Process & Procedure

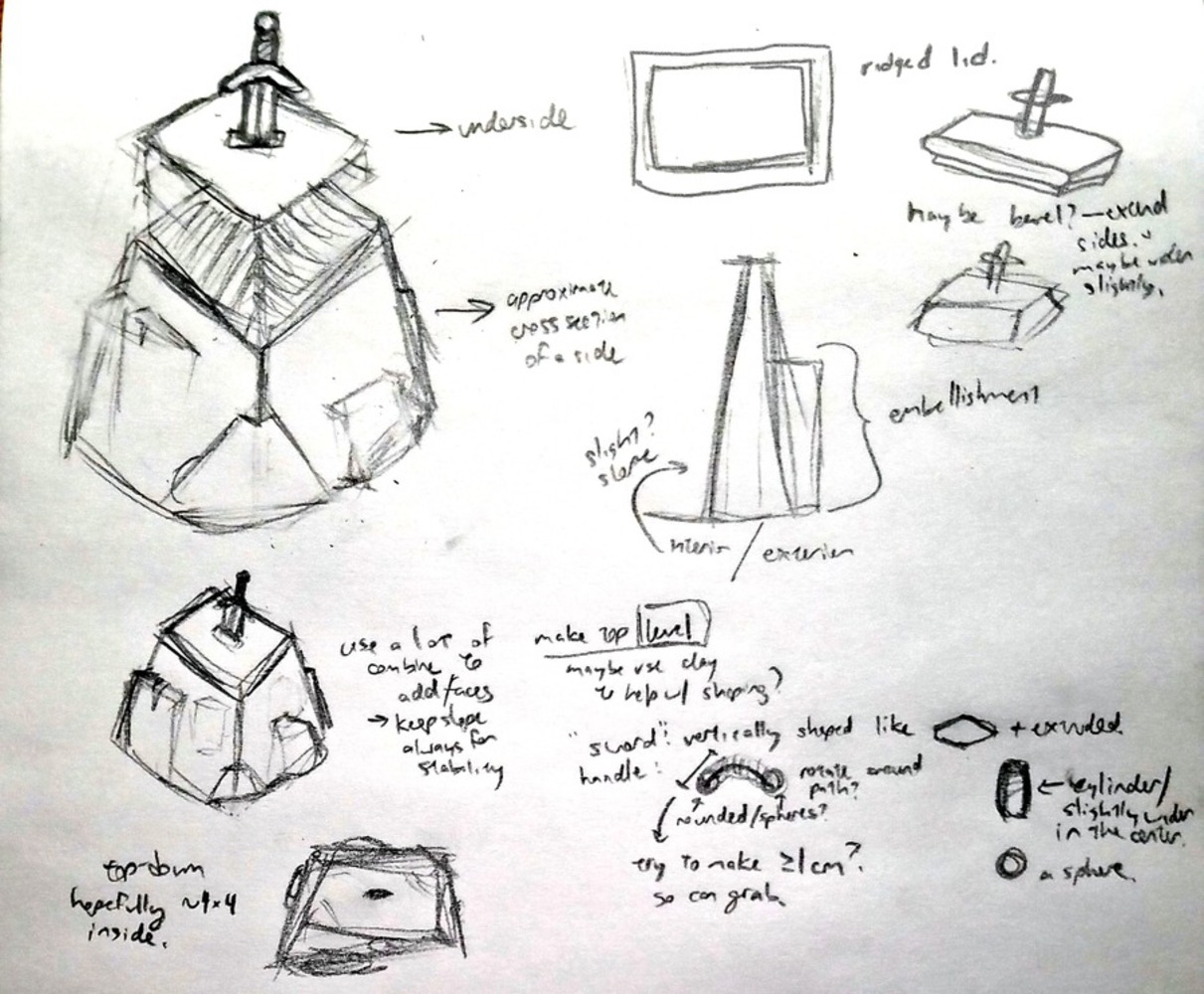

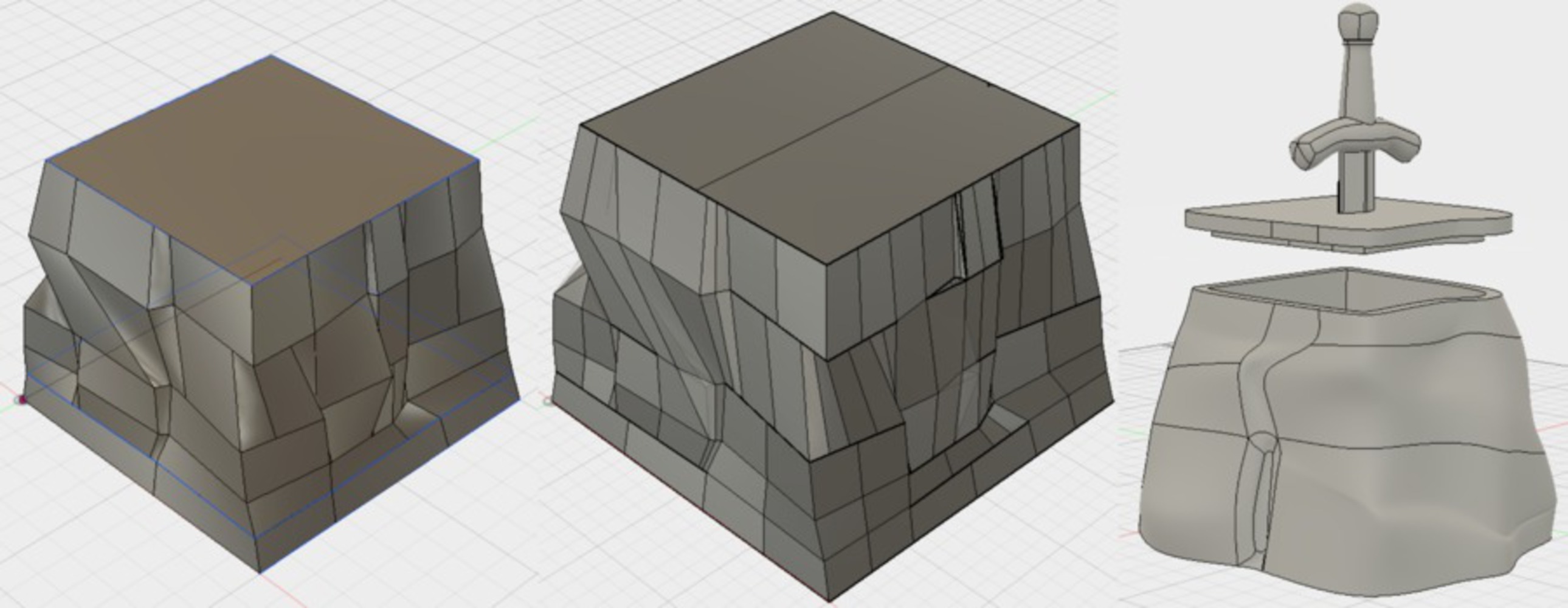

To model the holder, I worked exclusively in Fusion 360. Initially, my plan was to create a series of sketches offset from the X-Y plane to represent the horizontal cross-sections of the base and then to loft them together, adjusting the result in the sculpt environment. Unfortunately, these did not result in T-Splines which I could work with, so I had to take a different approach.

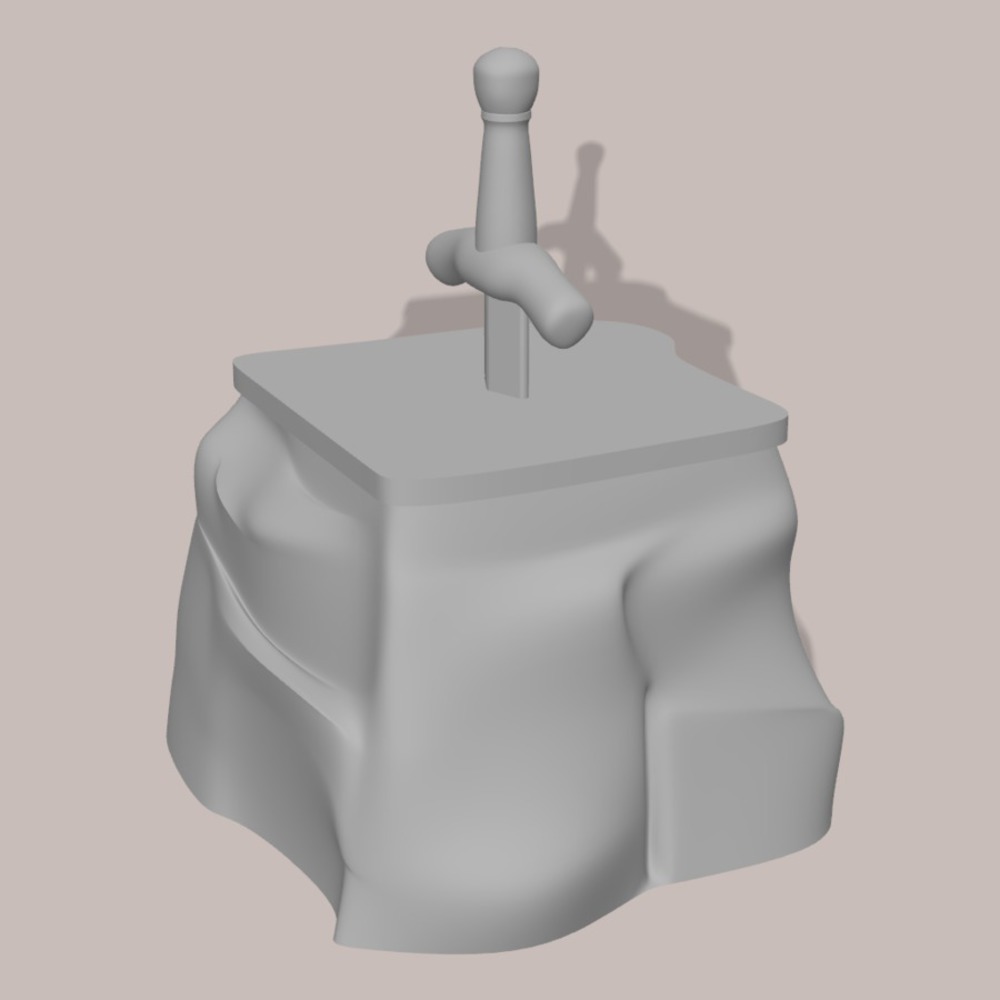

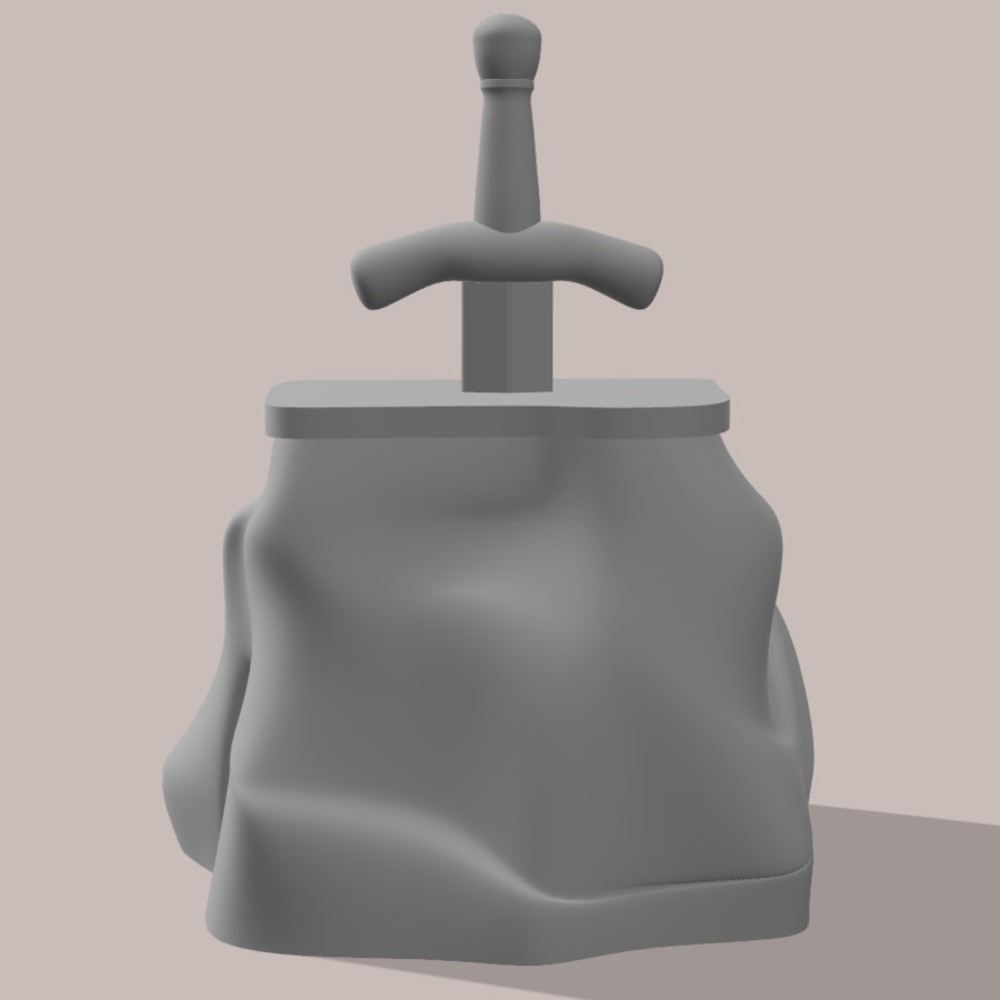

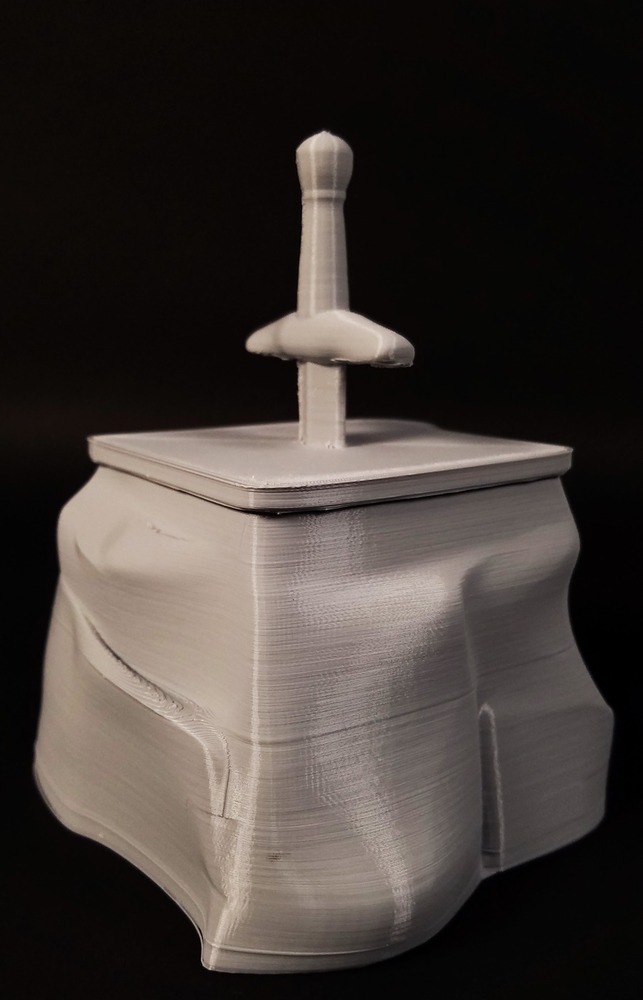

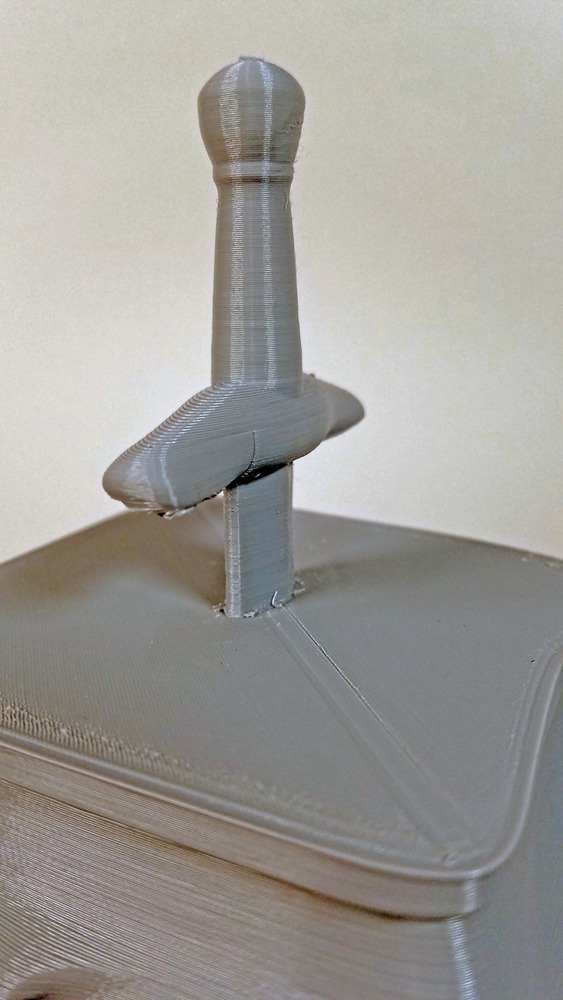

I then made a cube in the sculpt environment, adding many faces and moving them around with the Edit Form command until I was satisfied with the shape (fighting bad topologies/self-intersecting faces often). I then patched and made a solid BRep model from this. I extruded and scaled the top layer to make the lid. I used a shell along a reference body extruded from the top layer to make a smaller geometry to manually shell the body so that it would be 3mm thick at the top (I realize now that the "offset" command in the sketch palette may have done this more efficiently). I made another 1mm shell to make the lip. The handle then resulted from extruding a sketch (the blade), sculpting a cylinder (the grip), sweeping along a path (the guard), making a quadball/another cylinder (the pommel), and sculpting along symmetries to refine it all. I finally combined the bodies for the lid and exported an STL for the lid and the base, sending it to print.

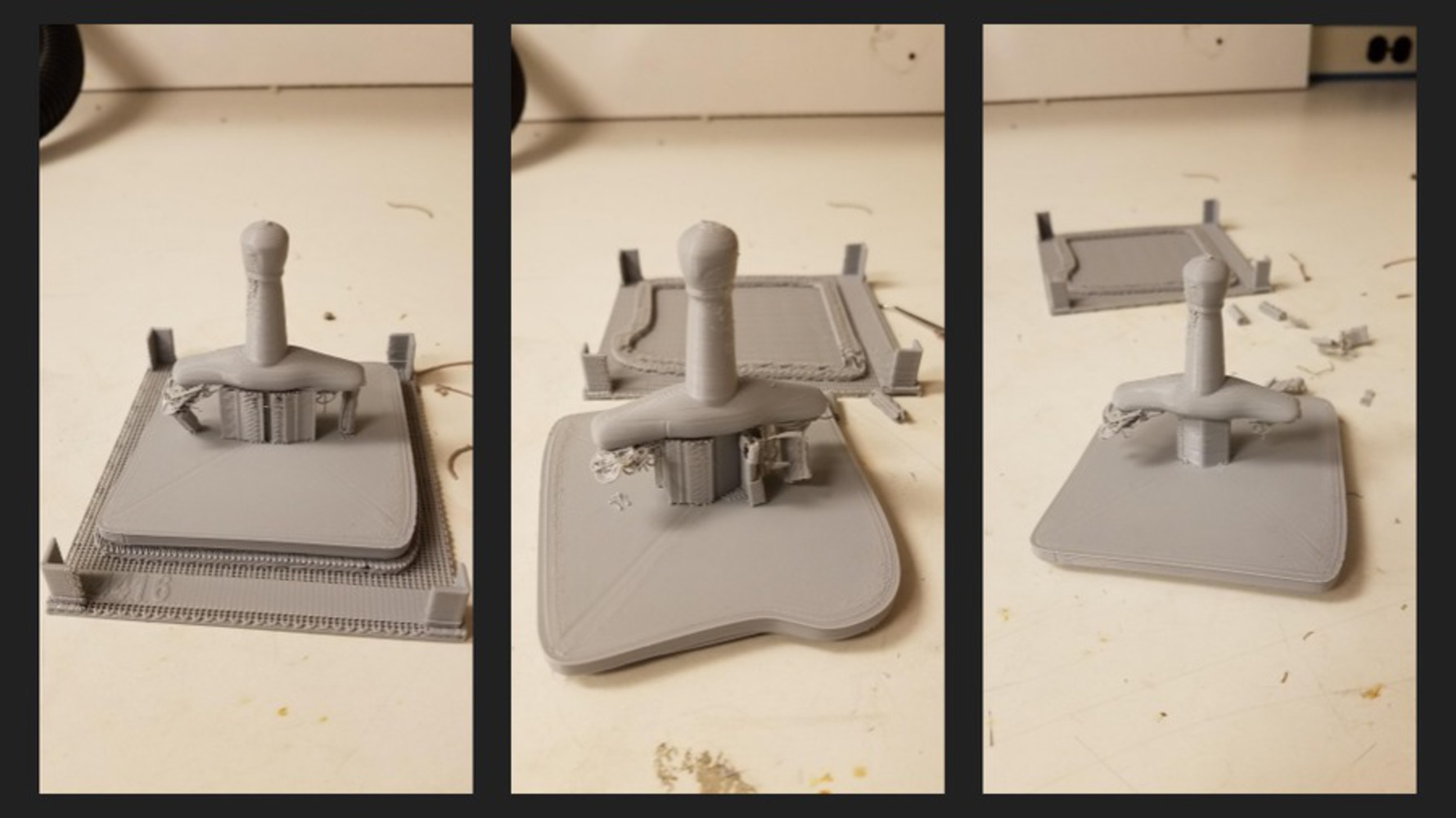

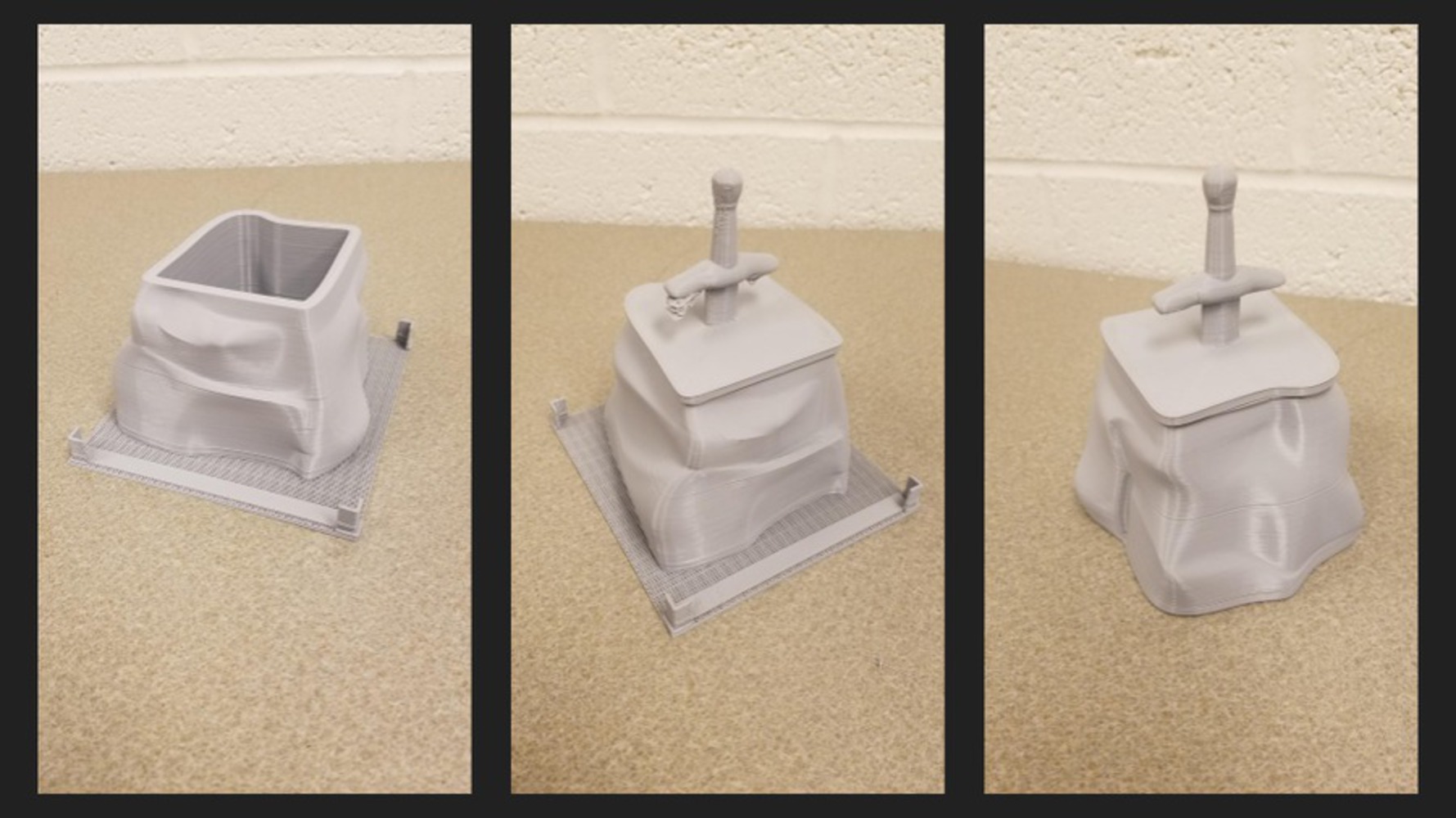

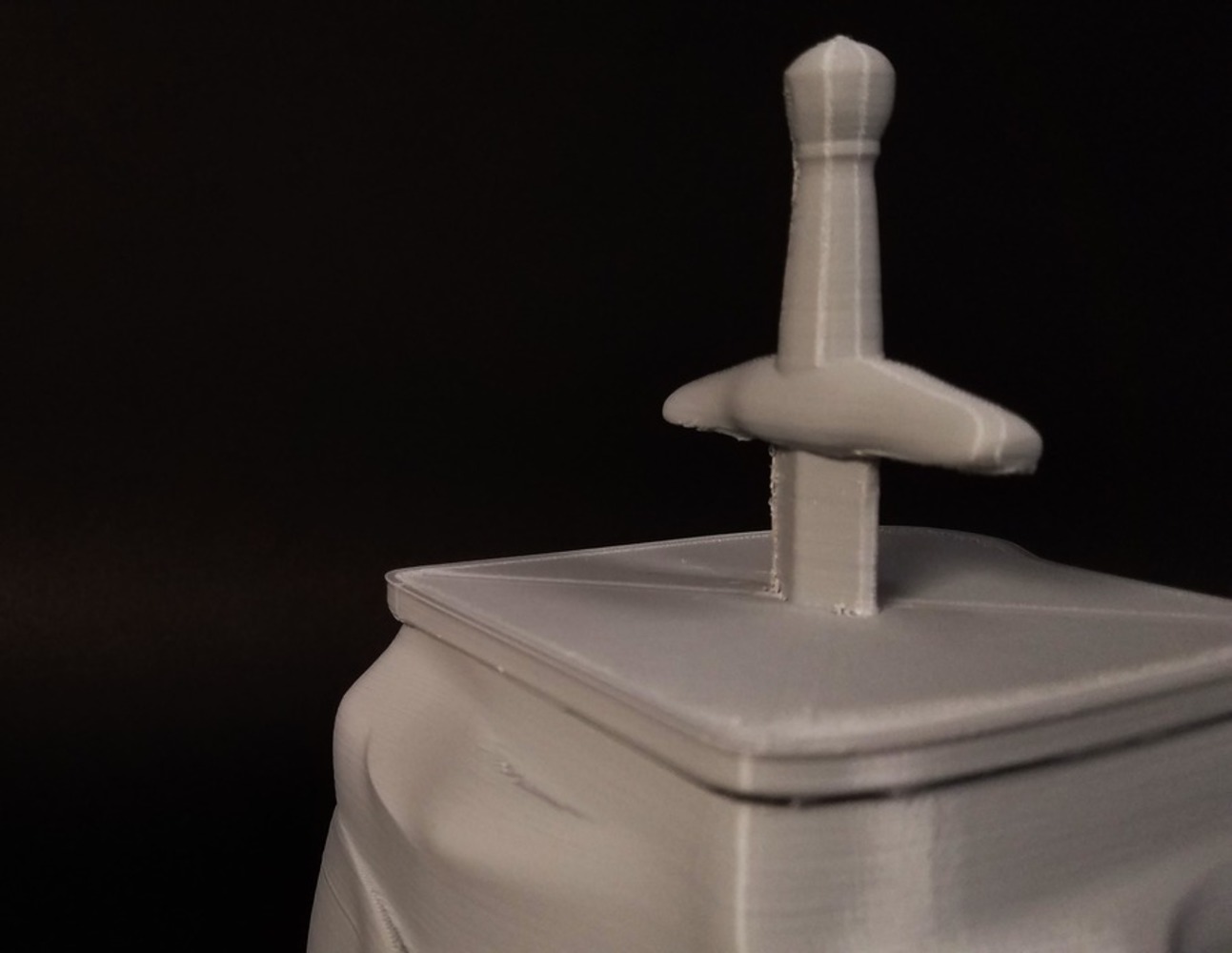

Unfortunately the round portion of the guard did not work well with the supports and ended up very stringy/messy. The rest of the supports around the blade were quite difficult to remove and required a fair amount of time with the dental tools. However, the lid did fit well in the base (perhaps a little loose, so I could have made the lip slightly bigger). Then, I used a utility knife to cut off the stringy parts so the handle ended up mostly flat. It looked pretty good/was still functional then, so I decided that I didn't need to reprint it. I also thought that the unpainted result looked fine as is, so I left it that way and proceeded to use it to start storing tiny parts for my next project.