Process

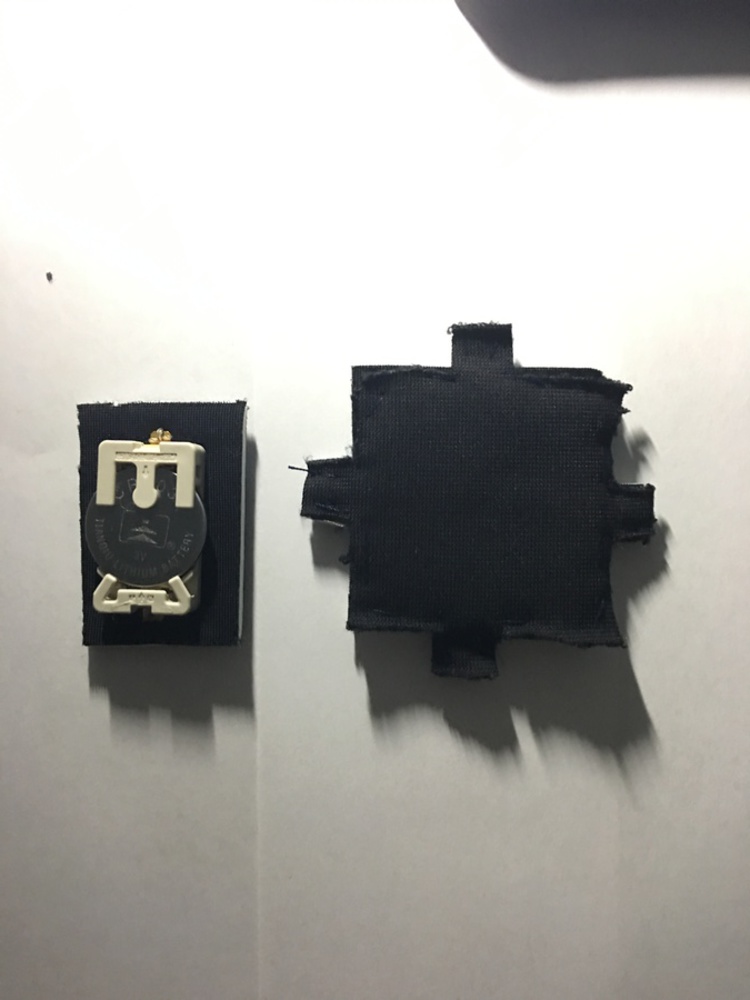

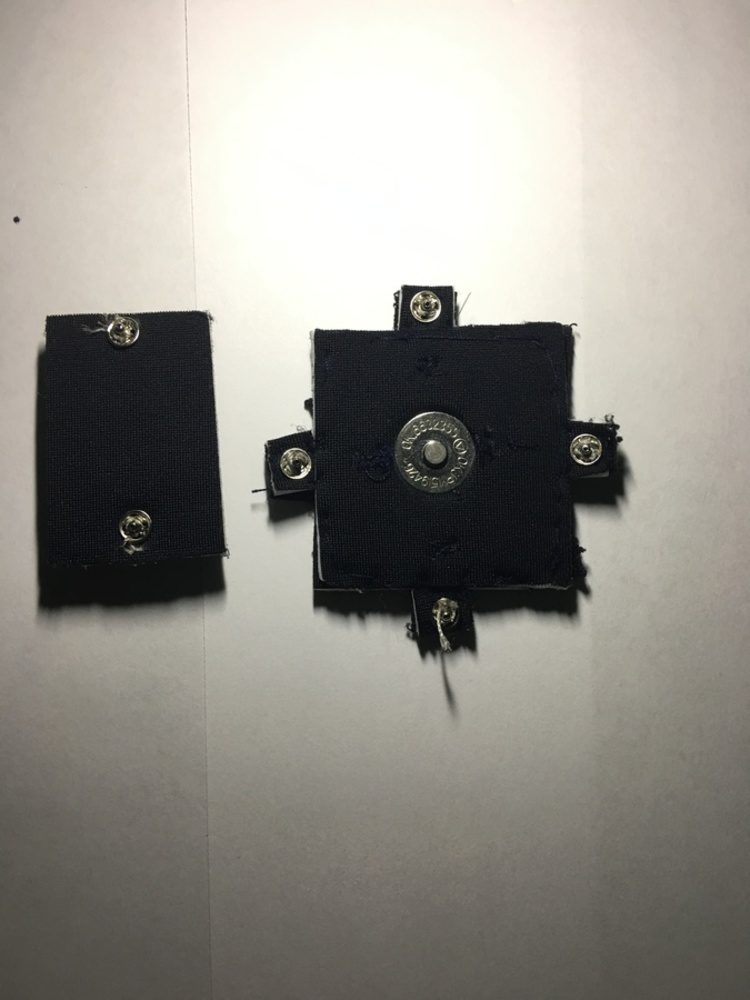

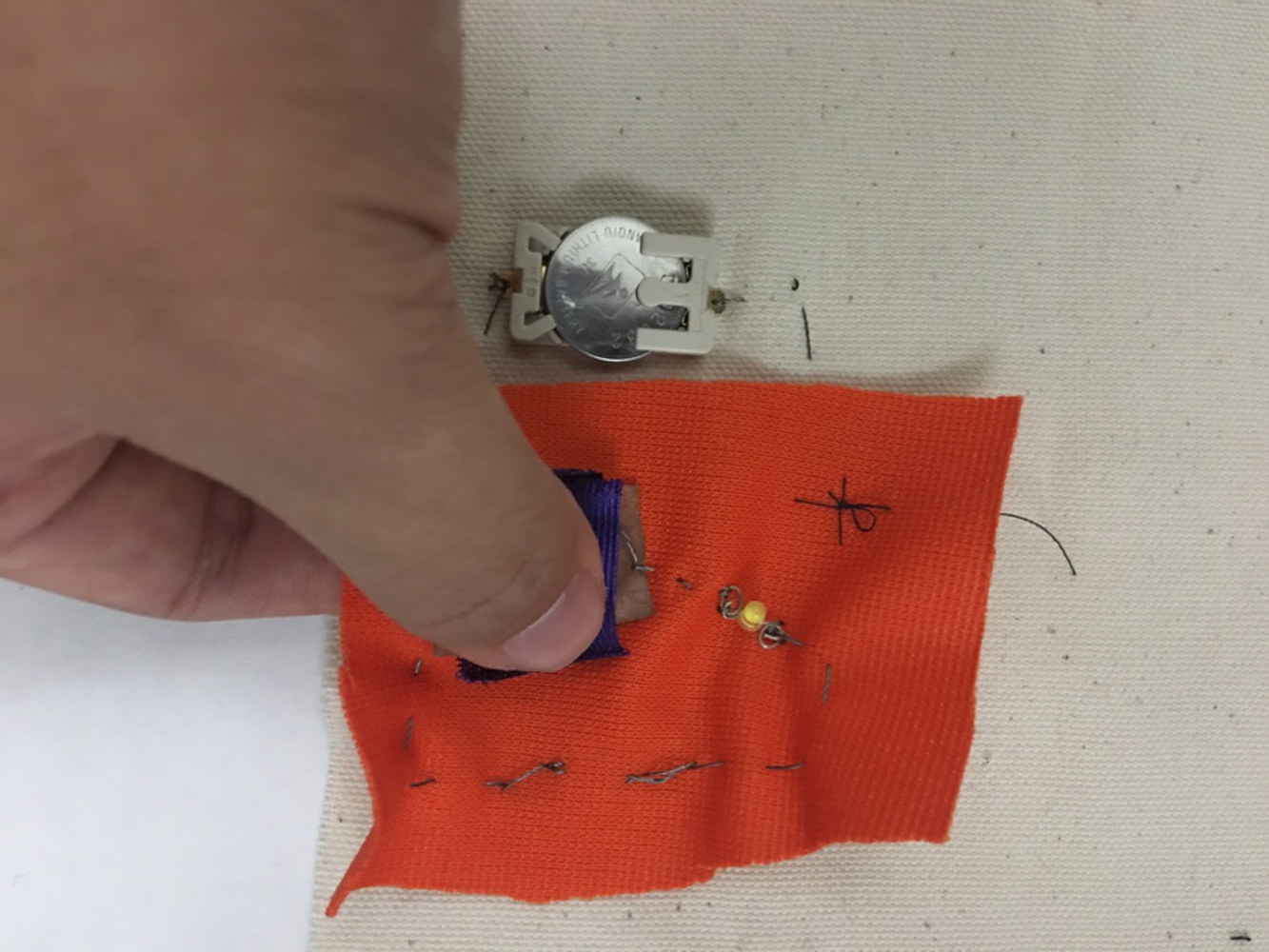

I had initially decided to make the joystick circular; however I only had one single piece of Velostat cut to a circular shape, and thus the "joystick" became somewhat square. I still wanted to maintain the modular nature of the joystick, in case I wanted to test other configurations of the joystick in the future. I also wanted to make the power supply modular, in this case more because I wanted to have the power removable for safety reasons.

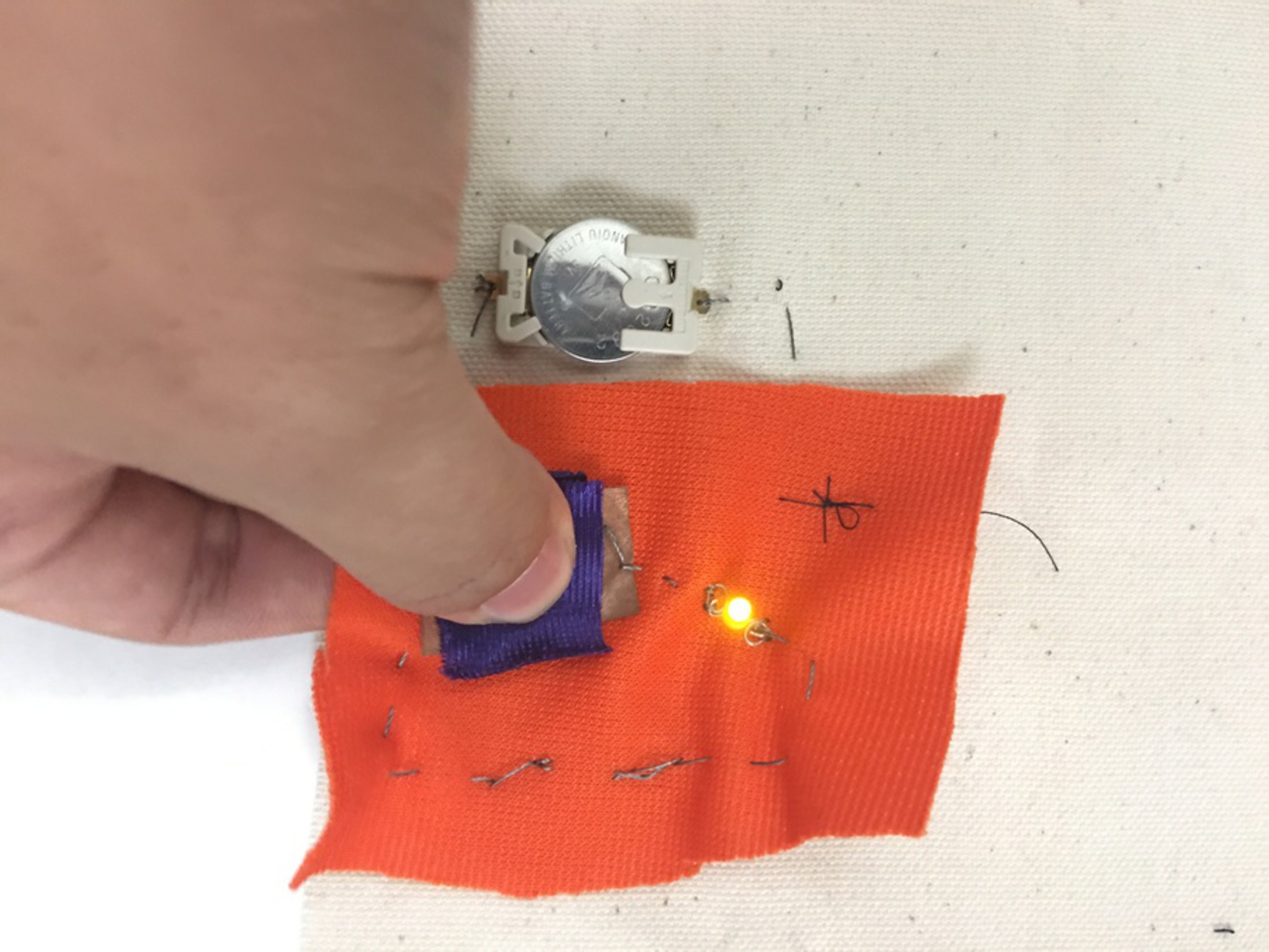

I first started by assembling the joystick, starting with a square of material and placing one half of a magnetic snap into it. I then placed the laser cut Velostat disc on top and hand-sewed the two components together in order to ensure contact.

Right away, I realized a slight problem. The Velostat goes down in resistivity with pressure, so by sewing it tightly to the magnetic snap, there would be regions of conduction in the material. However, I thought the effect of this to be low, as I had done the same for the button circuit.

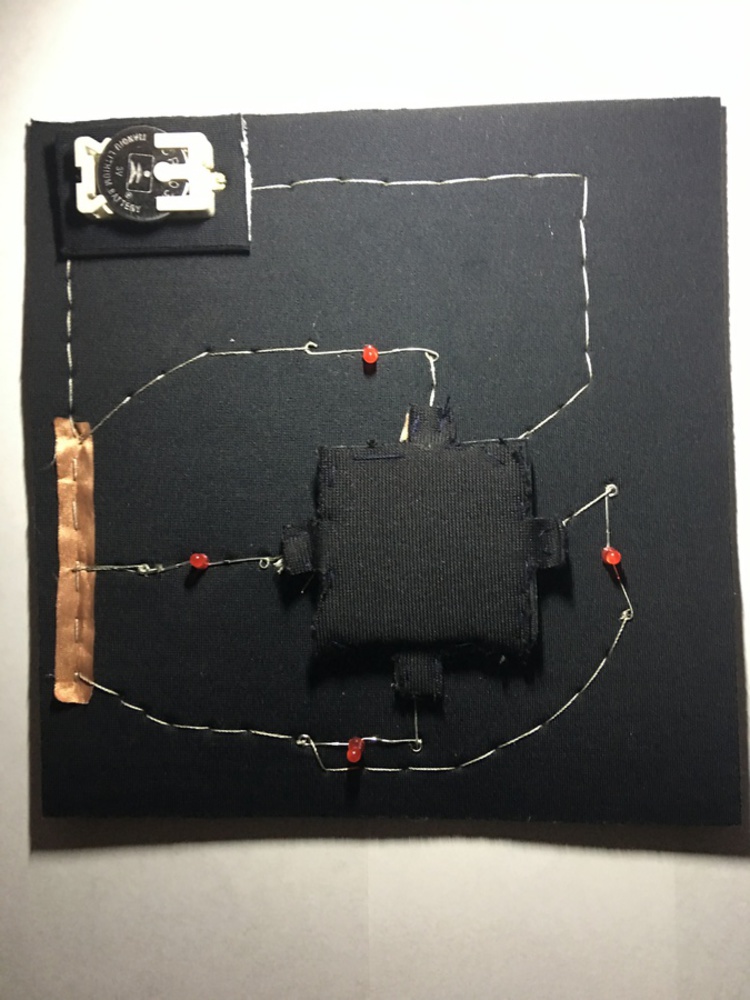

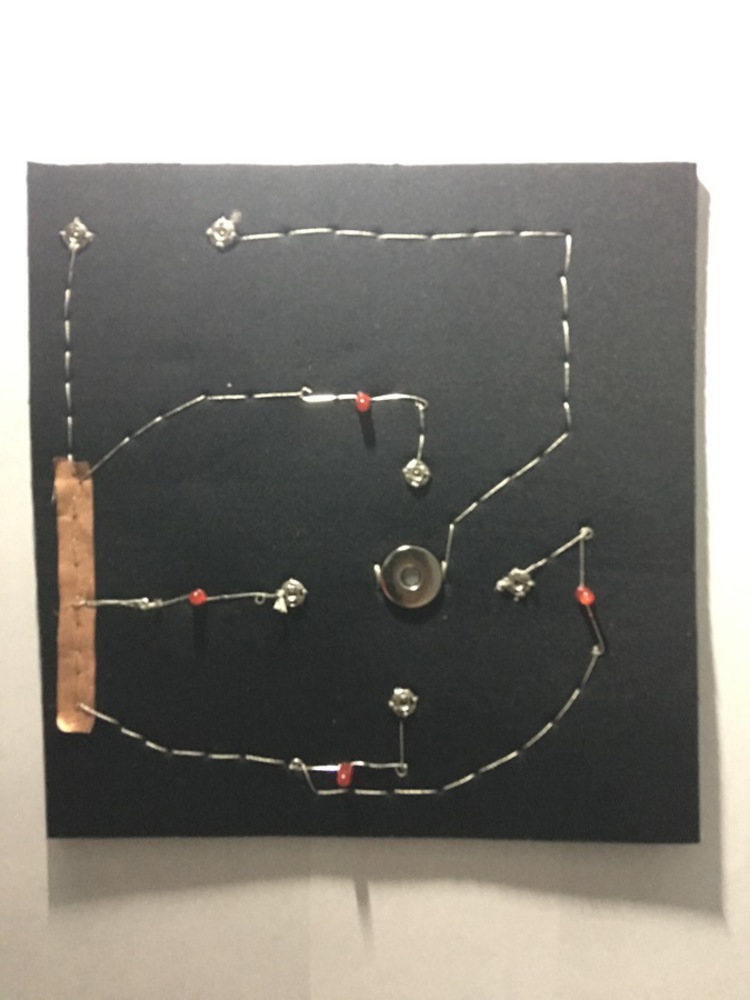

I then started to sew in strips of copper coated fabric as the four axes of the joystick. Using some scraps of the base fabric, I made little tabs for smaller snaps that would lead into the LEDs. Finally, I covered the mechanism with a square piece of the base fabric.

The battery piece was much simpler to fashion, as I just had to sew two small snaps to a piece of base material and have it connect to the battery.

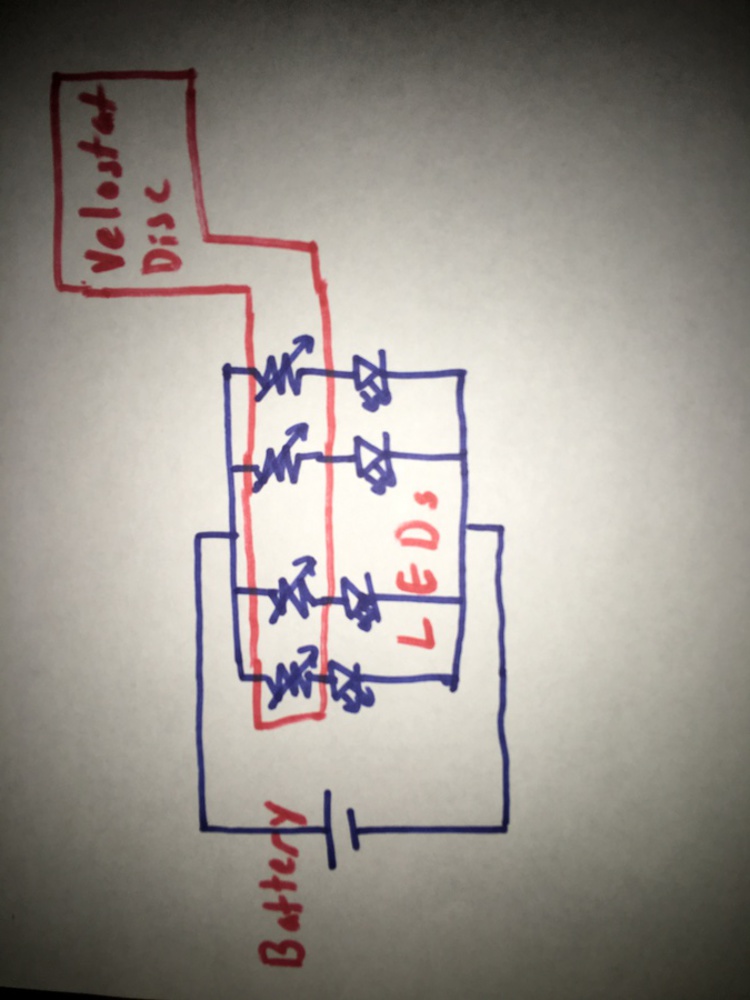

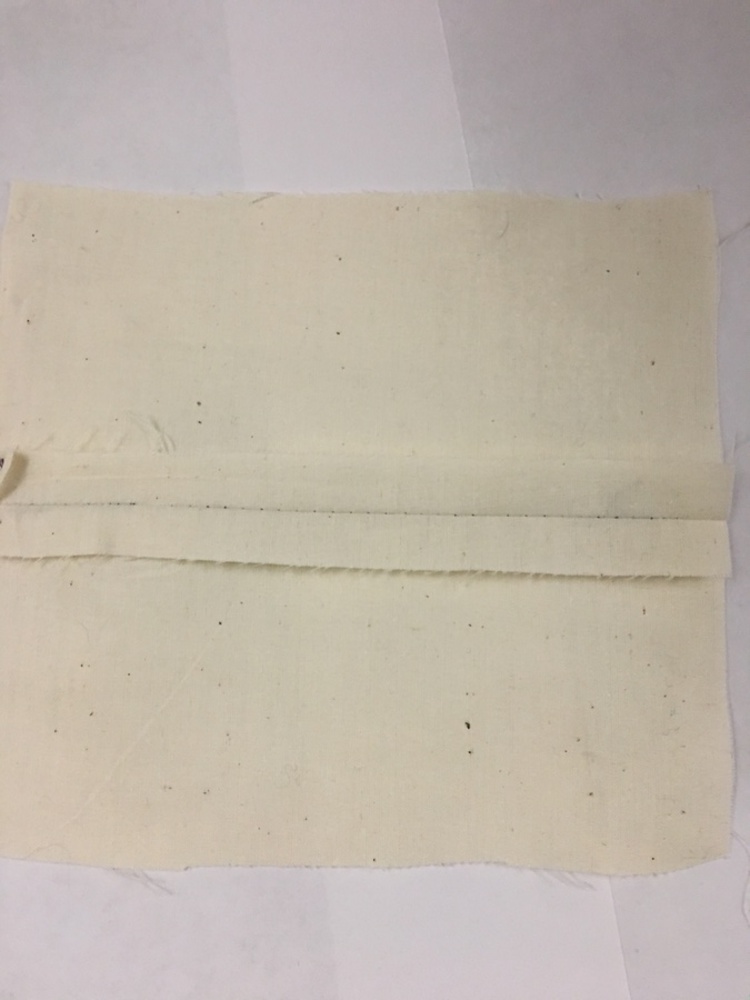

Finally, I fashioned the "circuitboard", hand sewing with a back stitch (for clarity) the "wires" that lead to the magnetic snap's other half, the LEDs and a copper strip as one end of a parallel sequence of wiring for the LEDs.