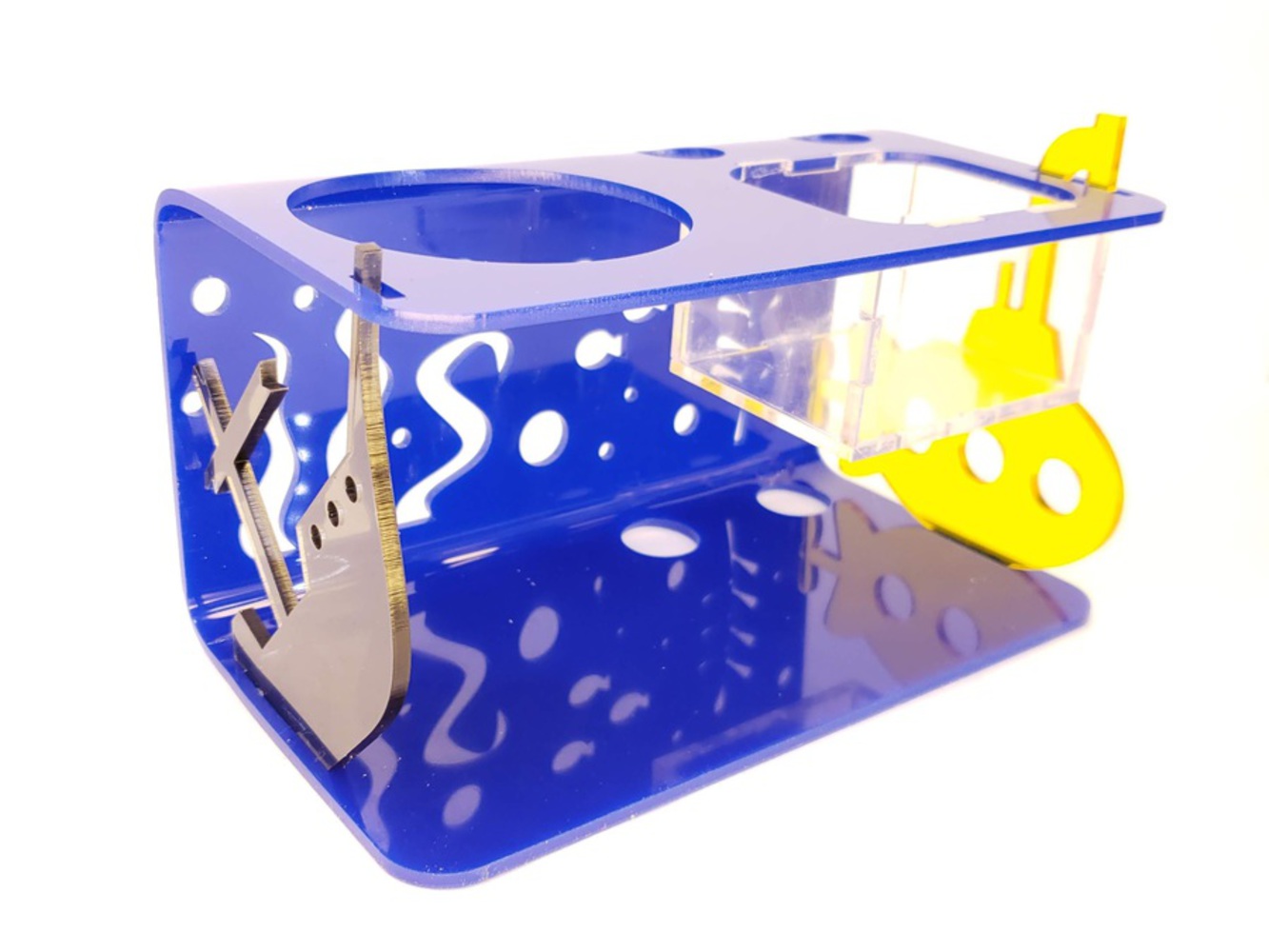

Ideation

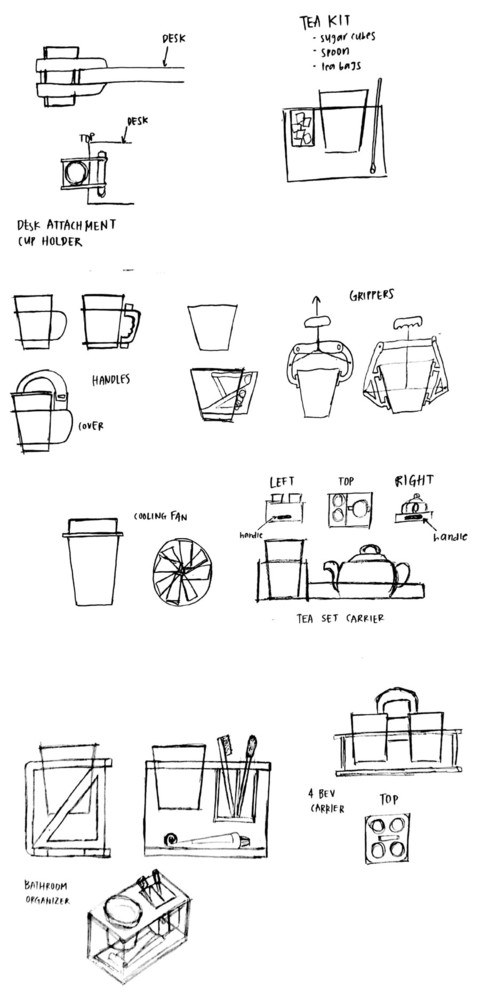

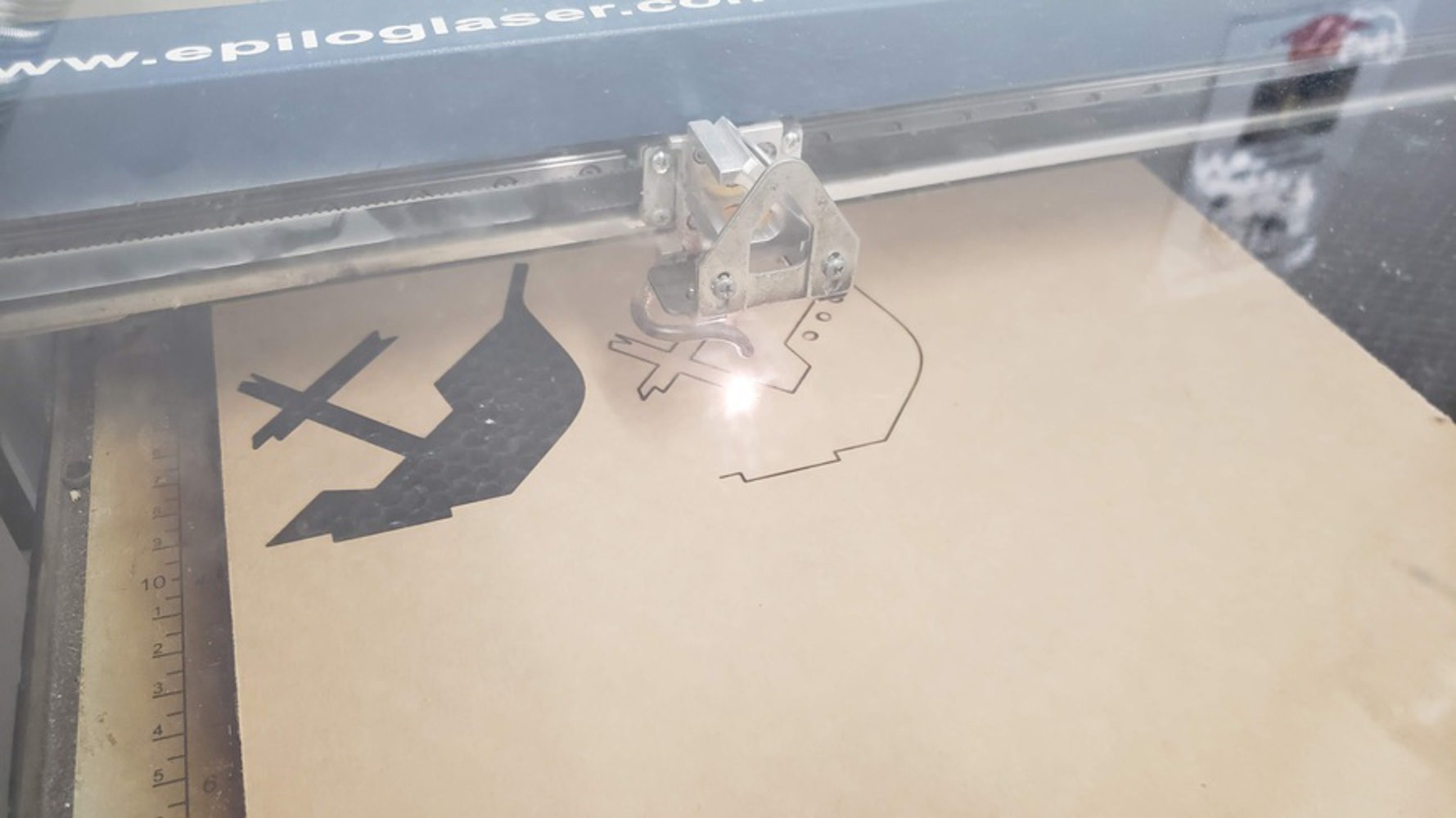

At the start of the design process, I tried to think of things that I would want for a cup. Sketching them out onto paper helped me flesh out both their functionality and feasibility. I love drinking tea, so a lot of my initial ideas revolved around tea sets and beverage holders.

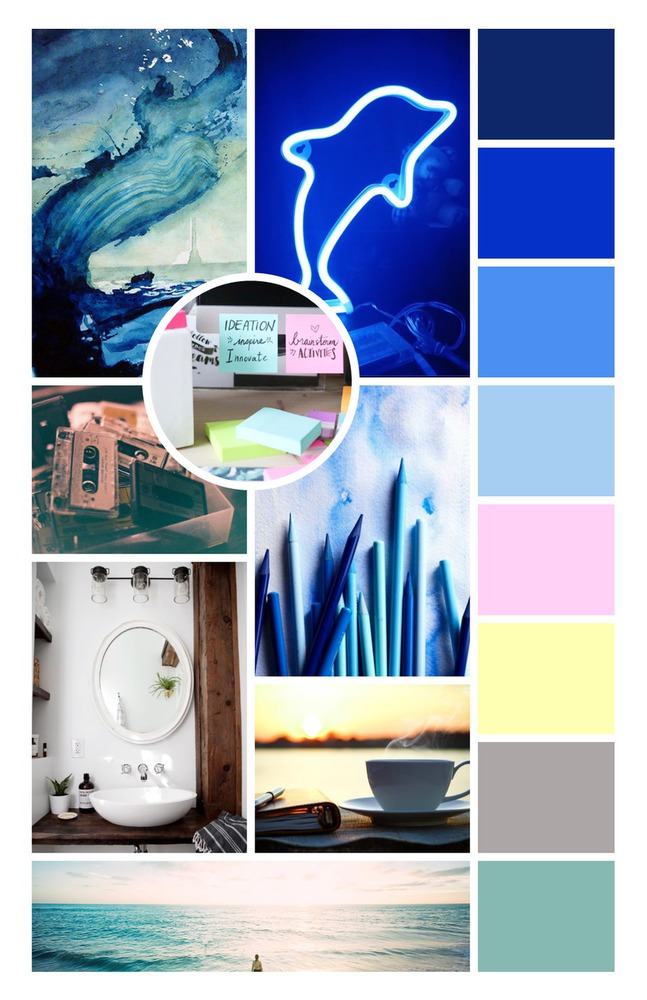

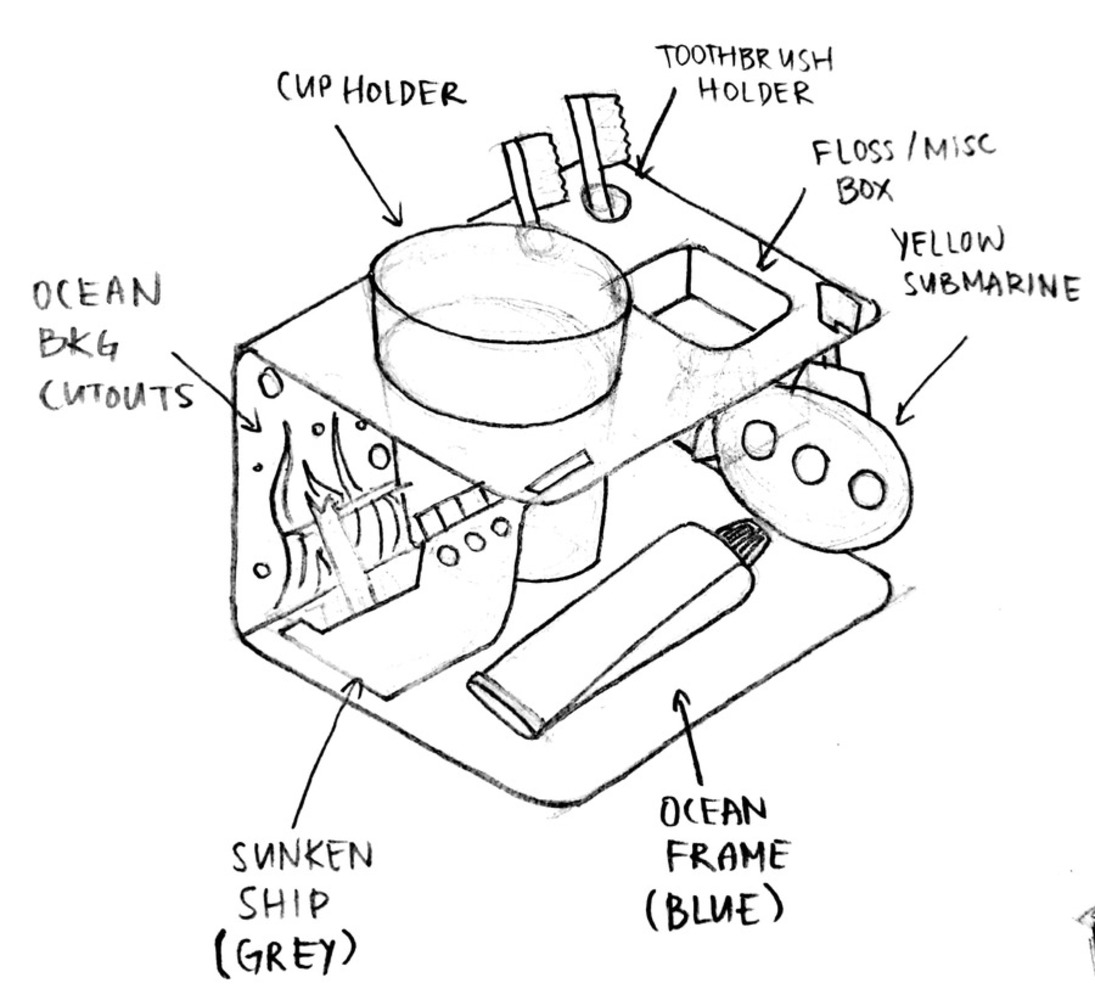

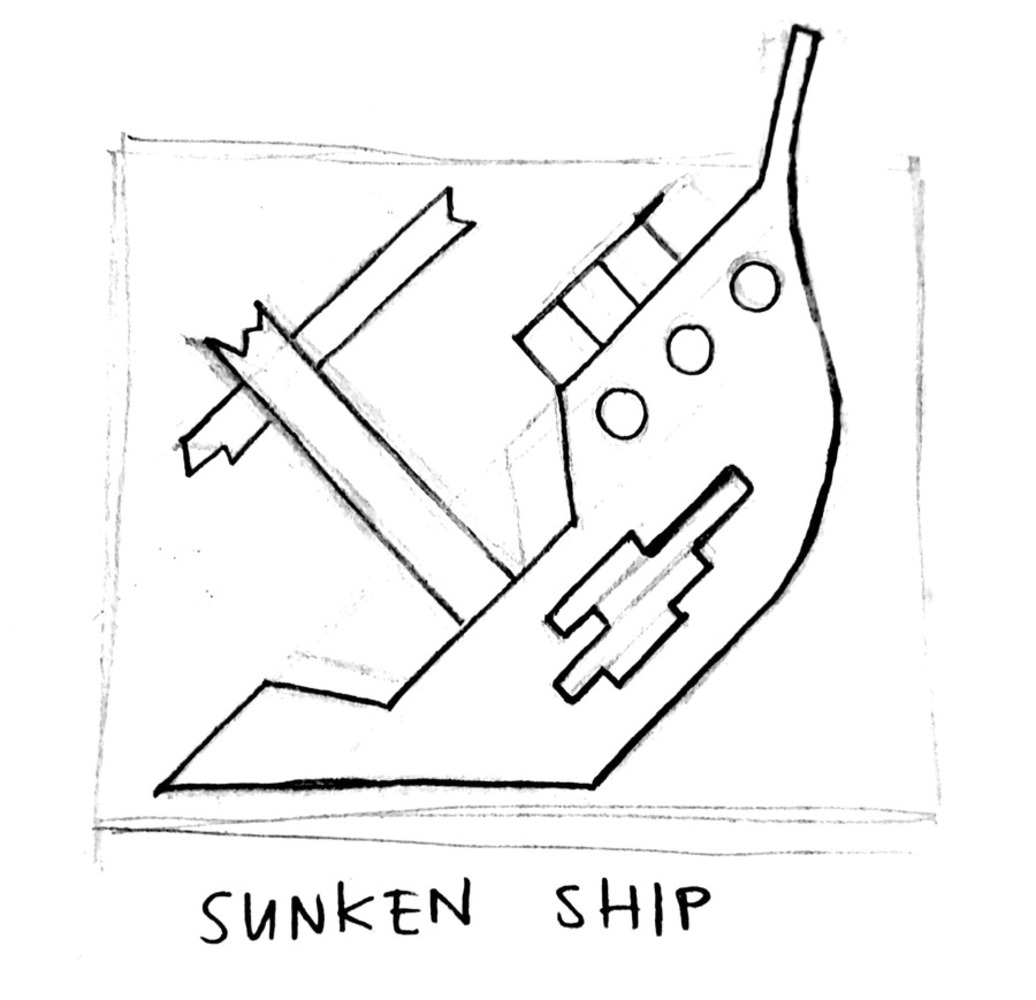

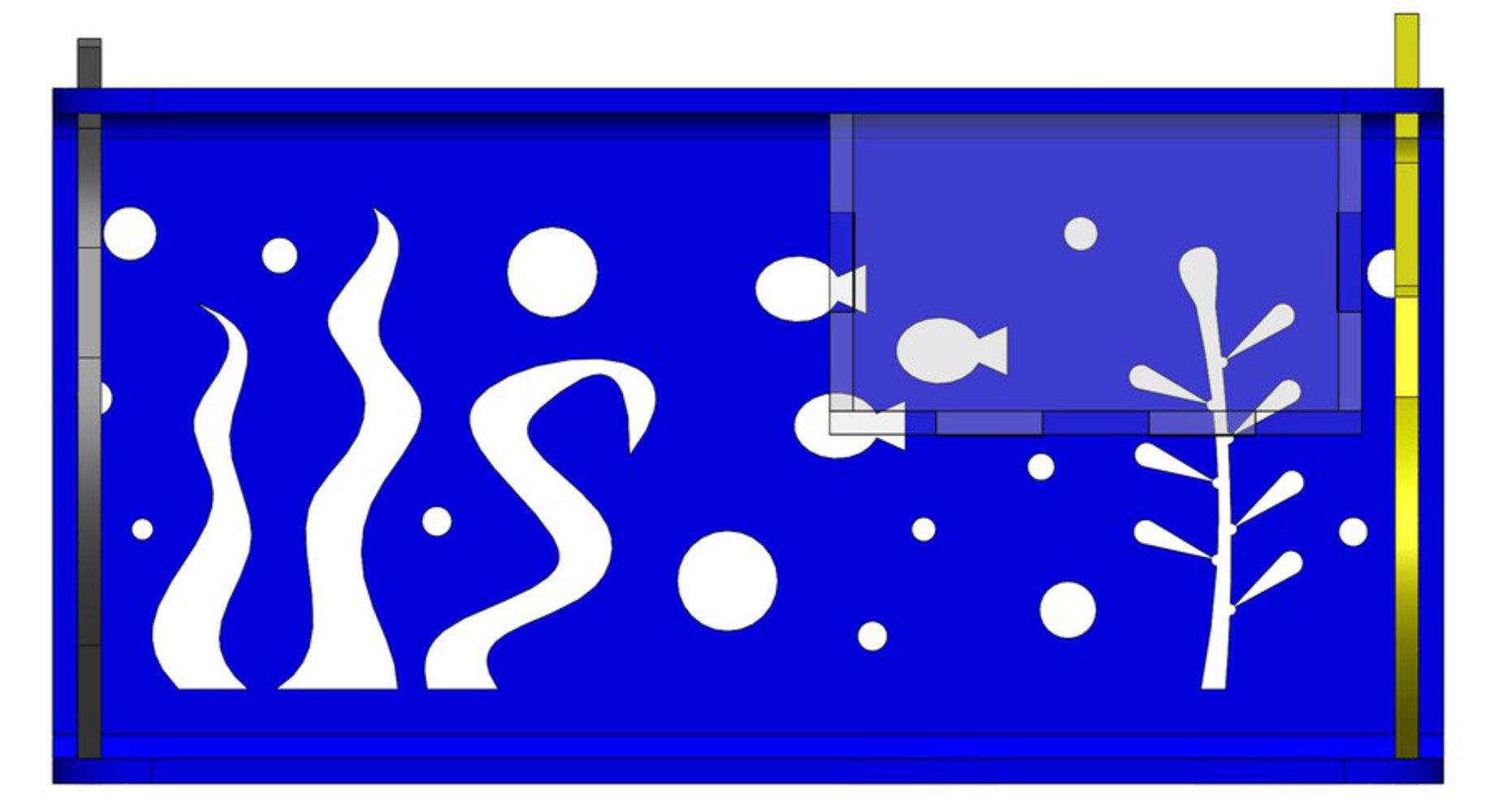

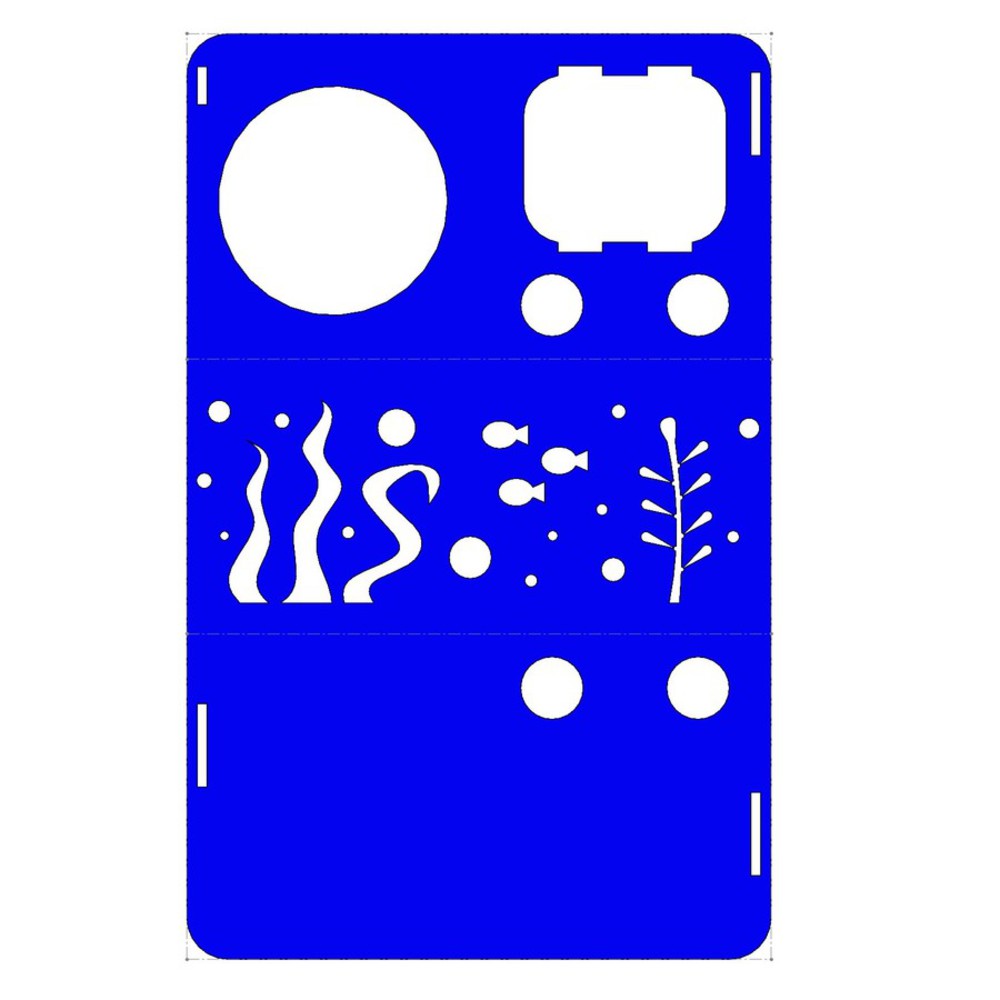

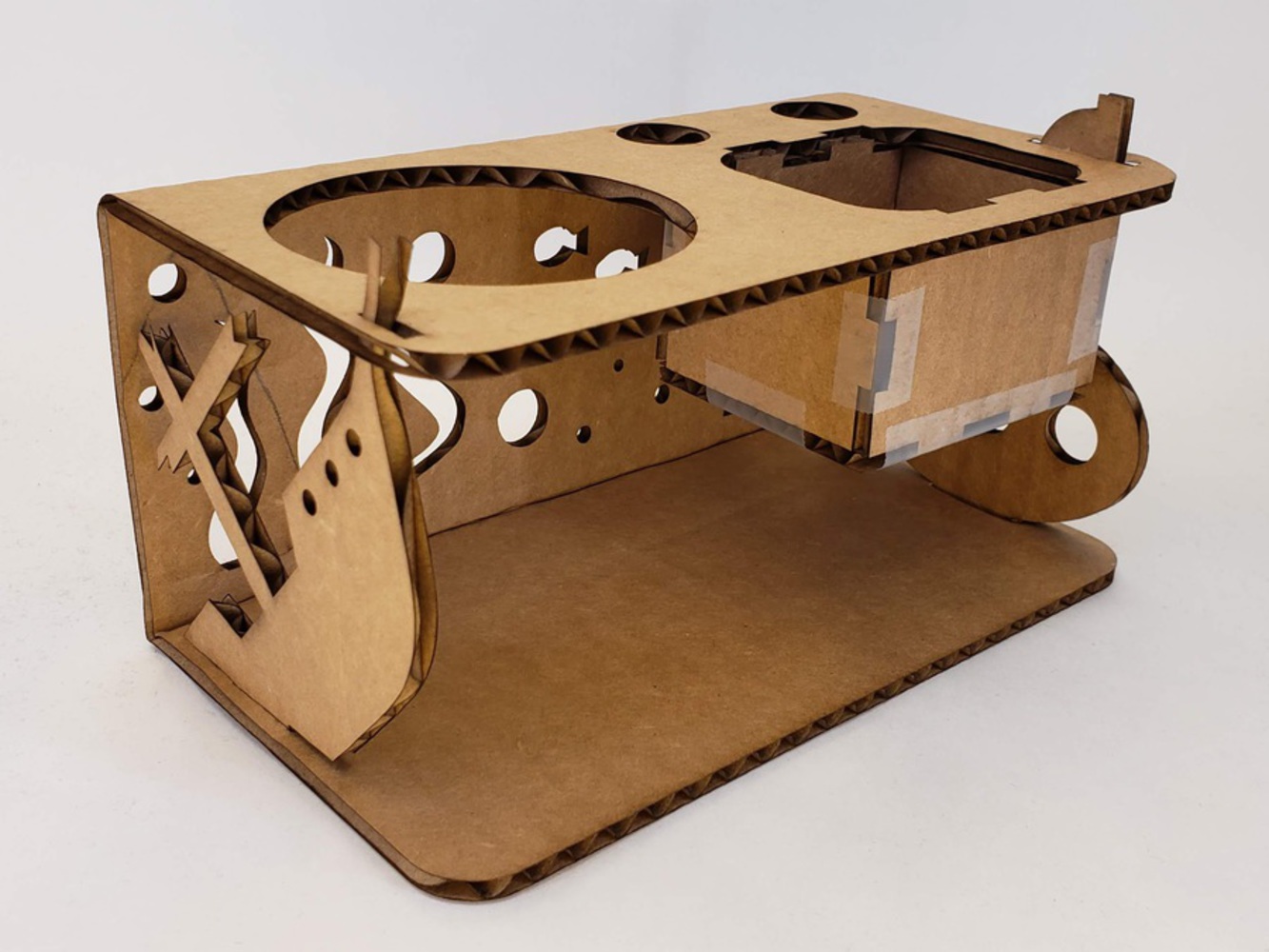

Later on, however, I thought it might be cool to approach the problem from another angle. When people just think about tea and coffee cups, ideas can get pretty similar. Every year we see a lot of handles and cup lids. I opened my scope from drinking beverages to this question: "What cup do I use every day?" After some thought I remembered that I brush my teeth and rinse with water from a cup twice a day, so this could be a great starting point for my project. I sketched out a simplistic but functional bathroom organizer and was happy to move forward with the idea.