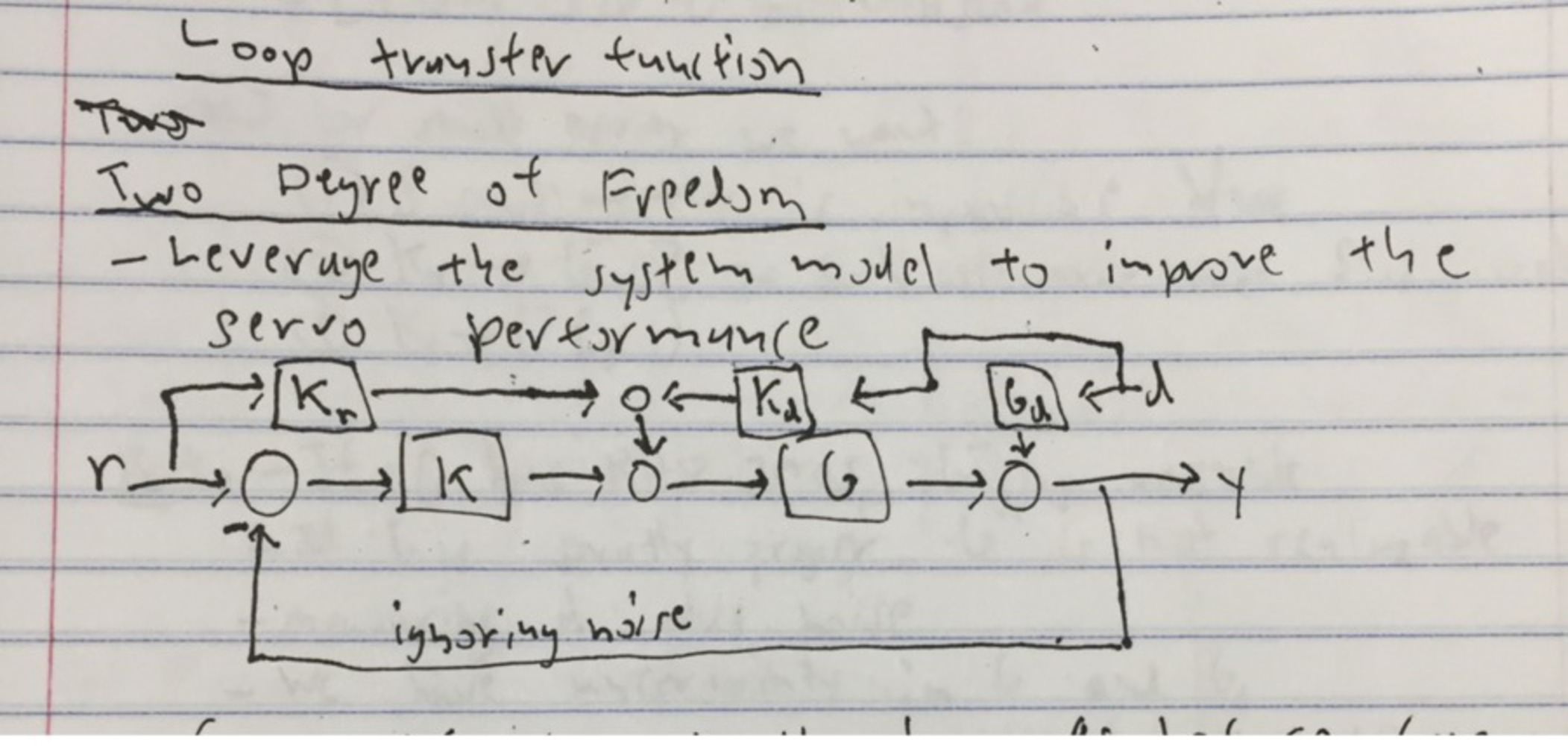

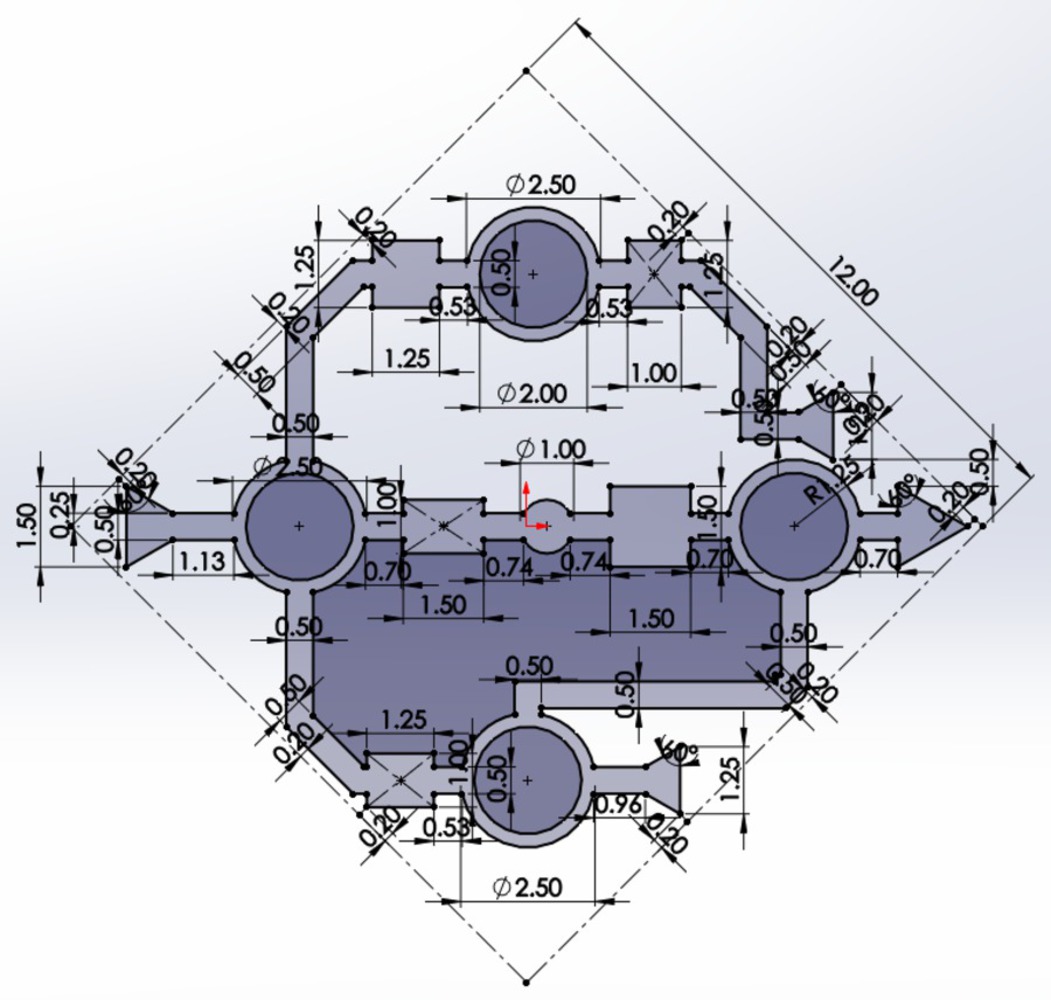

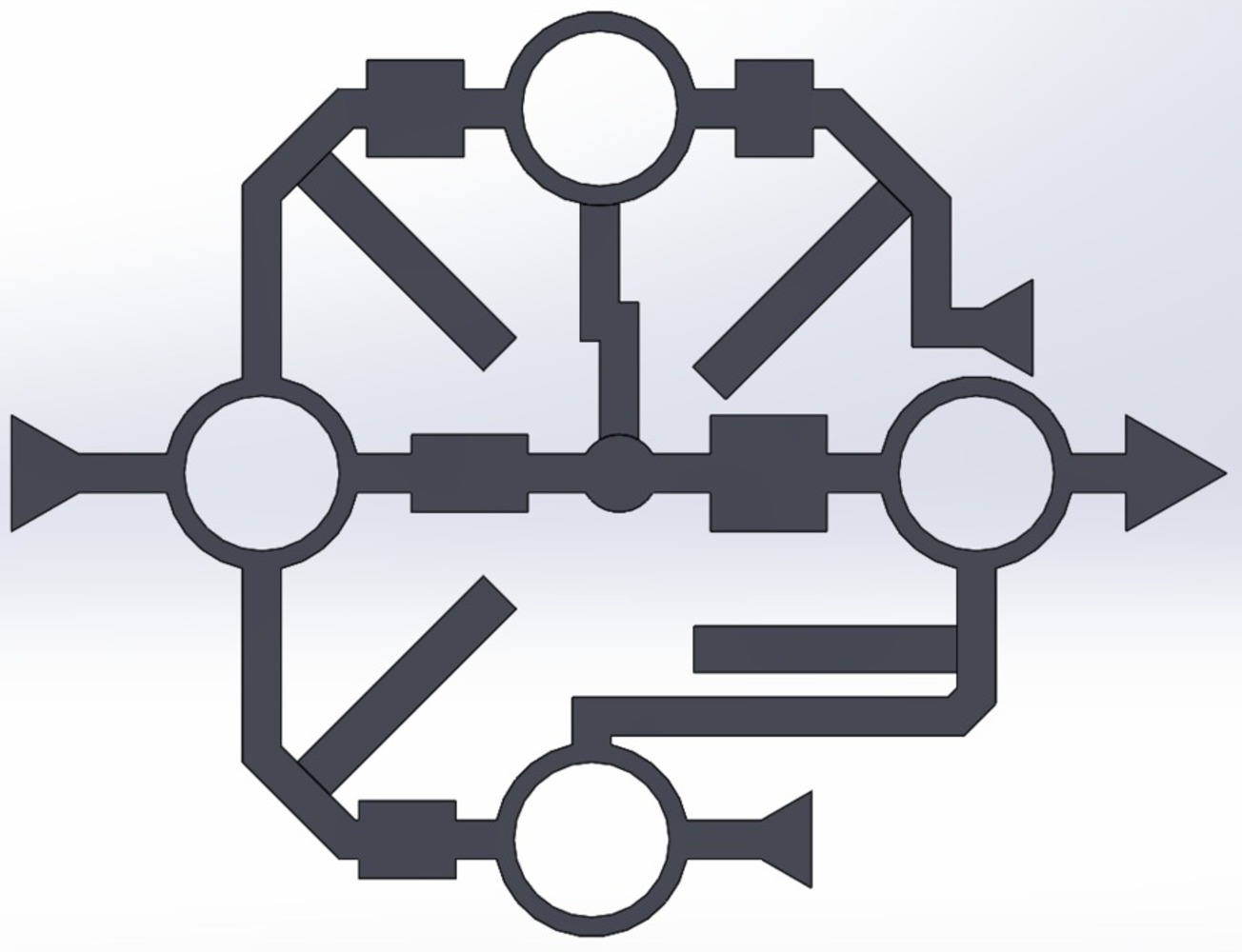

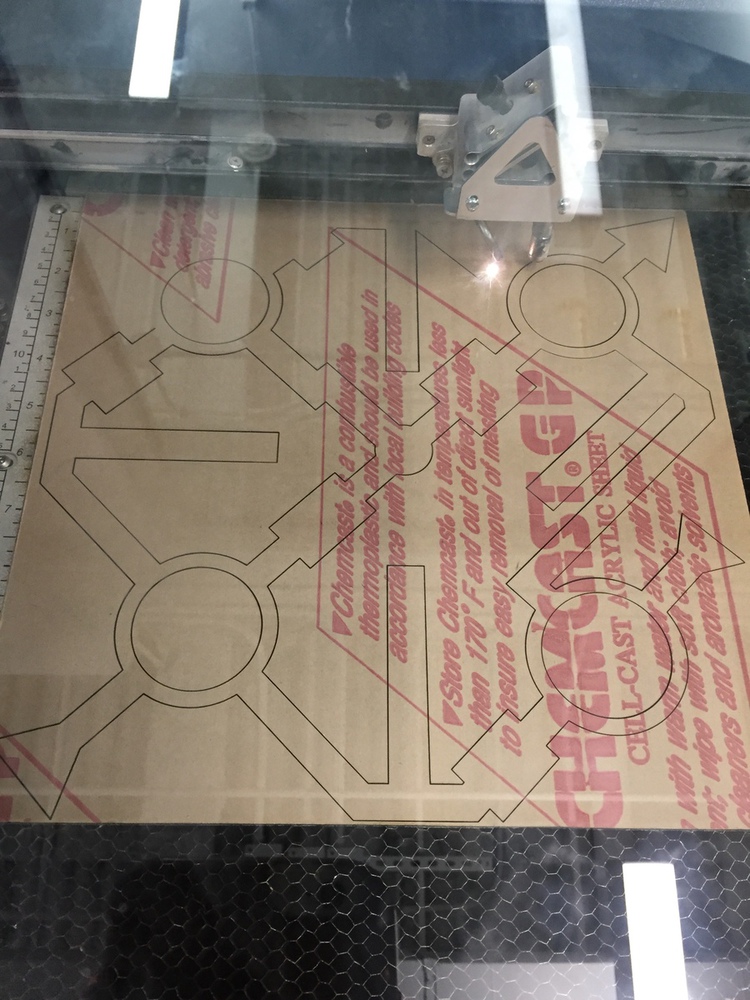

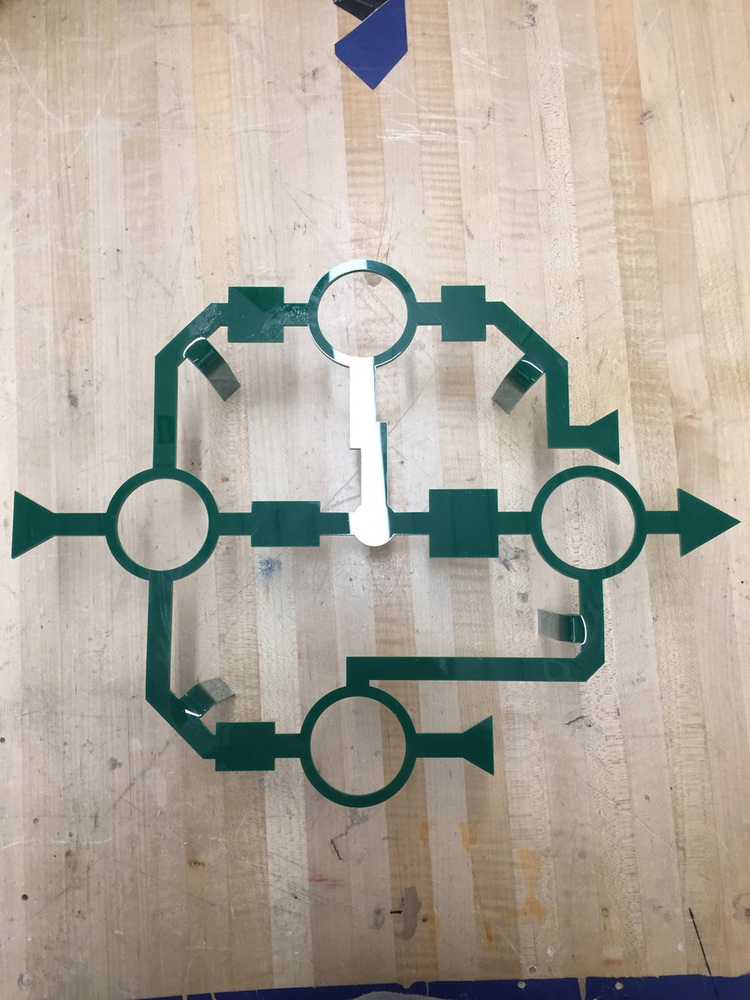

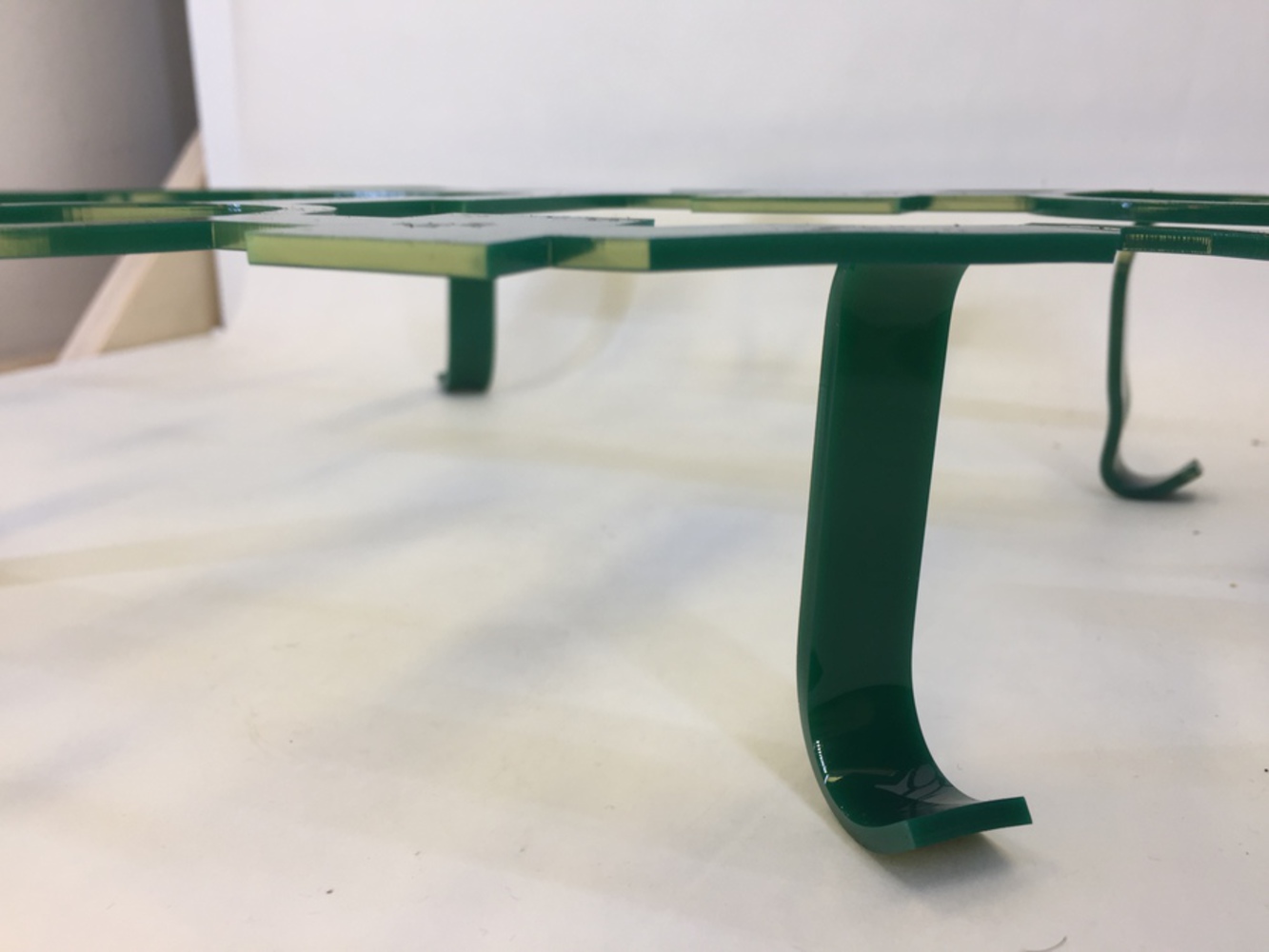

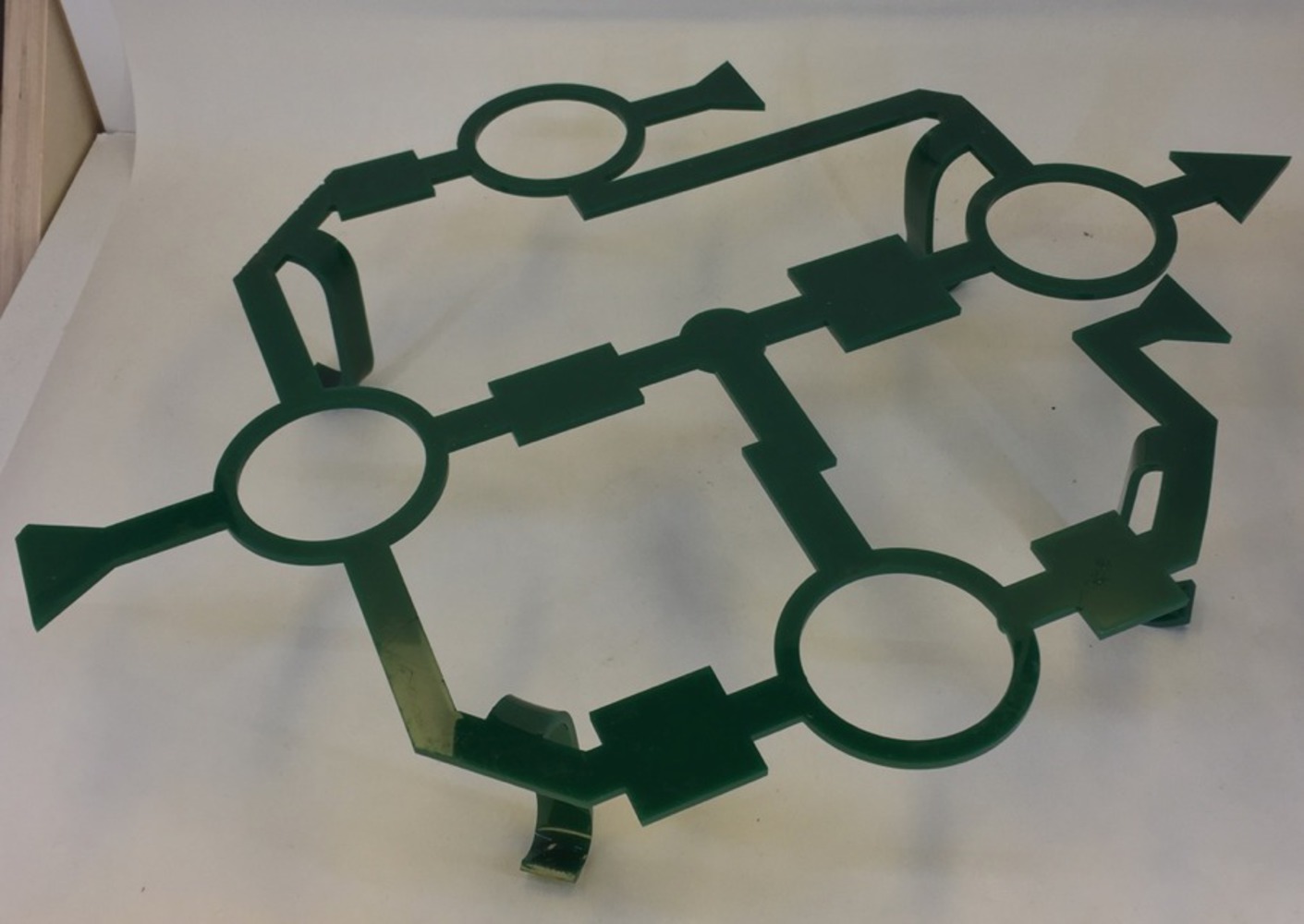

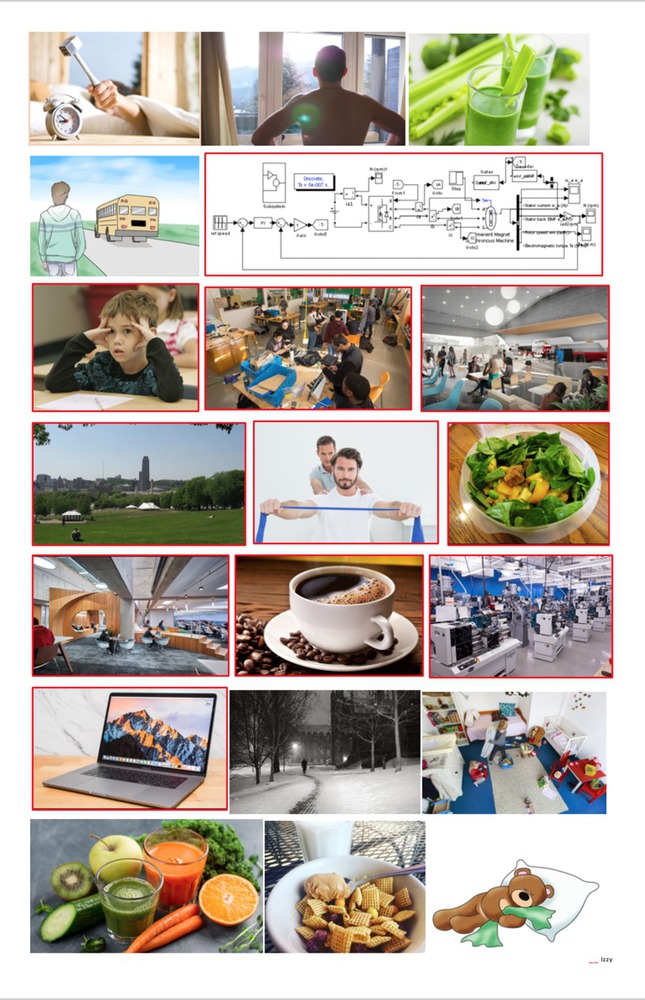

Within the last year I’ve grown to like coffee more and more. At first I would drink it just for the caffeine buzz but now I drink it more casually, whether it be with a friend or by myself. I enjoy it in all forms. For this project I decided I wanted to make a cup holder that could hold multiple espresso shots. And since coffee has helped me get through many of my engineering projects I wanted to include some sort of engineering aspect to my cup holder design. I’m very interested in control theory and one of the coolest aspects of this kind of engineering is the control loop diagrams. I thought that a control loop diagram with the summation junctions acting as the espresso shot holders would be a cool cup holder that I would actually end up using. So I first went back through my classical control notes to decide on a loop diagram that I liked. I decided on the general two degree of freedom control loop diagram shown below.