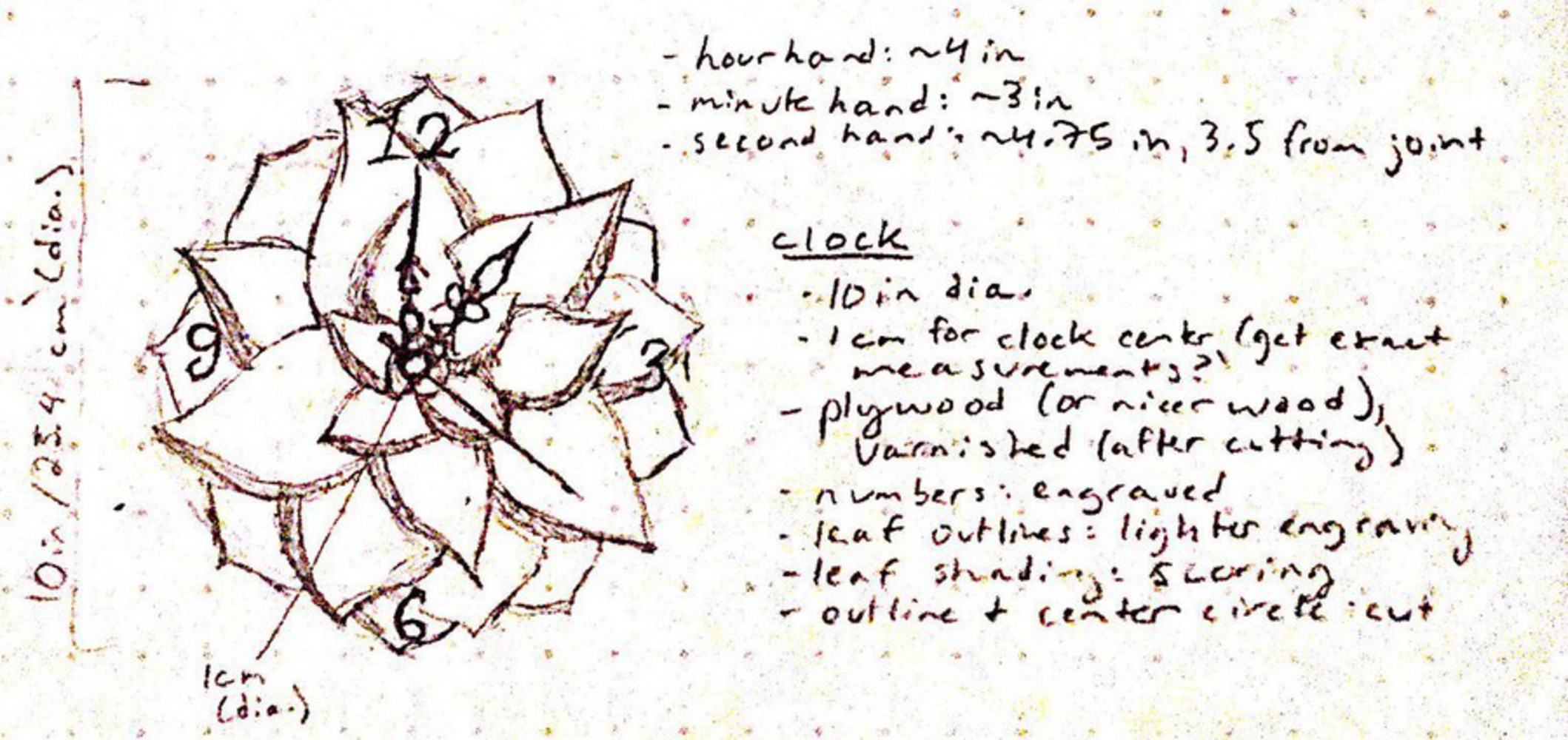

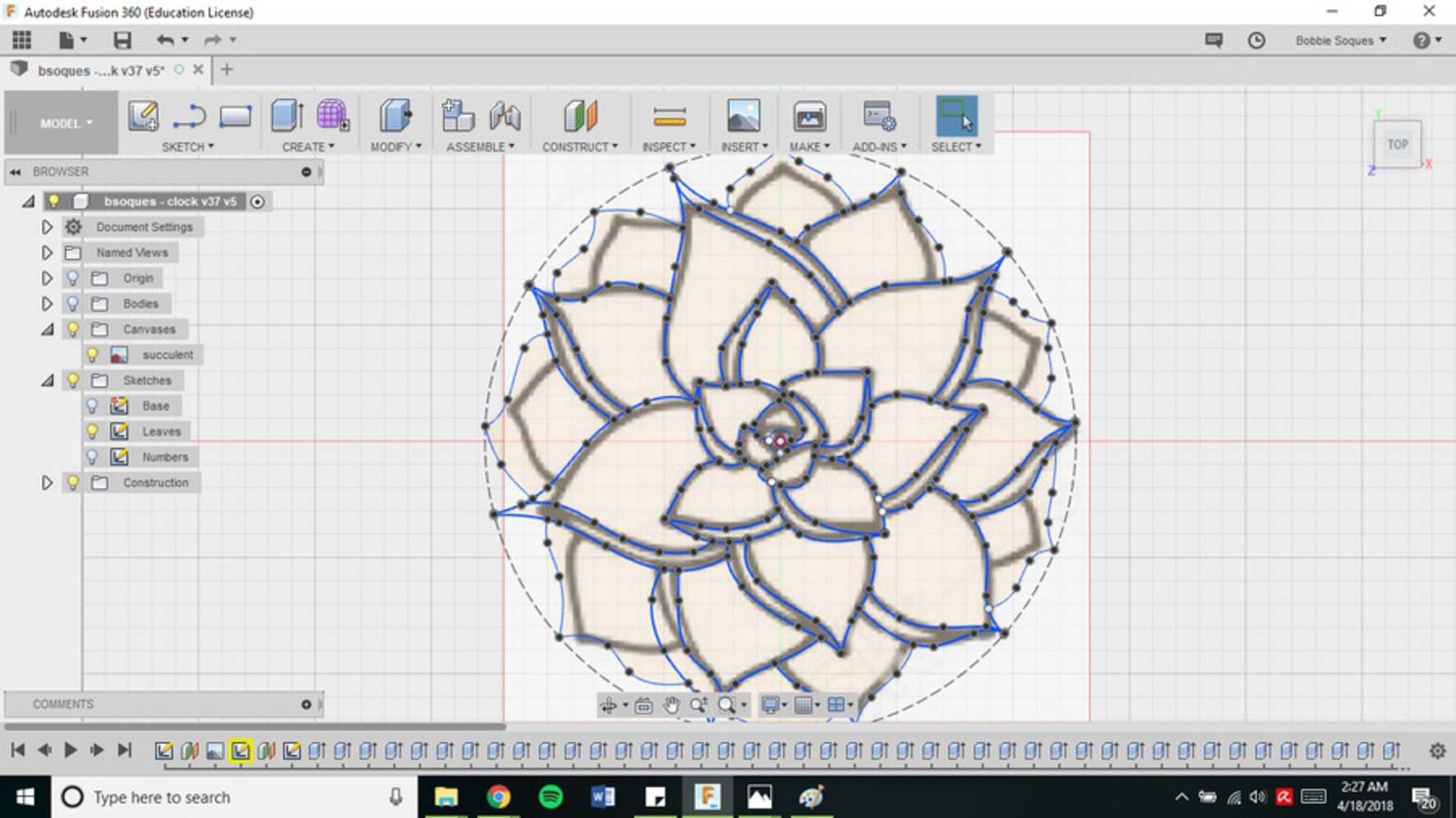

After that, I dropped the numbers on top of the leaves in the appropriate places and extruded the whole piece. Originally, I wanted the shading on the leaves to be engraved--more lightly than the numbers--so my model reflected that.

When I converted this drawing to a DXF and went to test cut it, I encountered my first problem--I couldn't cut out the outer shape of the clock, since the laser cut software processed each spline as something to be cut continuously. So, I went back to Illustrator, and began the tedious process of splitting each spline that was part of an outer leaf, so that the splines that made up the outer edge were separate from the inner splines.

During this process, I encountered a lot of overlapping lines--two line segments in the same place--that I had to delete. If the laser cut software processed these, it would cut (or engrave) twice over in the same place, which would cause problems with the design (like accidentally cutting all the way through in places where I wanted to score). I don't know where they all came from, since each spline was a single entity in Fusion, but I caught as many of them as I could in both Illustrator and in the laser cut software.

Another fallout of this drawing was that the software didn't treat each leaf or leaf shading as a complete entity--meaning that I couldn't engrave the shading on the leaves, since they weren't closed shapes. The software only treated each spline as an individual entity, and to change that I'd have to go back and change the construction of my entire drawing. So, I changed my design to simply score each line, and engrave the numbers only.

On my first successful pass, I didn't unite the lines in the laser cut software--doing that united the lines that made up the outer leaves, meaning I couldn't select the outline of the clock as separate from the inner lines. Unfortunately, that meant that the software didn't treat the numbers as complete objects, so they weren't engraved. On my next pass, I went back and united the lines after I set the outline to be cut (and deleted yet another overlapping line on the 12), which fixed the problem with engraving the numbers.