Intention

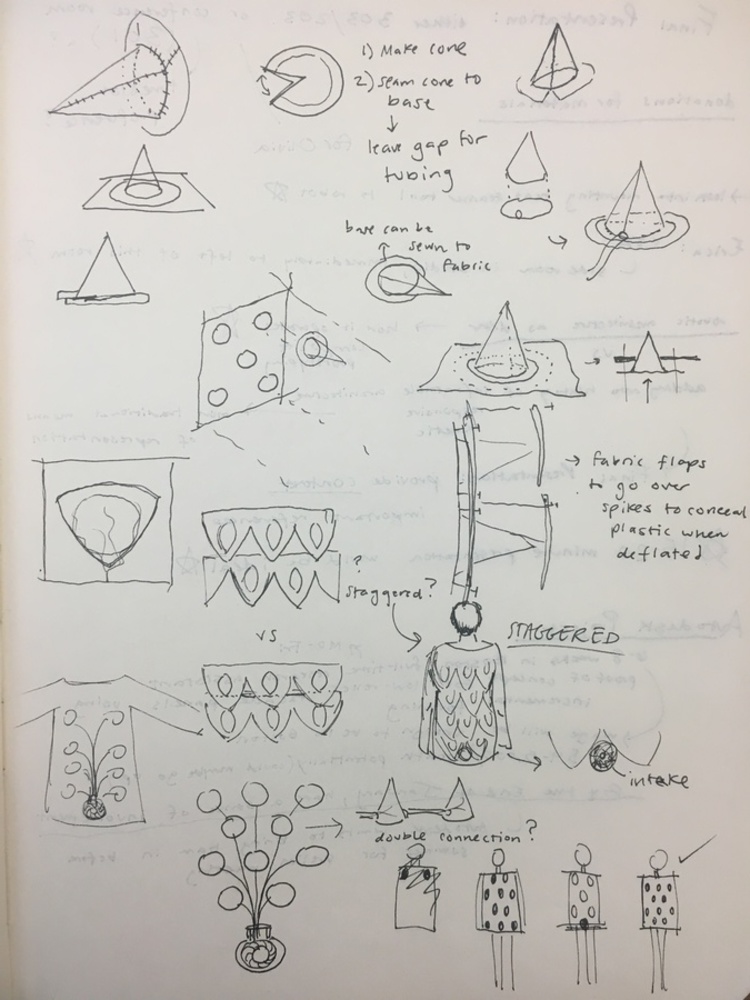

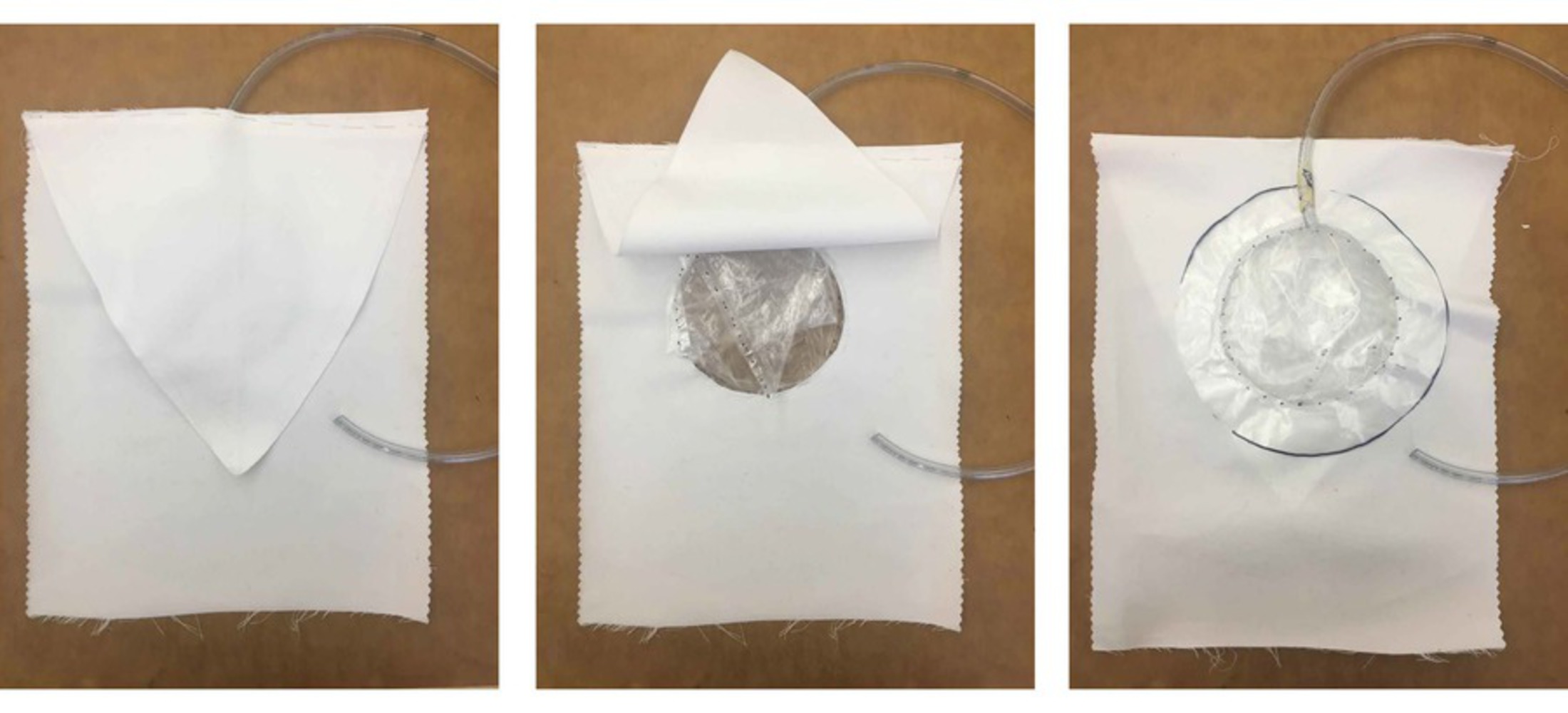

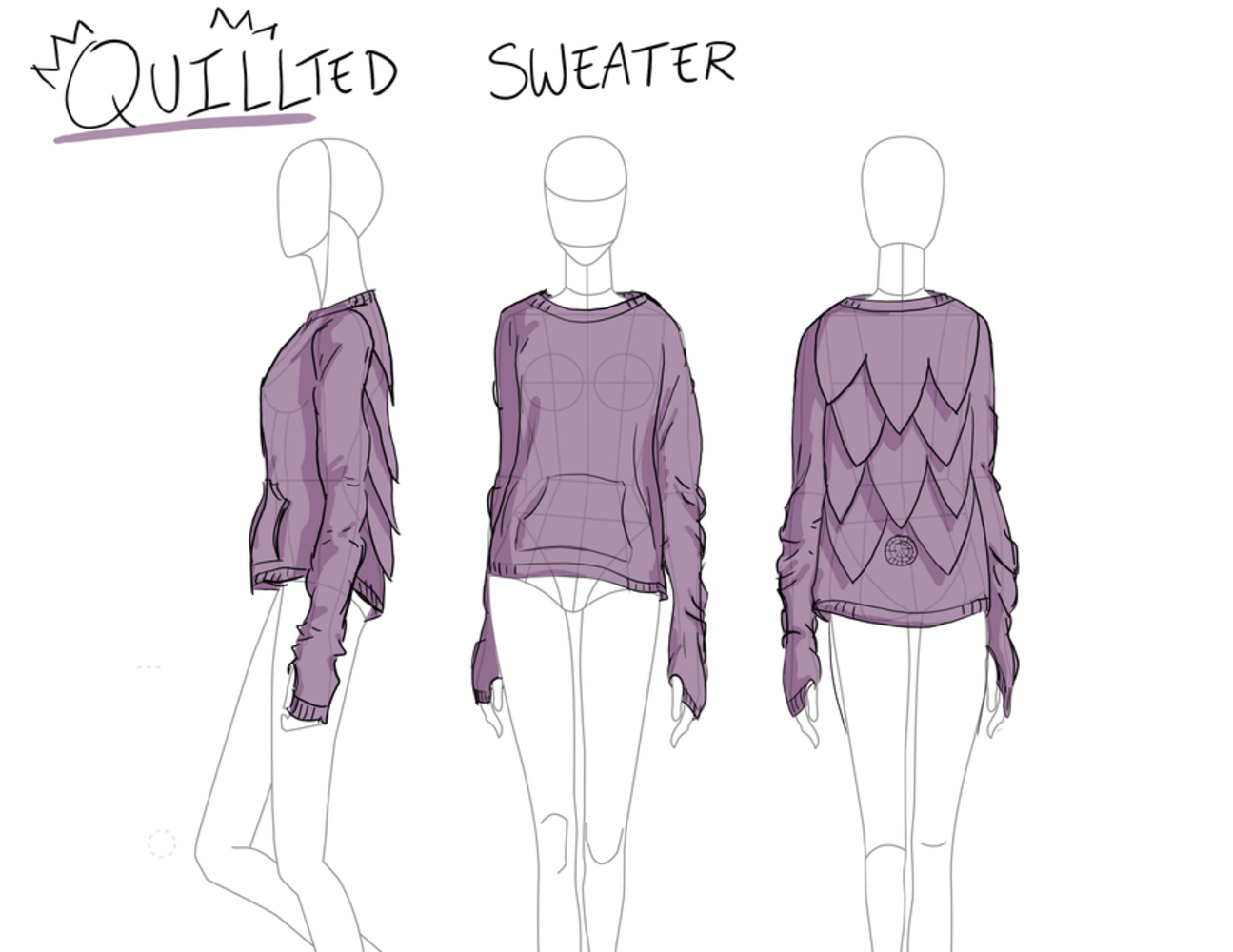

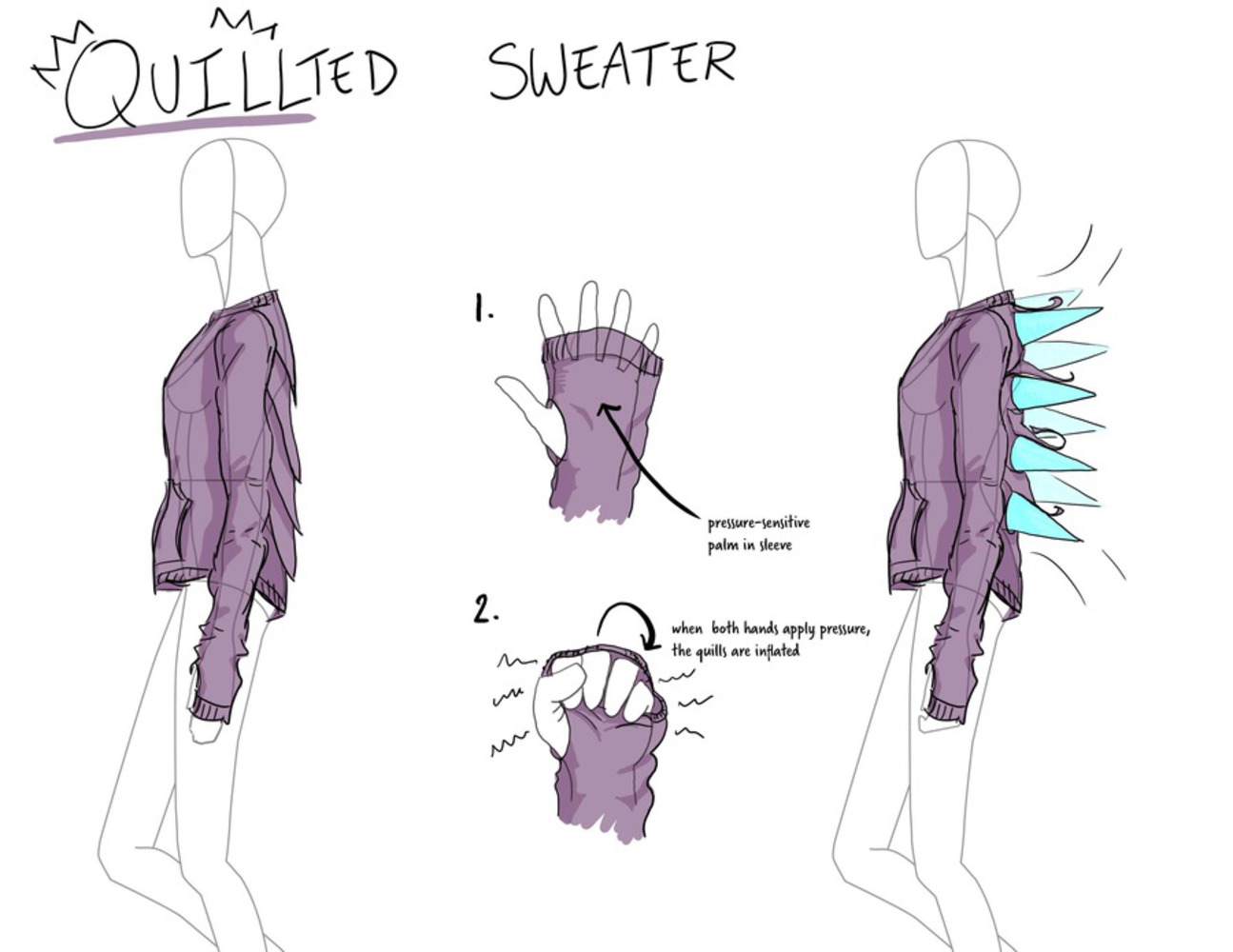

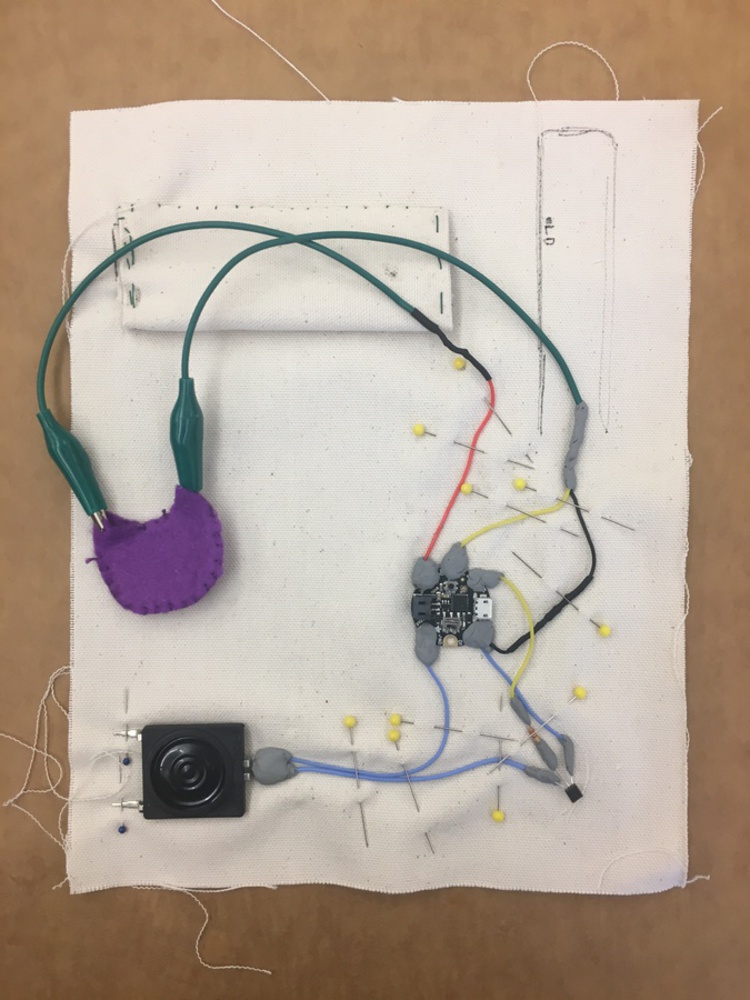

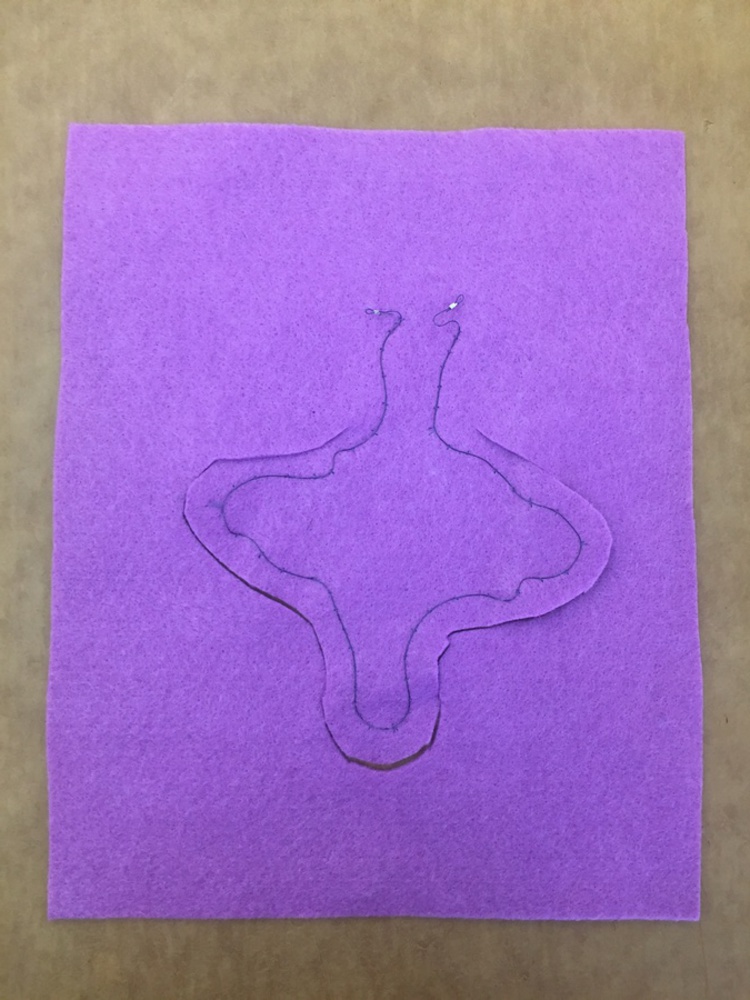

For this project, I wanted to combine the skills I learned in E-Textiles with my current thesis research on inflatables. I was interested in creating a dynamic and transformable garment, thus Quillted Sweater was born: a sweatshirt with 'quills' hidden up and down the wearer's back that inflate when pressure is applied through the sleeves. My initial inspiration came from projects like Anouk Wipprecht's Spider Dress and the BioLogic research at the MIT Tangible Media Lab. Unlike these projects, where the transformation is triggered by environmental or biological factors, I wanted my outfit to transform only when the person wearing it intentionally wanted the change. I imagined my outfit to be something a person could wear that would allow them to show when they're feeling really angry or frustrated. A natural gesture when feeling these emotions is to clench your hands into fists, so by locating a pressure sensor in the sleeves the wearer wouldn't have to think about pressing a specific button or flipping a switch.