Intention

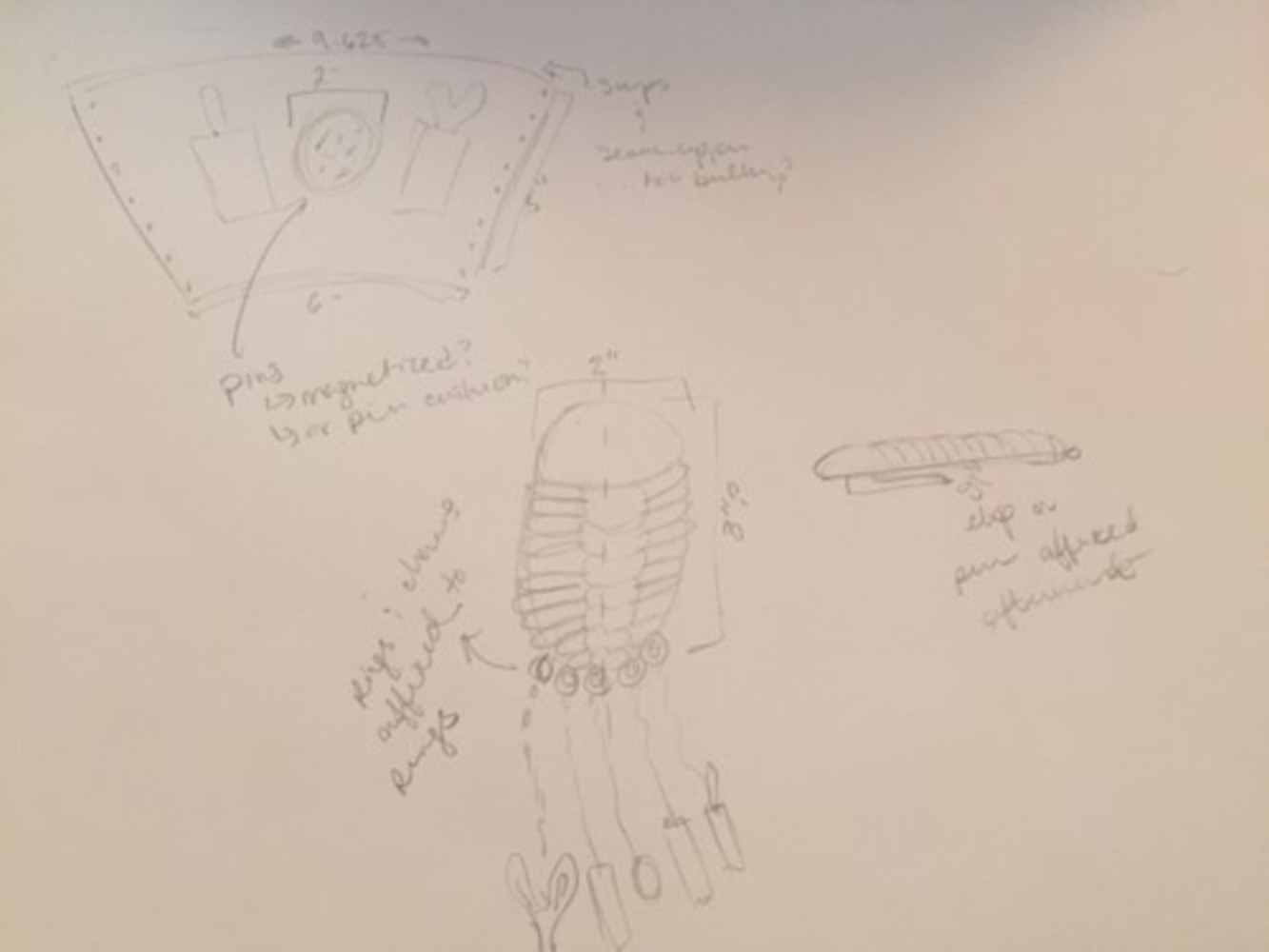

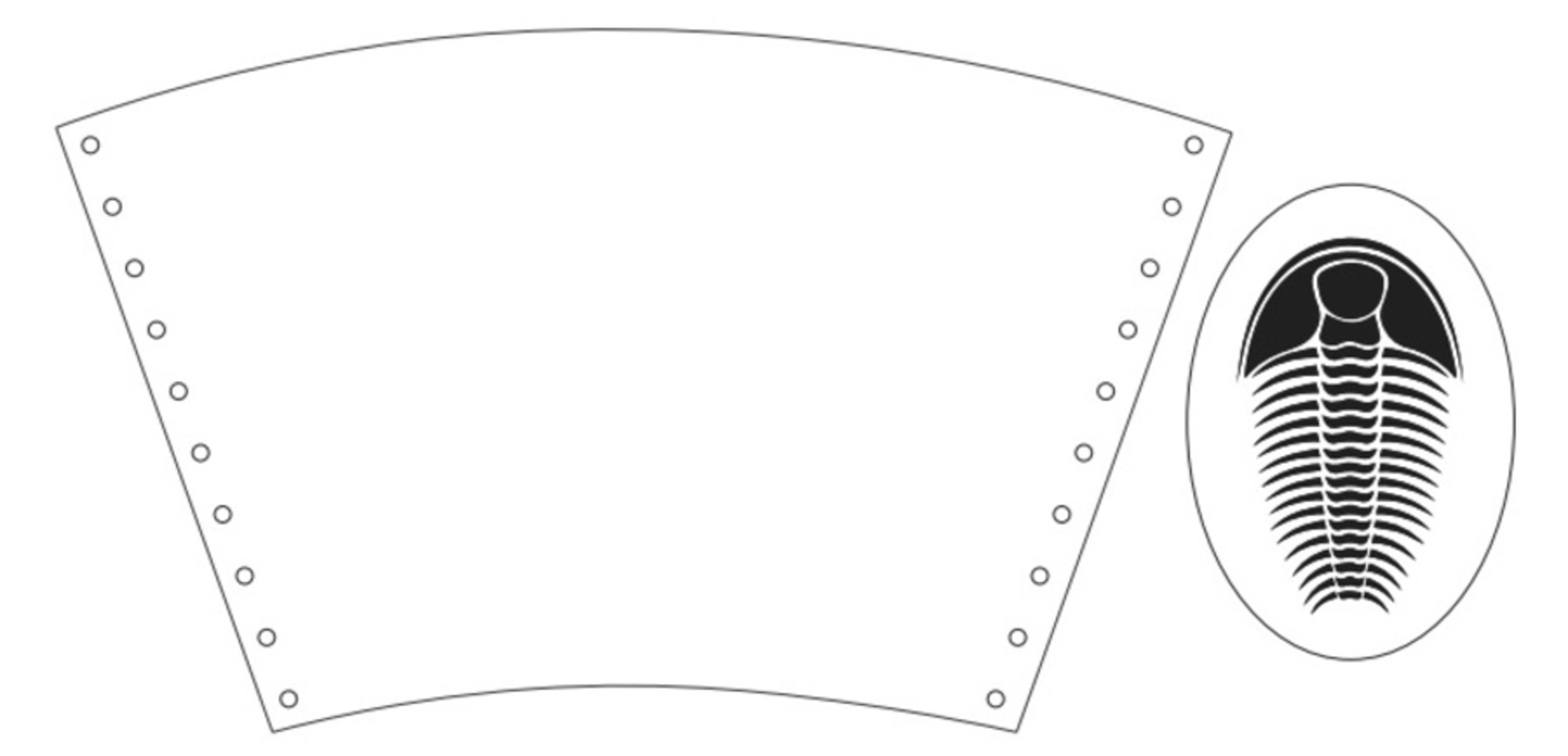

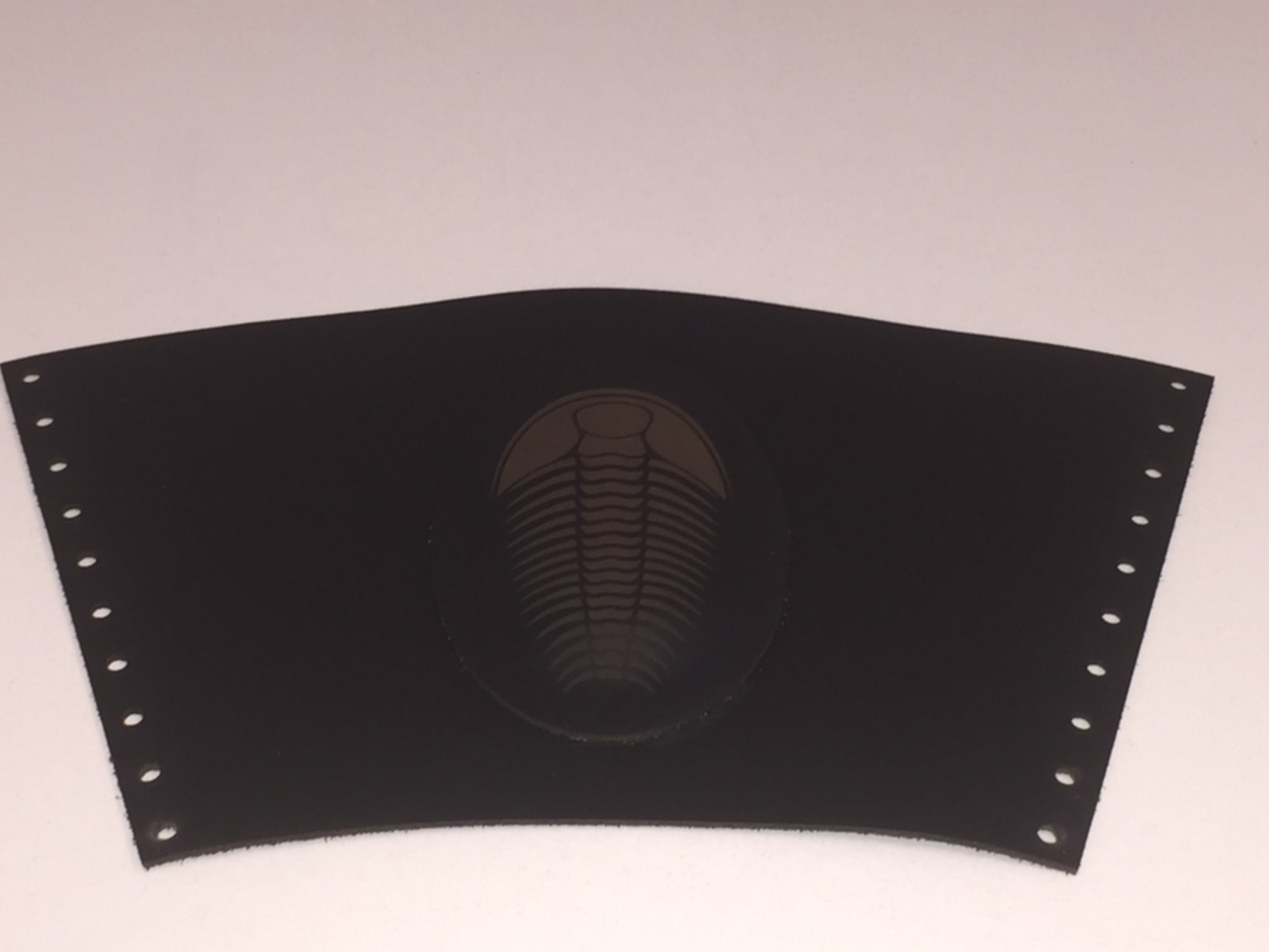

In fittings, my hands are often occupied with actively handling the clothes and adjusting it on the person. This makes it difficult to to reach for tools or pins, even when they are actively needed. I had a bulky magnet bracelet that slid around my wrist. Eventually it broke, leaving me with no good way to hold pins nearby. The bracer will allow for a tight fit on the arm, and the leather will be more comfortable than the generically fit plastic I used previously.

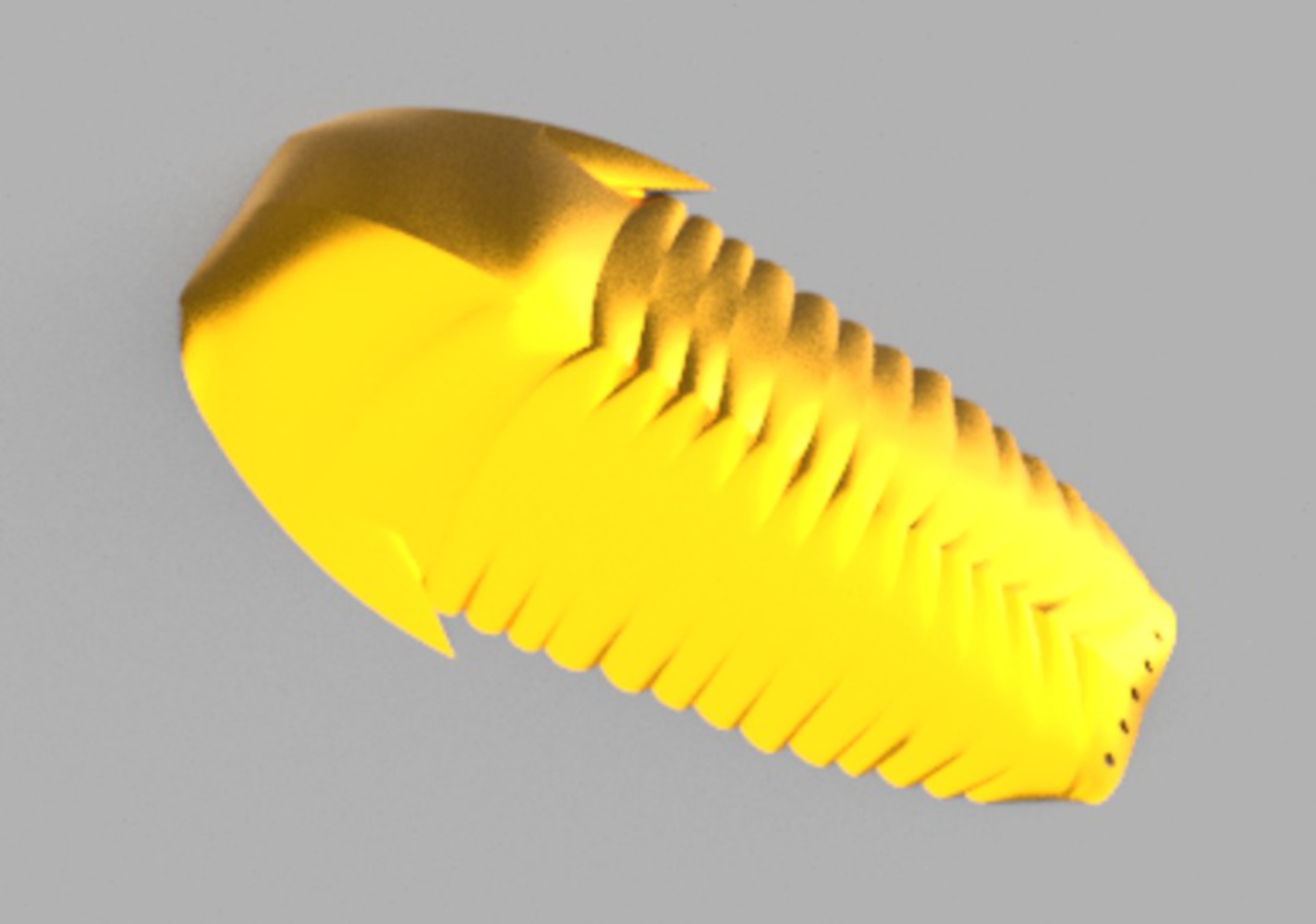

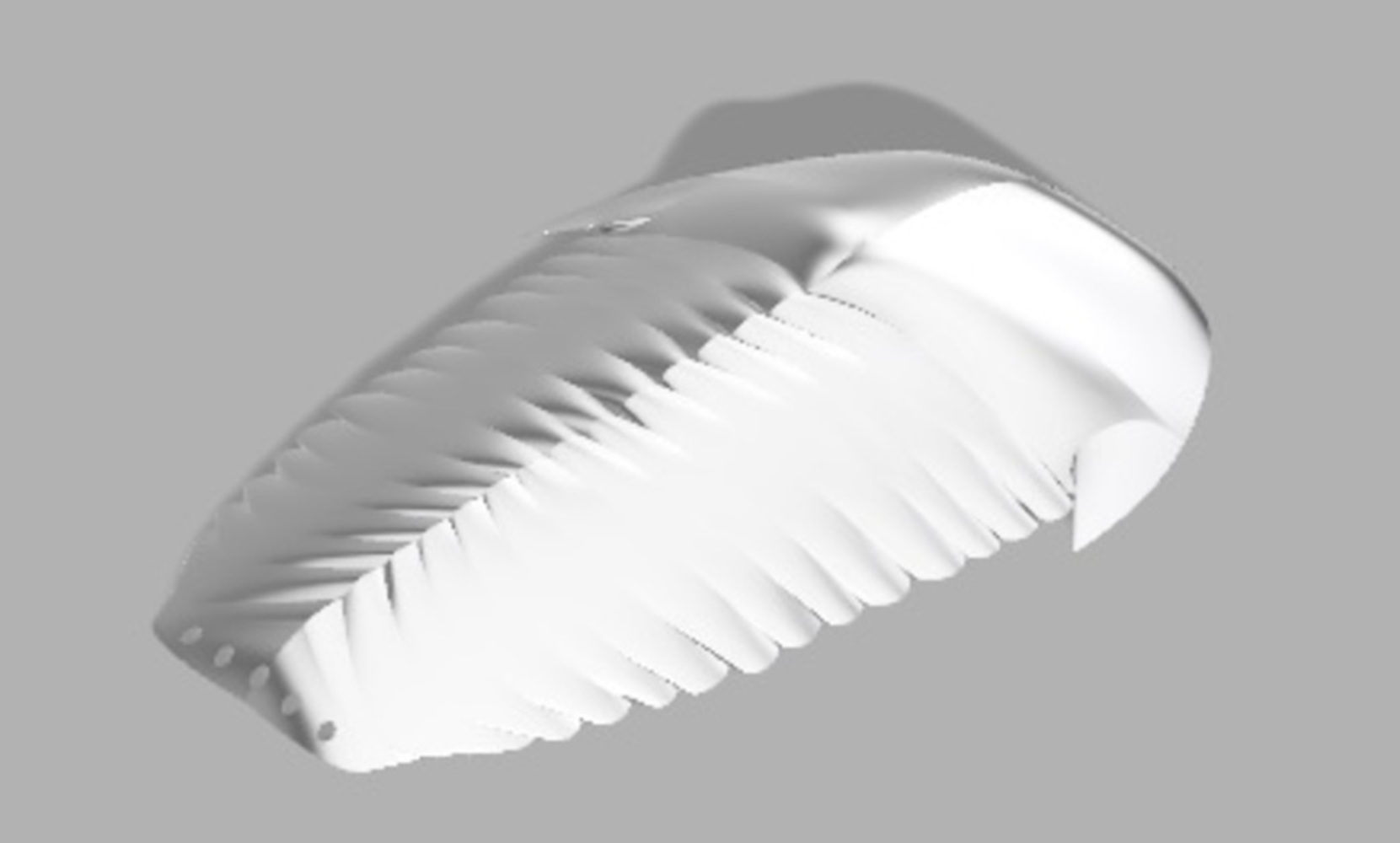

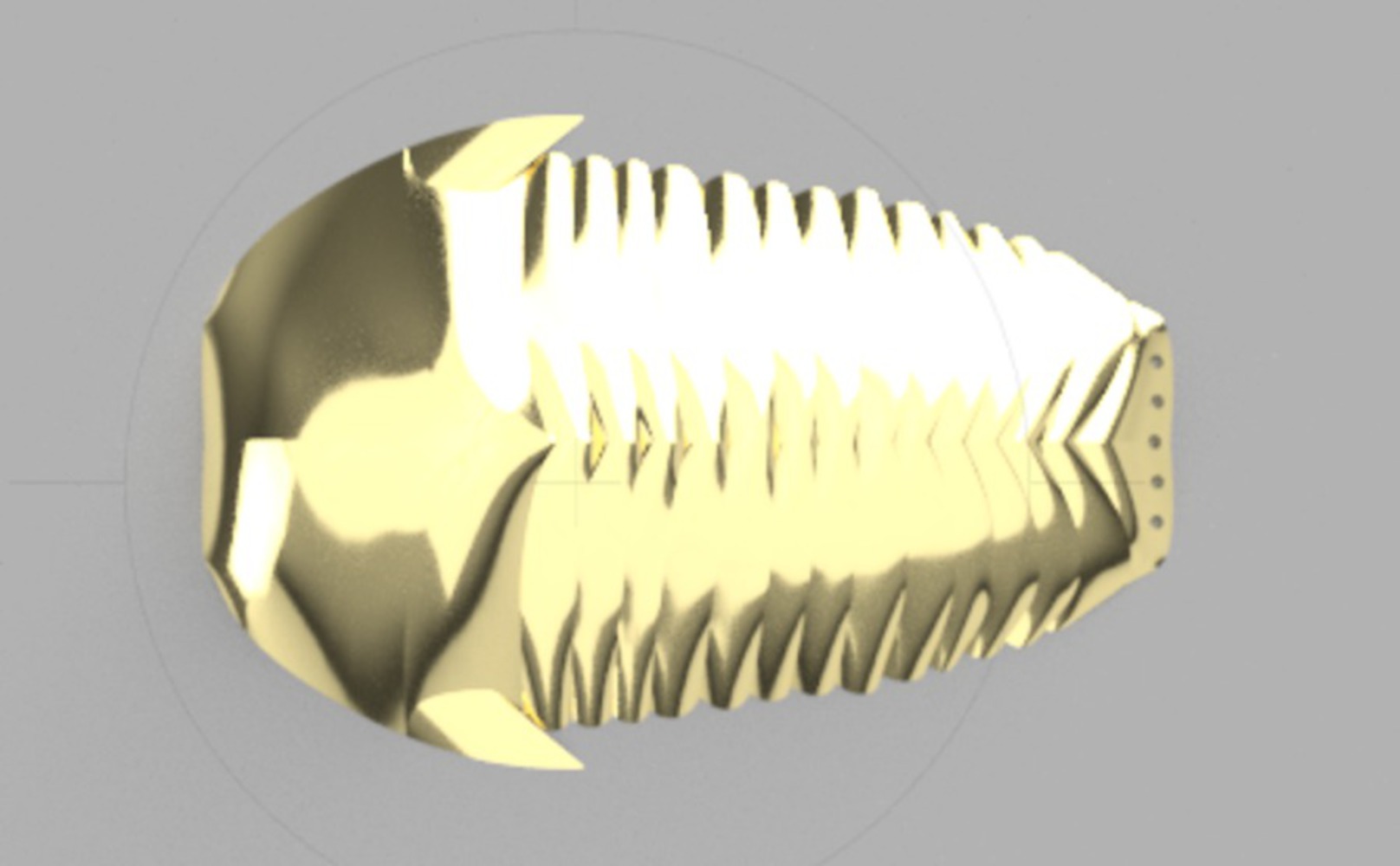

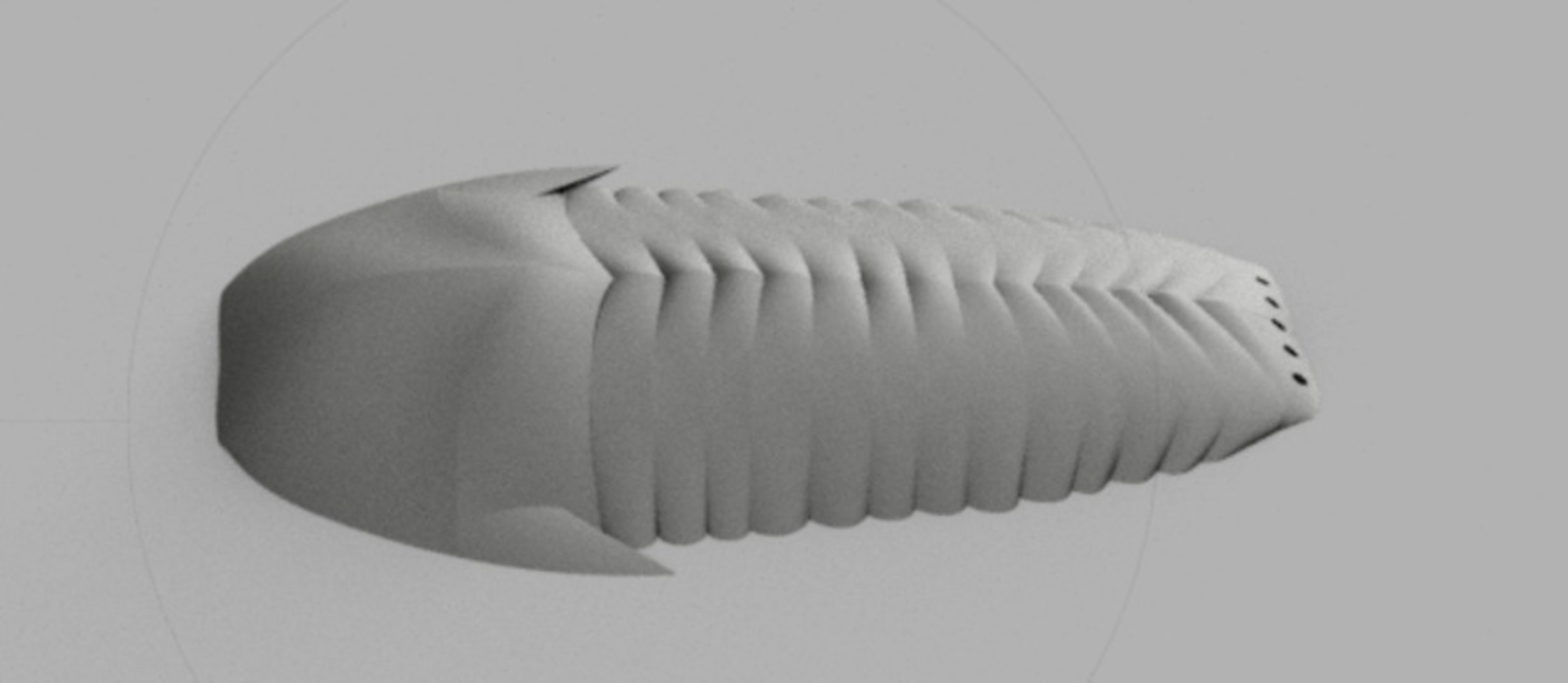

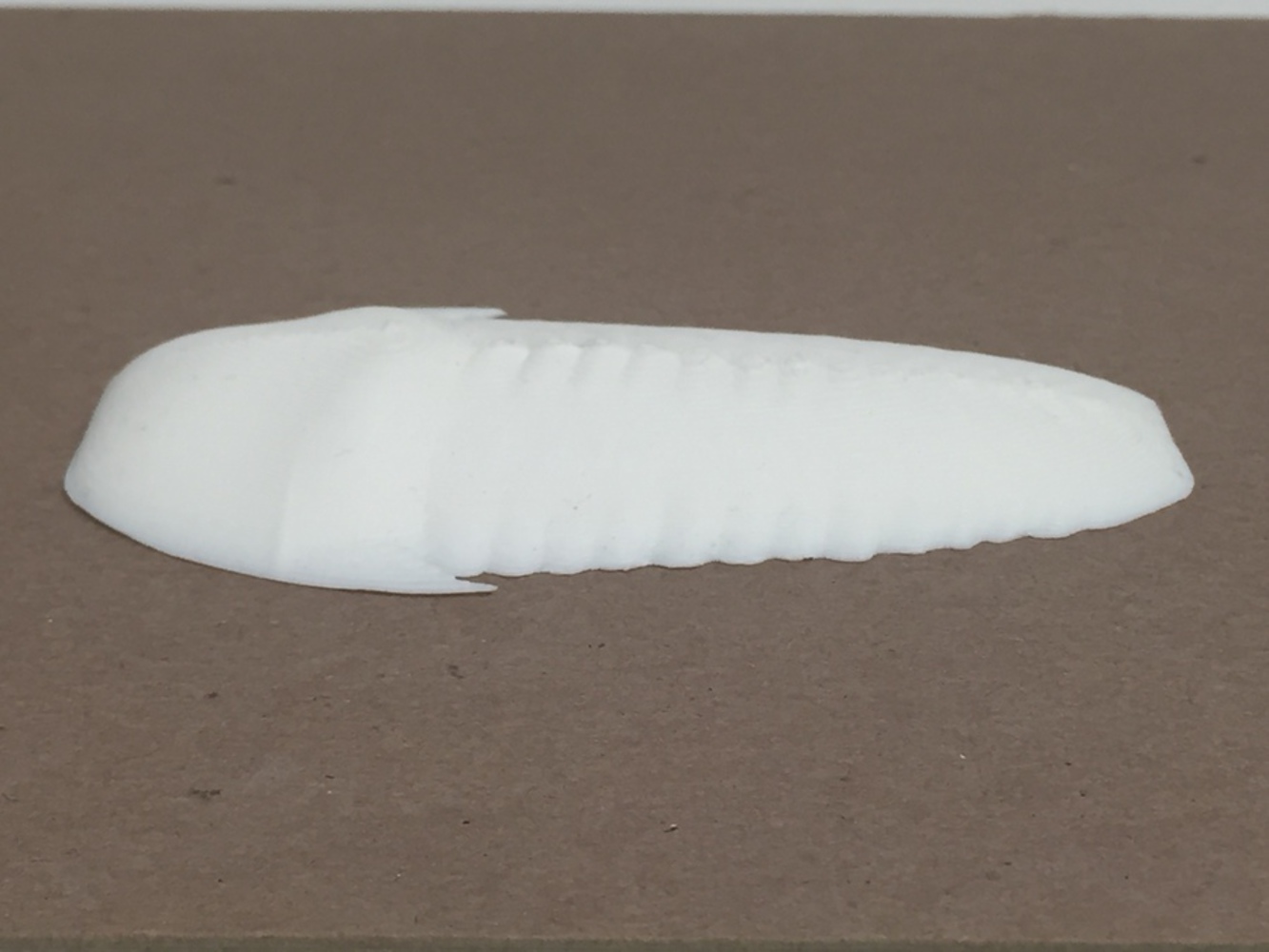

To compliment the bracer is a 3D printed brooch based off a Victorian chatelaine: a decorative brooch that held chained tools. It is to be worn on the waist to have all tools nearby, and still remain hands free. These chains can hold a seam ripper, small scissors, and other helpful items.