Unexpected Challenges

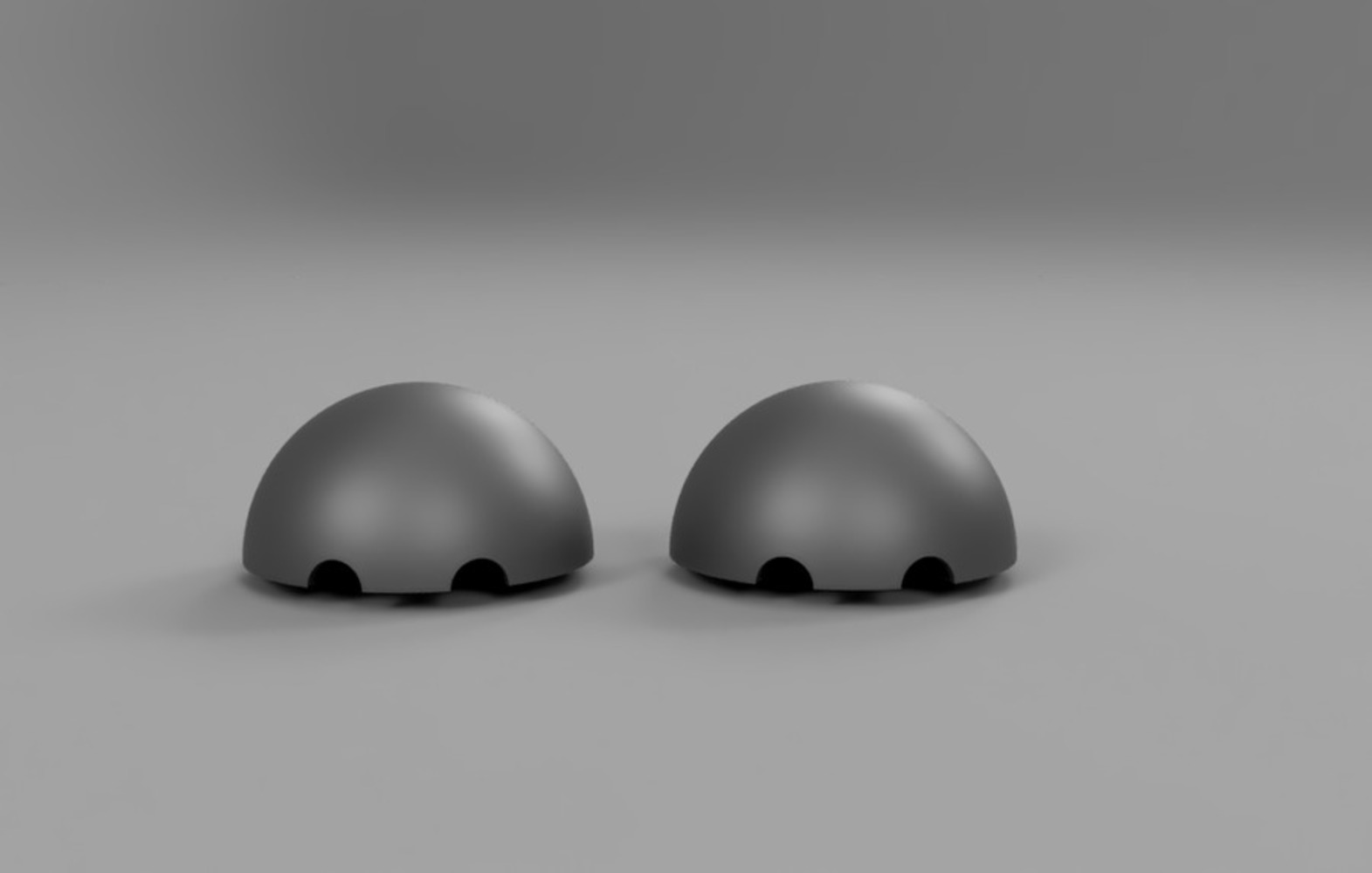

Initially, for my first two prototypes, I attempted to use Slicer through Fusion 360 to create a hollow form with cross-sections, but the program wasn't able to deal with the curvature of the hole I created, and instead suggested I cut it into vertically stacked circles.

It also took a surprising amount of time to glue each slice together, and it was difficult to get them all lined up correctly.

In addition, the second prototype, made of acrylic, disintegrated the second it bumped into anything at all. Hot glue was not the correct adhesive to use, and it fell apart easily. As you can see in the process pictures, the acrylic slices had fallen apart, and both ends of the sphere were missing pieces. It was unstable when I expected that prototype to be the most structurally sound.

The acrylic prototype was also a bit squashed in its form, as I thought it was the same thickness as cardboard, but was mistaken, so when I modeled it after cardboard width it ended up looking more like an ovoid after being assembled.

Finally, there were some worrisome moments with the availability of the 3D printers, but in the end, I was able to find time to print my project.

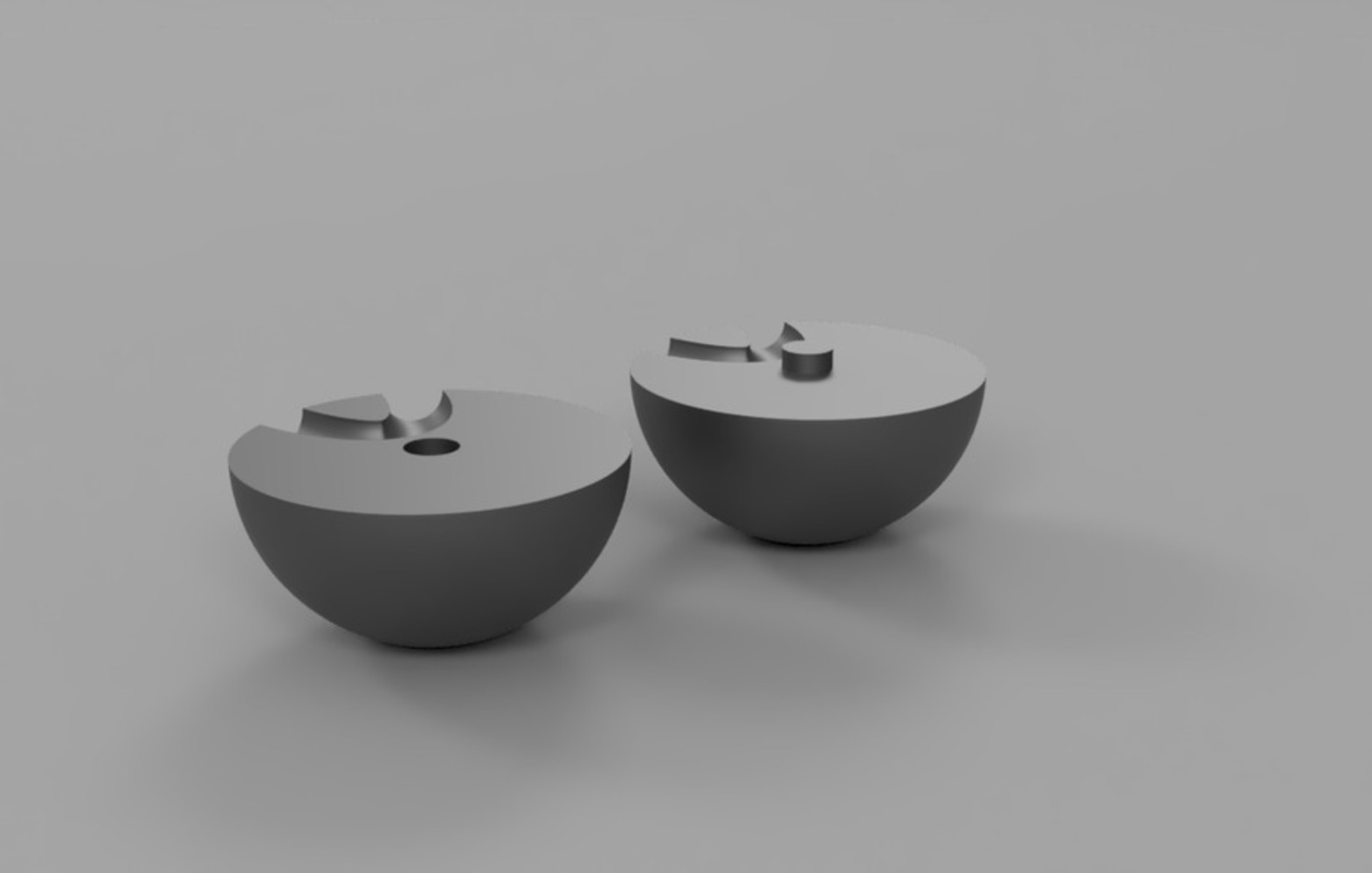

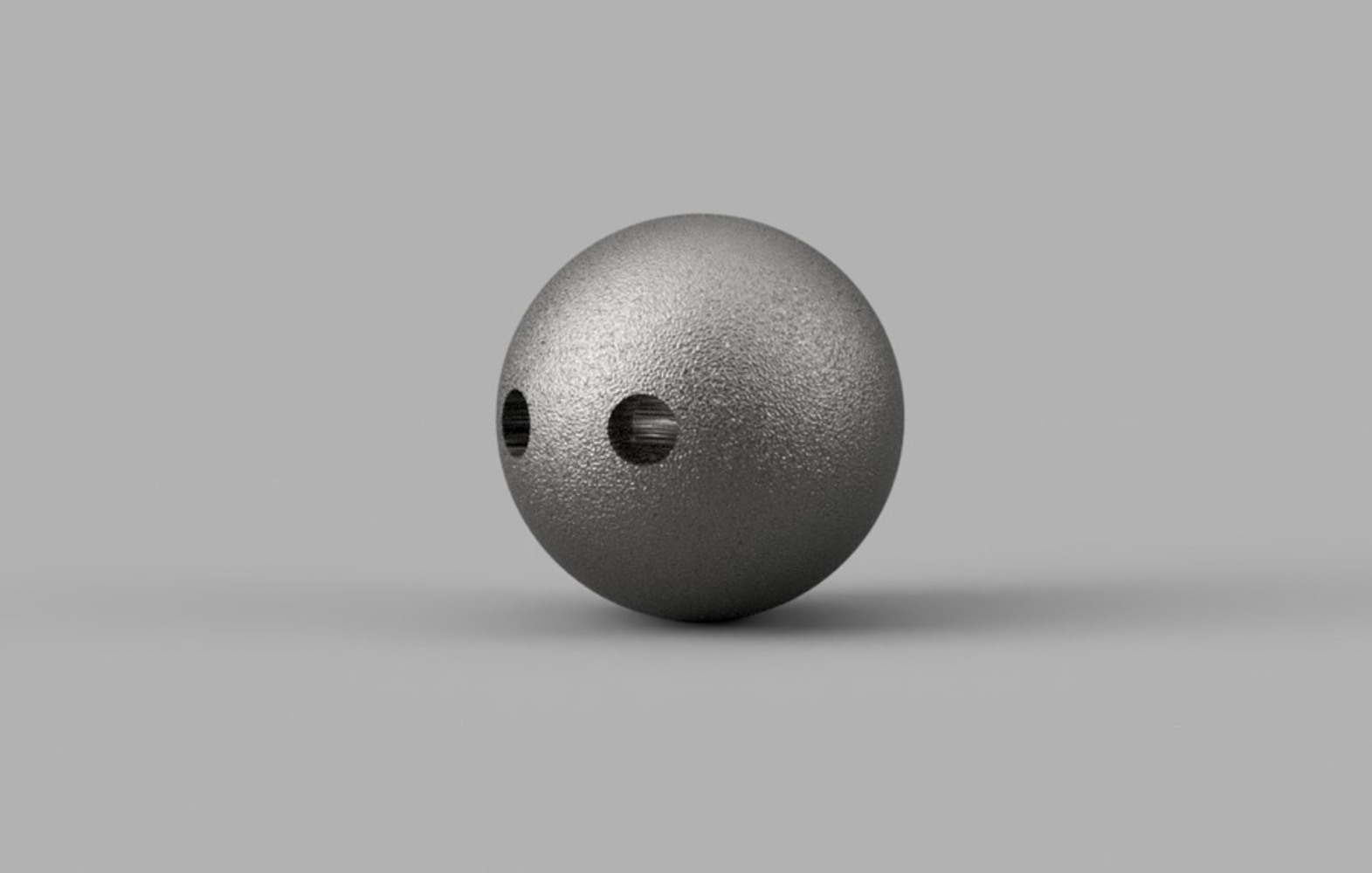

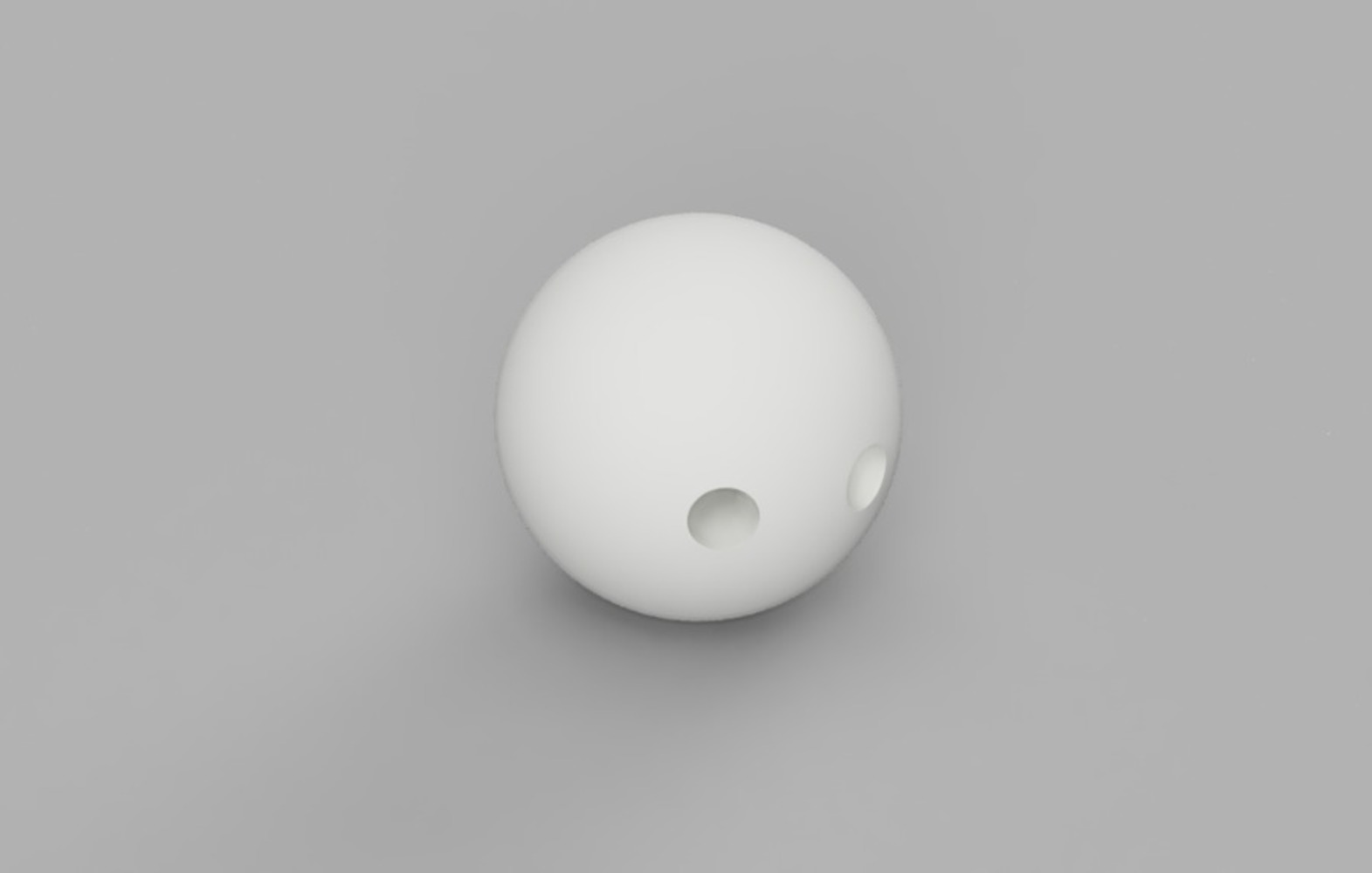

As a side note, for some reason, I didn't have any environments downloaded into Fusion 360, and I was unable to position my renderings in any way with them, but the renderings came out nicely and still describe the form perfectly well.