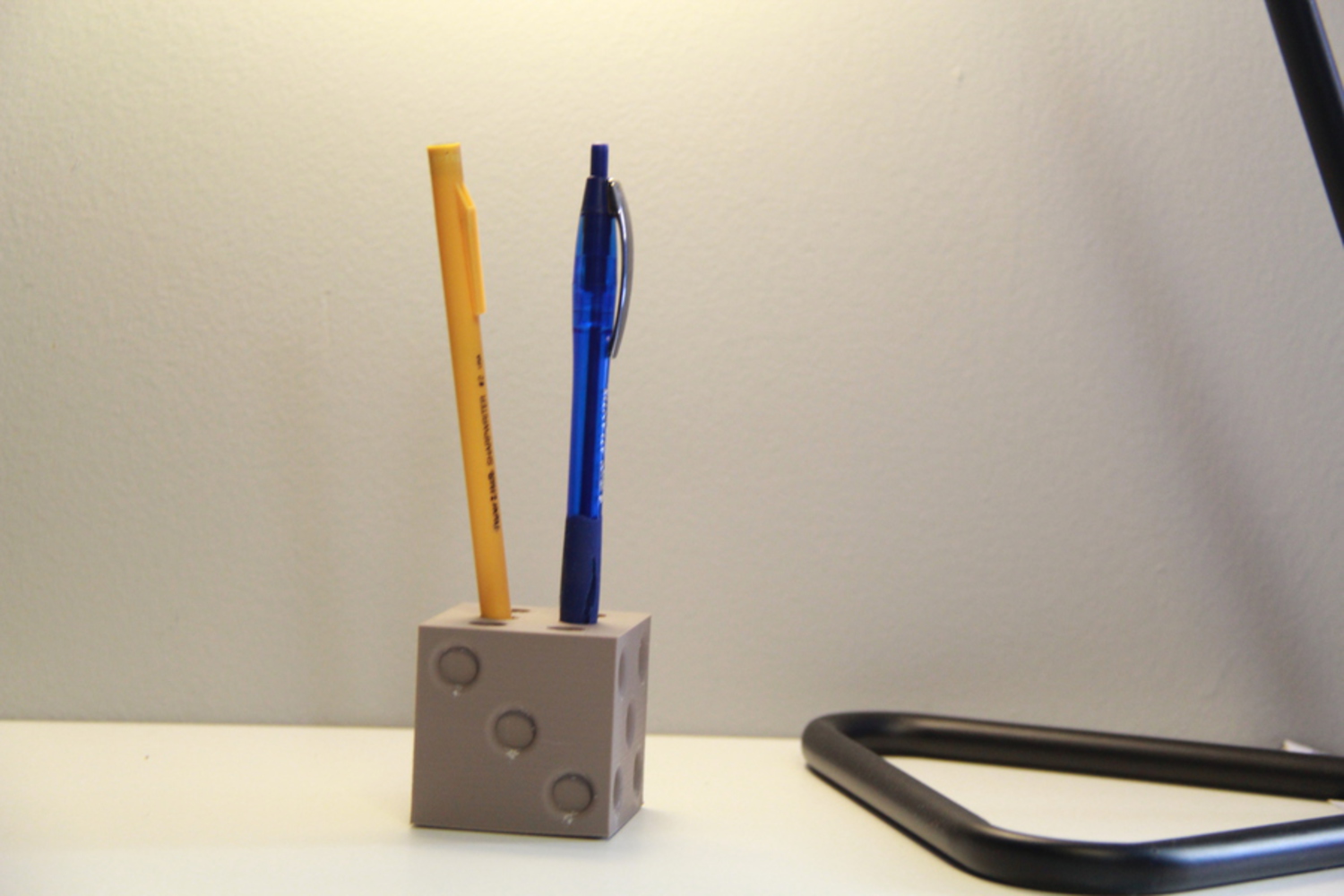

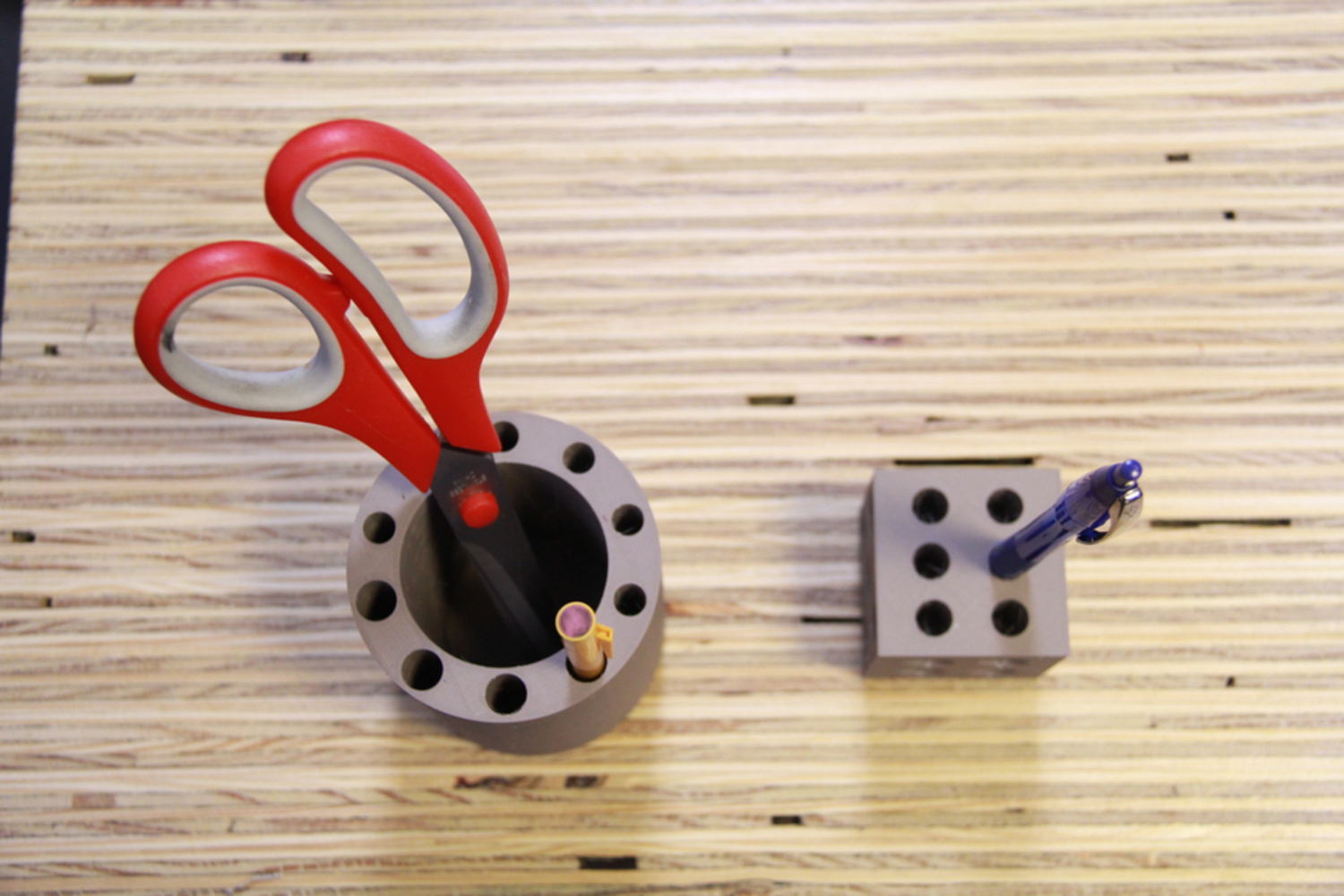

My process followed the basic design process. I started off by just brainstorming some ideas, and after coming to the conclusion that I wanted to create a dice-shaped pencil holder, I started sketching out my ideas. Below is a sketch of my idea. Then I carried over my design to Fusion360 - below are also some screenshots of my design.

The design of the project was not too complicated, as I simply had to follow the concept I had thought of. I had the choice of following the design of my inspiration above, by cutting holes in all sides of the dice, or simply the 6 side. I decided with going with the latter, as I thought it would look a little more neat if I carved out a circular dent into the other sides but still kept the holes closed, as you can see in the screenshot below. I used detailed measurements to make sure my design was not too big for a 3D printing, that pens/pencils could fit in the holes, and that the circles were properly and evenly spaced from each other throughout the design.

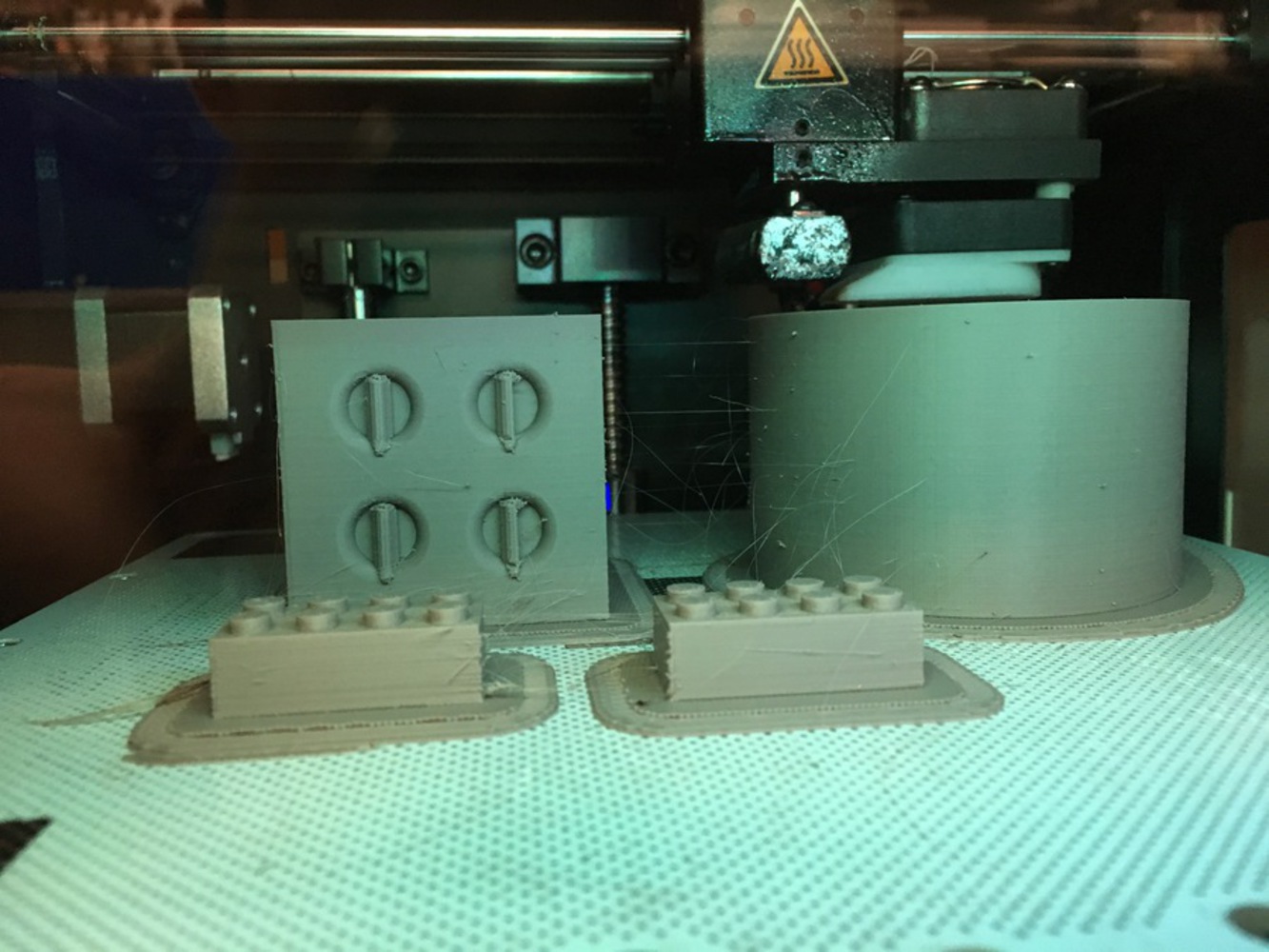

I then saved my Fusion360 design as a .STL file. Because the queue for Nvbots was quite long, my friend Wilson, who is also in the class, and I decided to use Zortrax to upload our STL files to the 3D printer. The print options chosen were medium infill and high quality. Wilson and I borrowed an SD card from the lending desk, exported the files to the SD card, and then printed the files on the Zortrax M200 machines.