Process + Procedure

1.) I first started by sketching out possible designs based on the specifications stated above.

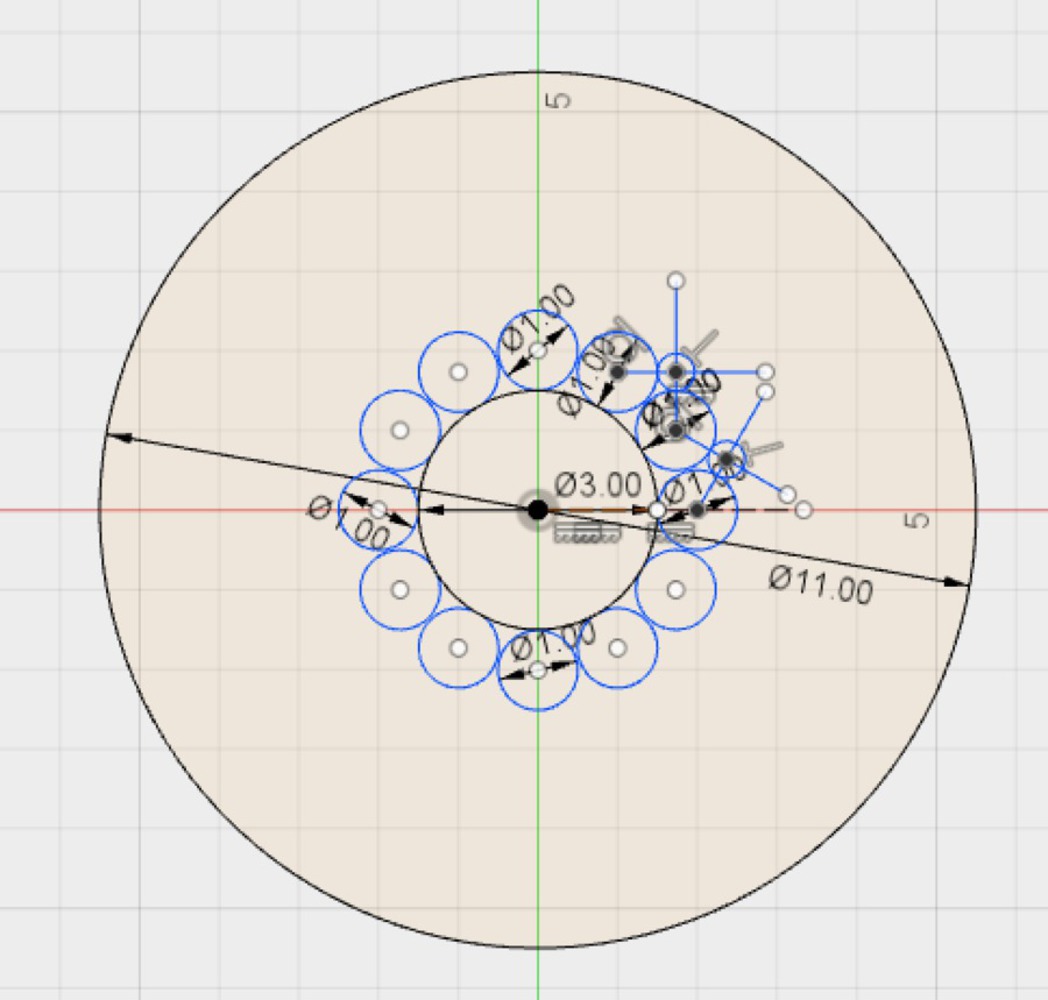

2.) I entered Fusion 360 and modeled the clock. I had to make sure that the clock I was going to make would be able to fit the actual dimensions for the materials I had available to me, so I decided upon the clock having an 11 inch diameter and for the hole in the middle for the clock hands to be 1 centimeter.

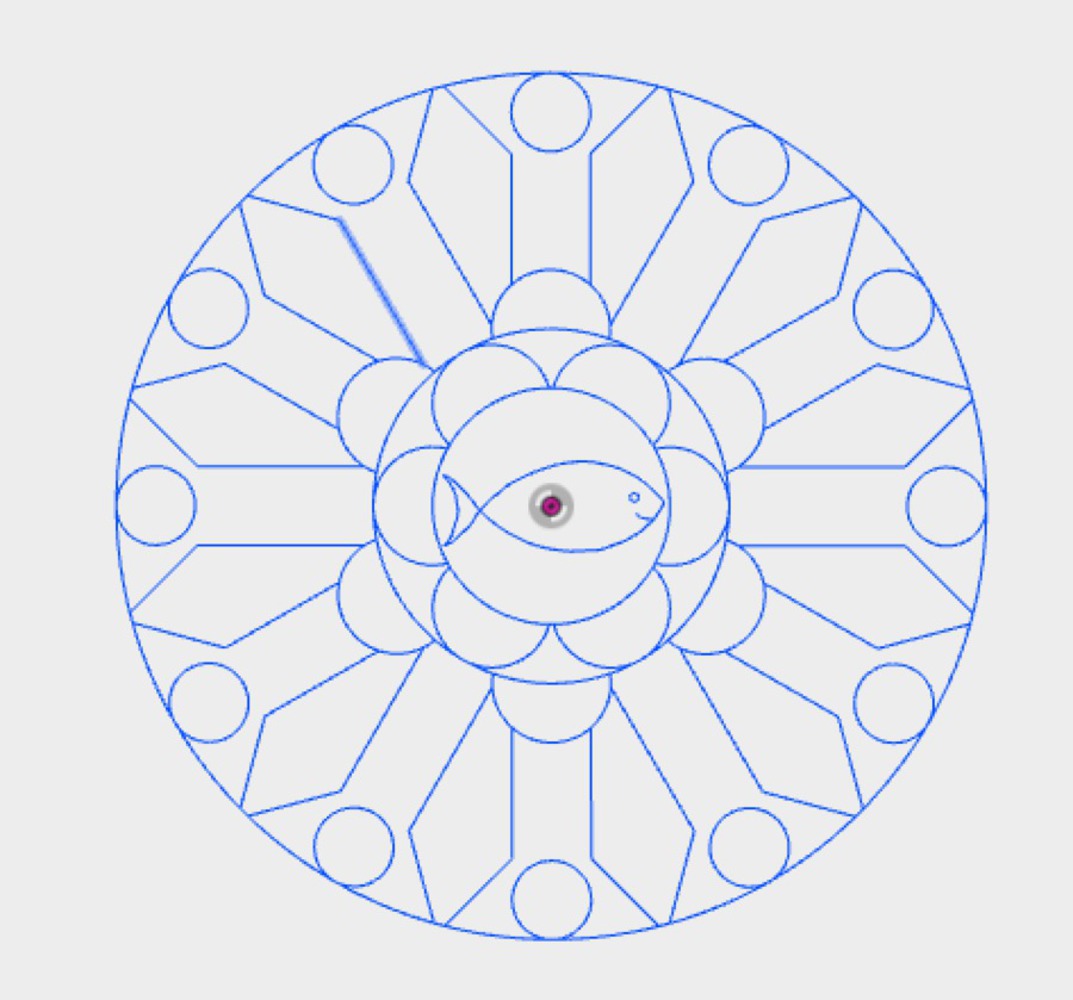

3.) After making the initial circle for the clock to be in, I imported a photo of the Wholey's sign and used the splice tool to create the shape I wanted. I then started messing around with different combinations of circular symmetry in an effort to create a visually appealing clock.

4.) I ultimately decided upon the design that I created, and went to print it by exporting the sketch as a dxf file.

5.) My first attempt was a failure, because some of the components to my clock (e.g. the engraved semi-circles) weren't registering as closed paths in the LaserCut program.

6.) I then had to manipulate the file that I had in Fusion 360 to allow for the sections I wanted to engrave have the ability to do so.

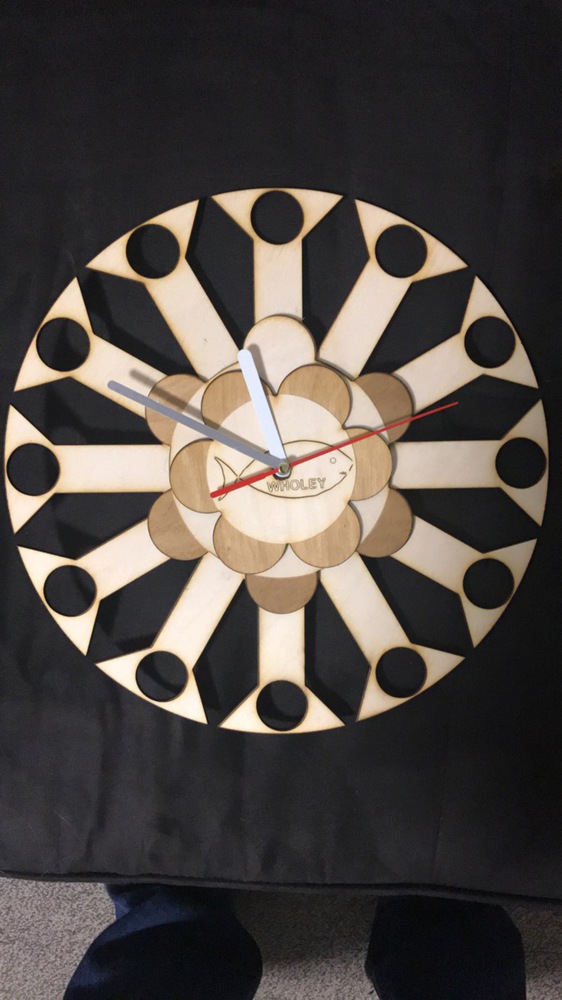

7.) I realized that the most efficient way of doing this was to have my clock have multiple layers its different sections.

8.) Since I made this clock with different layers, I had to glue them all together and put the clock kit through all of them.