Process and Procedure:

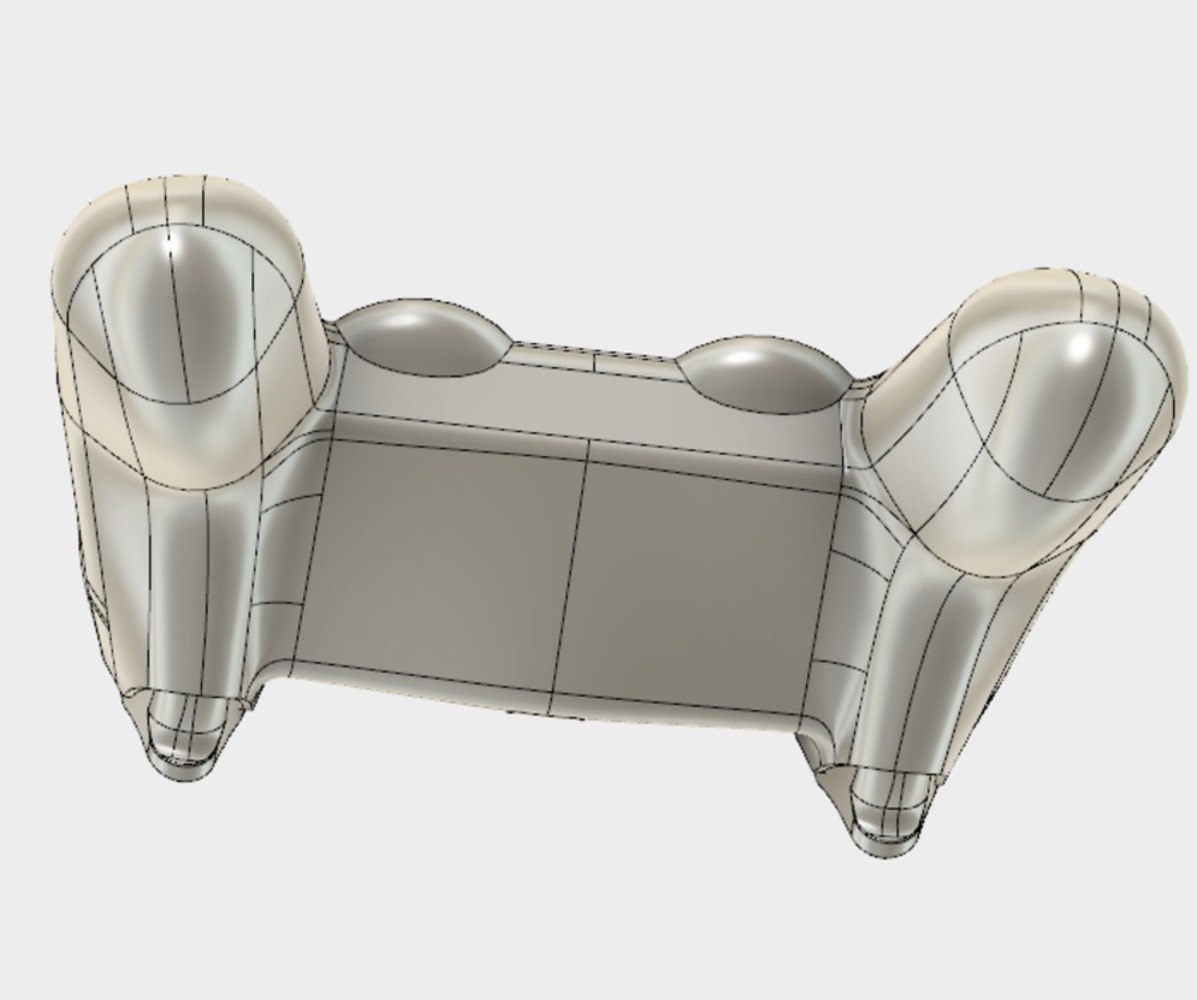

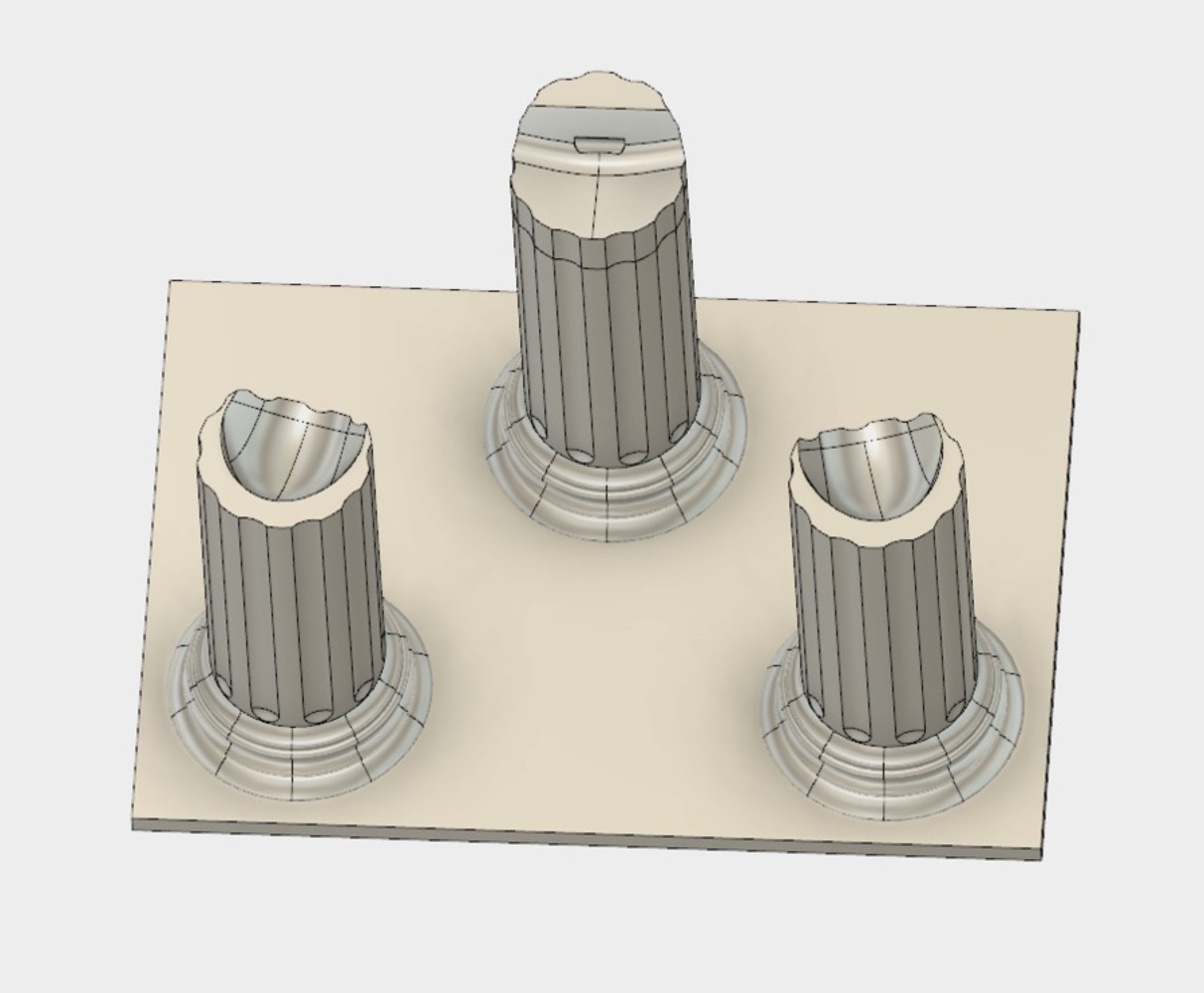

Initially I planned on making the holder with one column that then branched out like a tree at the top to hold the controller. After thinking about this design I decided it would be a more stable structure and would print better on a 3D printer if i used 3 separate columns instead of one large one with "branches" stemming off of it at small angles. To aid in my design I found a CAD model of a controller online.

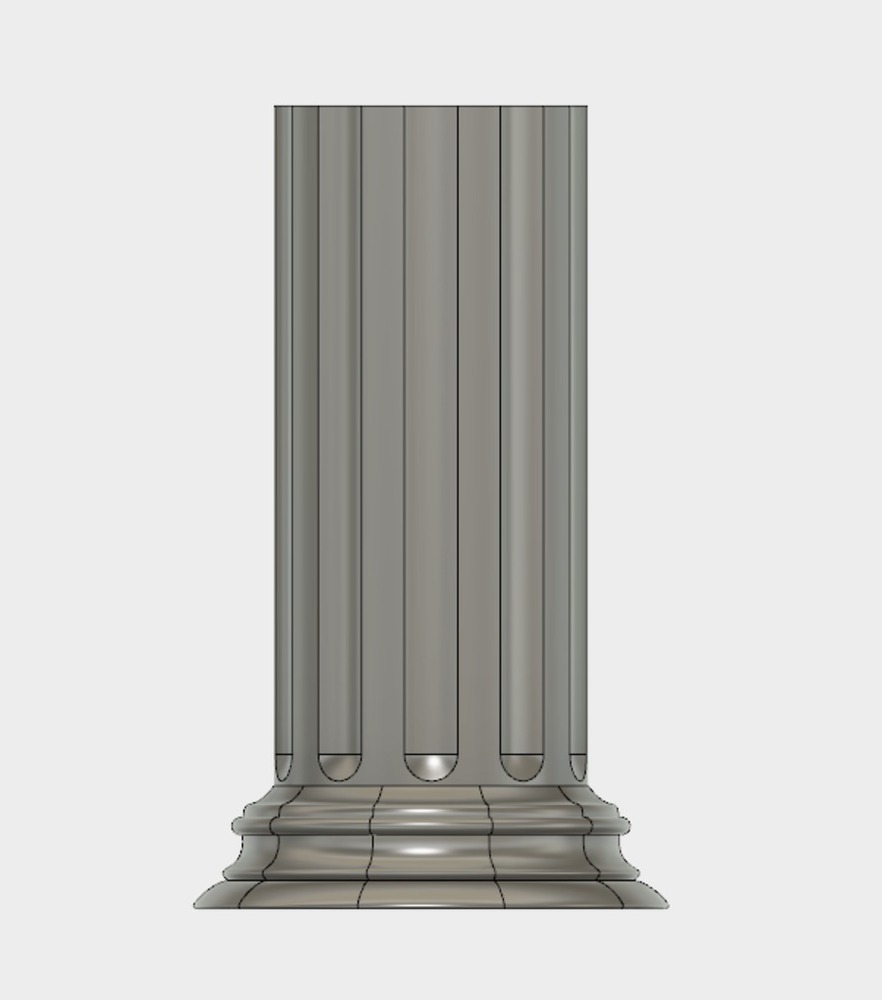

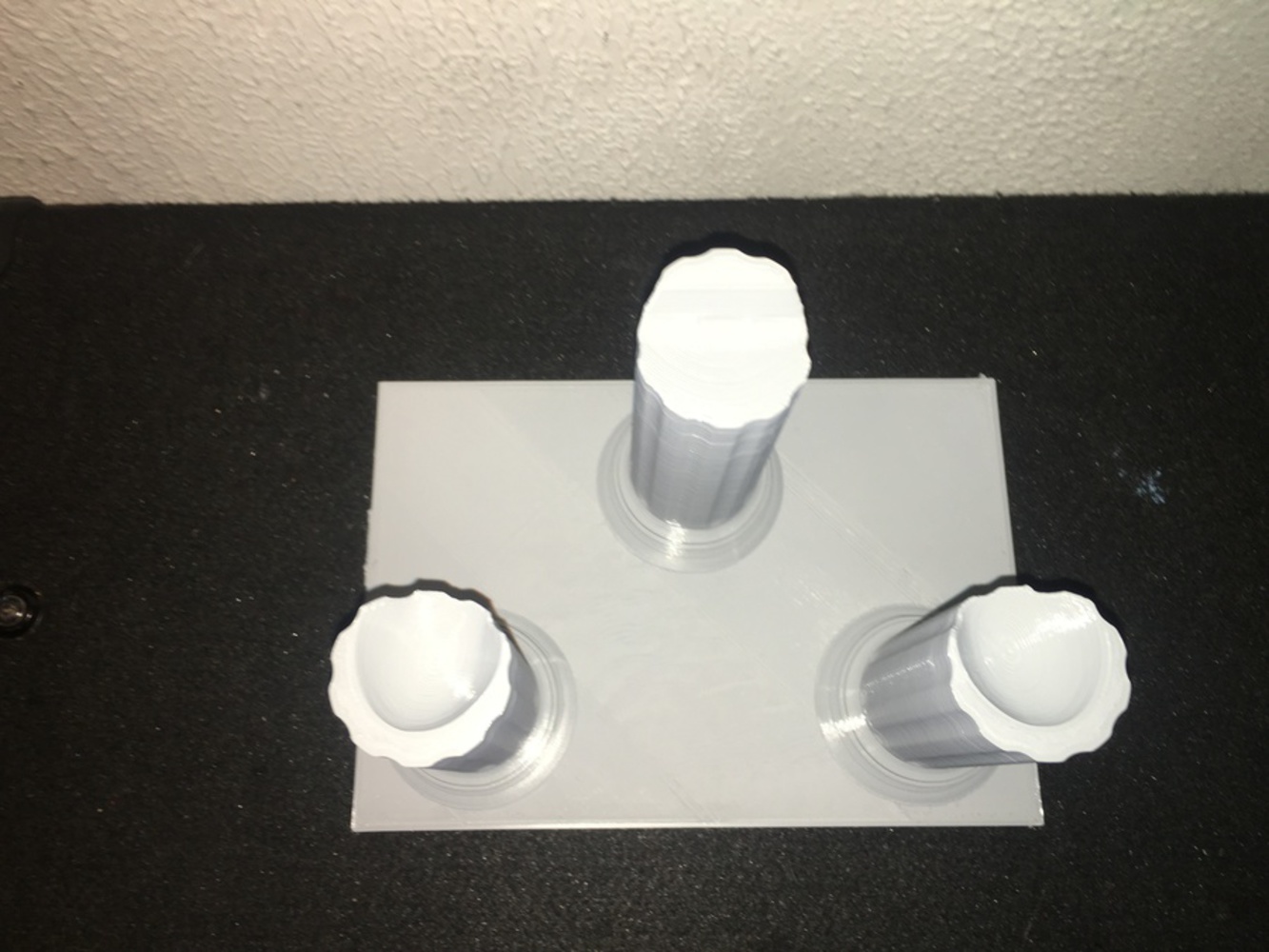

When modeling the holder, the first thing I needed to do was model the column I was going to use. I found an image for the column that I liked (picture above), I then used the image and the spline tool in Fusion to creat an outline of half of the column. I then used the revolve tool to make the column 3 dimensional. I then designed the top and extruded it.

Once the column was designed I was able to take the column and the CAD model of the Controller and combine them to make the holder. I first made a base for the columns and used joints to fasten the columns to the base. Then I extruded the columns past the bottom of the controller at each point. Then I used the combine tool to cut the columns to the contour of the controller, leaving me with the finished holder that I then exported to be 3D printed.