Process & Procedure

[Outline your approach to the project. What steps did you take to design, model, sketch, and prototype this projects? What ideas did you generate and how did you refine or reject them? How did you use cutting, etching, scoring? What challenges were encountered and how did you resolve them? Include photos of prototypes, redesigned sketches, design worksheets, and failed trails.]

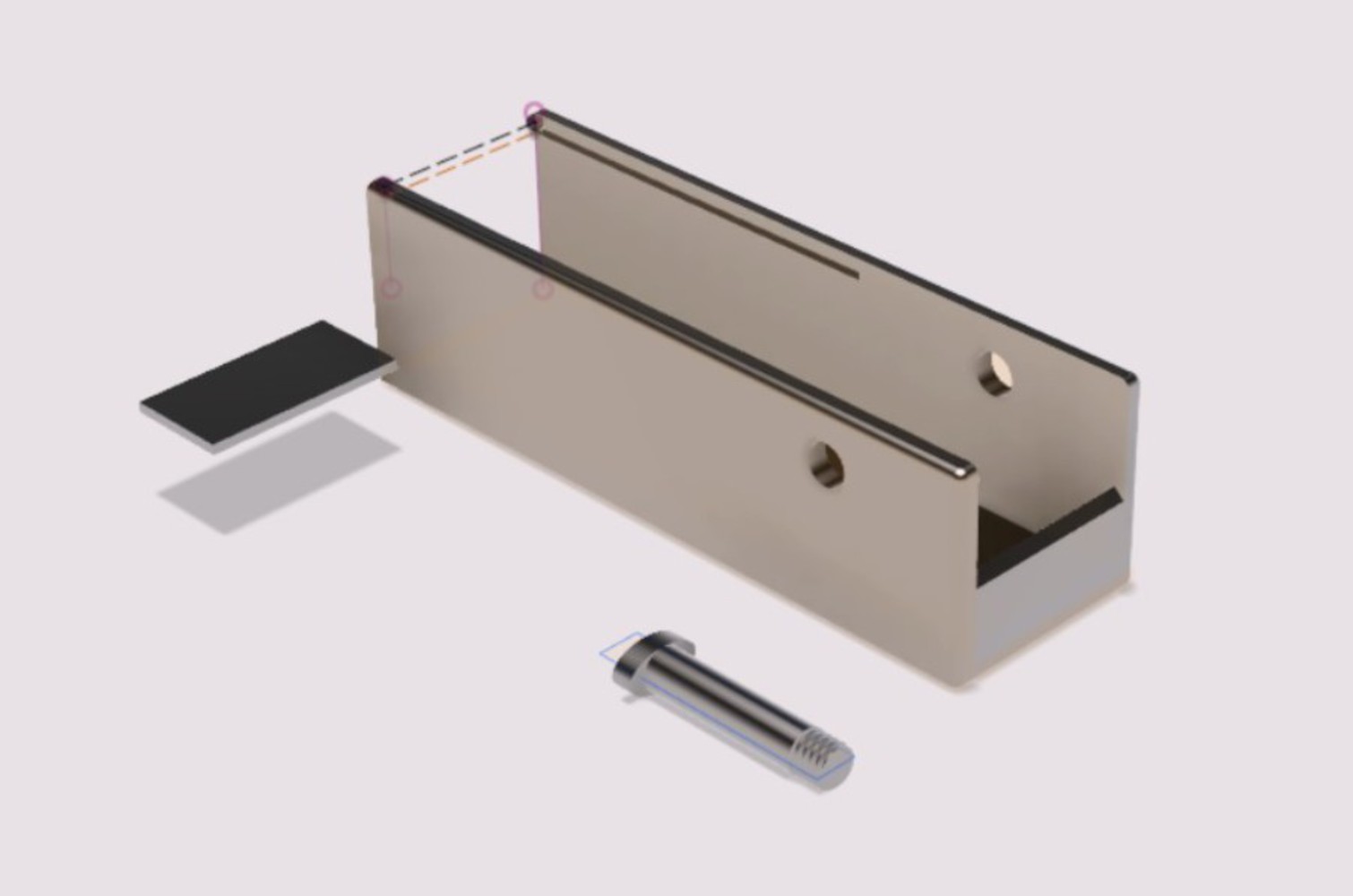

First draft

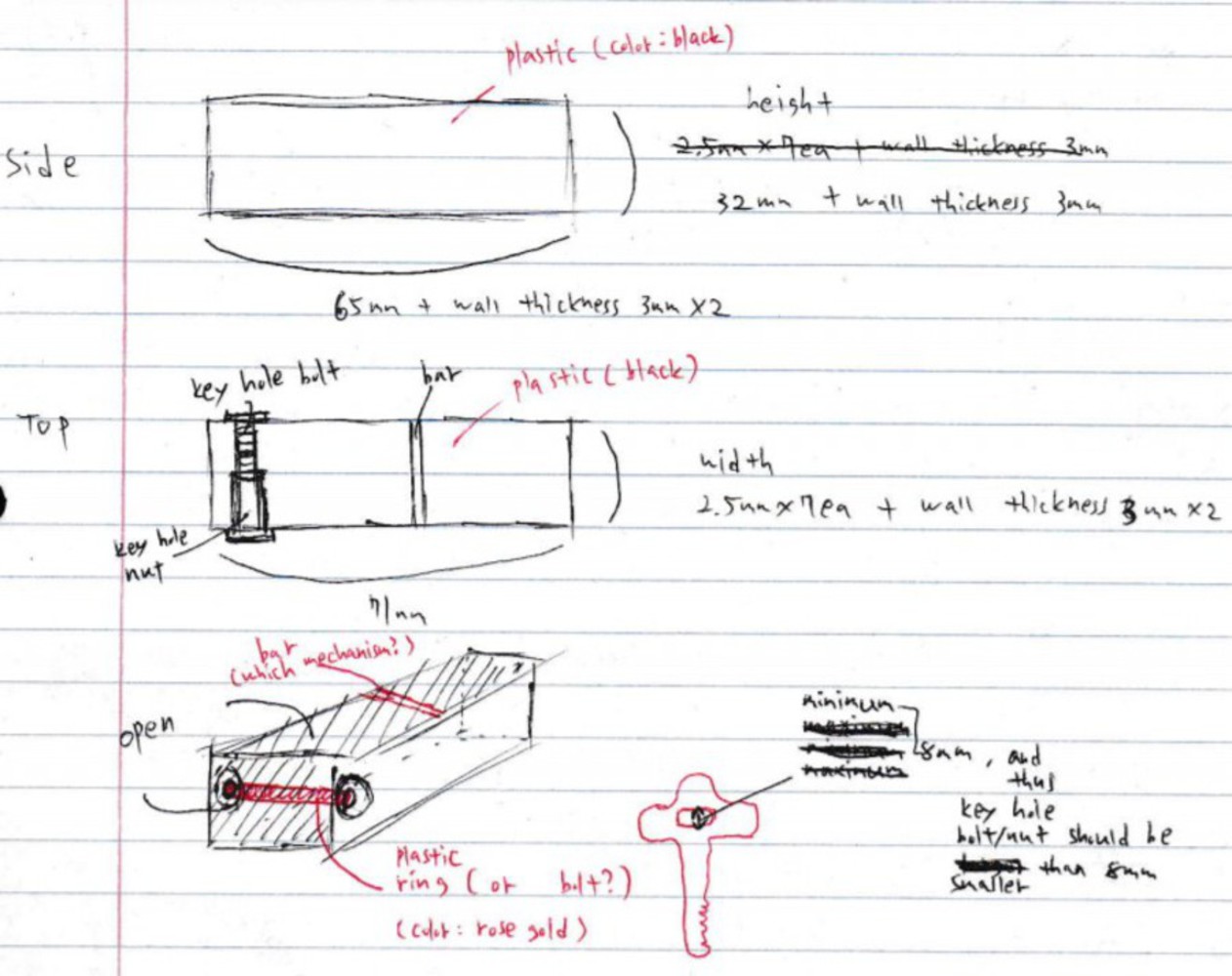

- Dimension: I can determine the length and width of the key holder by measuring my keys. The longest key’s length would be selected as the total length of my key holder. The total thickness of my keys will be the height of the holder. Also, the diameter of the ring would be determined according to the opening size of keys.

- Color: The color of the body box should be dark gray or black because those colors look luxurious and they are resistant to stains. The bolt and bar color should be metallic color to make a contrast to the body color. I think the rose gold color will be a good choice as well. I would spray the bolt, nut, and bar in Rose Gold color. The combination of black body and rose gold joints would elevate the fanciness of the key holder surely.

- Material: The body material is plastic and the joint would be also made of plastic. I can carve bolts and nuts with 3D printer and they will be the joint of the body and the ring.

- Design and Prototype: I will model the body first via Fusion 360 and add a flat magnet on the bottom of the body.

After one trial

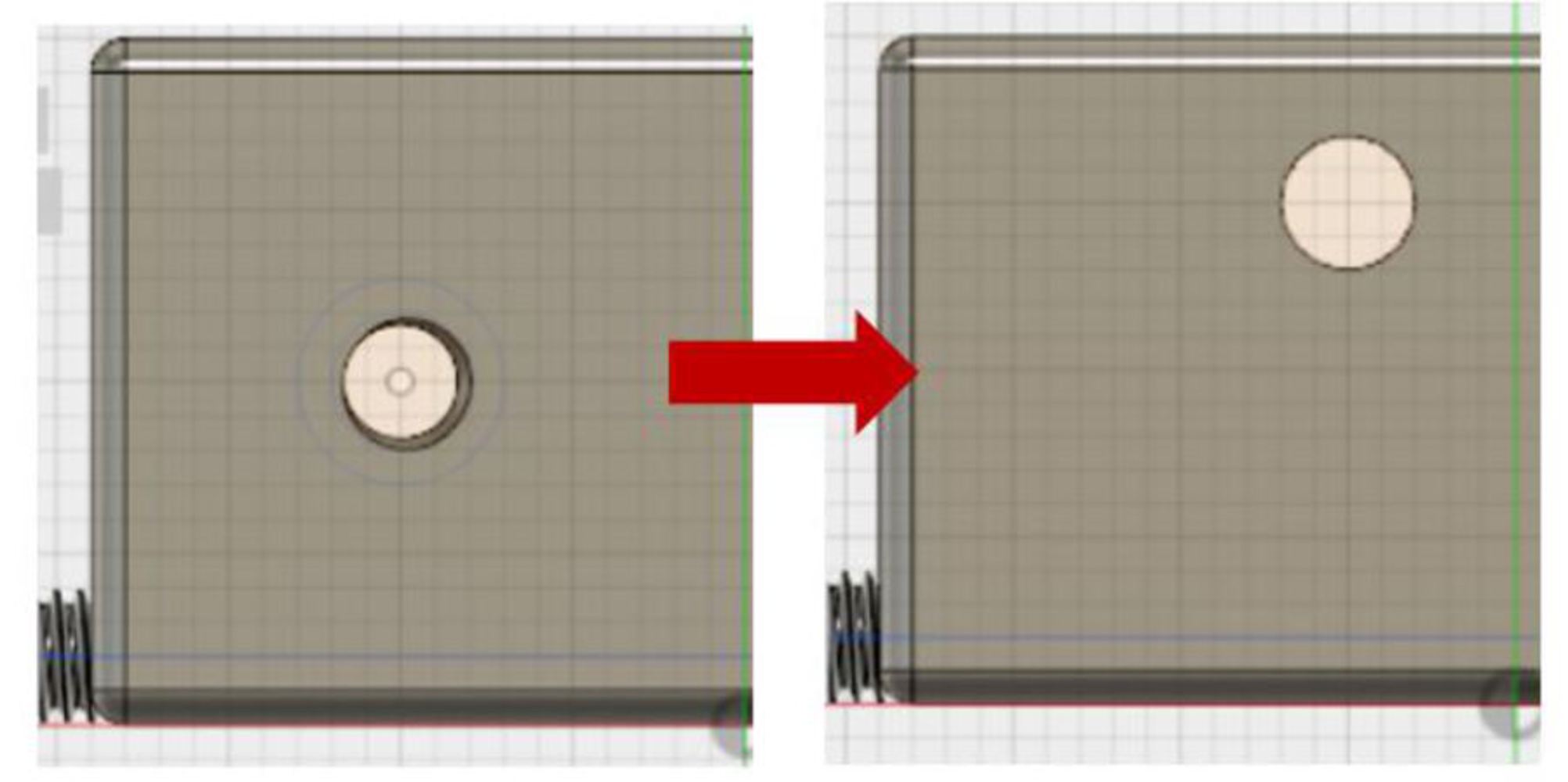

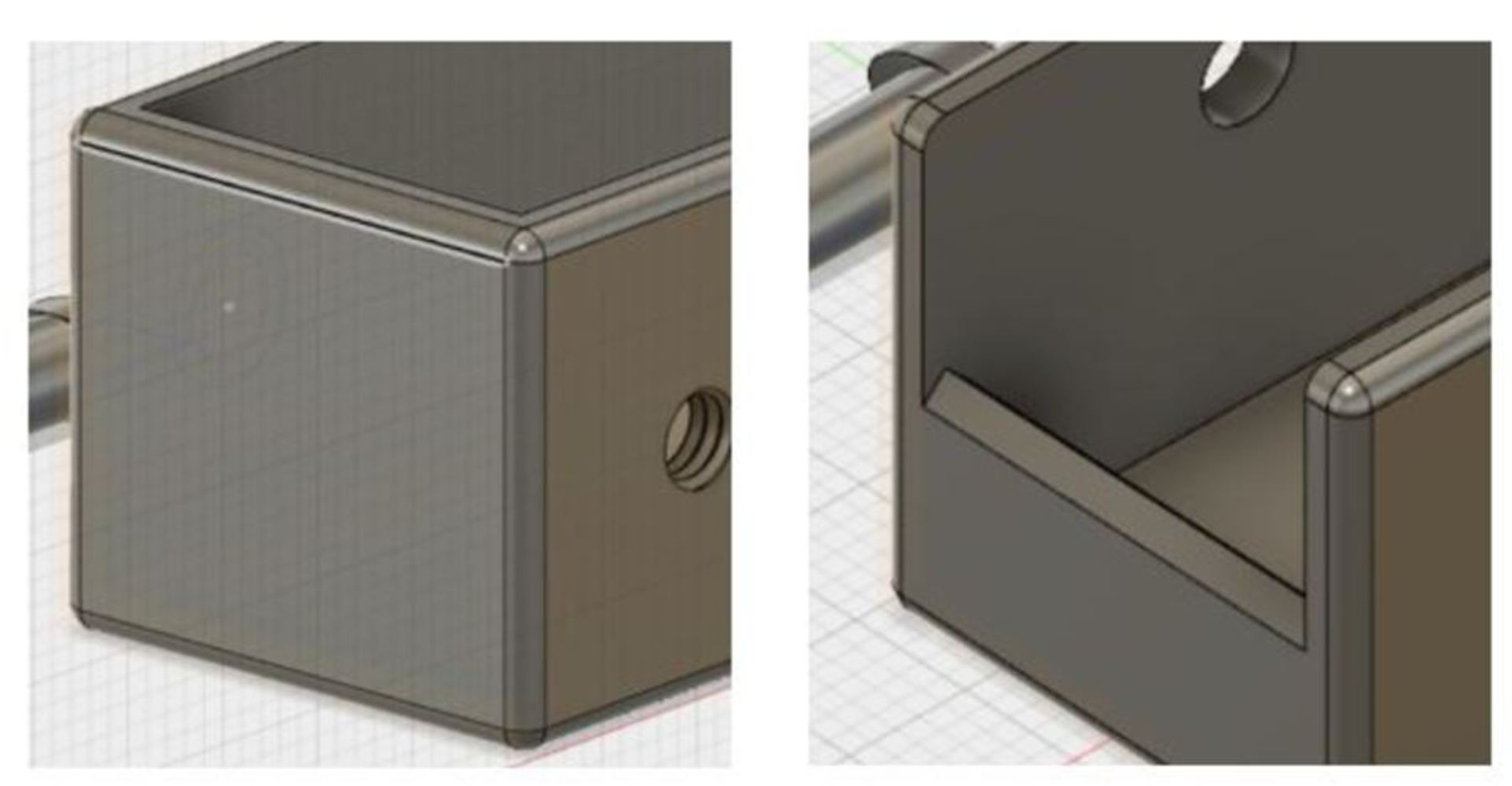

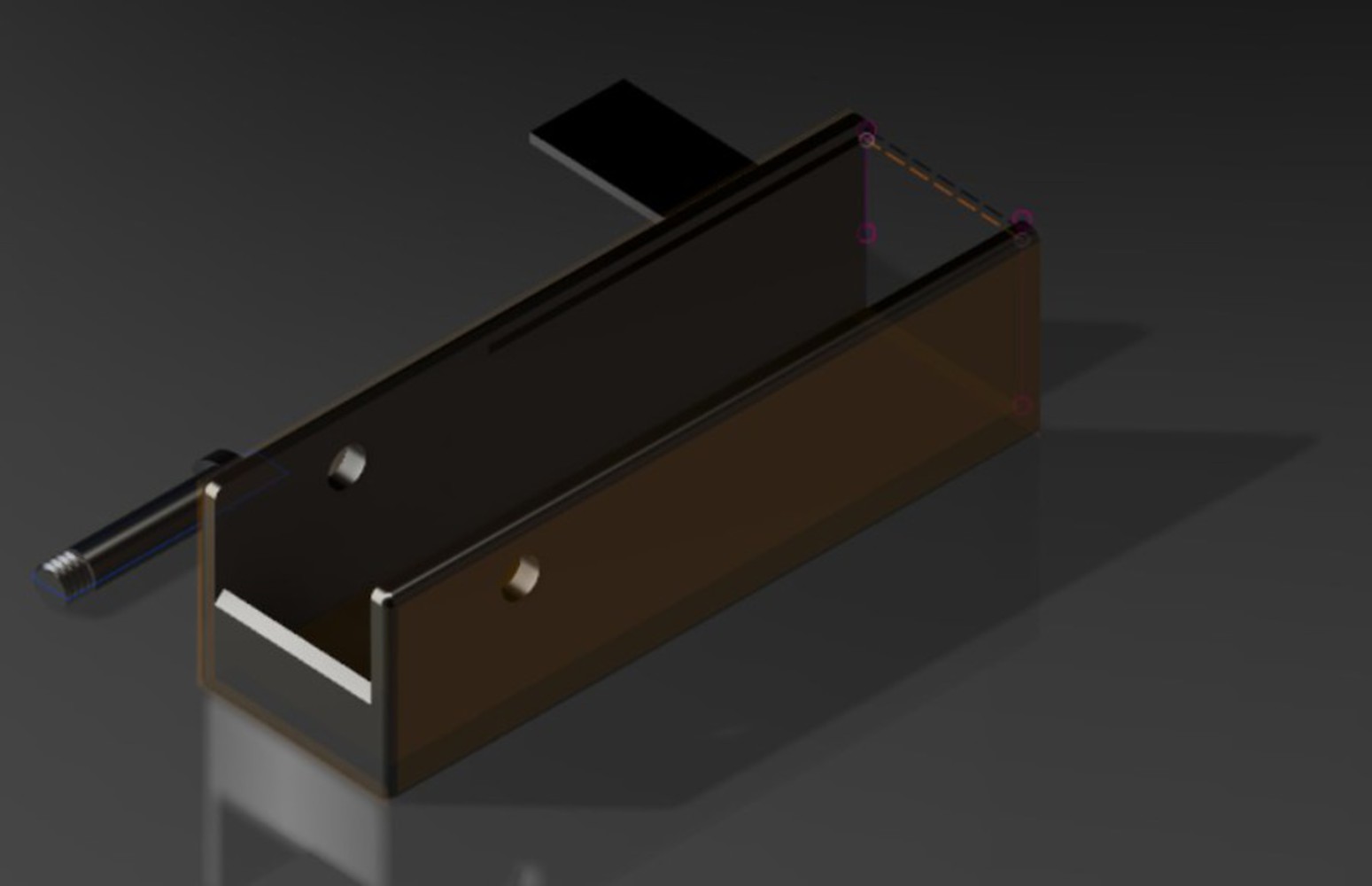

- Dimension: All dimensions were okay except the position of the joint hole. The hole was too close to boundary so that the keys were not able to swing 360 degrees when they were linked in the joint. I have moved the hole location X:5 mm Y:5 mm to the opposite direction. Also, the threads if the bolt and nut were suffering from the lack of resolution. The threads did not appear properly and get smudged. I found the real metal bolt and nut fitting to the joint hole and I used them instead of the 3D printed bolt and nut.

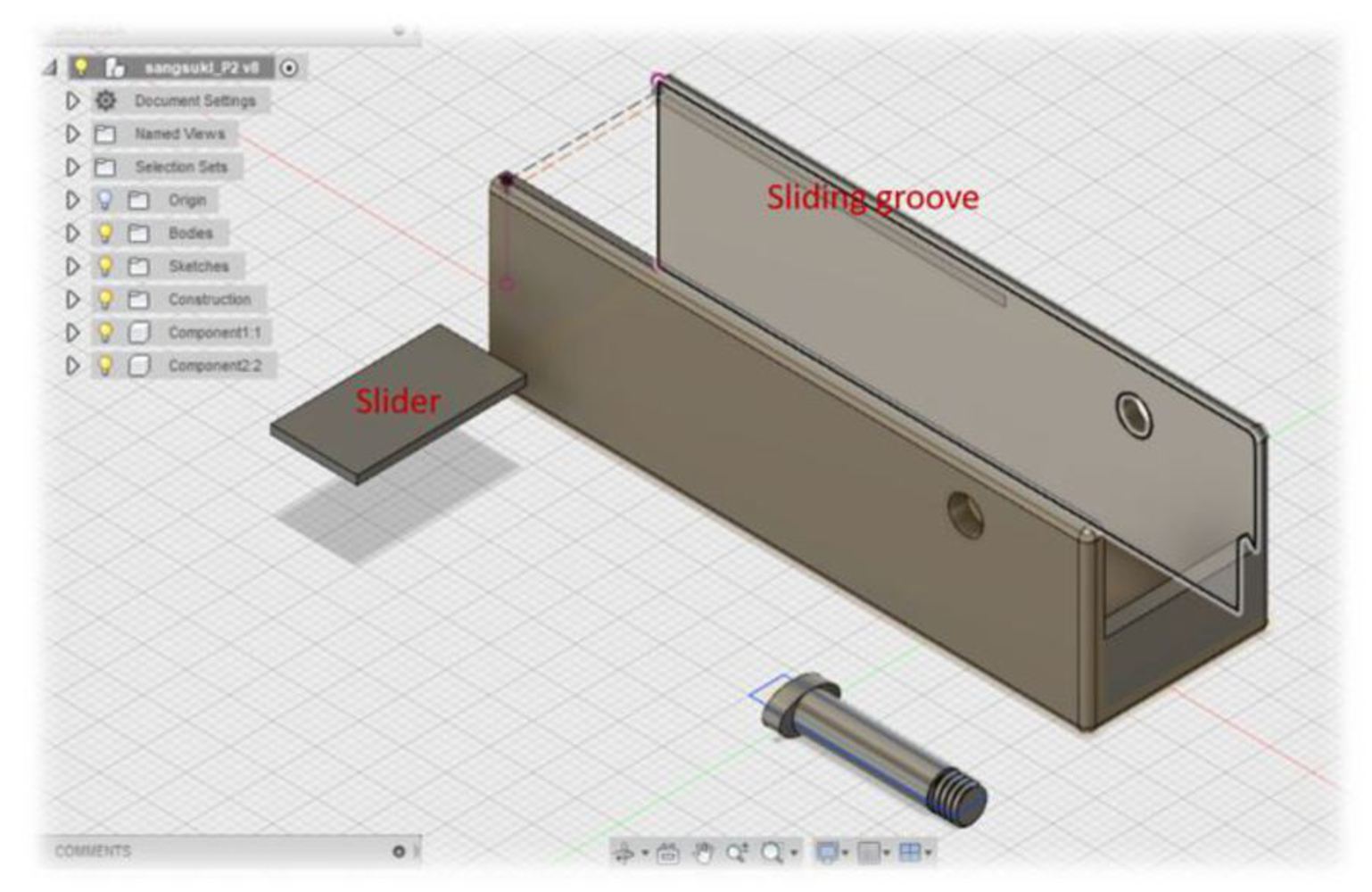

- Material: I was thinking the keys are iron and they would be attracted by magnet, but actually they were not iron but alloy. They did not attach to magnet and it was a critical functional error because the key holder would not be able to hold keys neatly. So, I cut grooves for inserting a slider to act as a bar.

- Design and Prototype: I also made some design changes after printing one prototype. I figured the printer can print thinner surface than now and I wanted the holder to be slim, so I decreased the thickness of wall. In order to make keys swing 360 degrees, I cut the half of the back surface. It would give more room to rotate.