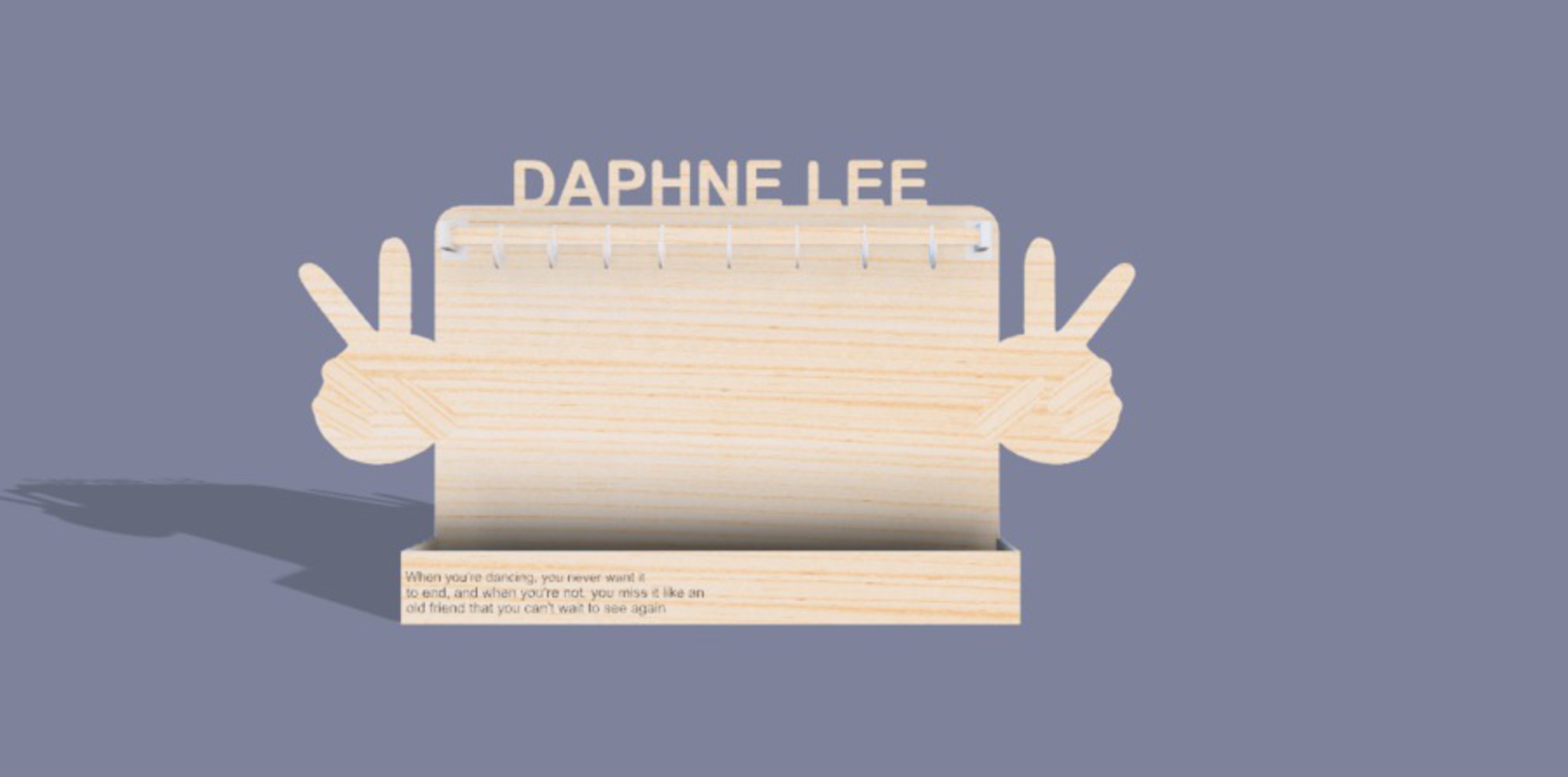

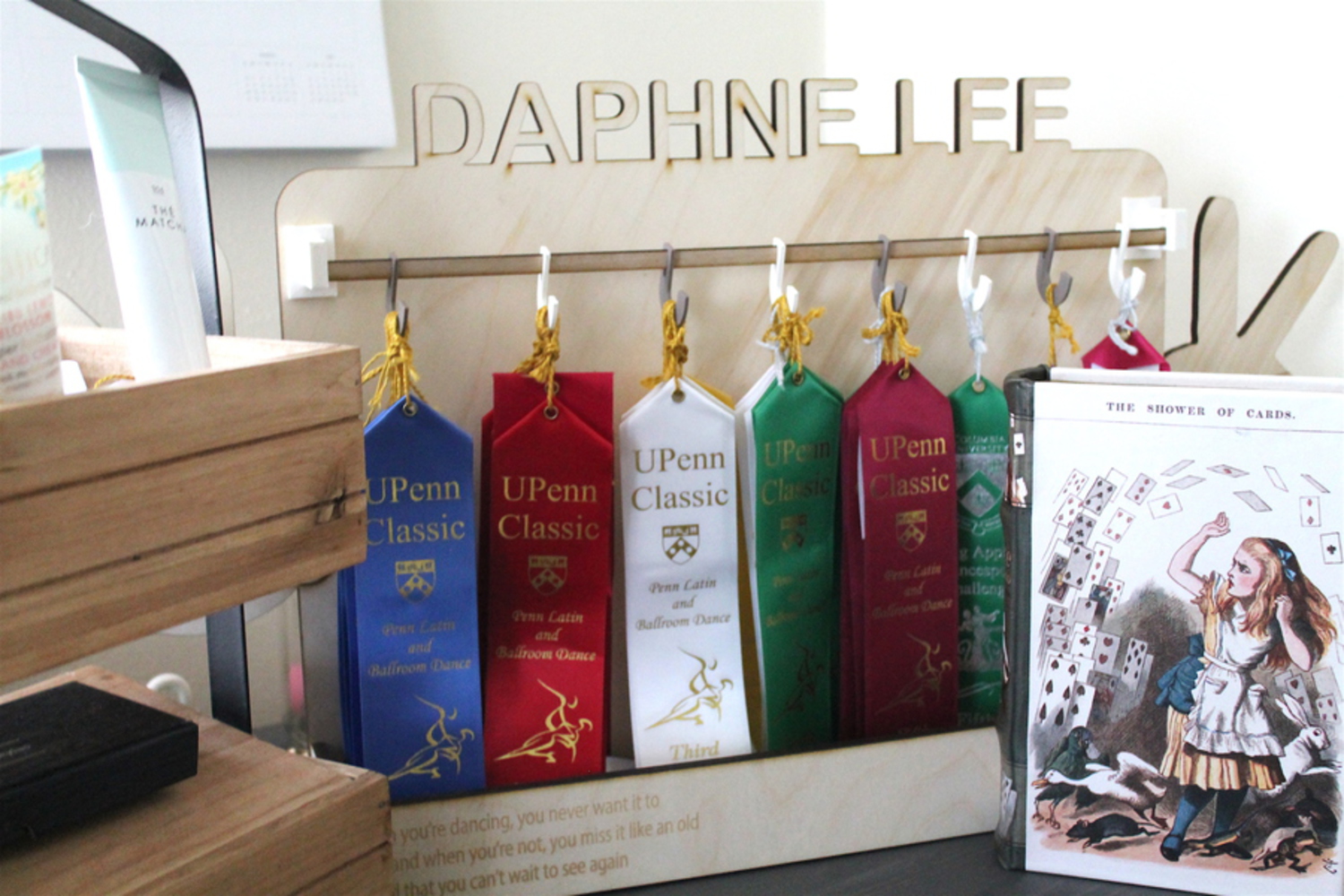

Intention

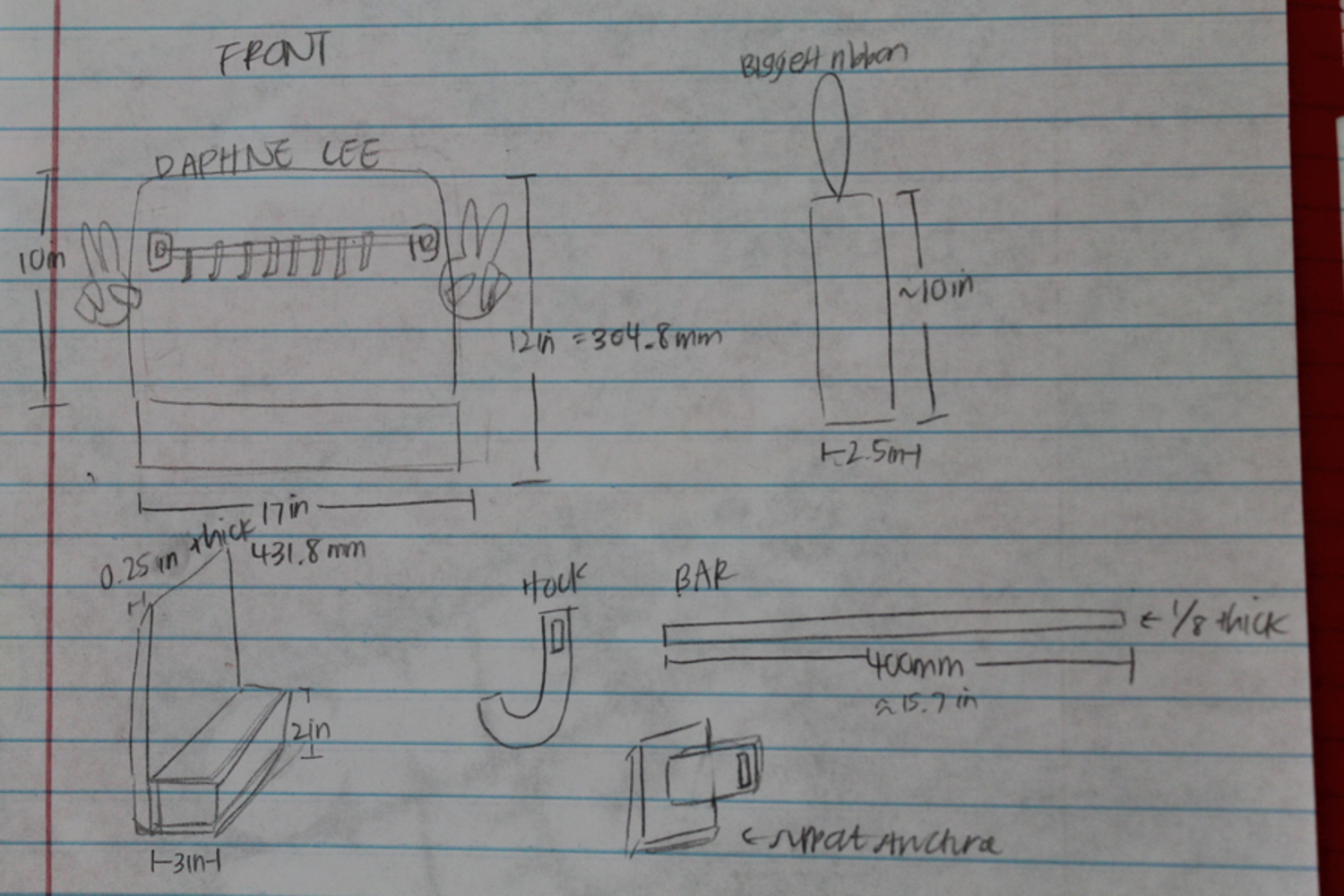

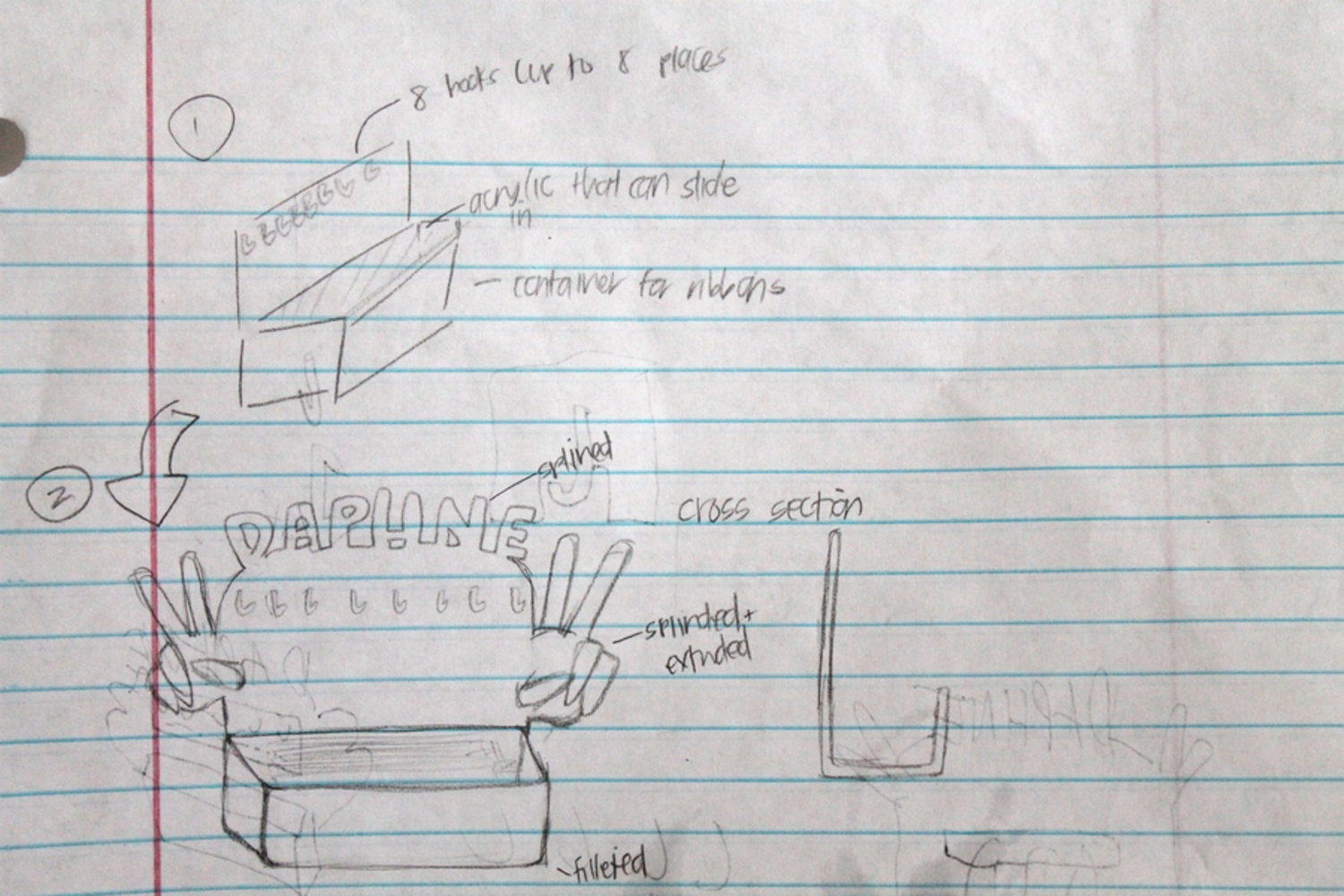

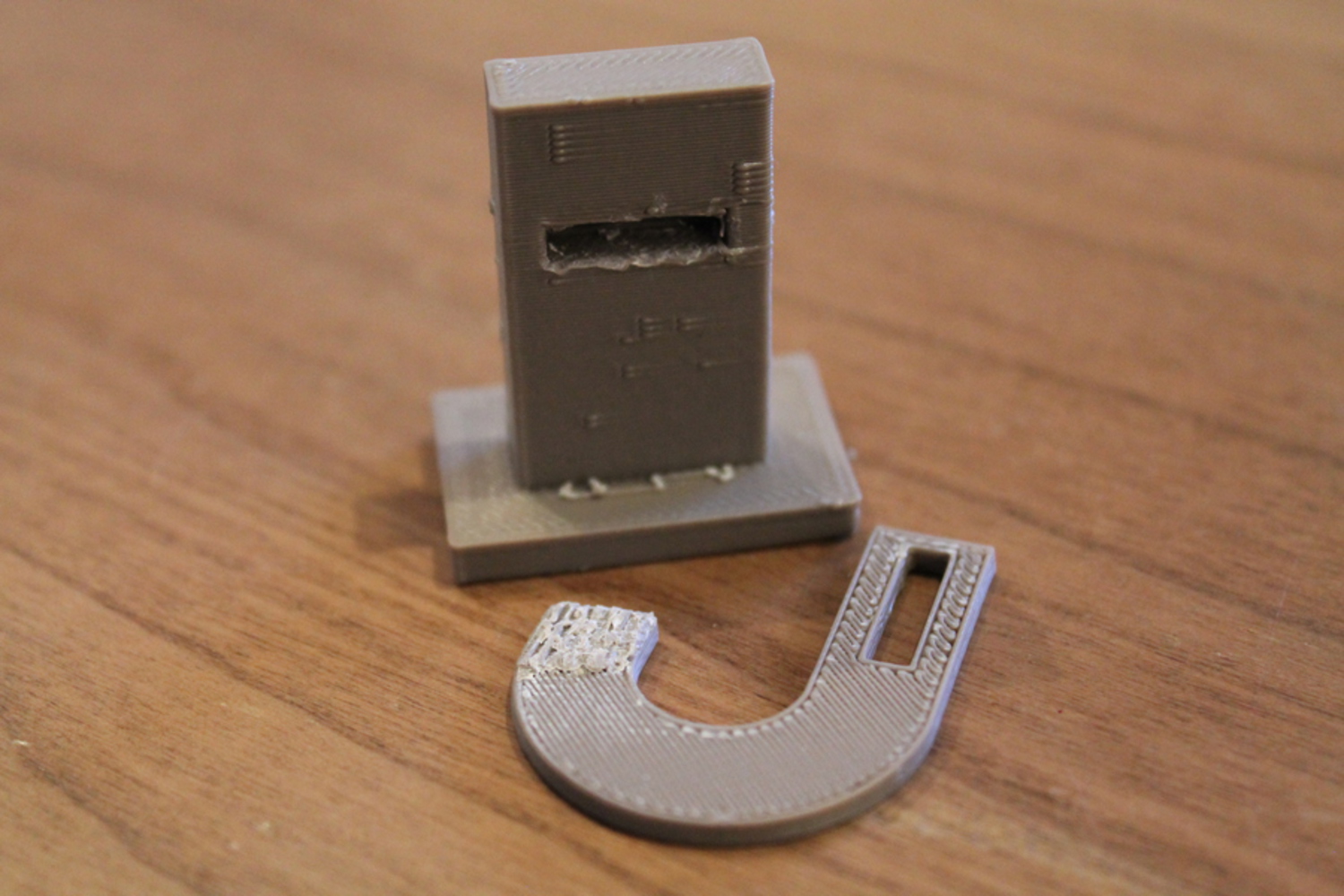

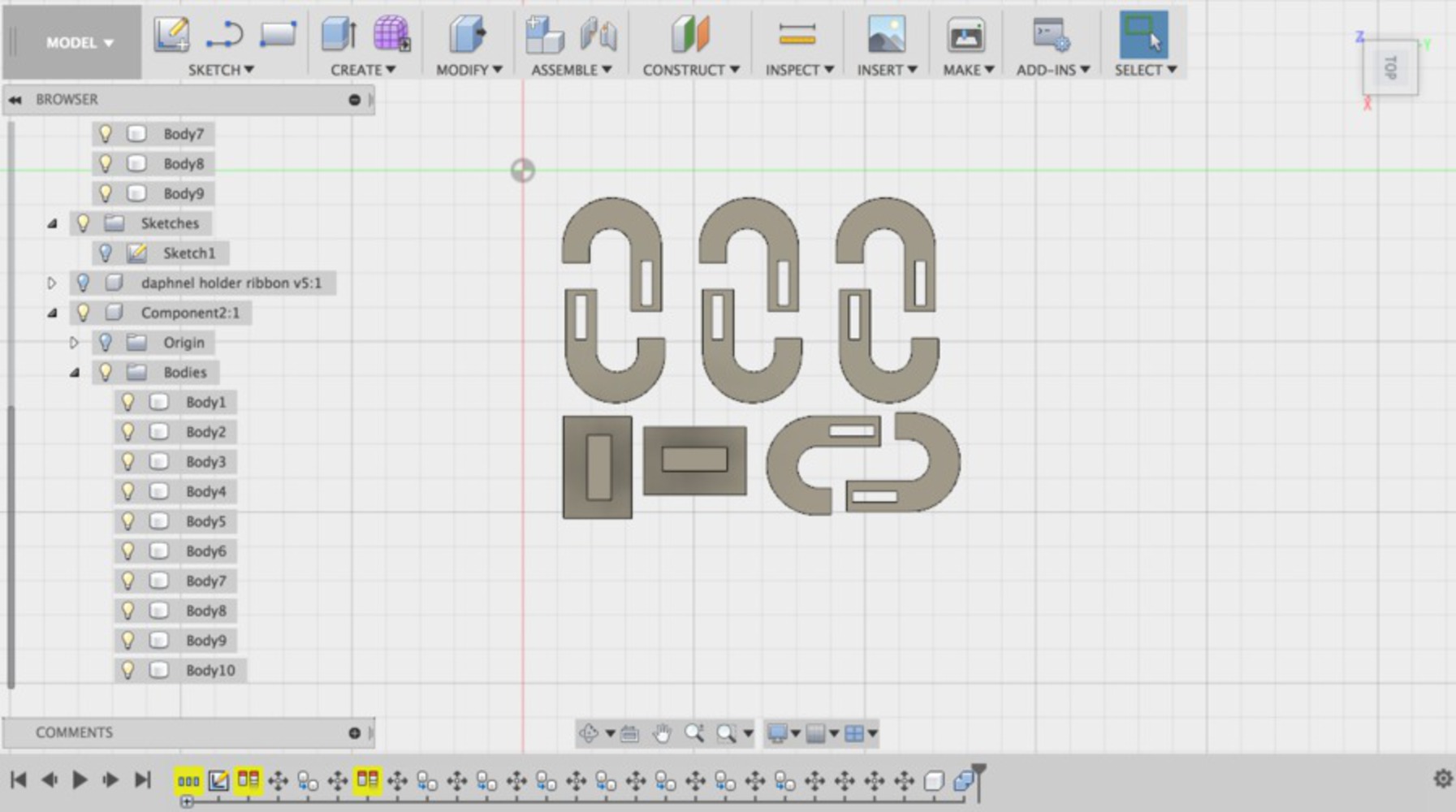

The main problem I wanted to solve was my issue of losing my award ribbons. I joined a dance team during my freshman fall and we usually go to at least 6 competitions a year. Throughout those competitions, I have gathered a numerous amount of ribbons that I have sometimes lost or misplaced. These ribbons are special to me because they remind me of how far I have come and how I did during the level I was in during that time. My goal was to create some sort of holder that could not holy hold and display all of my ribbons properly but also aesthetically.