Process + Procedure

Design:

1. Package together a sample senior gift of the senior shirt, safety glasses, and a wristband.

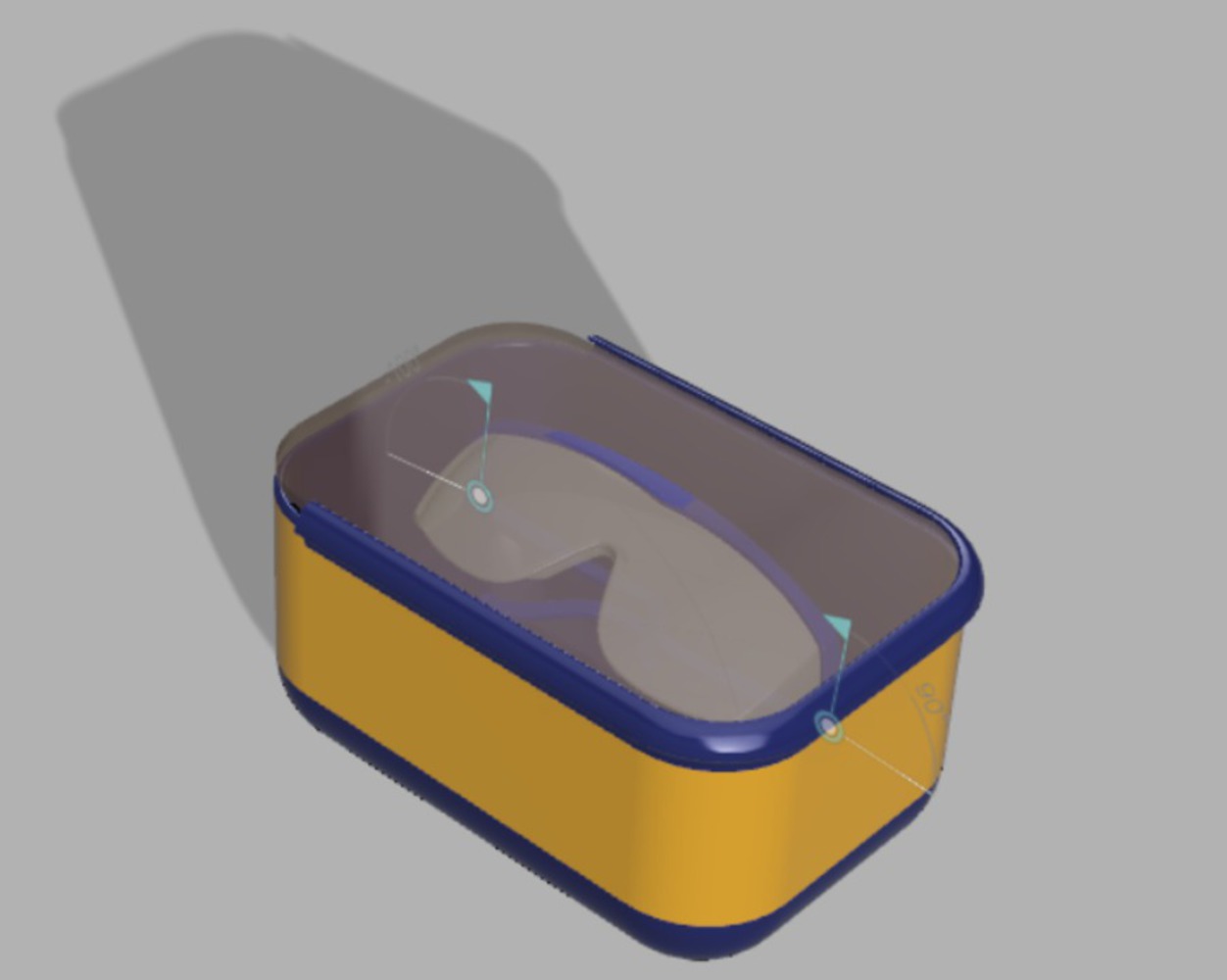

2. Measure the gift dimensions and add estimate container size since these are soft goods.

3. Sketch container base in Fusion and extrude.

4. Add initial modifications (fillets).

5. Shell the container base.

6. Sketch the profile of the mechanical slide notch. Ensure it has tolerances (0.4mm) for 3D printing interfaces.

7. Sketch the path for the notch (open on one side). Create a sweep.

8. Create the cover component using the container base geometry.

9. Find an import GrabCAD safety glasses as a different file.

10. Convert bodies to components and create revolve mates for the glasses side pieces. Rotate them to the folded position.

11. Copy (click-and-drag) the safety glasses file into the holder file. Orient the glasses in the box.

12. Set appearances to match school colors.

Fabrication - 3D Printing:

13. Export the STL and load it on NVBot Cloud.

14. Confirm transformations and supports.

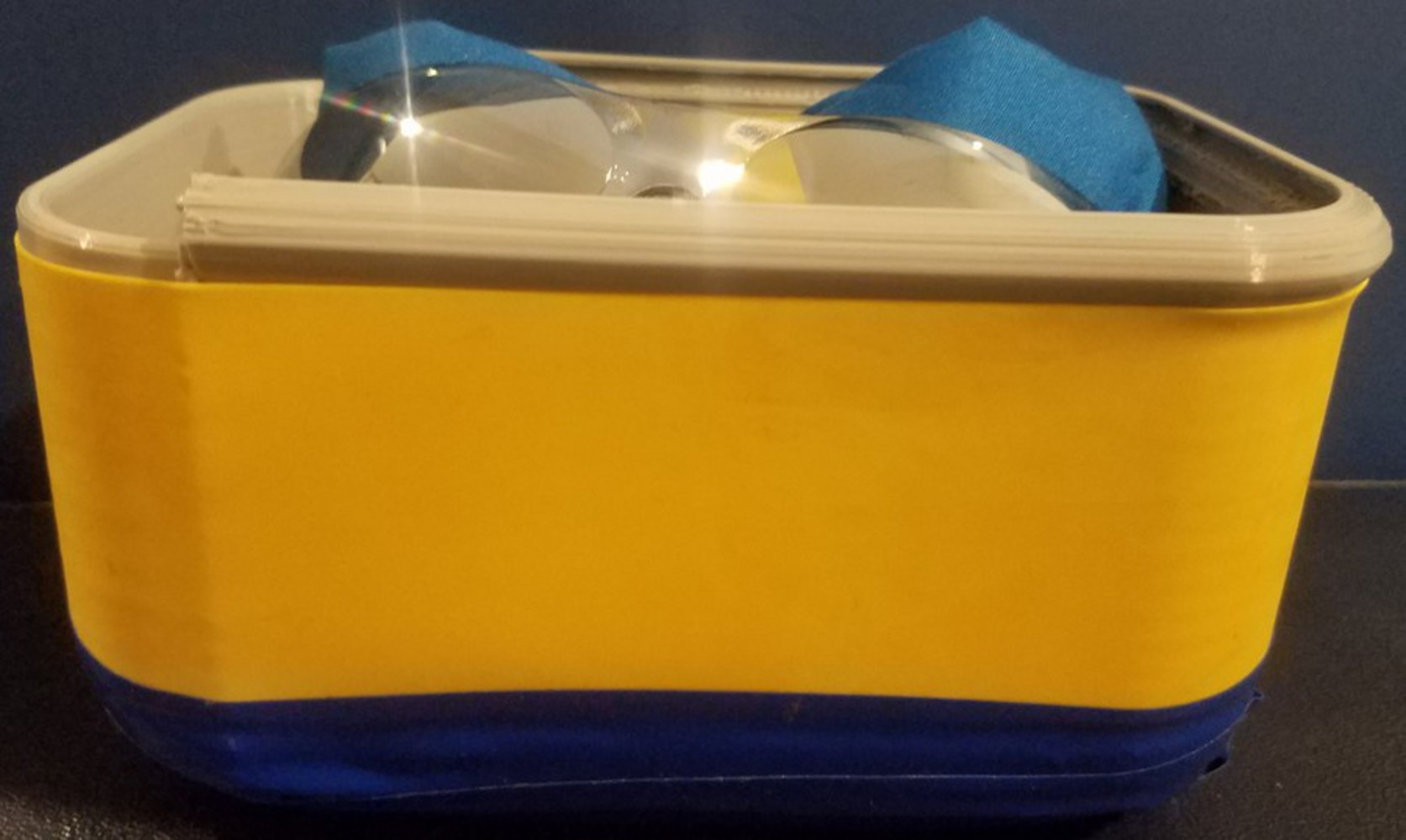

15. Submit print.

16. Clean up the completed print using dental picks.

17. Add soft goods covers to the outside of the box and put the senior gift in.

Fabrication - Laser Cutting:

18. Verify measurements and change cover based on as-built of the container bottom(wasn't necessary).

19. Export DXF and load into DraftSight. Clean up and convert to old version.

20. Import into LaserCut. Position, unite lines, and set speed and power.

21. Cut 3mm acrylic.

22. Clean edges and insert cover into slide notch.

This worked pretty much as expected, though the safety glasses GrabCAD isn't of the actual glasses I used, so the CAD does differ in that regard. The final colors are also slightly different.