Process + Procedure

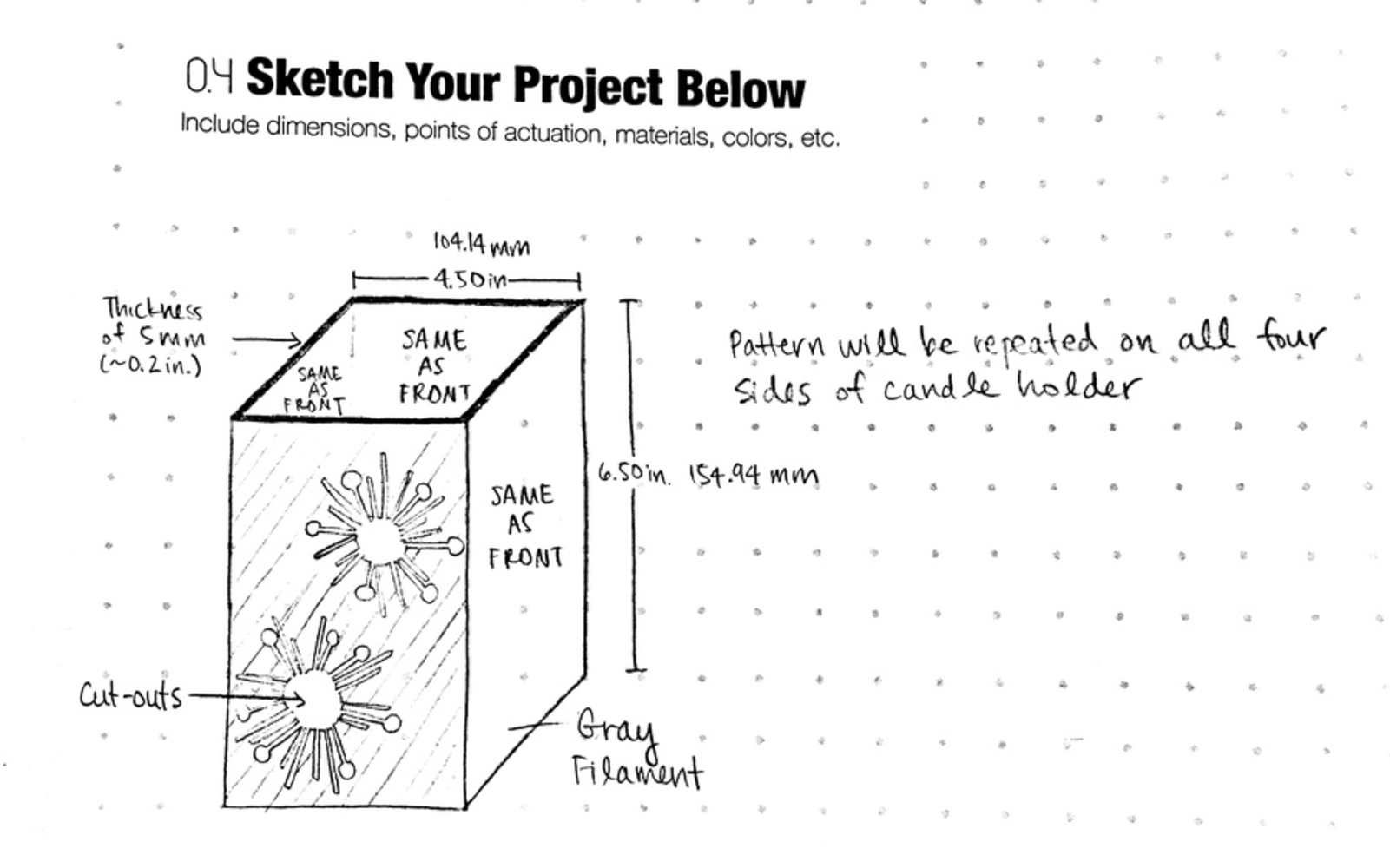

After deciding on a box-shaped candle holder, I looked up a few measurements of candles and decided to make my box about 4 inches wide and 6 inches tall, since many candles were either this size or smaller. I then made an initial sketch of what I imagined my candle holder to look like (shown below in "Sketches" section).

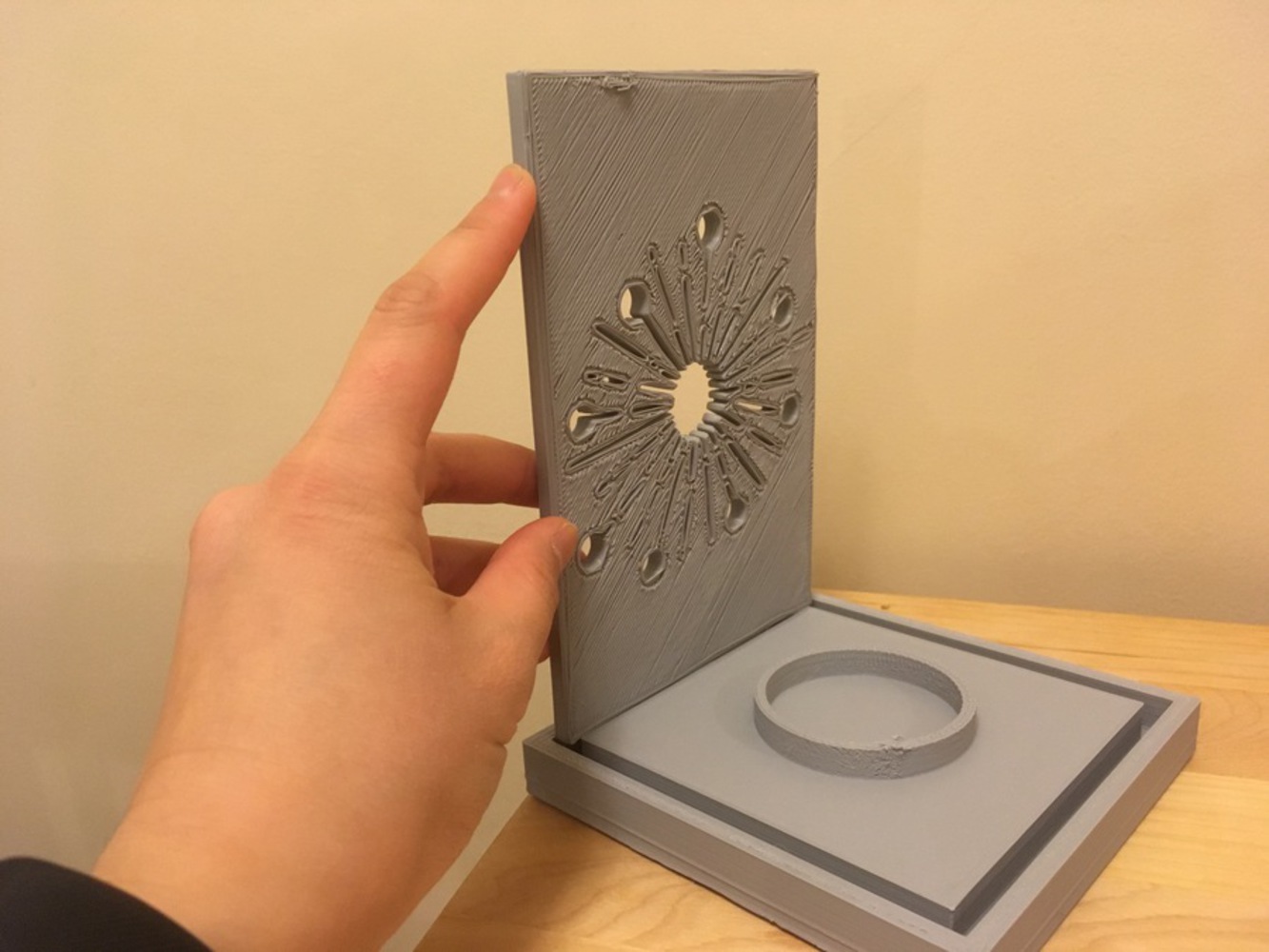

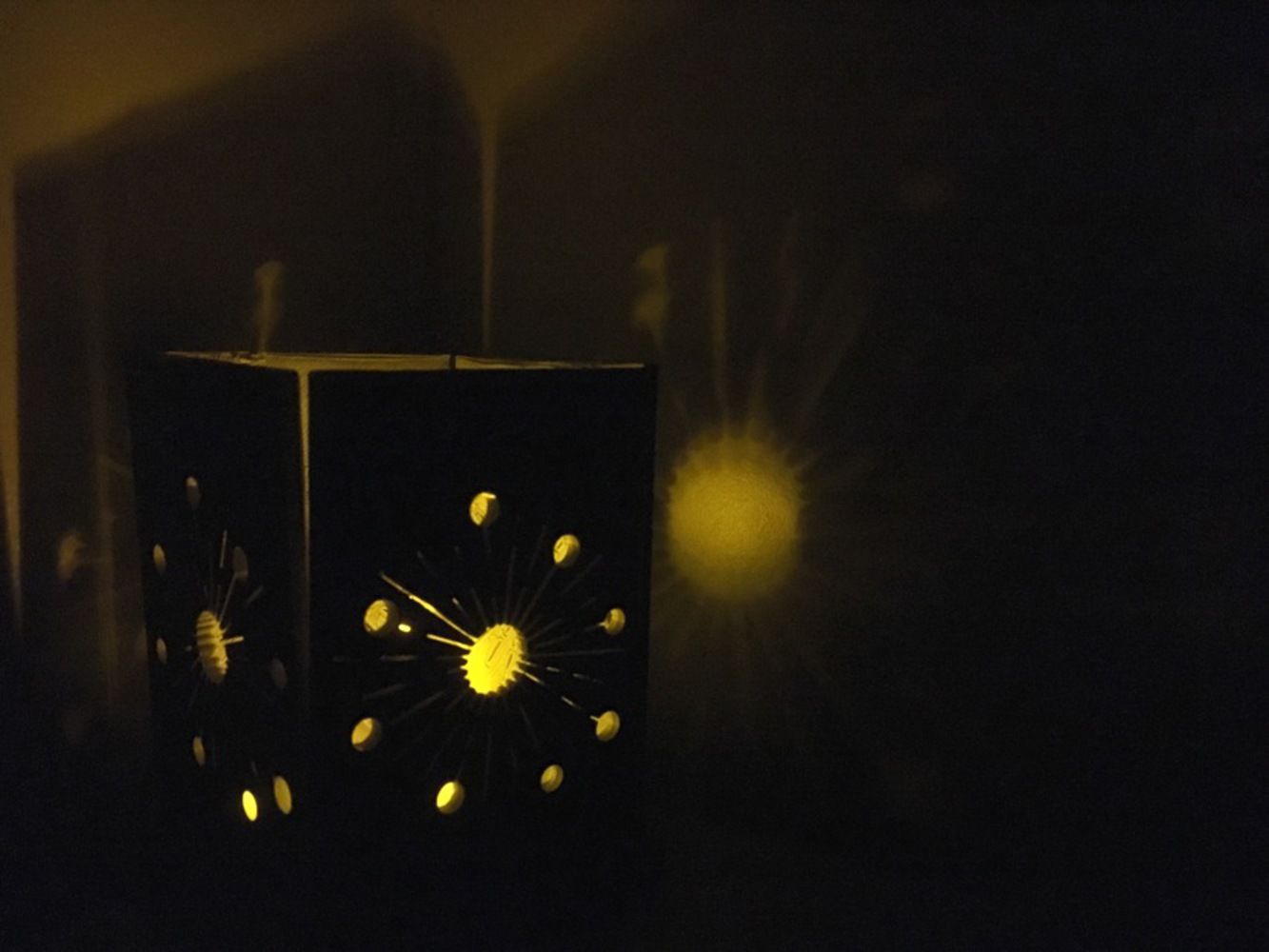

I began modeling this sketch on Fusion360, which is when I ran into a bit of trouble. First off, I realized that having two starburst designs on one face was not a good idea, as they would have been extremely small and the printer probably would not have been able to create the holes for the starburst cutouts, due to tolerance levels. I had also been trying to freehand a starburst by myself, which did not work, so I ended up finding a file using The Noun Project and modifying it a bit. After creating the starburst I wanted and making four walls that lined up with each other, I then came upon a different issue. I realized that if I just printed my holder as one piece, with the walls standing up, the cutouts probably would not have turned out nicely. Since the cutouts were so small, there probably would not be enough room for supports, or the supports would have just filled in all of the gaps and been impossible to take out, so I decided to print all four walls as separate pieces that would lay horizontally. Having decided this, I also created a base with a track that the four walls could click into so they would be able to stand up vertically on the base.

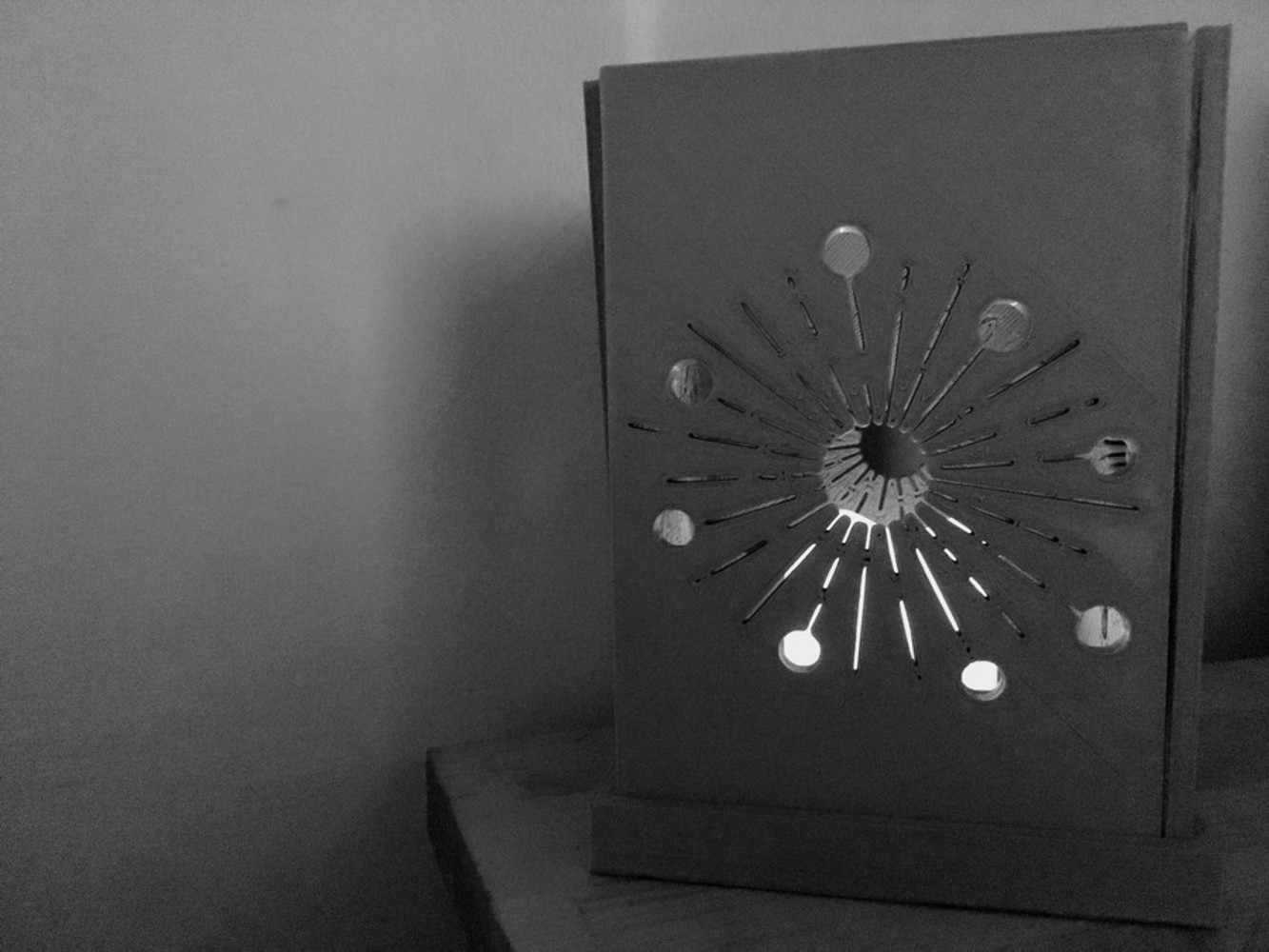

My first task was to print one of the walls by itself before printing the other ones. I was a bit unsure of whether the starburst design would work or not, since the lines were so thin, so this was my test trial to determine whether I could proceed with this design, or I would have to change it. Luckily, it worked, and I then went on to print the other three walls with no trouble.

Printing the base, though, is where I did run into trouble. When creating the base on Fusion360, I had fitted it around the four walls, and built in a tolerance of 0.4 mm, as suggested. However, upon retrieving the printed walls and base, I found that my walls would not fit into the track I had designed for the base. I then widened the track by 1 mm in hopes that it would be enough space for the walls to fit inside, and that new base is currently waiting to be printed. Likewise, the circle I had made for the candle to rest in was not wide enough for the candle, and this had to be adjusted similarly.