Process

The first part to decide on the project was to finalize which device to use for haptic feedback such that it could be mobile(mounted on hand along with the power supply) as well as feels natural. After going through multiple things such as piezos, vibration motors as well as a metal plate for passing a tiny current through the finger, I decided to go ahead with vibration motors. Then came the part where I tried different ways of connecting the motors at fingertips.

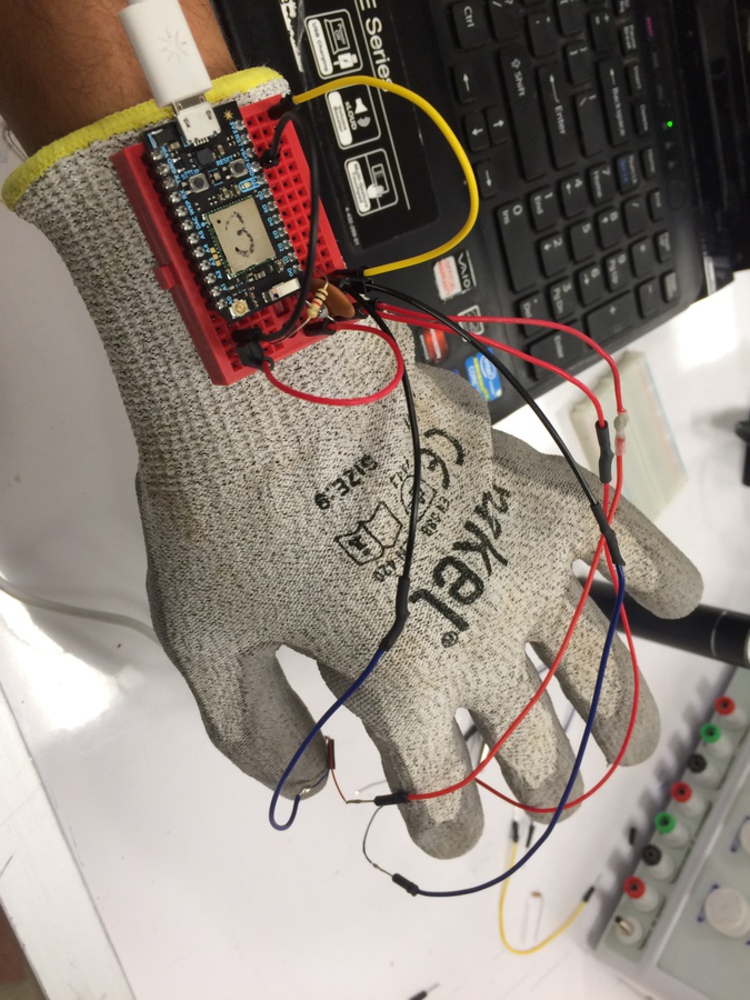

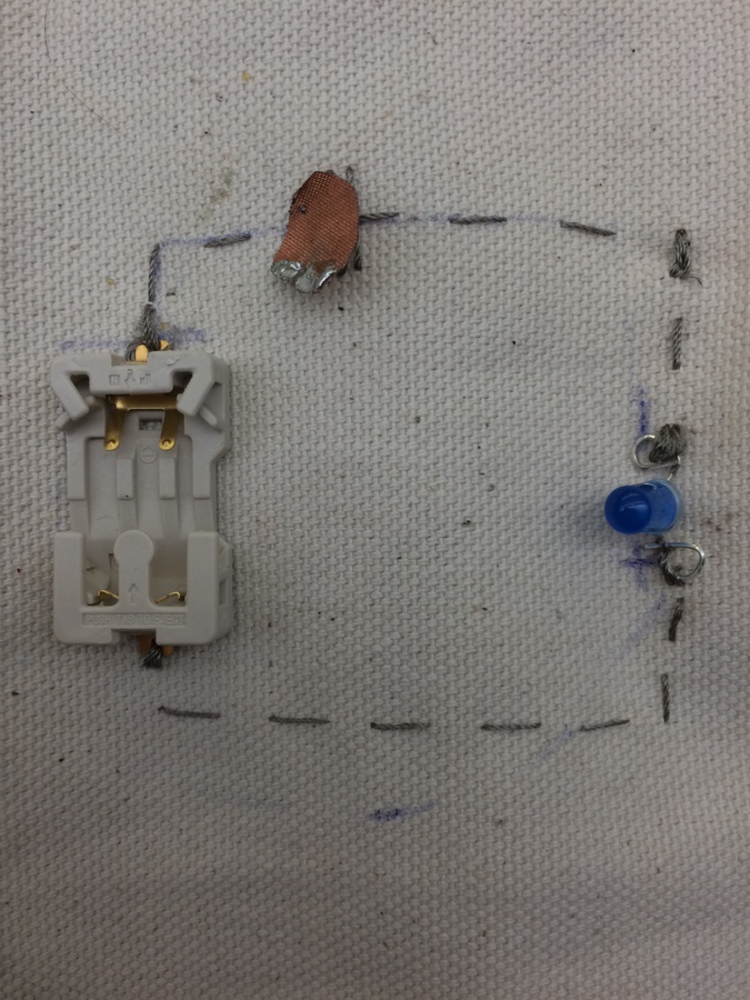

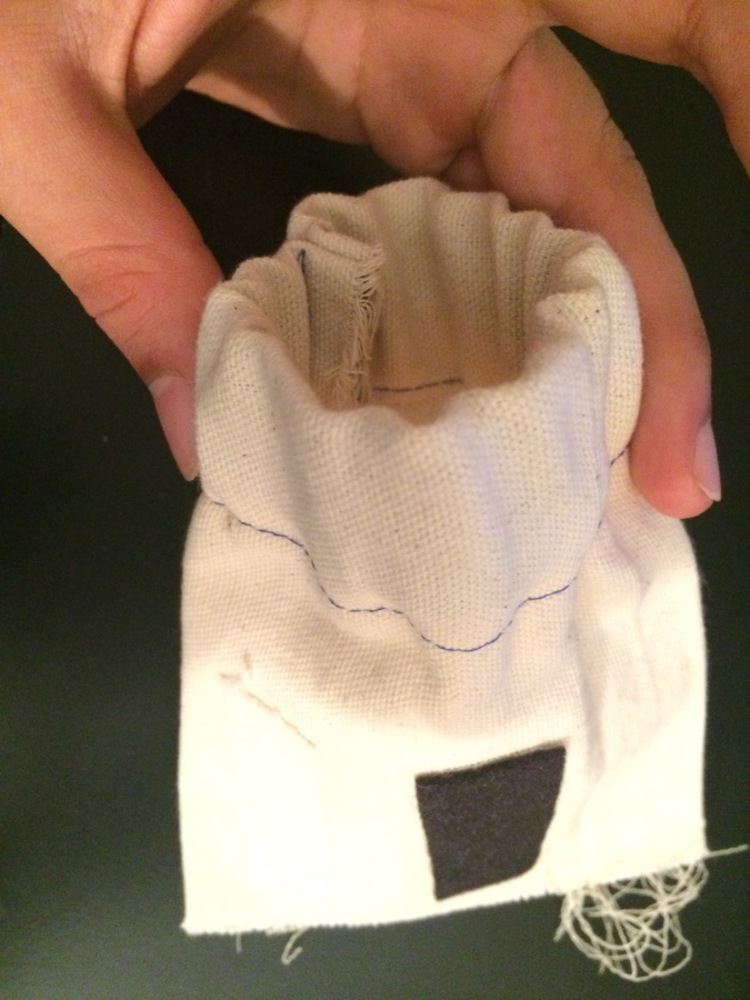

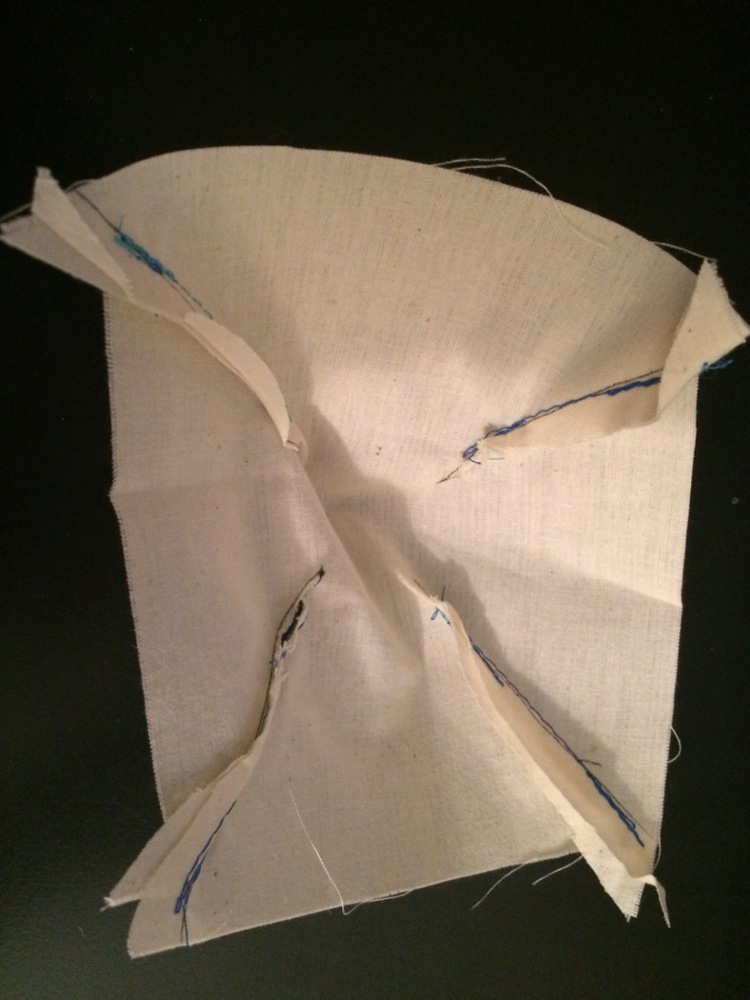

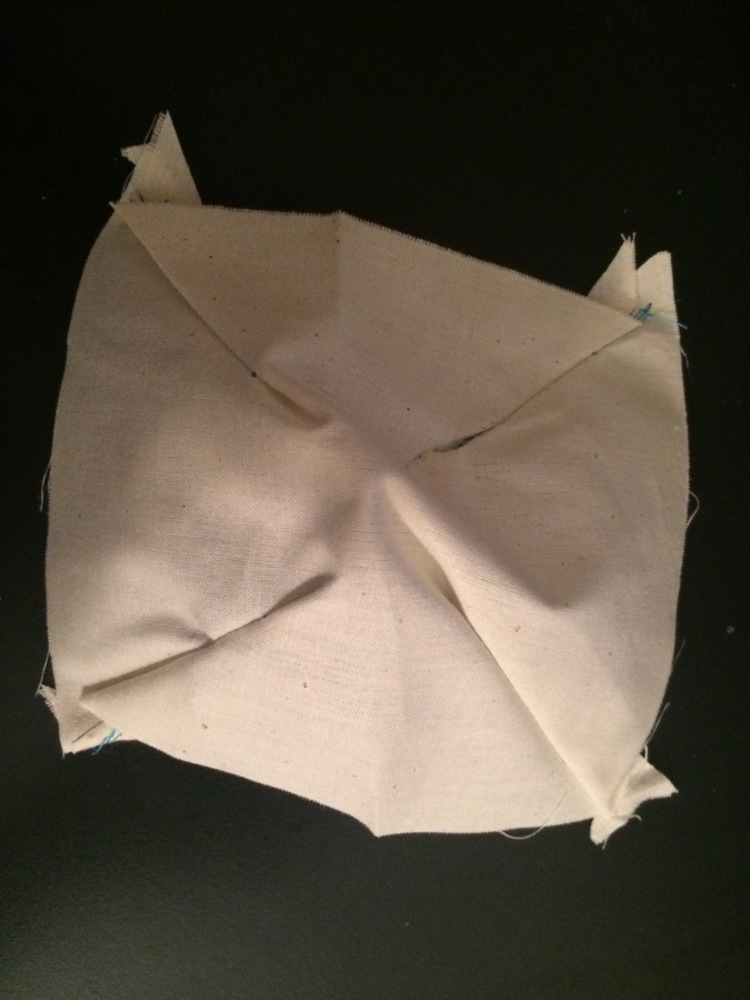

The first iteration was just to stick the motors at the fingertips using glue to get the right motor position and vibration intensity. it looked like this -