Process + Procedure

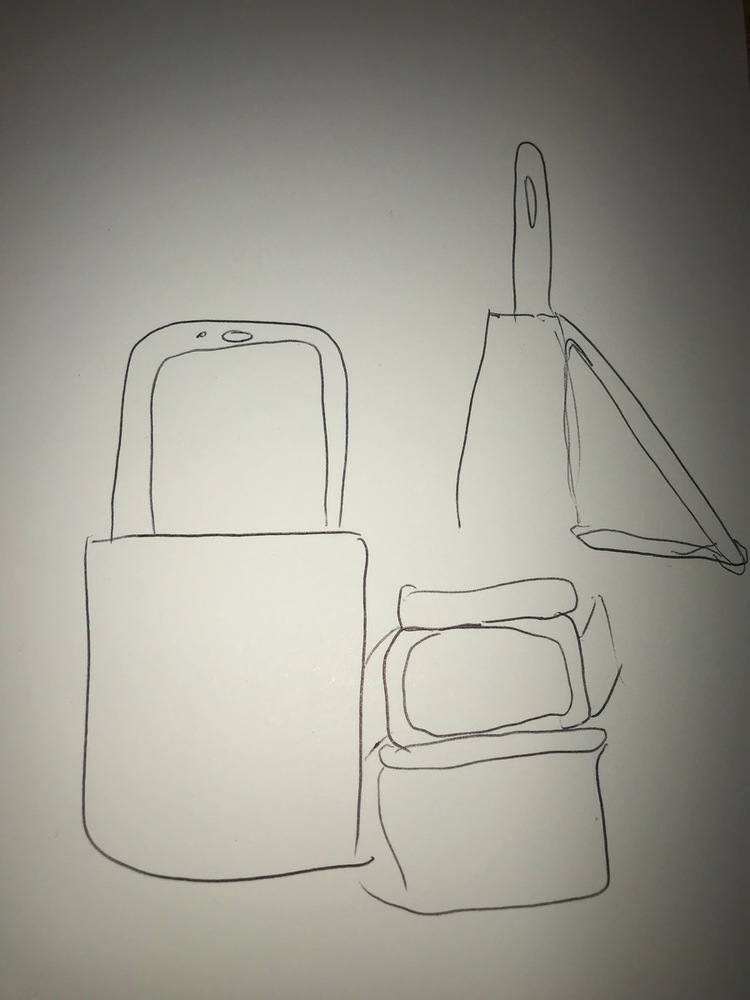

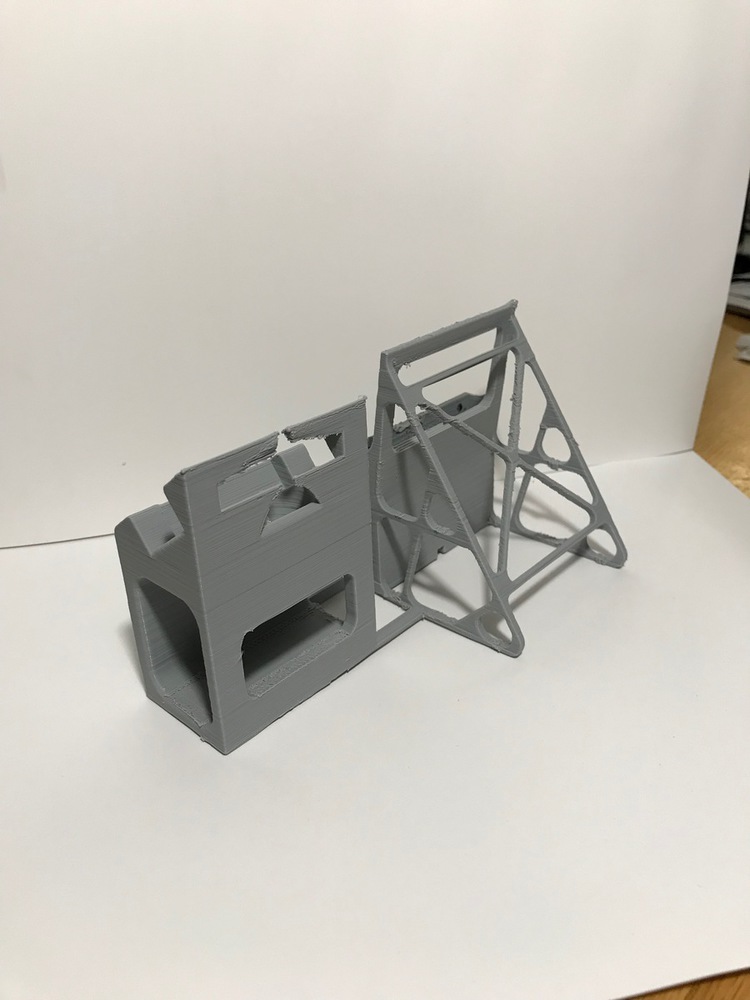

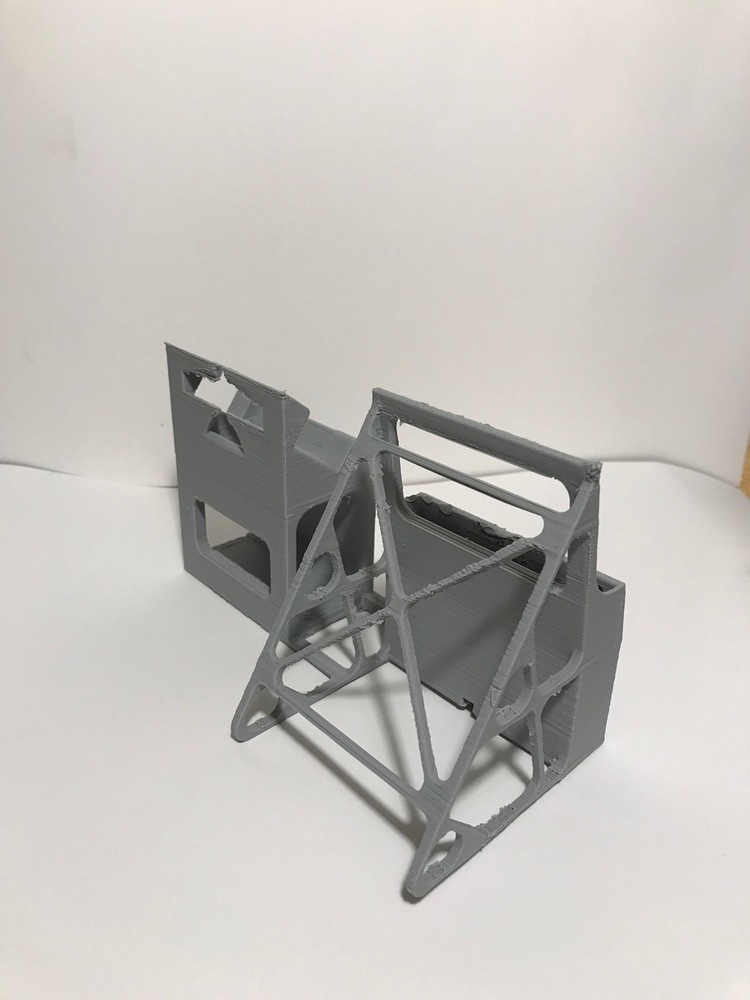

I used Autodesk Fusion 360 to model my project. I did my sketching by hand ompletely digitally and began by modeling a raised phone stand that fit the specifications of my phone and charger (I hand measured the dimensions) and estimated how much wire I was willing to bend in my design. I then modeled the watch portion and tried to match the general aesthetic of the phone portion.

I tried to minimize the amount of material, which is why I made the design hollow and with thin supports. Keeping in mind that PLA was going to be generally light, I made a support on the back of the phone portion.

I used an NVBot 3D printer to print my product and used PLA as a material. After printing, I realized that the hole for the wire was a little too small, so I tried to sand it to make it a little bigger, but that proved to be really difficult. I then used a heated exacto knife to try and cut it bigger, which worked, but I accidentally melted other parts of the material (without compromising functionality). Since I had used a lot of material to begin with, I didn't want to reprint and use even more. Honestly, since functionality was of primary importance to me, I didn't mind a cosmetic flaw.