Intention

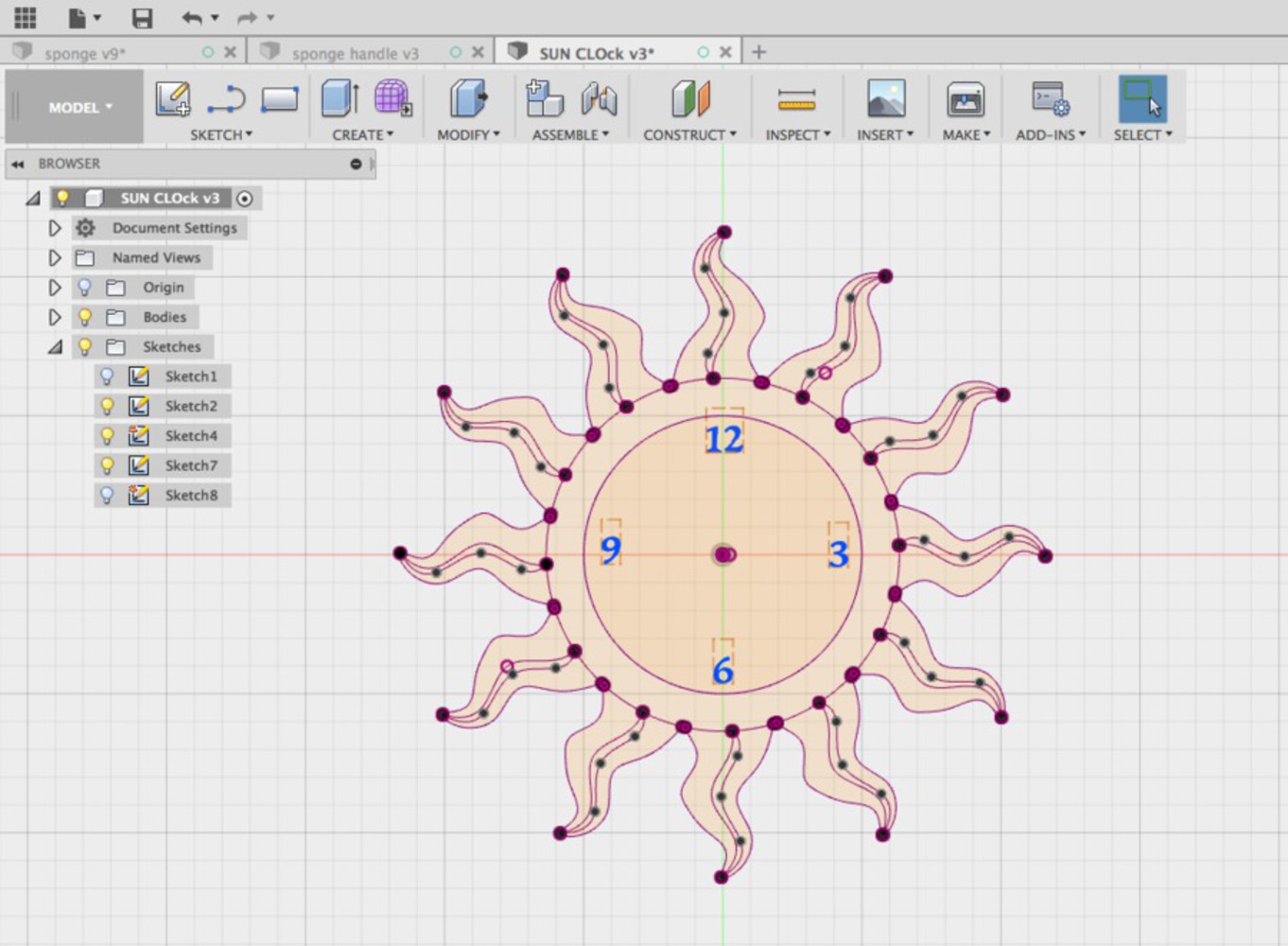

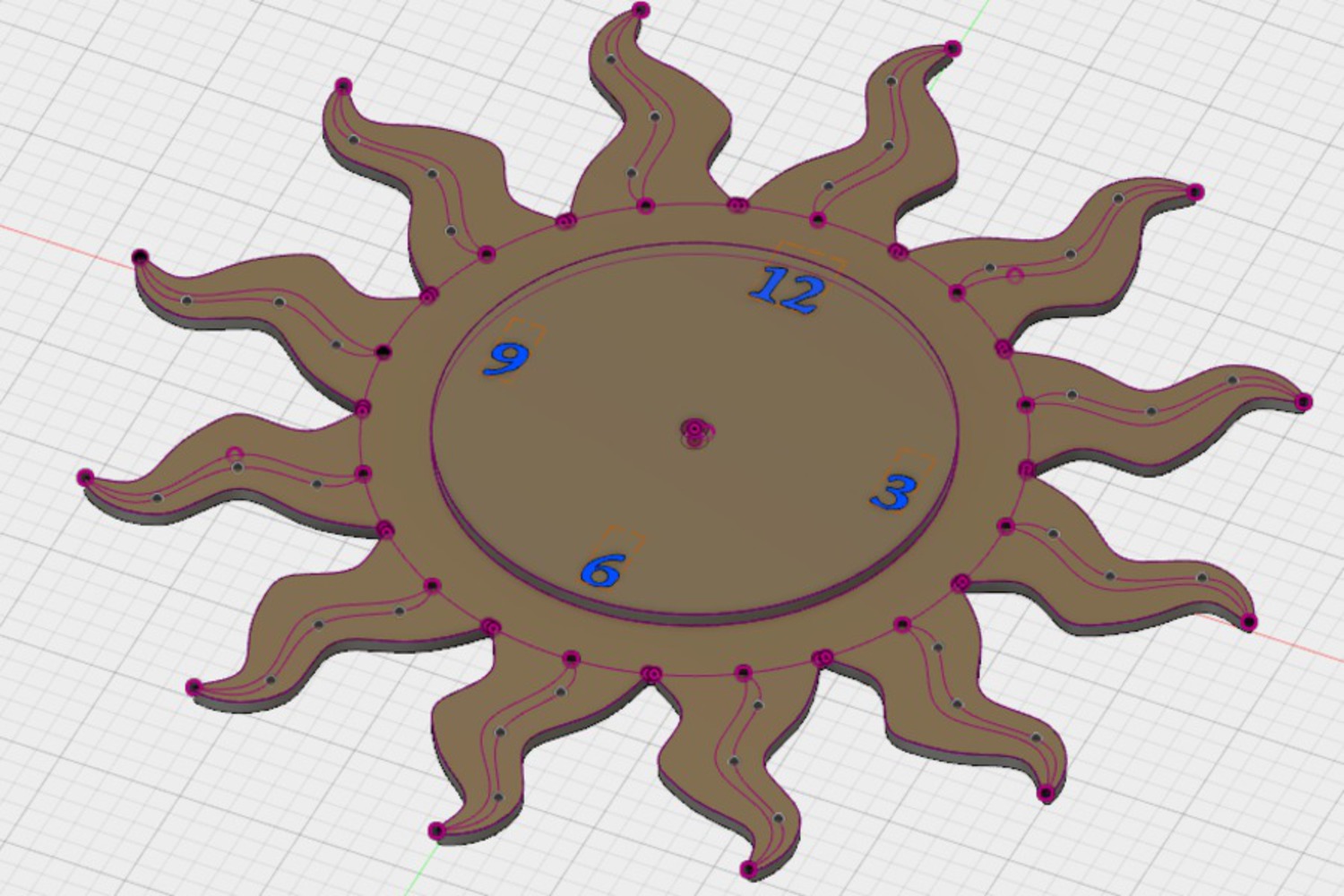

The goal was to design and cut a clock using the Rabbit Laser Cutter and wood and acrylic. I wanted to create a design which was simple yet eye-catching. I chose to do a sun design for my clock because sunny days always put me in a good mood, while checking the time is usually a stressful reminder of how little time I have left before deadlines... :(