Overview

My favorite part of a long day of work is coming home to enjoy a beer while catching up on my interests and hobbies. But as a college student, I like to be economic with my spending and would prefer to get the most buzz for my buck. That being said, it's rare for me to want to spend my money on the pricier glass bottles, as opposed to cheaper, more economical beer cans. That being said, I still enjoy drinking from a bottle far more than I do from a can.

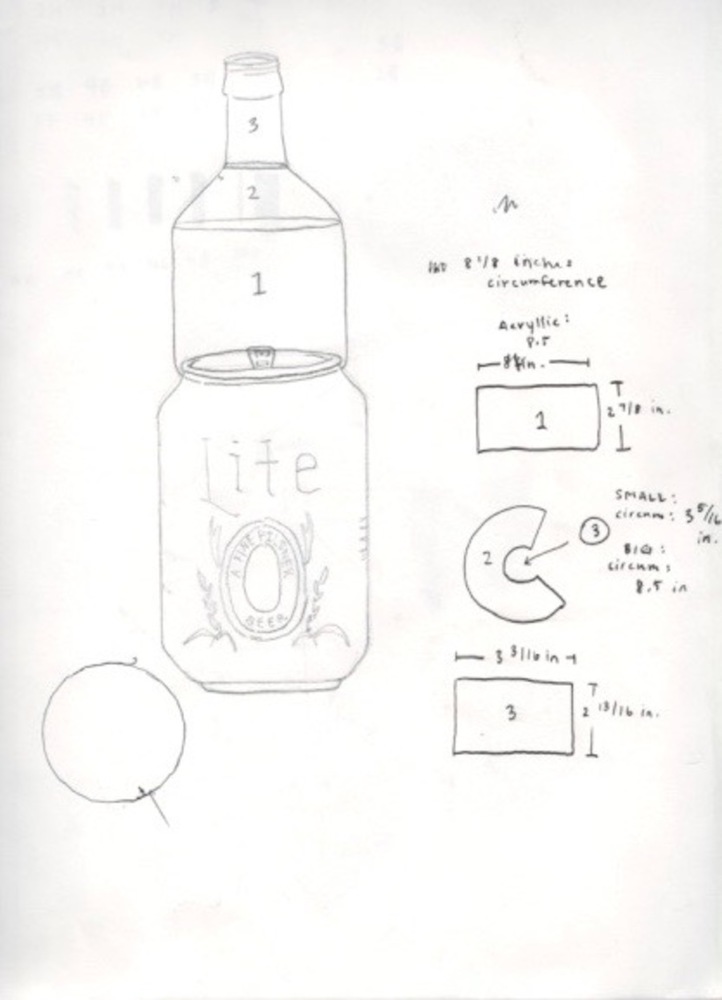

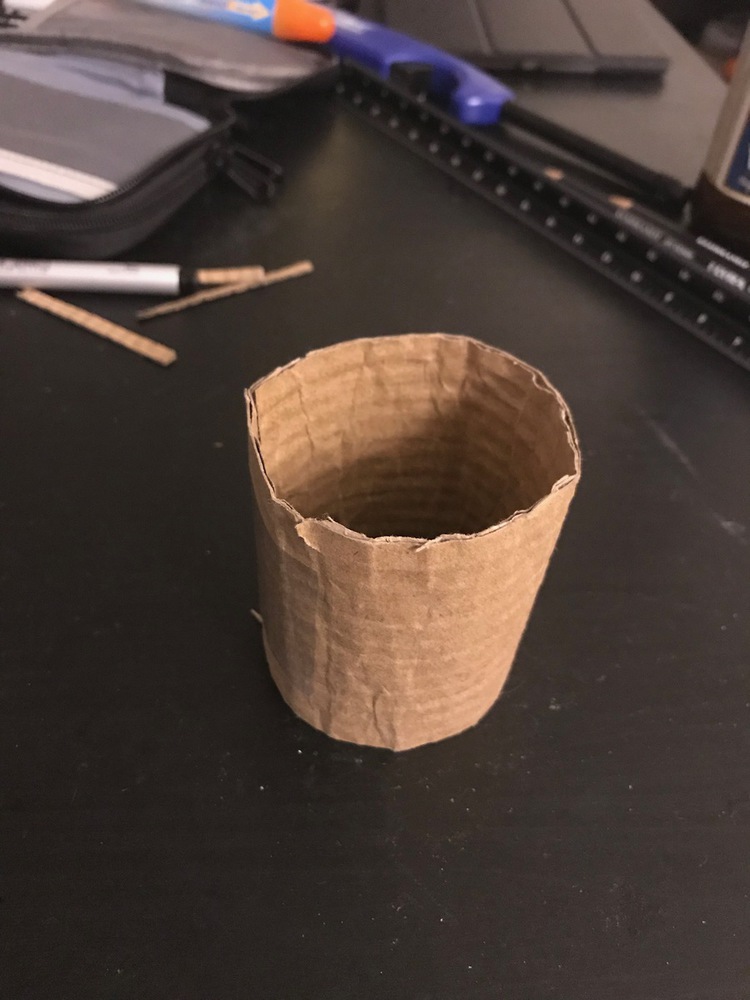

Because I don't have the economic power or influence to change the prices of bottled beer, I decided to design and create a reusable aluminum can slip-on for the sake of replicating the feeling of drinking from a bottle. I also came to the realization that I tend to take sips from my beer too aggressively at times and the beer will often bubble out, making a mess. To prevent any future spillage or accidents, I decided that designing a makeshift cork was also necessary.