Process:

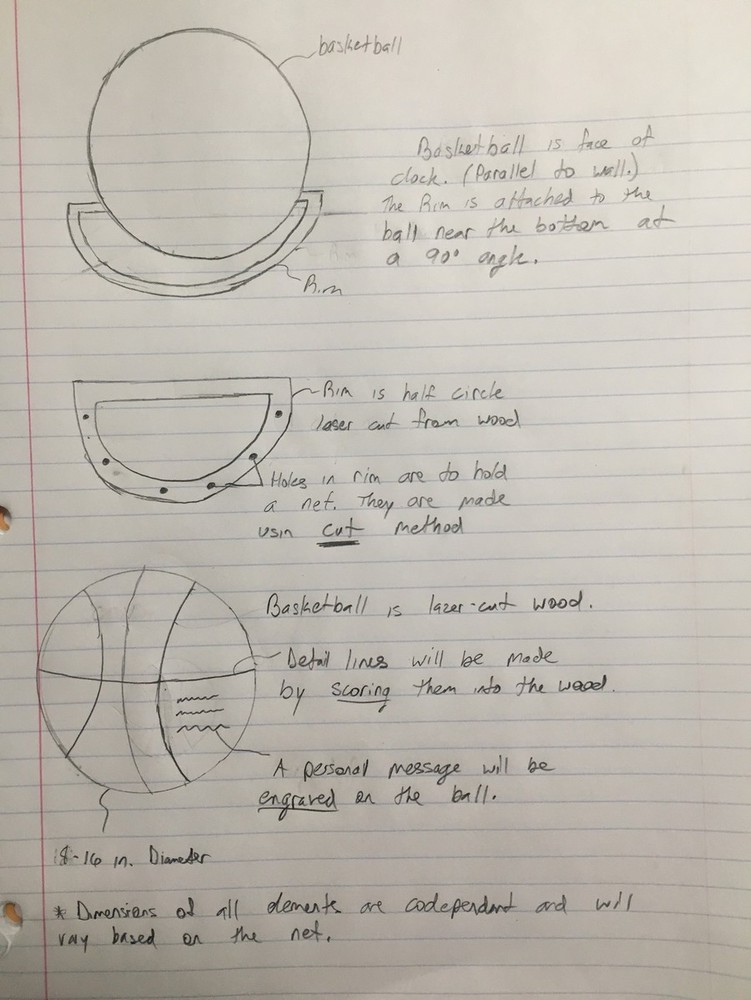

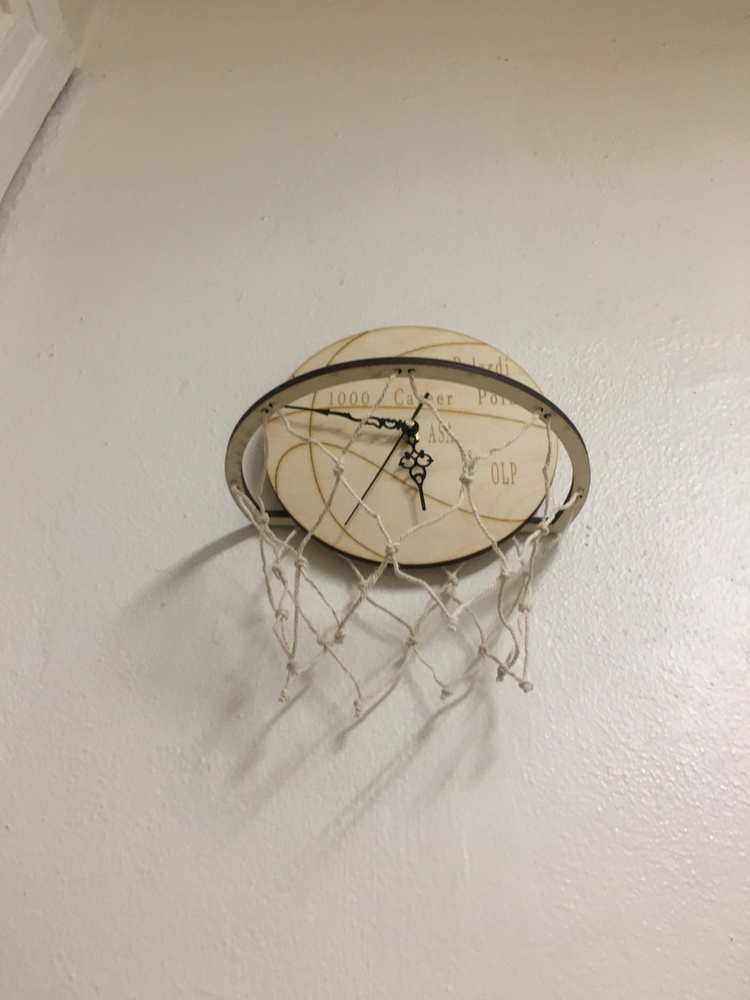

I began by sketching my ideas. Once I had a rough design finalized, I began modelling the clock in Fusion 360. I made sure to keep my models simple and easy to edit. This was mainly because originally my biggest concern was finding a net. I thought that the net would be the driving force of my clock in terms of the size of the components. This would have been the case had I not found a video on YouTube that demonstrated how to tie nets for a basketball hoop.

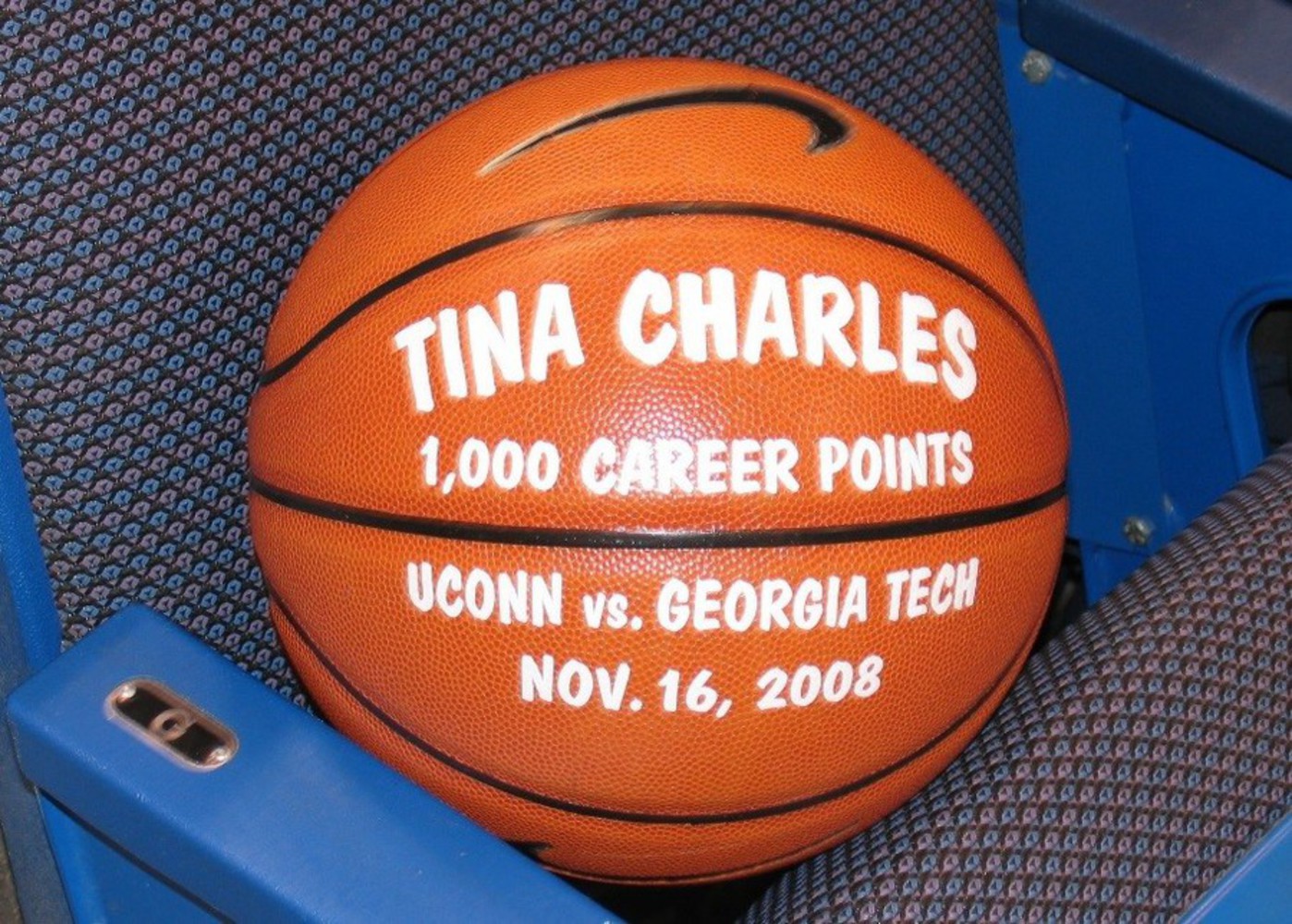

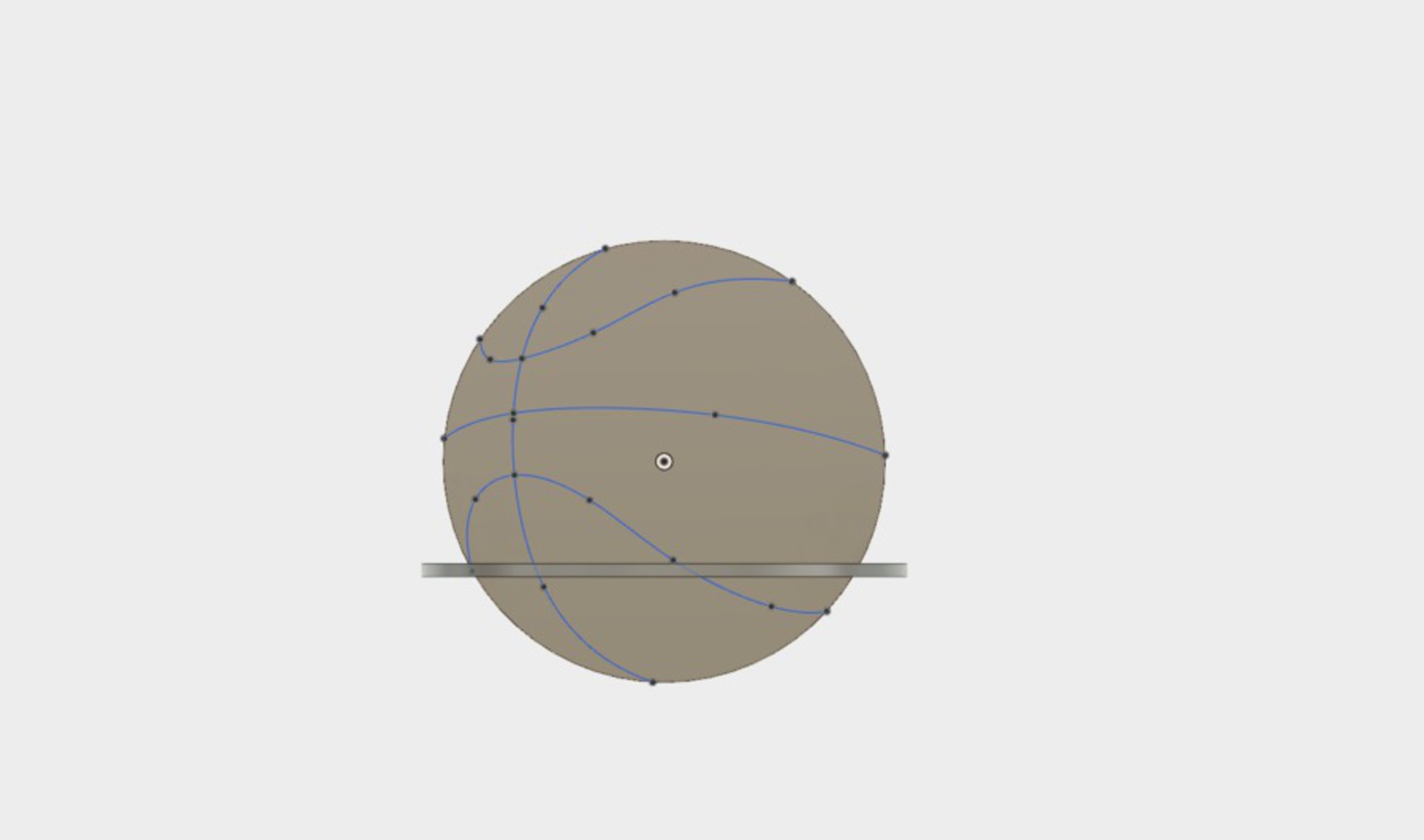

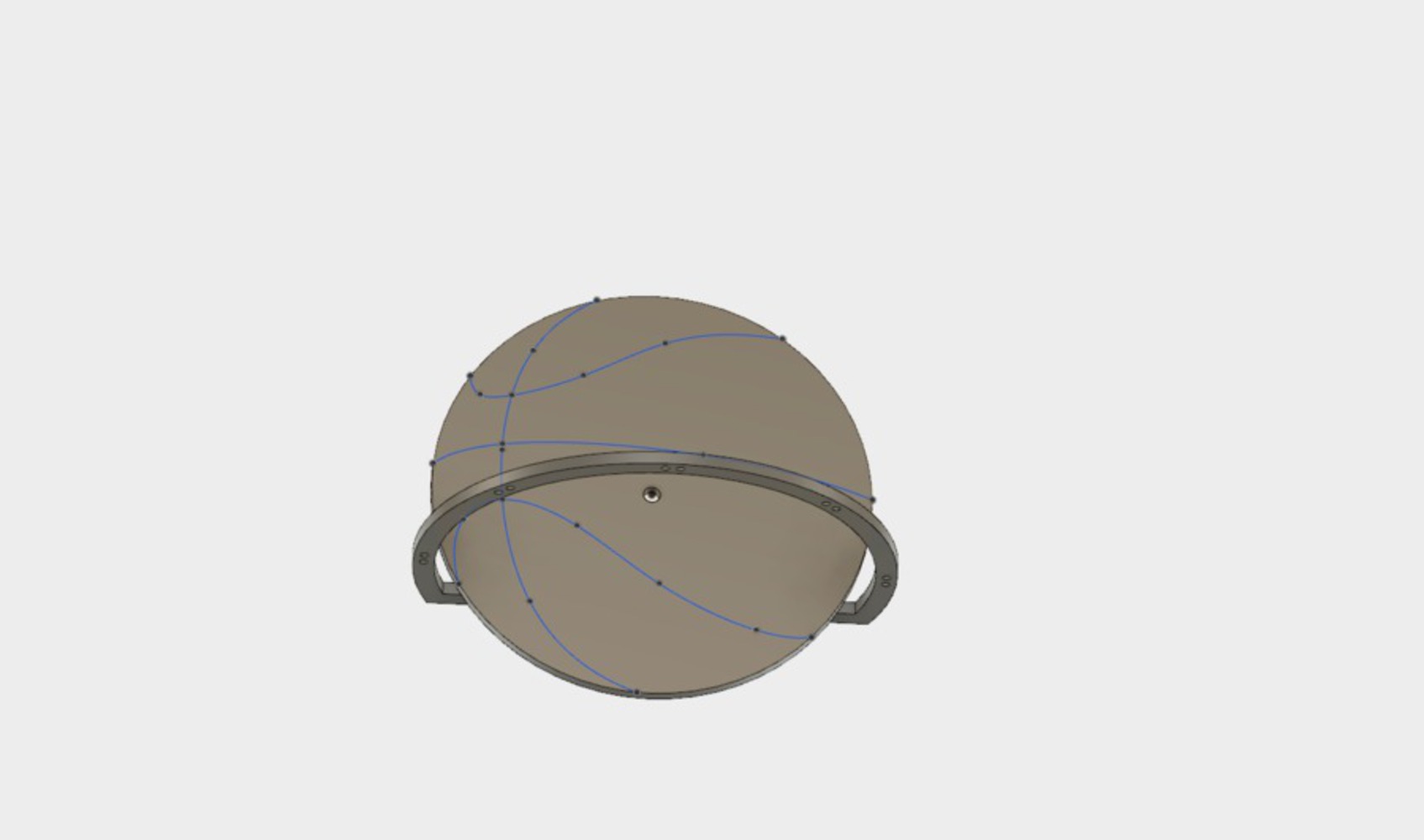

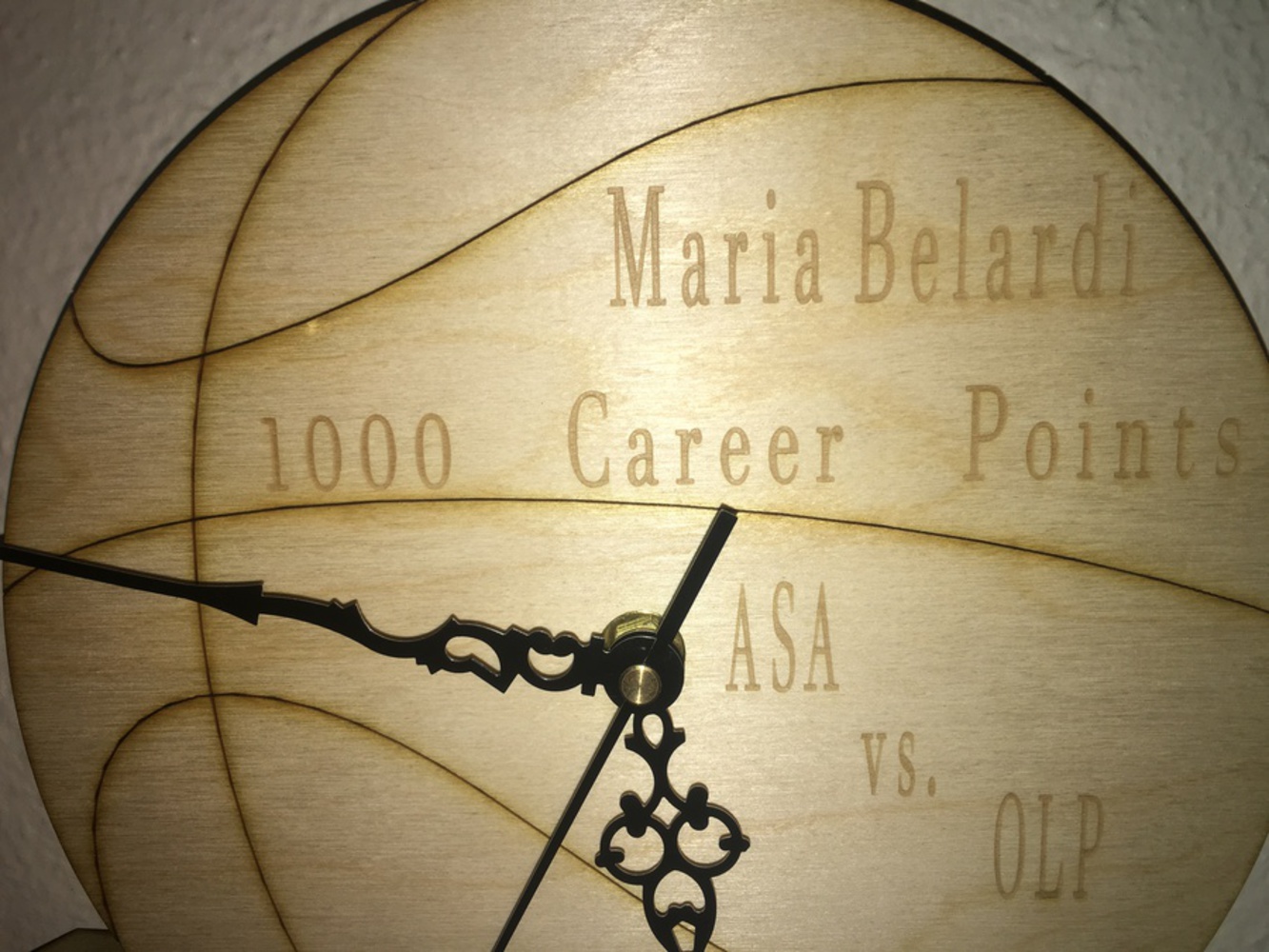

Now that I knew I did not have to focus so much on the net, I began to finalize my designs with dimensions that I liked rather than dimensions that were driven by another aspect of my clock. When I was satisfied with size and layout of everything, I began designing the face of the clock. I used a picture of a basketball and created a sketch of the defining lines of the ball using the spline tool in Fusion 360. I then decided what text to put on the face and prepared it.

Once all of the designs were finalized, I exported them to be laser cut and engraved. After cutting the two components, I cut strips of string out, fed them through the holes on the rim, and tied them as instructed by the video. Next, I fastened the ball to the rim using gorilla glue. I then added the clock kit. Finally I fastened 2 metal brackets with holes in them onto the back of the clock using glue and tied a string from one to the other so the clock can hang from a nail on a wall.