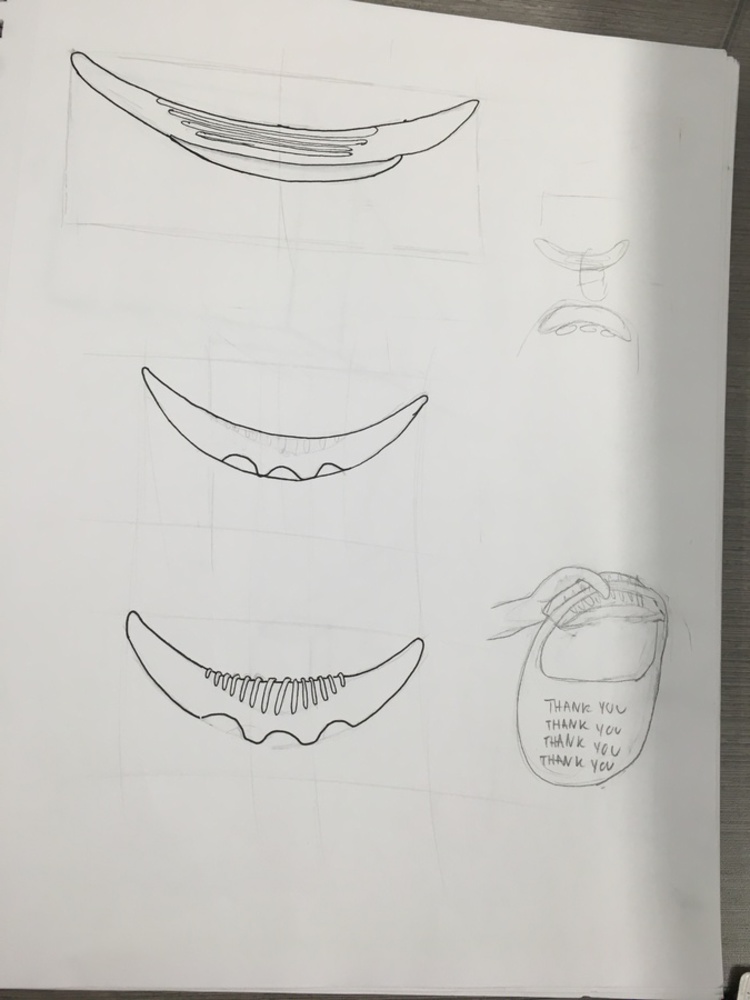

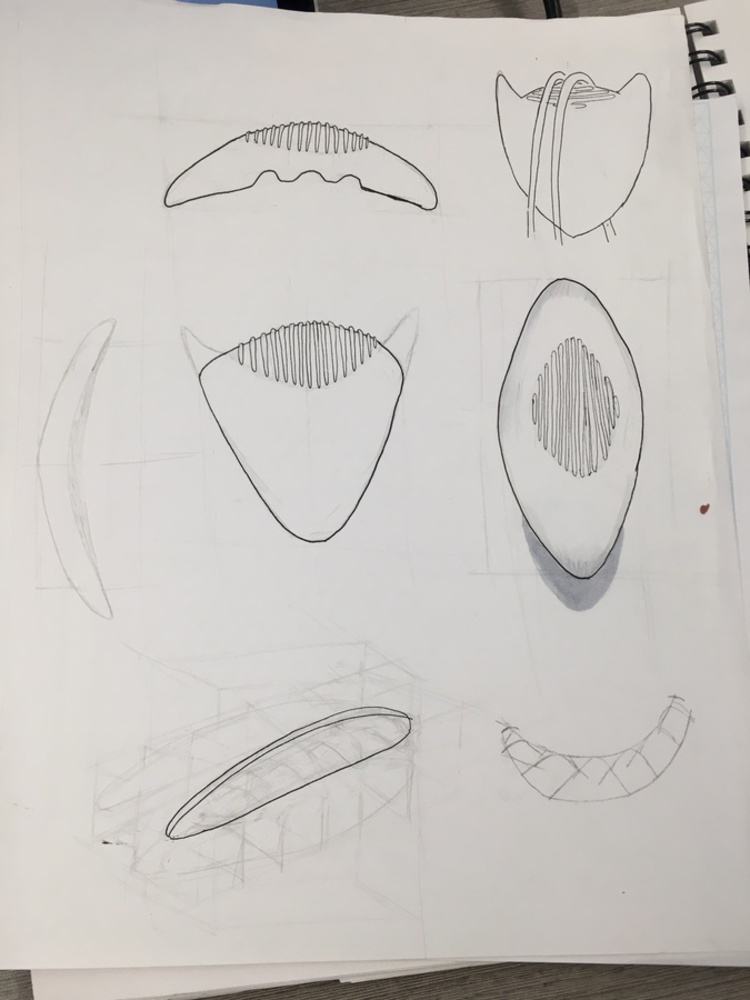

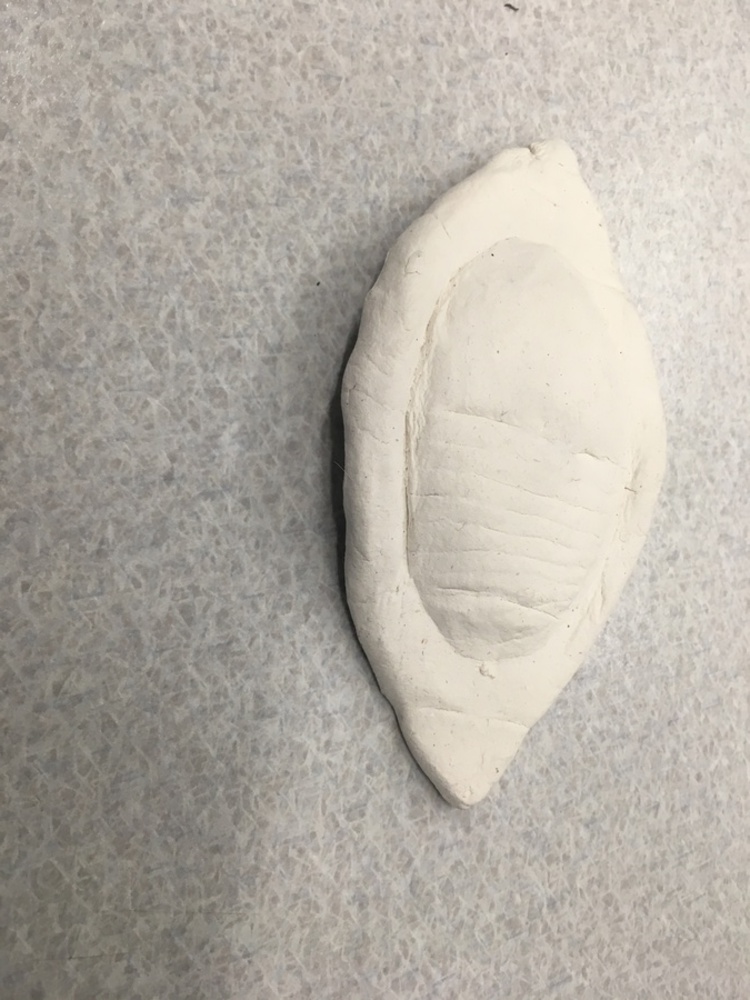

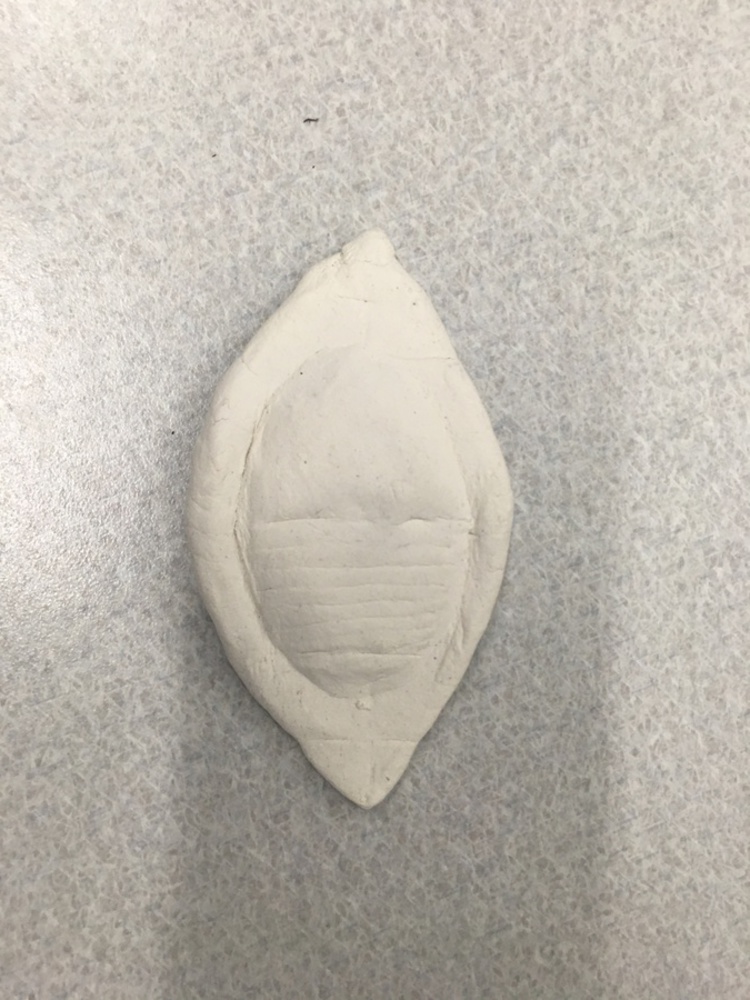

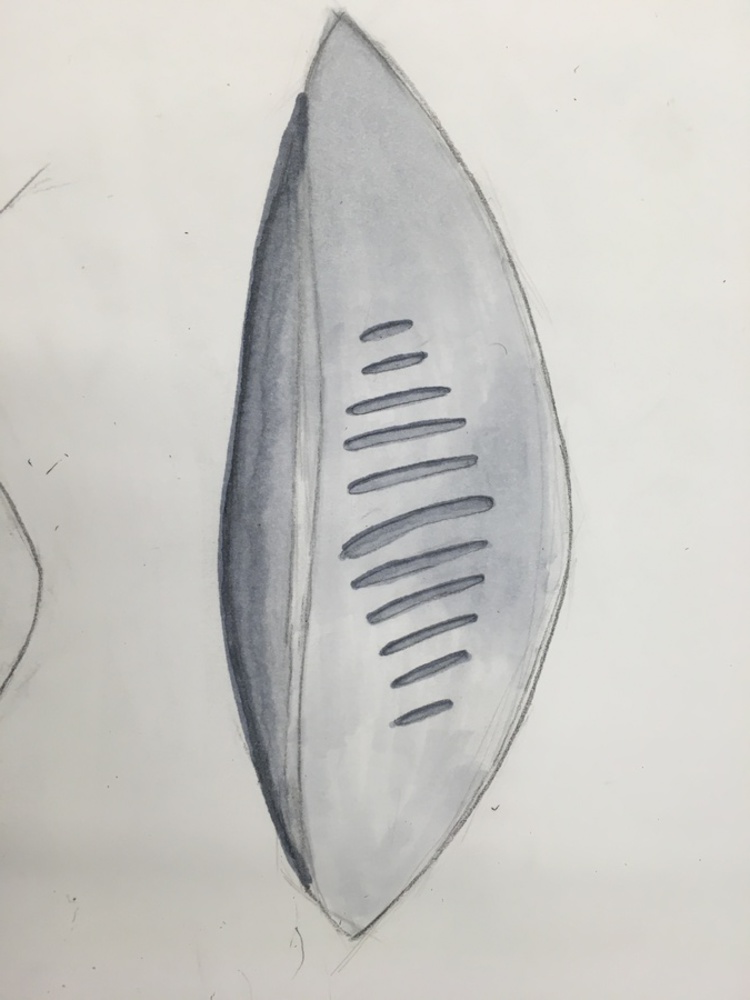

Ideation

As someone who lives off-campus with no meal plan, I have to do a lot of grocery shopping. A part of my grocery shopping trips is carrying lots of heavy bags to the public bus or an uber all at once. Anyone who has ever tried to carry all of their grocery bags in one trip knows that the stringy plastic handles always dig into your arms or fingers. To alleviate this pain I've designed a handle that sits in the palm of your hand (or your forearm if need be) that supports the weight of your grocery bags.