Process & Procedure

[Outline your approach to the project. What steps did you take to design, model, sketch, and prototype this projects? What ideas did you generate and how did you refine or reject them? How did you use cutting, etching, scoring? What challenges were encountered and how did you resolve them? Include photos of prototypes, redesigned sketches, design worksheets, and failed trails.]

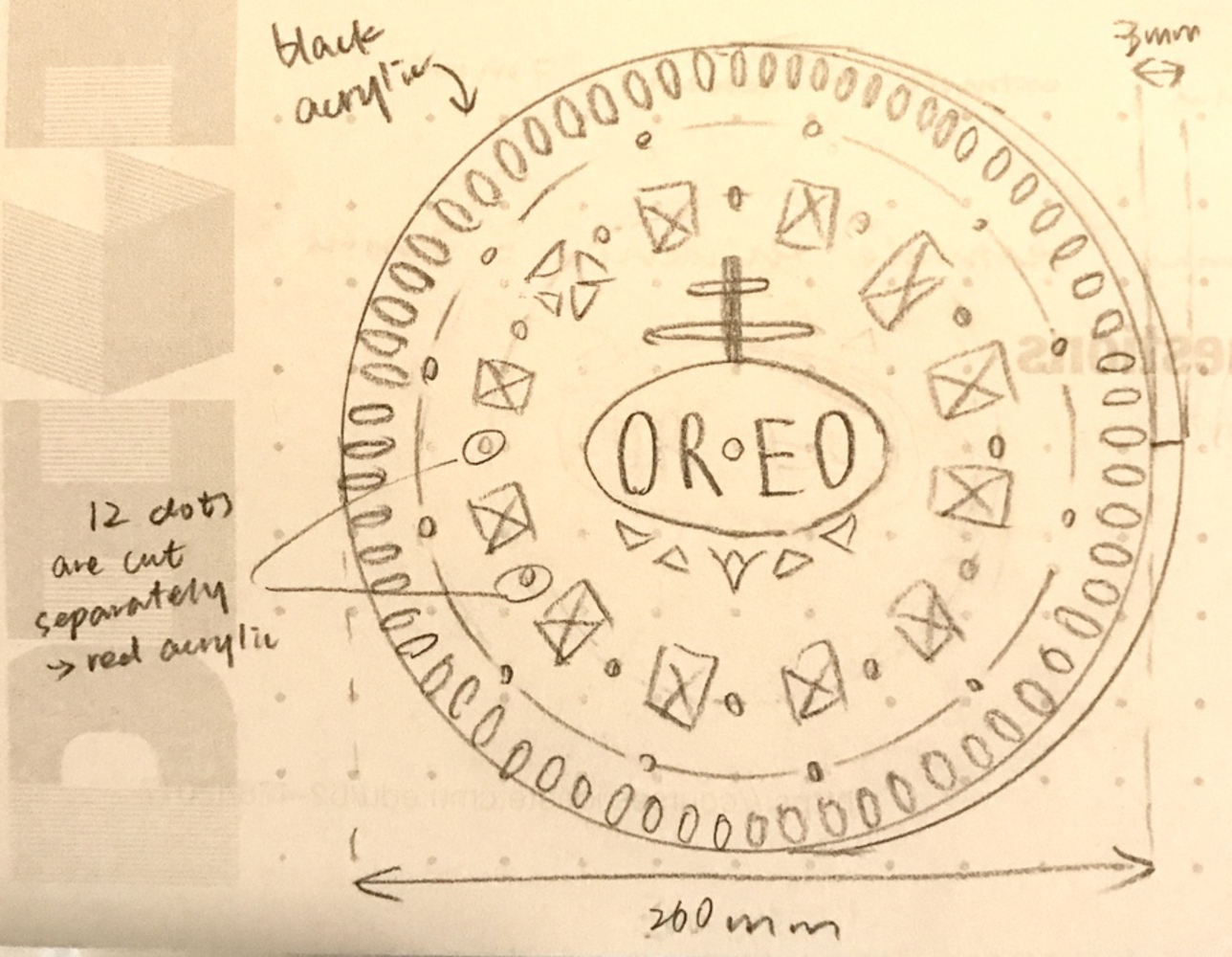

First of all, I traced the Oreo pattern using Fusion 360. This process took me much longer than expected, because Fusion 360 was extremely slow when there were too many objects in the same sketch. To optimize this process, I used creating circular pattern function instead of mirroring for the repetitive elements, so that Fusion would not freeze too often.

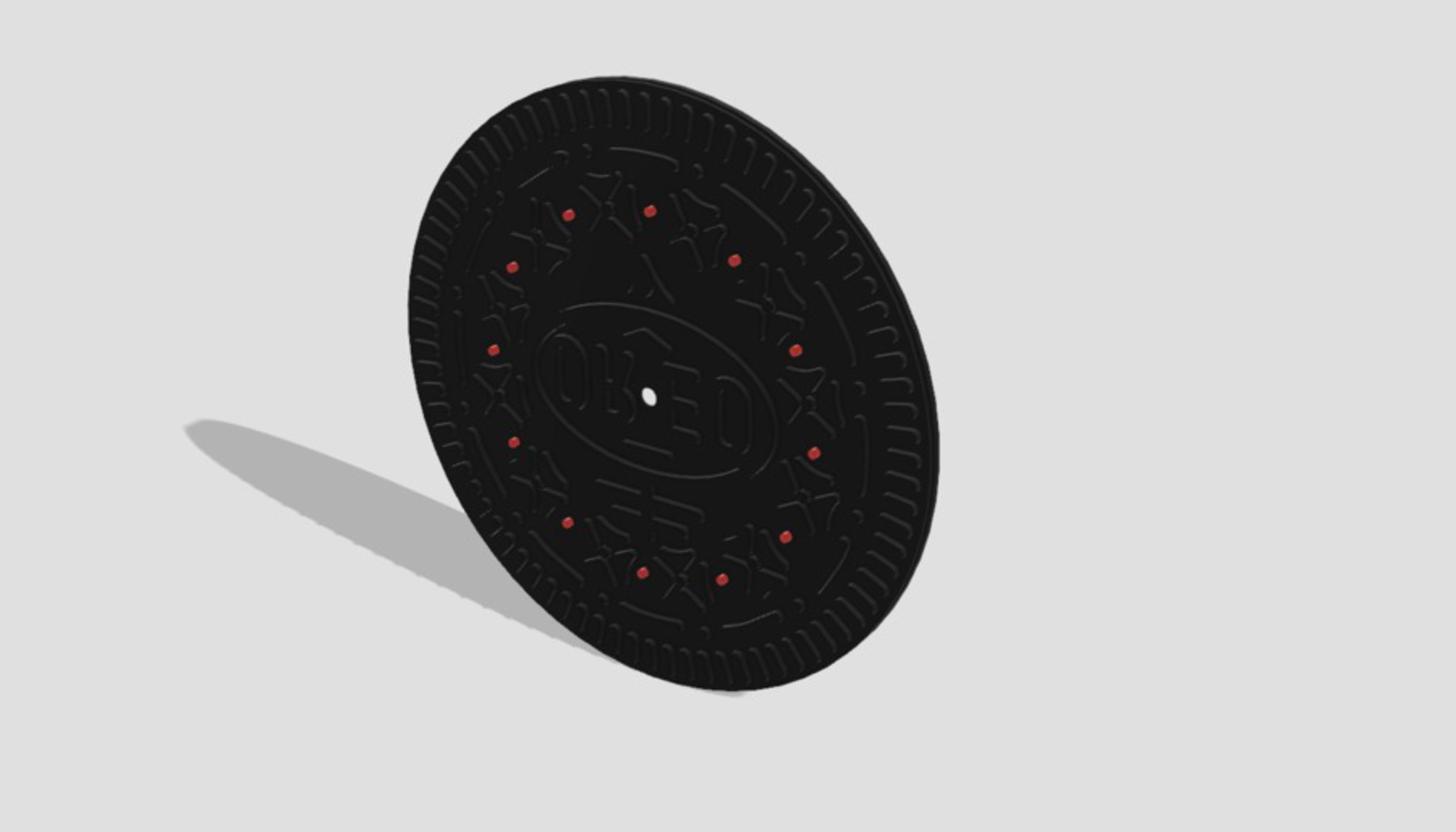

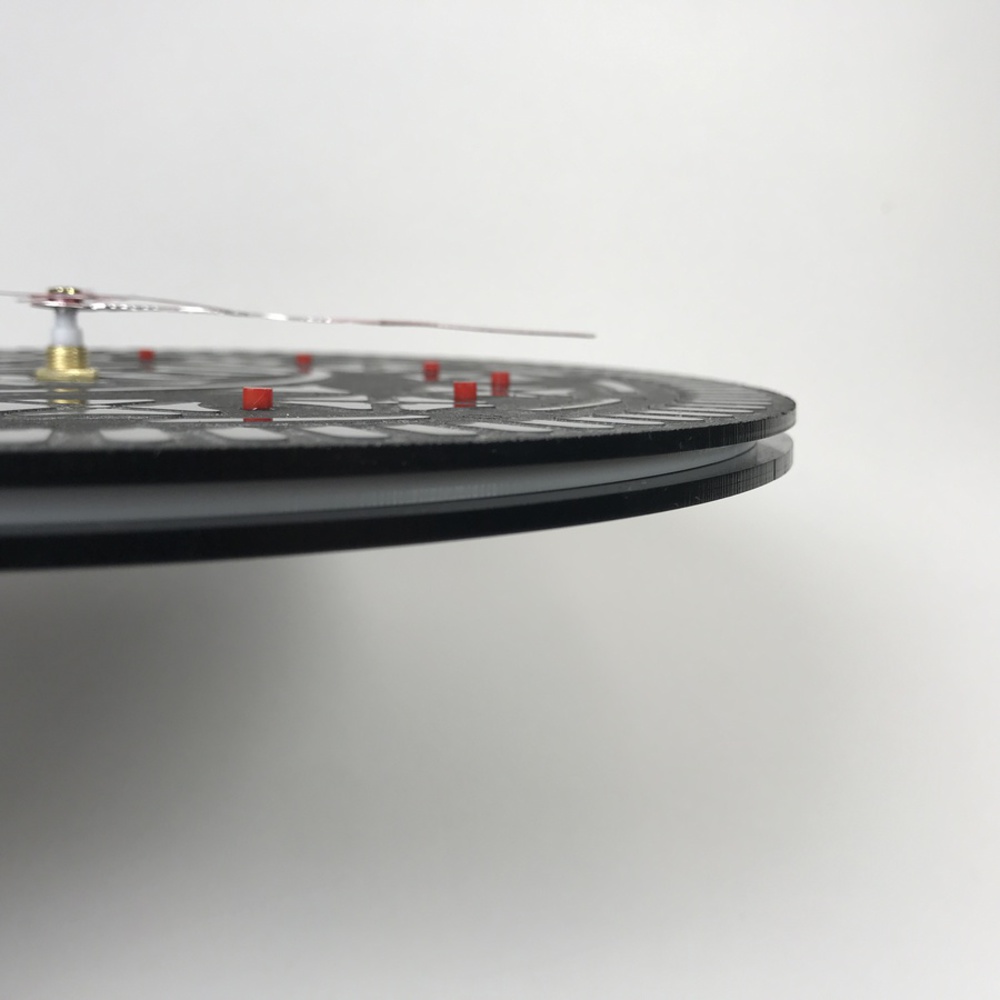

Since an entirely black background would make it hard to tell time, I decided to cut twelve dots in red acrylic and stick them onto the clock body. I chose red because it is also the color of the clock hands.

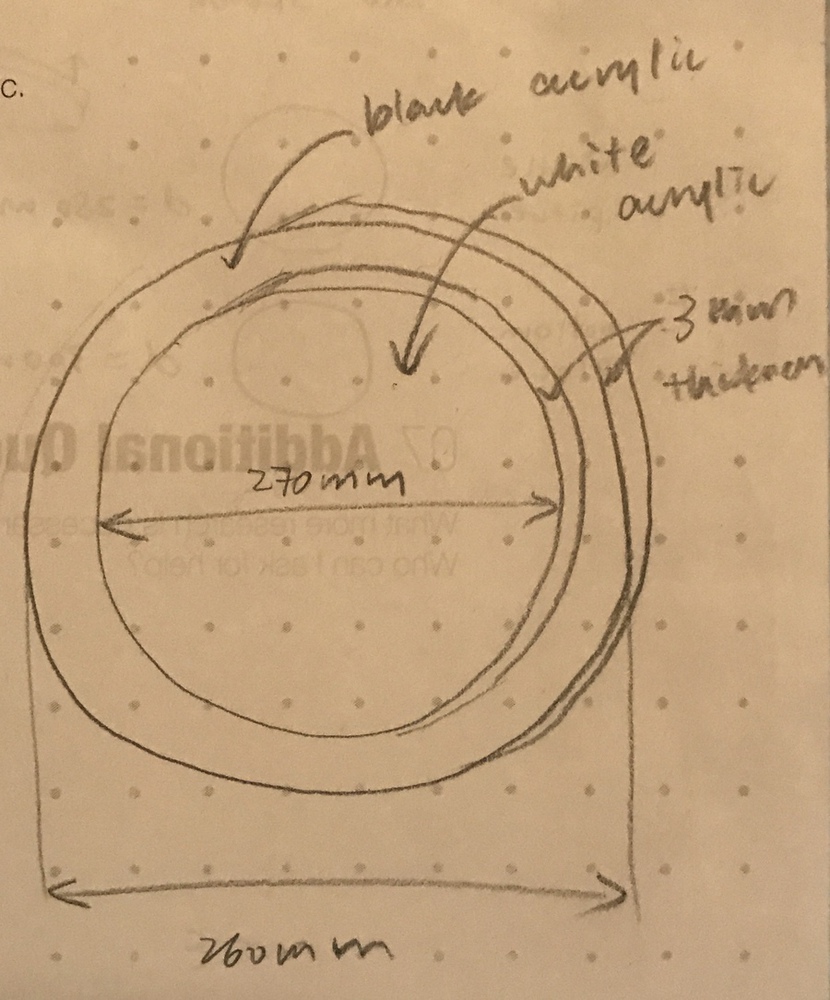

As a part of my design, the clock would have three layers to resemble an actual Oreo cookie, and the thickness of three layers of acrylic might be too much for the clock kit. Therefore, I decided to cut out a house-like shape at the center of the two back layers to fit the clock kit.

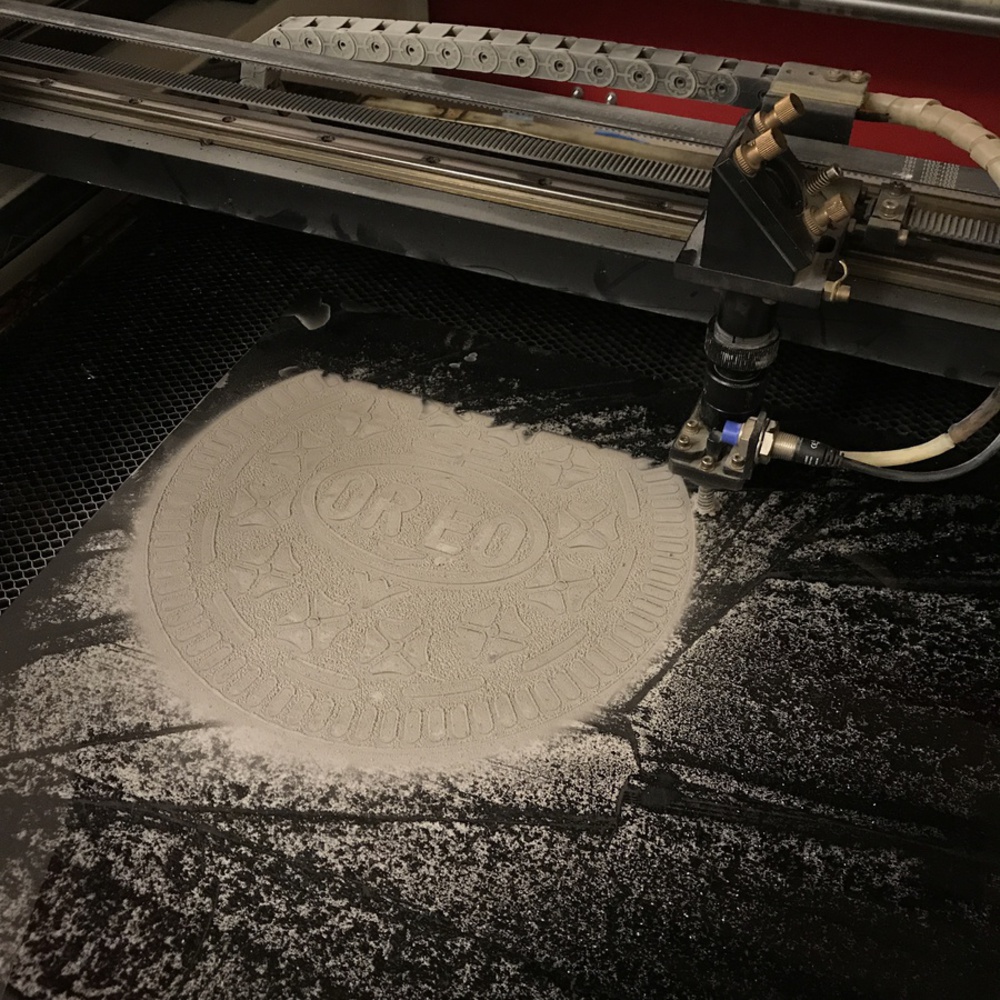

Another challenge with engraving is that my plan was not to engrave the selected objects, but the area surrounding the objects to create an "extrusion" feeling of the objects. To achieve this, I copied and pasted the outermost circle and set it to engraving in addition the one set to cutting. Before the actual 80-minute engraving, I first tested this technique on another piece of acrylic to make sure it would work the way I wanted.