Process & Procedure

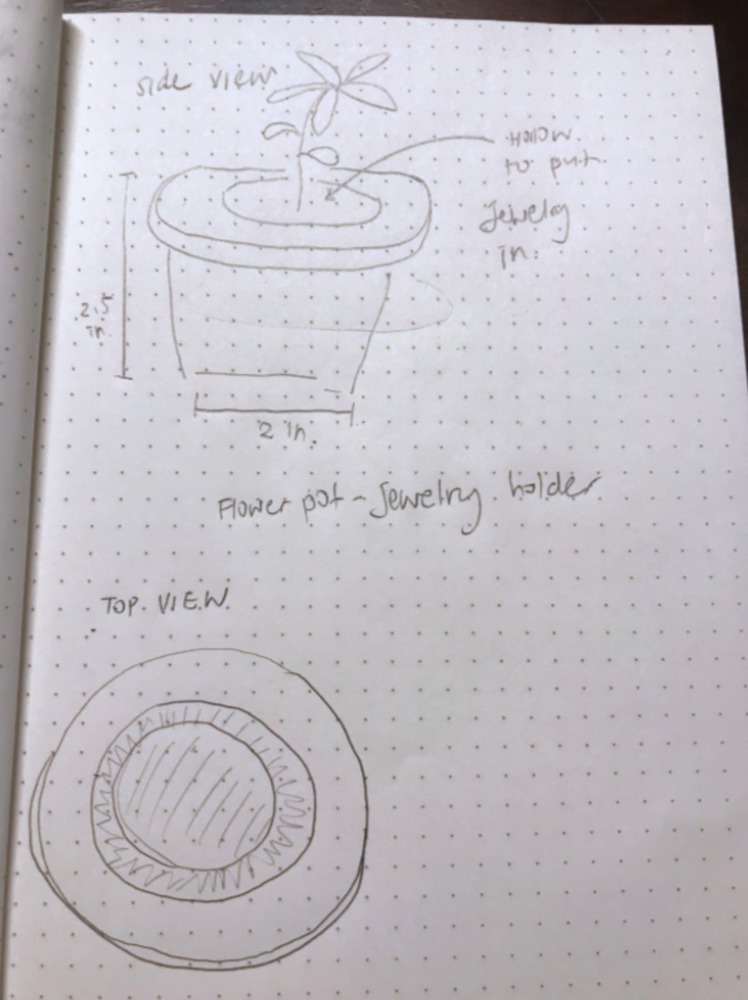

Originally, I wanted to add another element of elegance in my prototype: a flower hanger. However, while designing on CAD, I realized how difficult it would be to design and successfully print a flower design along with my original holder idea.

I was also inspired to make use of the different creating tools we learned in class, such as the torus tool which I had never even heard of before.

This helped define a simple, yet elegant design. However, I then started to face various difficulties in the 3-D printing of my final prototype. Our class was instructed to send our print jobs to NVBots, which would then make the final 3-D print job. My first attempt at printing ended up failing after printing a portion of the way through. I then saw that someone (TA) had sent my original print job to another NVBot printer. However, while I was watching this second 3-D print being done, I was alarmed to find that the machine was "air-printing." Essentially, the machine was going through all the motions of printing and thought it was printing. However, it was actually not, and was in fact printing in the air.

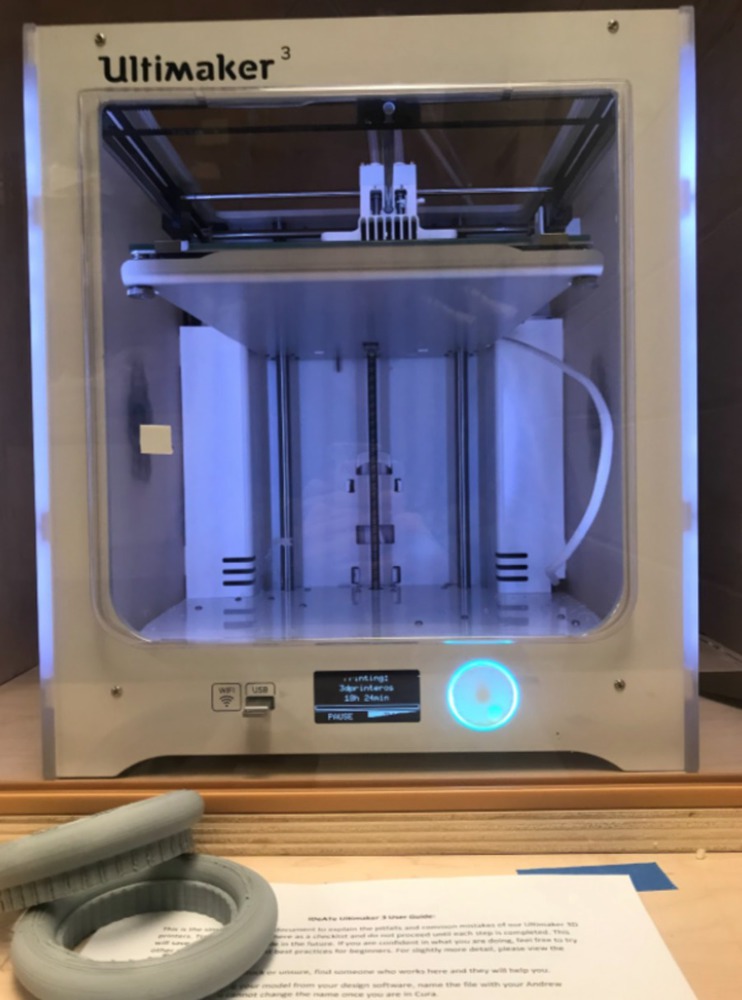

Cody Soska who happened to be fixing a machine in the Ideate Lab, helped look over my design. However, after going through various programs, we determined that there was nothing particularly faulty with the design.

Cody then sent the print job to another machine called Ultimaker (pictured below along with my two failed prototypes). After a print job that took about 18 hours, my final prototype was finally printed.