Overview

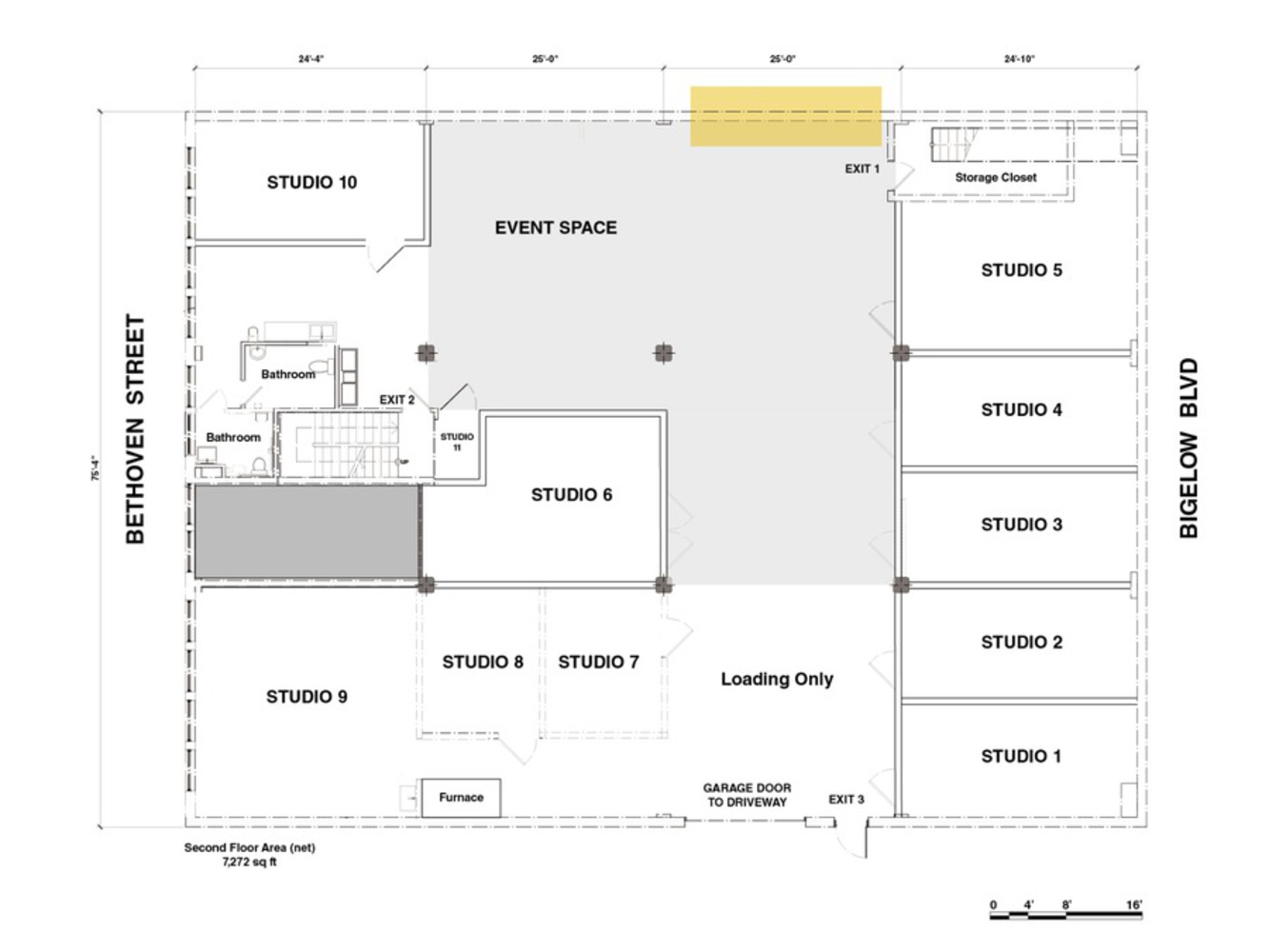

Pittsburgh In View is an interactive installation that aims to rejuvenate the barren common space of Studio 3577 by bringing to life the vibrant city around it.

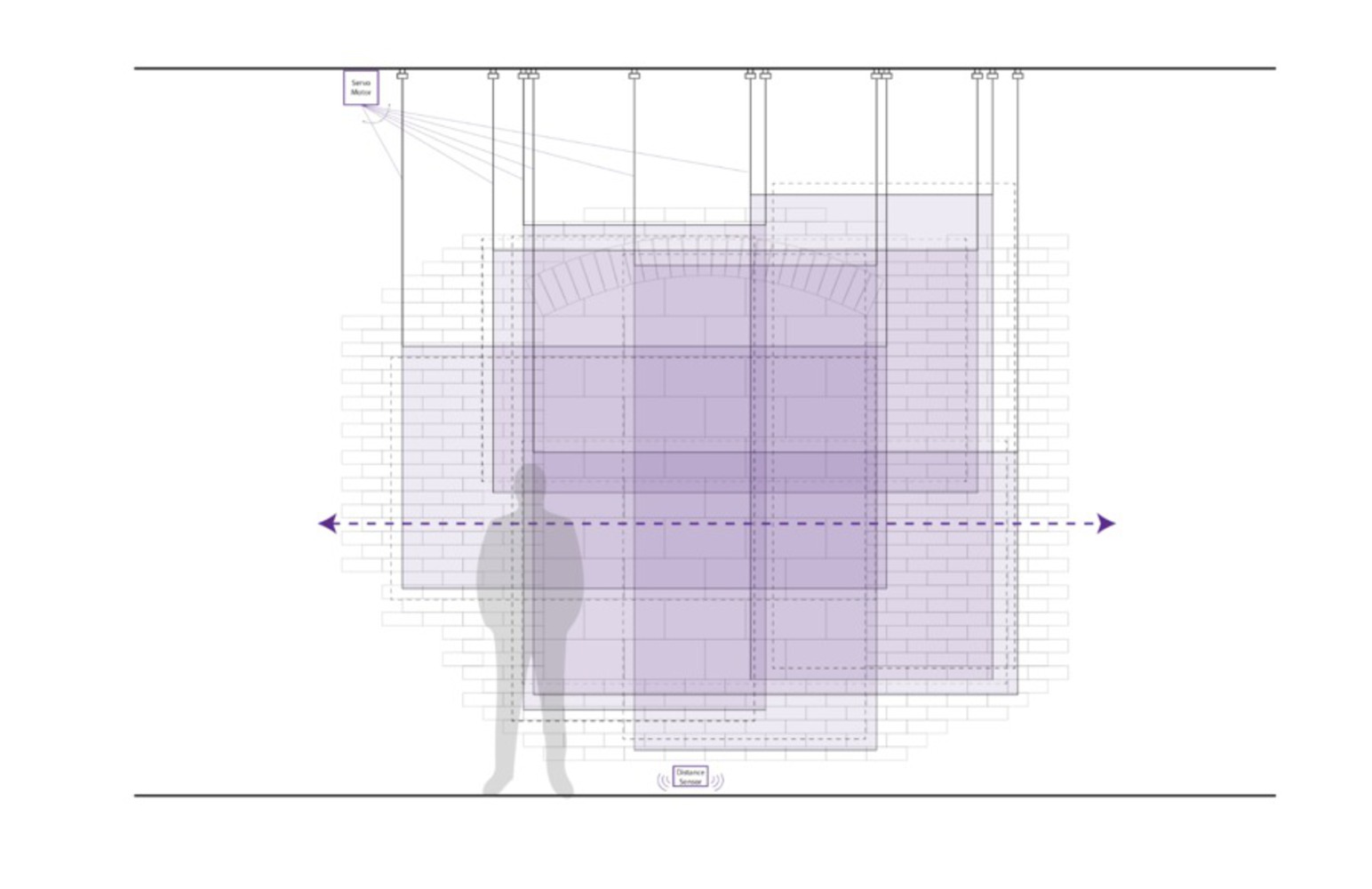

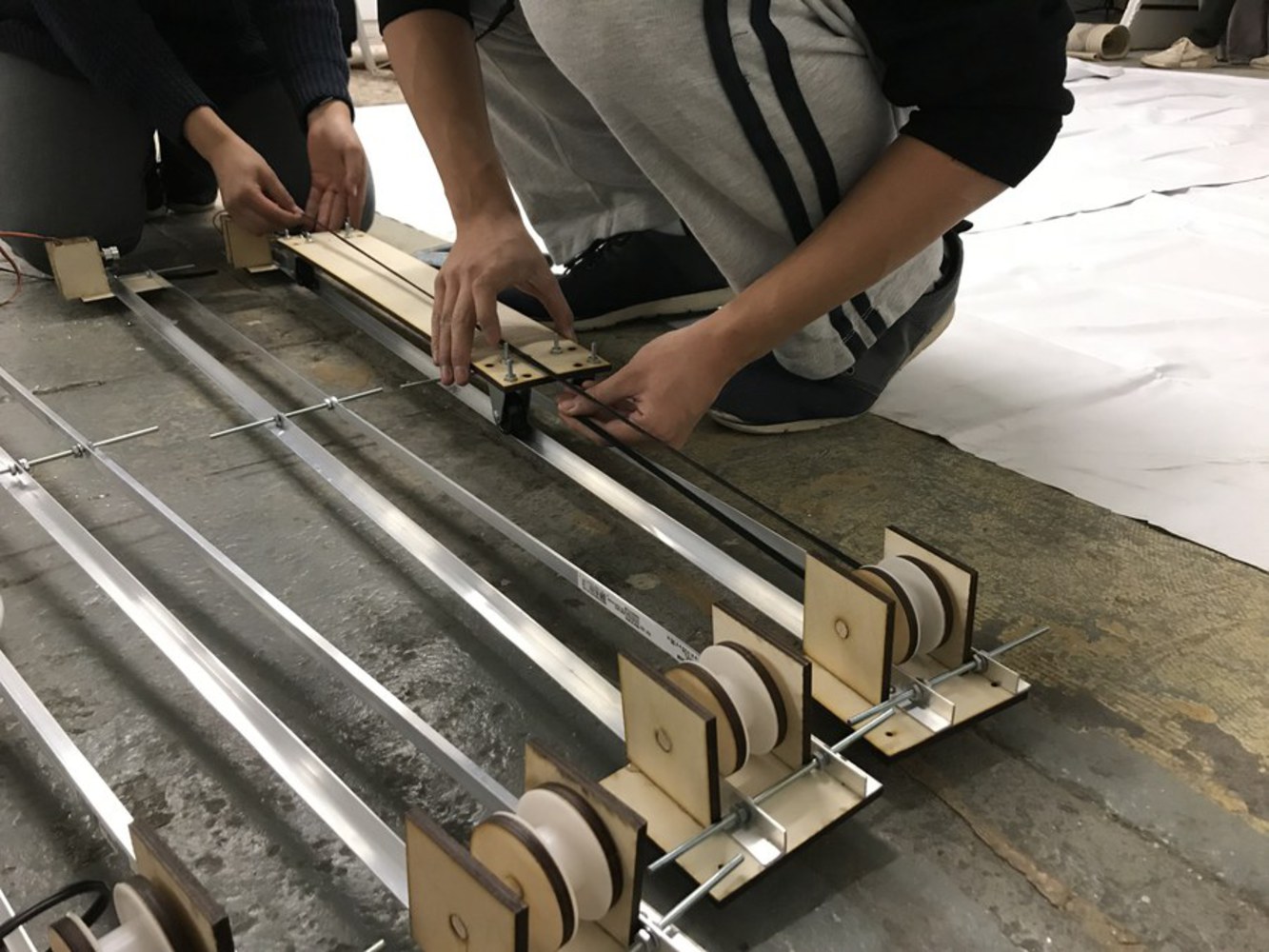

The installation is housed in one of the filled window frames and transforms the wall into a dynamic window. In front of the covered wall are several frames that each peel back layers of the city; the first panel shows what is directly behind the wall while the last panel shows the greater downtown area.

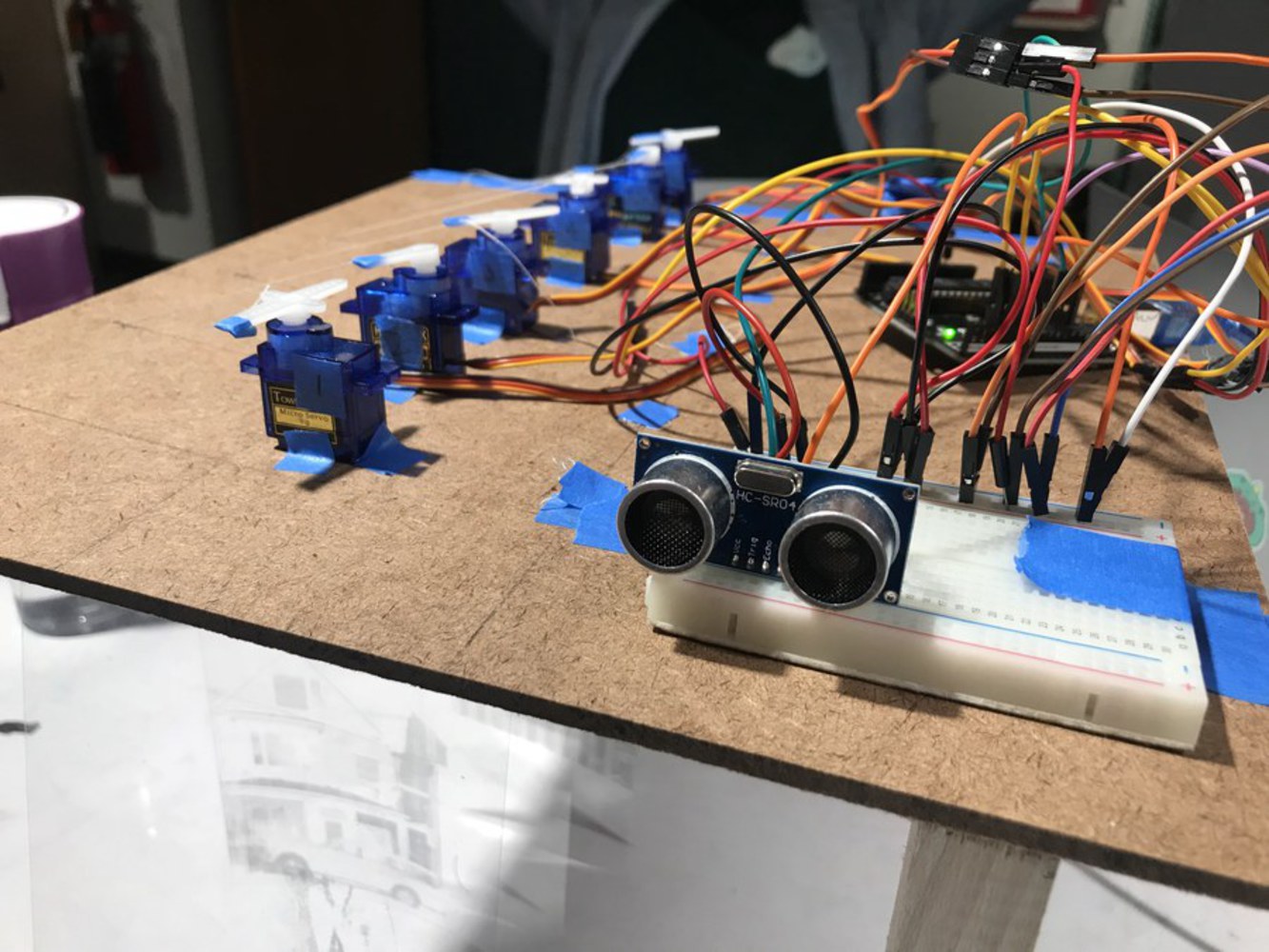

Finally, the installation is interactive in nature; when users near the installation, the image distorts (frames sway slightly). This is a commentary on how no matter how close a user gets to a photo, they will never have the same experience as if they travelled to the real location.