The Problem

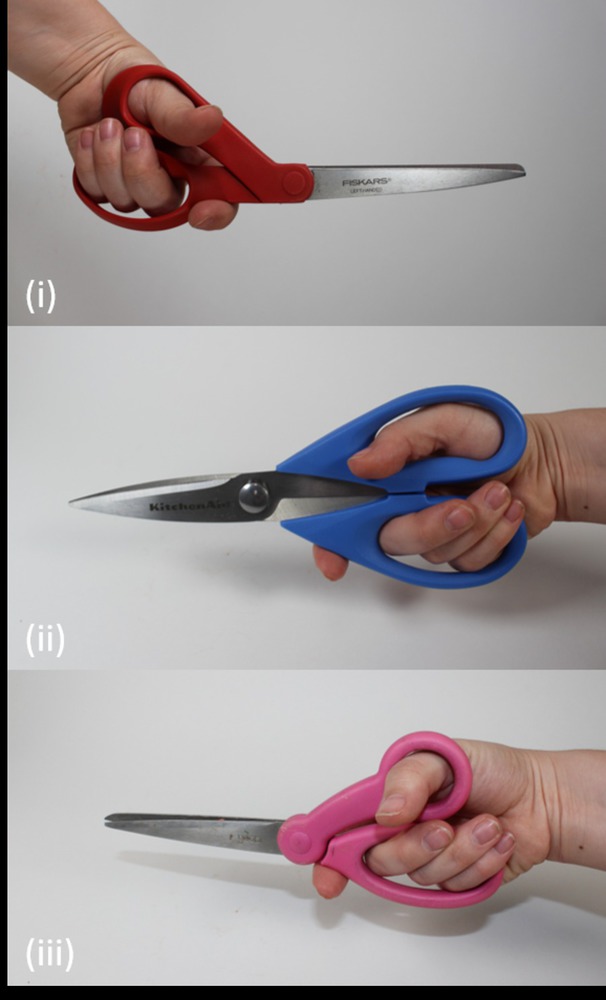

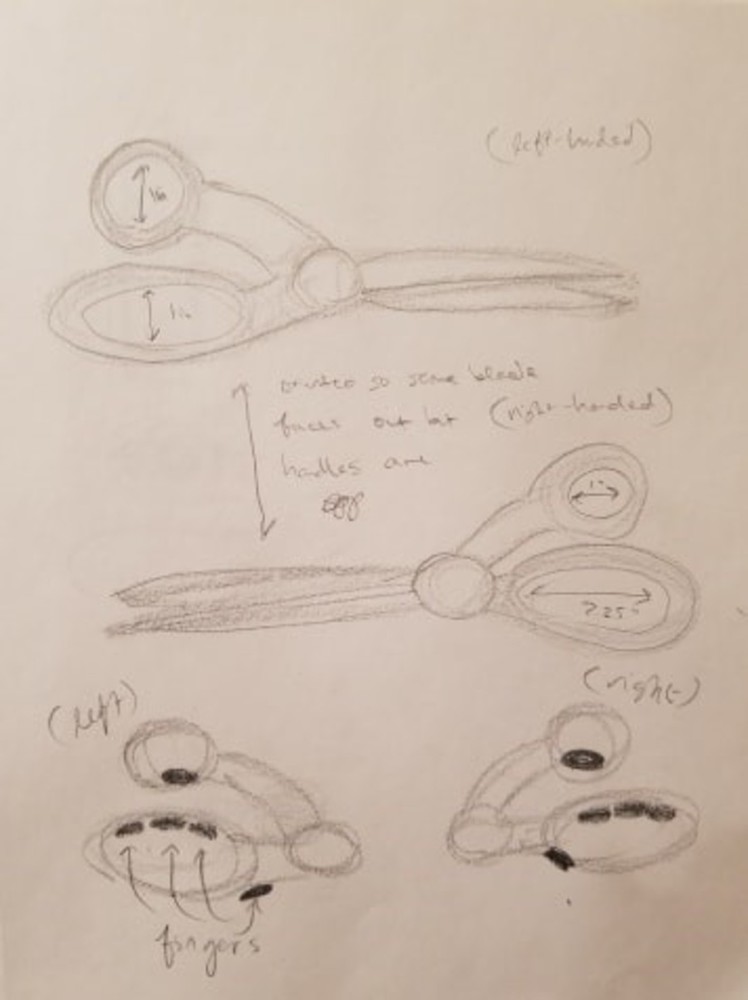

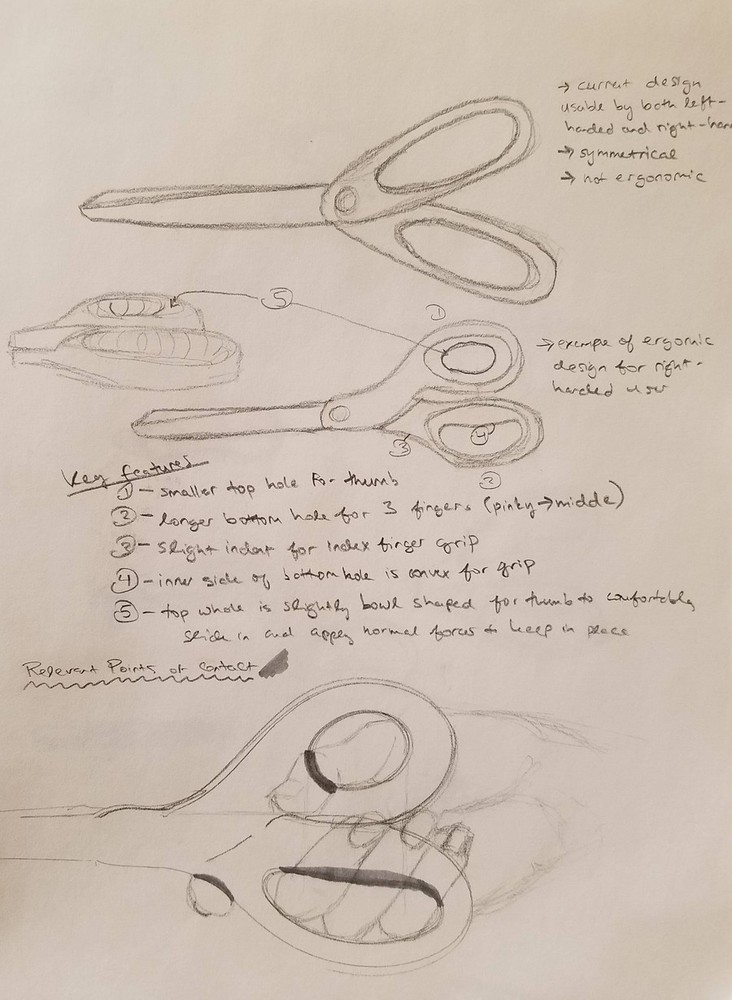

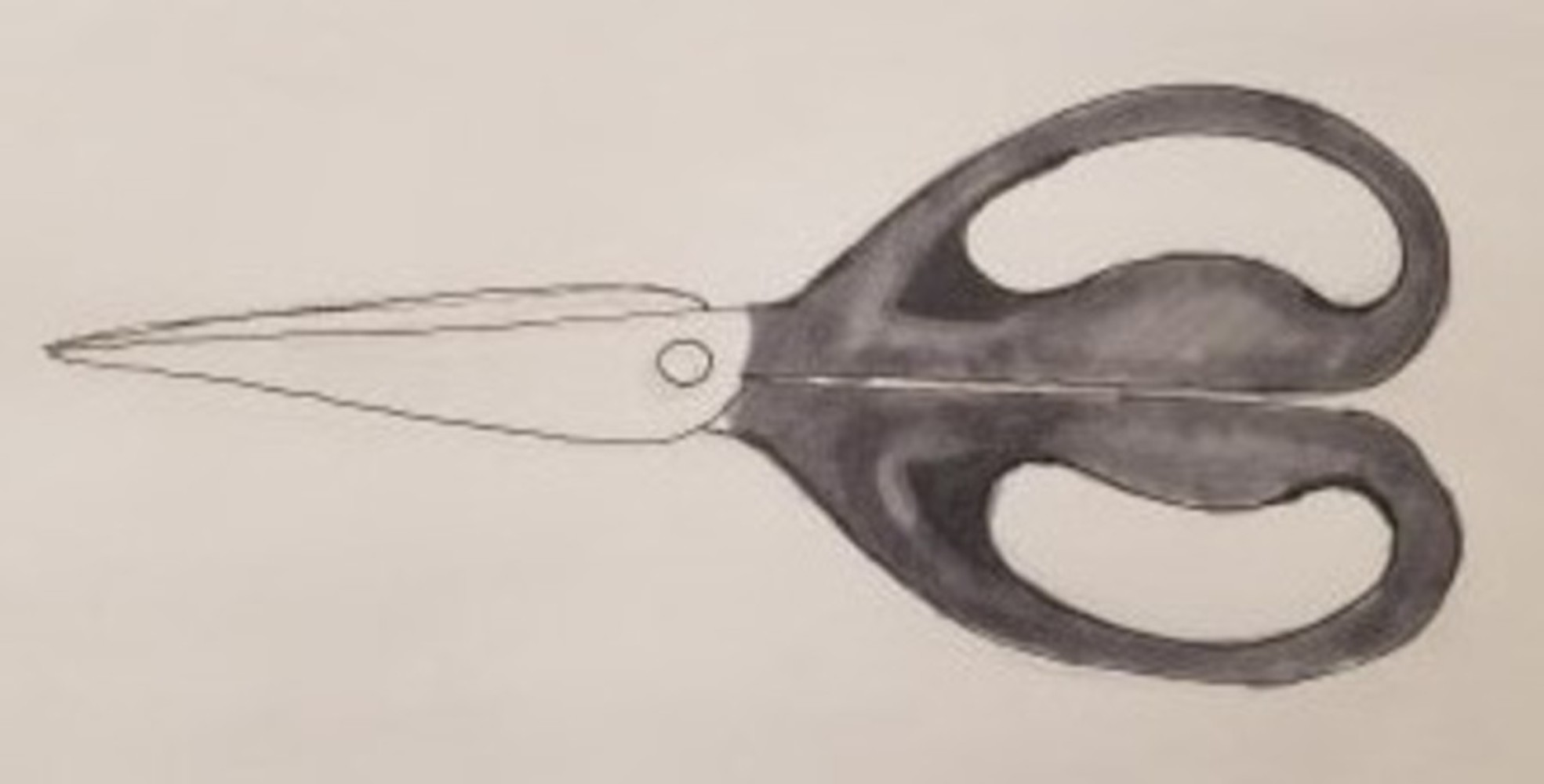

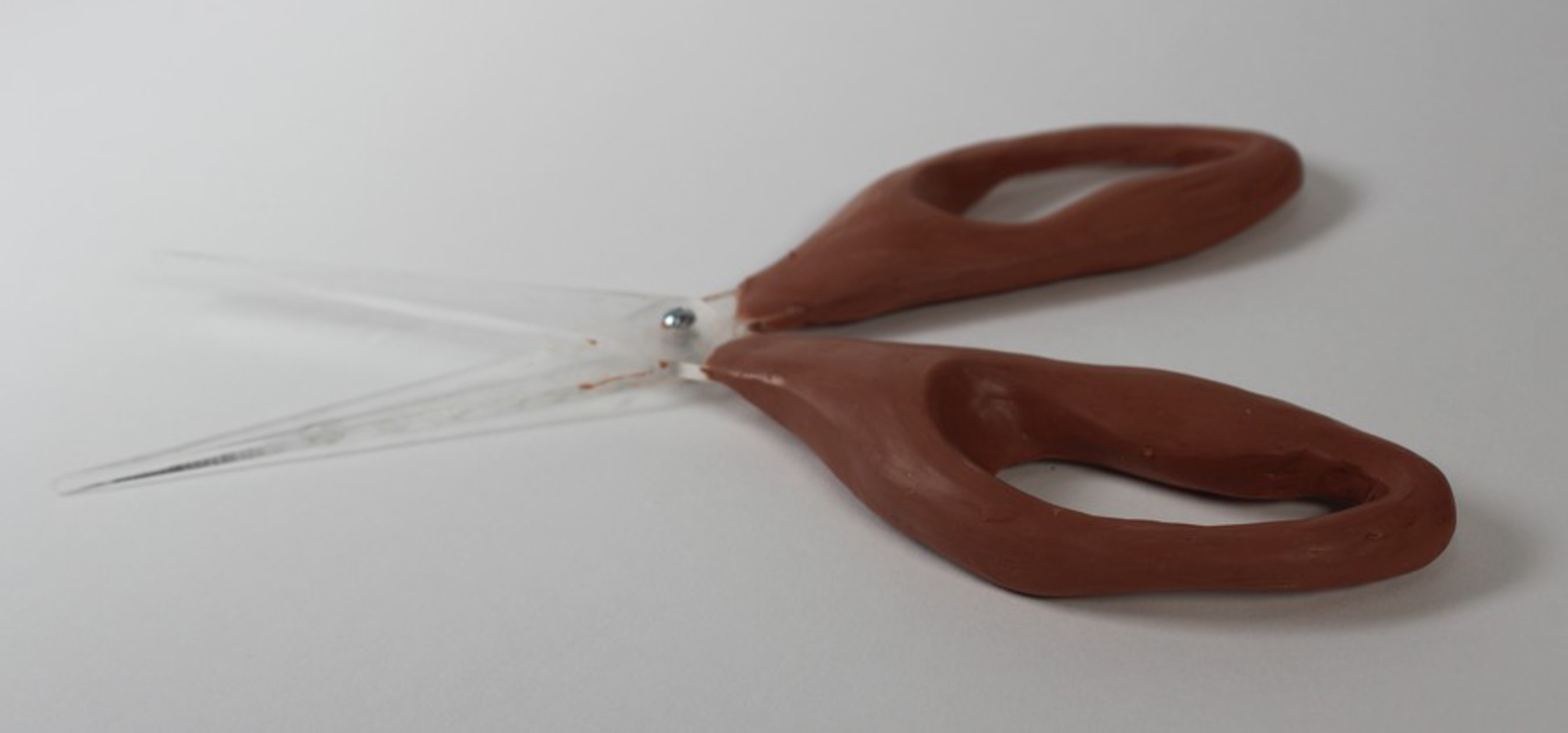

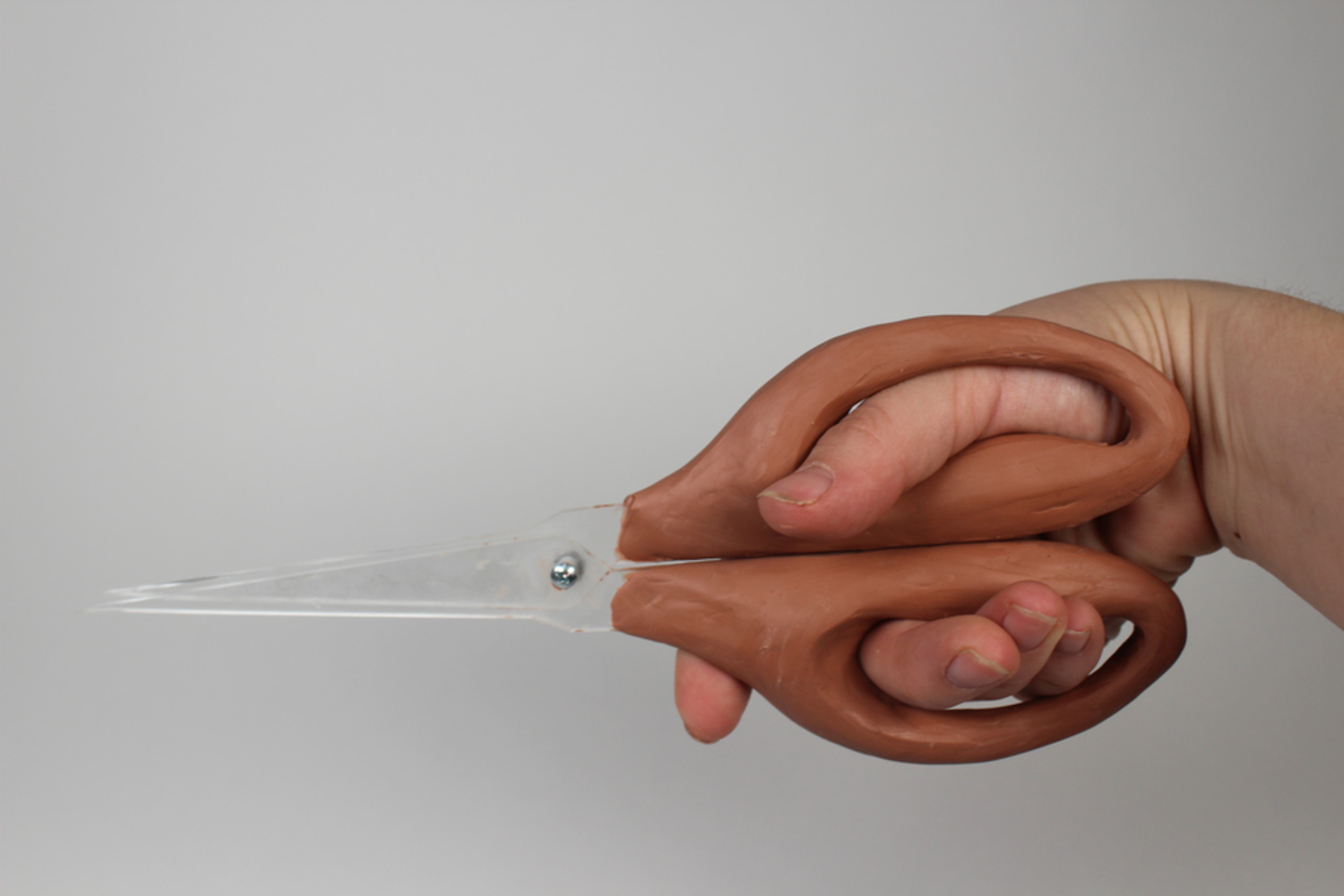

A common problem for left-handed people is that most scissors are difficult to use because they are designed with right-handed users in mind. This difficulty occurs for two reasons, one is that when scissors are designed with ergonomic handles for a right-handed person, the handles don’t fit a left-handed user’s grip the same way. Additionally, the placement of the blades (whether the lower or upper blade is facing inwards) makes cutting uncomfortable. This problem is usually solved by purchasing a pair of scissors specifically made for left-handed users, in which the handles are made to fit a left-handed person’s grip and the lower blade is facing inwards when cutting with the left hand. My goal for this project was to make scissor handles with an ergonomic grip that worked for both left-handed and right-handed users.