Intention

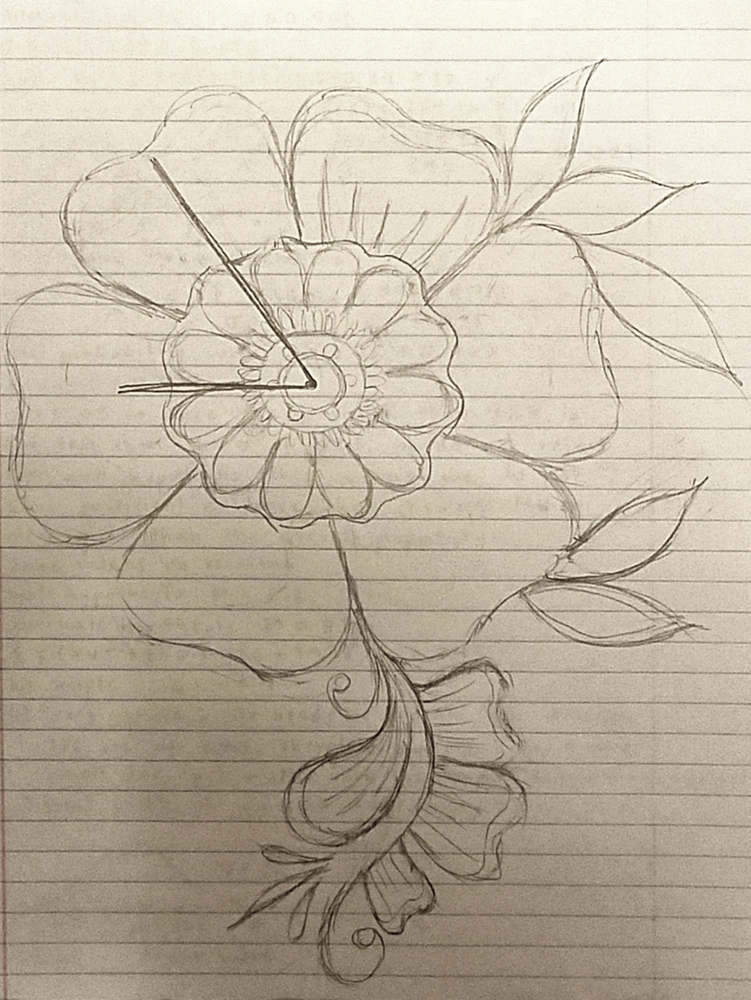

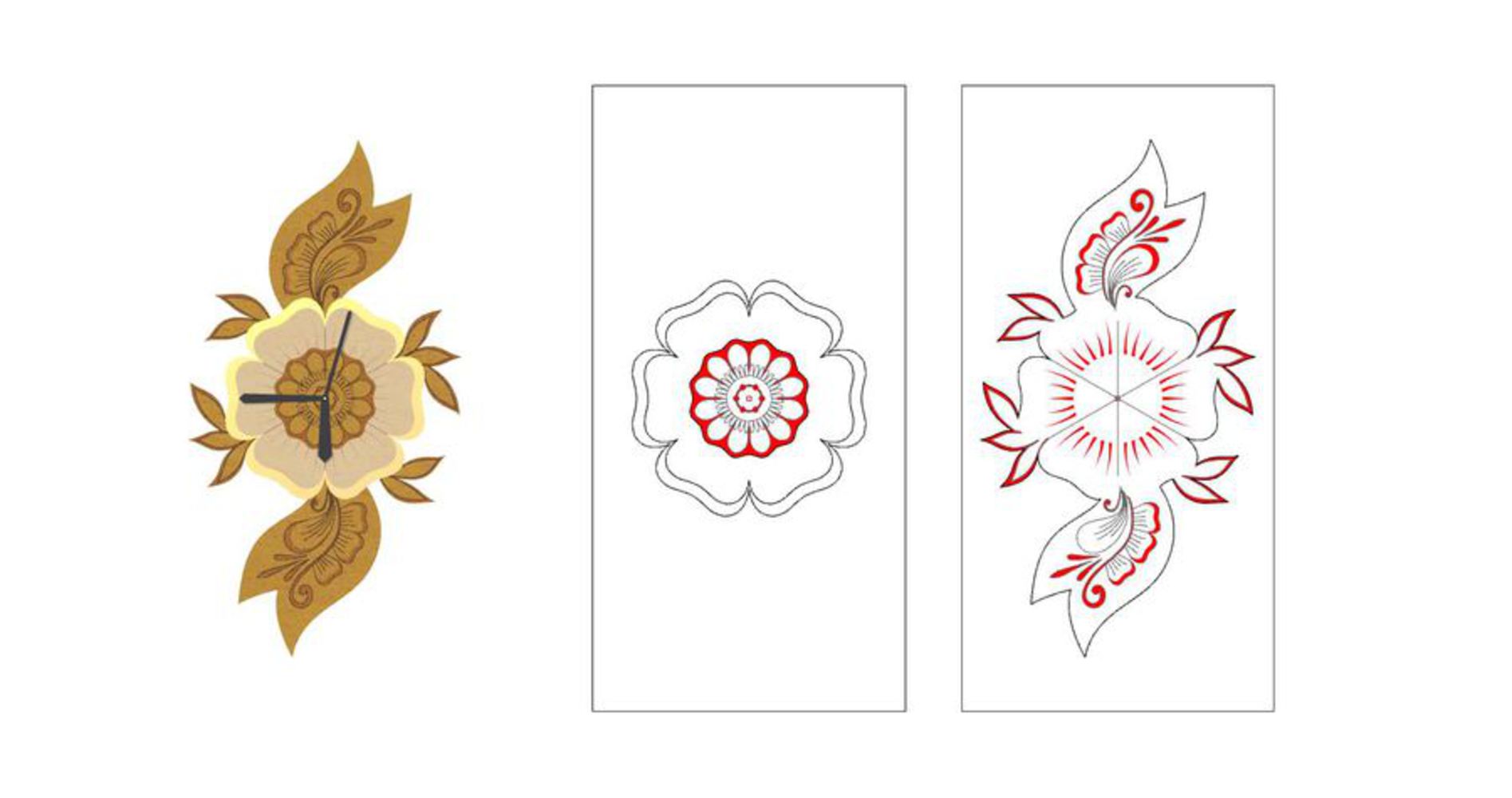

Growing up in an Indian family, I participated in the fun tradition of getting henna applied in intricate designs on my hands every marriage I attended and annual Diwali celebration. The wonderful thing about henna is it is always done freehand. The shapes commonly used in henna designs include forms influenced by nature: dots, leaves, flowers, and swirls. To add dimension to these lines, henna artists often add shading within the leaves and flower petals. I thought that this form of art would be a really interesting concept to laser cut, since I would be able to utilize the 3 major laser cutting techniques: cutting, scoring, and engraving. The scoring would serve as the fine lines found in henna, and the engraving would serve as the shading found in henna. In addition to being able to practice different laser cutting techniques, I also was inspired by henna because I find the designs very aesthetically pleasing and nostalgic.