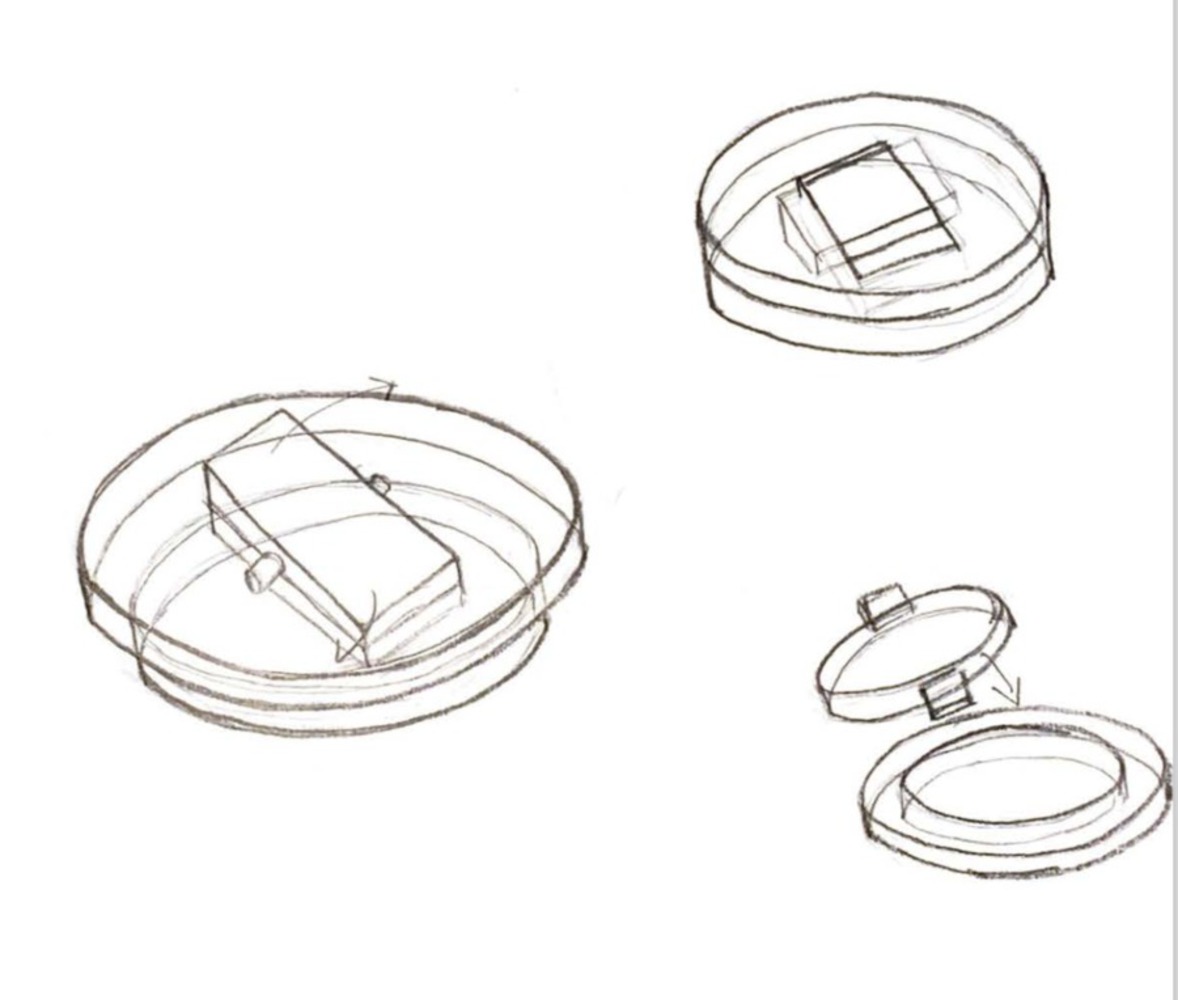

EARLY BRAINSTORMING AND MOODBOARD

I started my design process by thinking about my morning routine. My mornings are very standard; I make the same black coffee in the same $3 travel mug, walk to the bus stop, and take the bus to campus. I tend to wake up as late as possible, so my coffee finishes brewing about 30 seconds before I walk out the door. I generally don't start my coffee until I get to campus because it's too hot for me, and I can't open my lid to cool it down until I get to class.

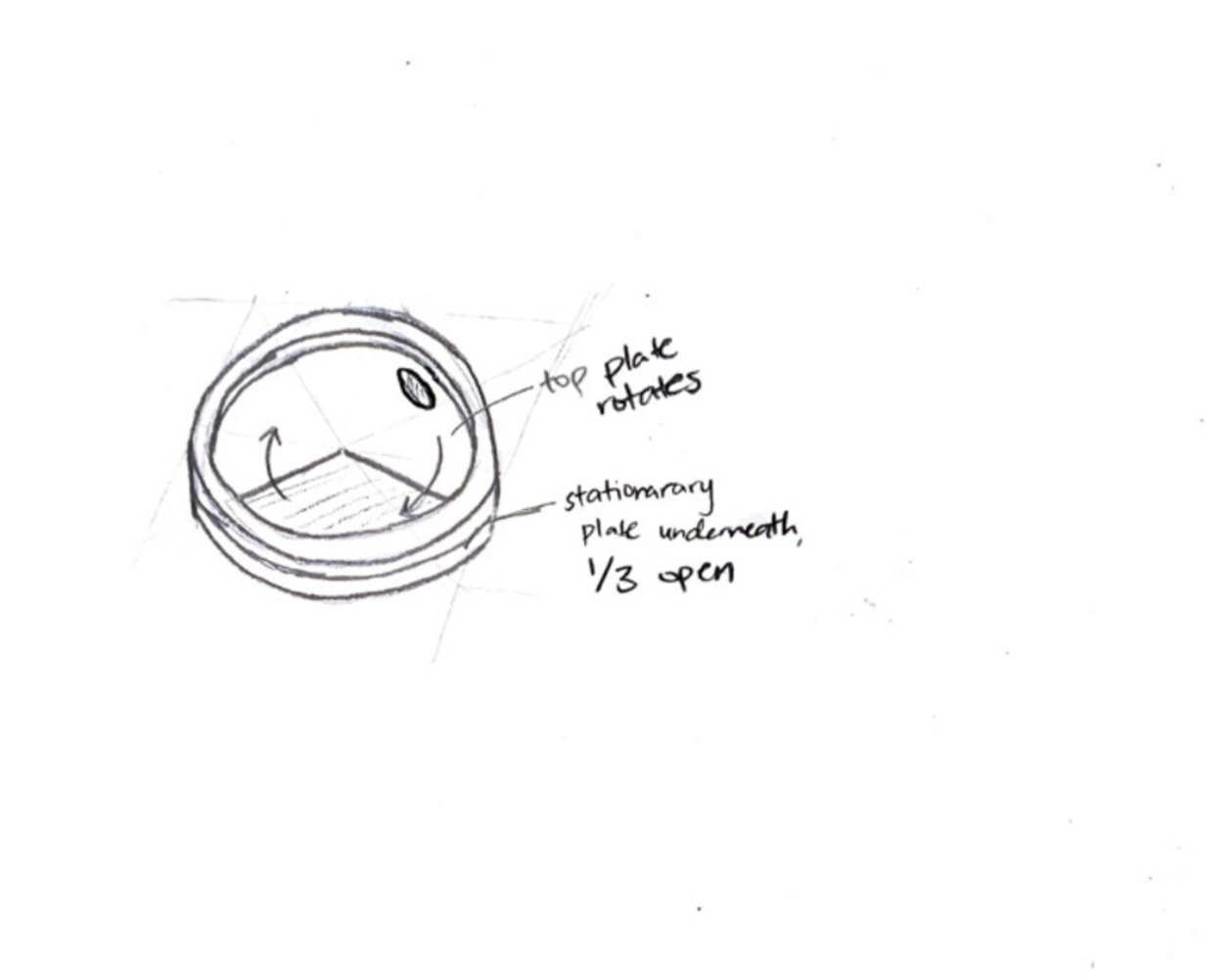

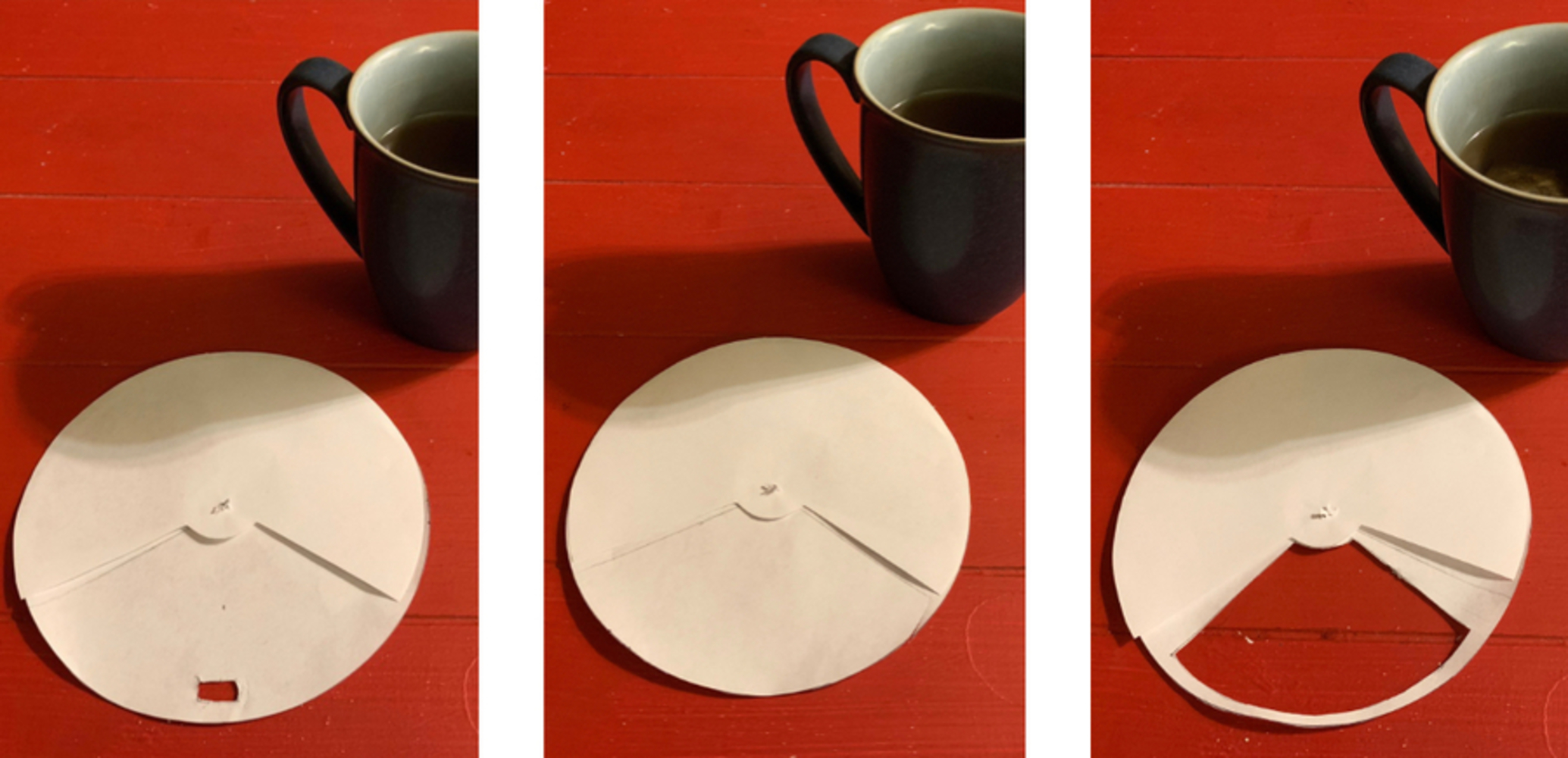

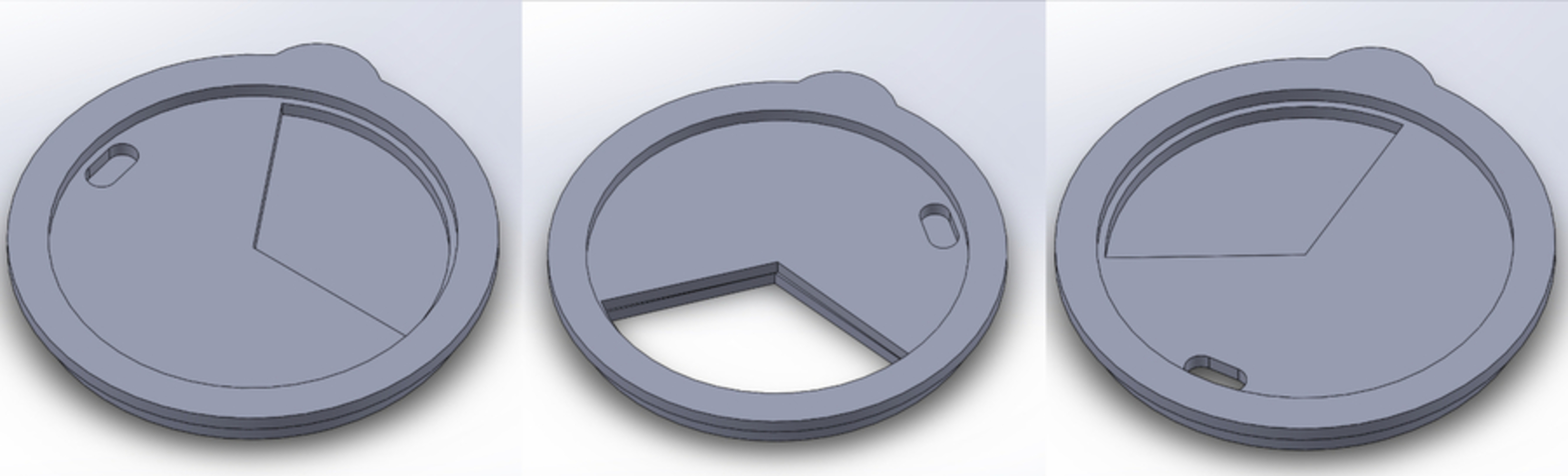

I realized that the perfect complement to my morning routine is a lid that can be easily opened to cool coffee while I'm rushing to the bus stop, without excessive spillage. Based on my moodboard, I decided to use colored acrylic for a pop of color on a grey Pittsburgh morning.