Outcome

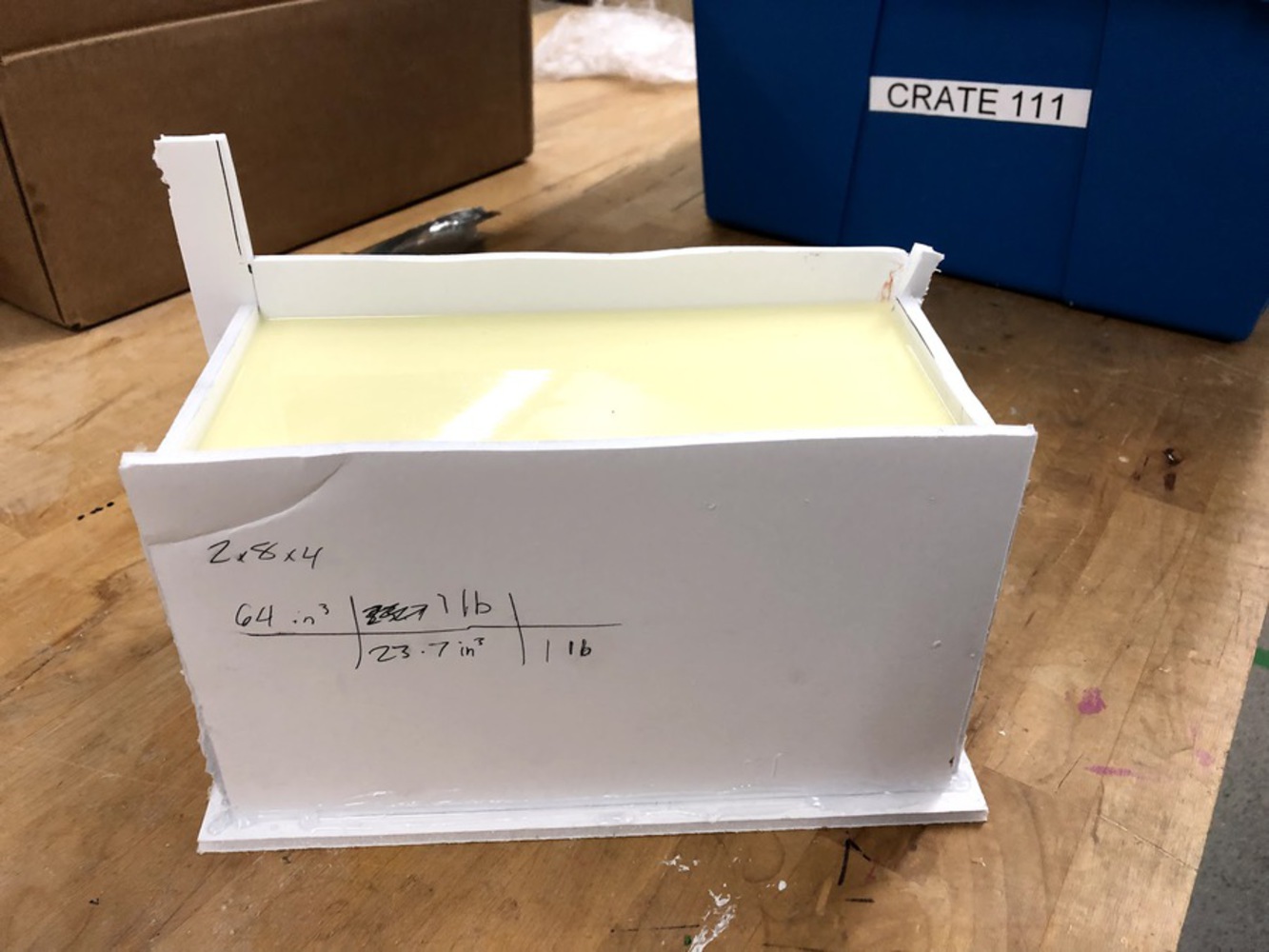

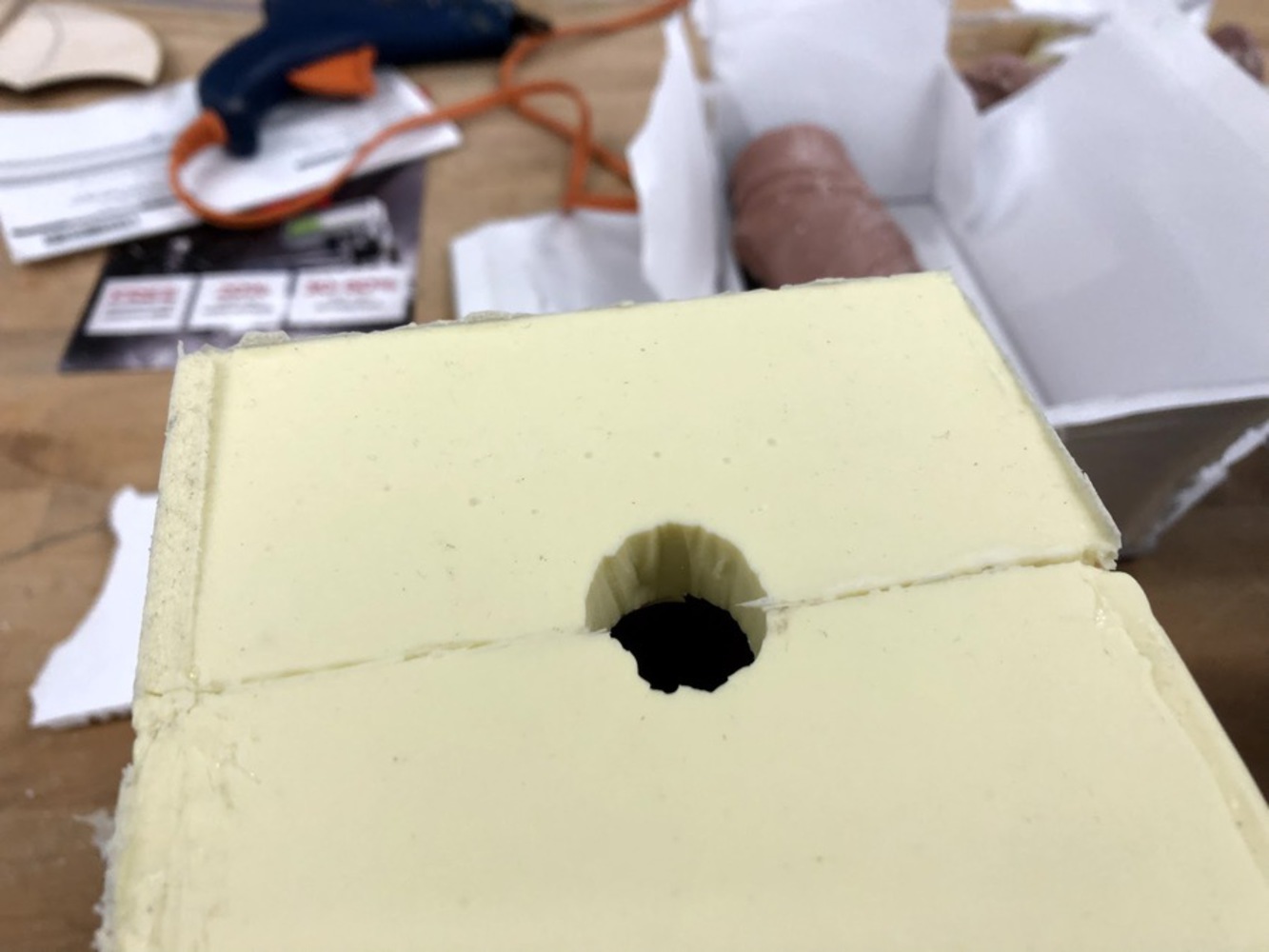

To create the silicone mould, I needed to use my clay model from last project. I set the model in soft, water based clay and glued a foam-core box around it. To make enough space between the edge of the mould and the space where the resin would take shape, I had to leave about an inch and a half of clay. I also poked holes in the clay that would later be filled in by the silicone. These would help the silicone mould stay together while the resin cured.

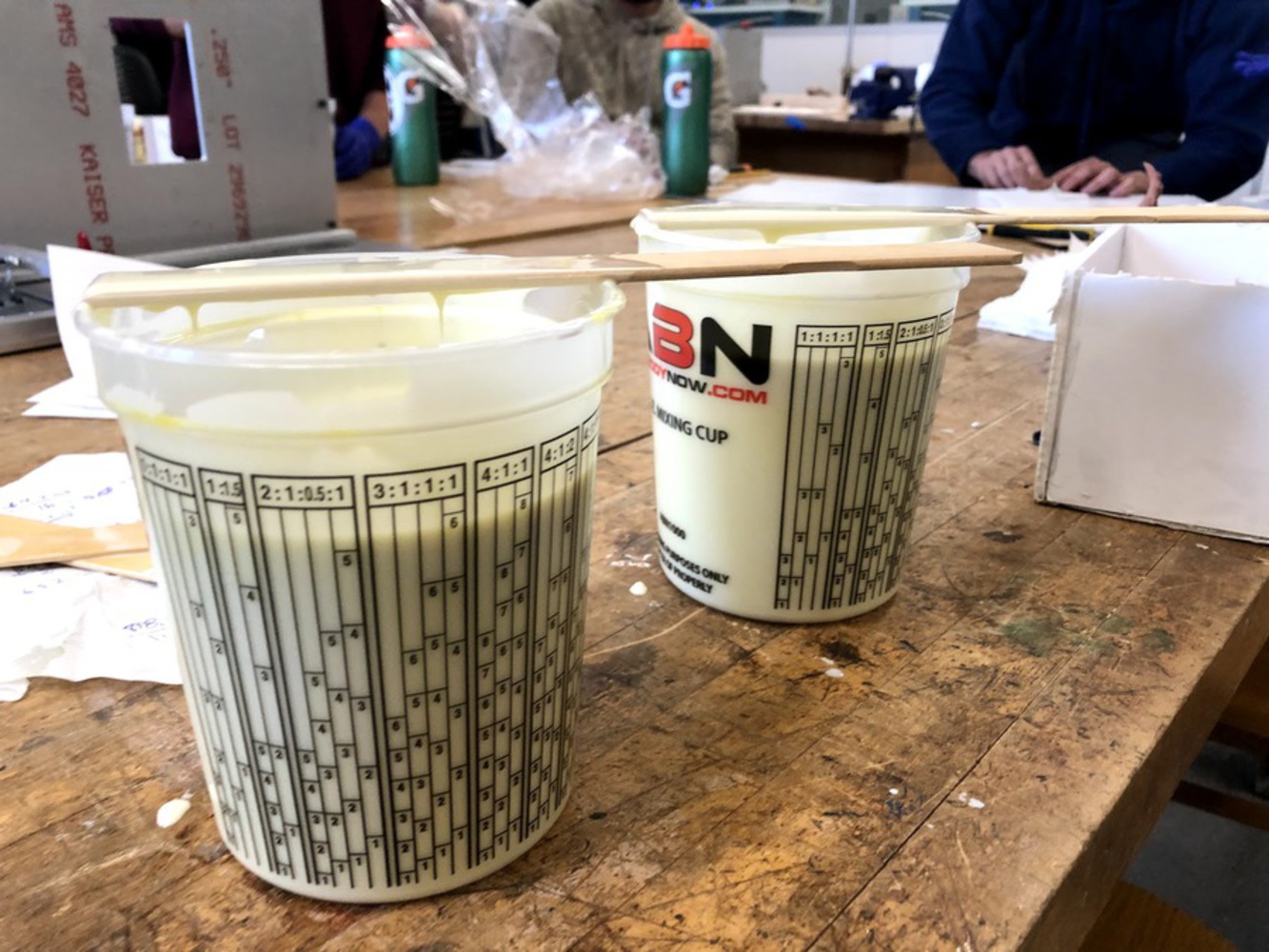

After pouring the silicone into the box, it then cured over 6 hours.

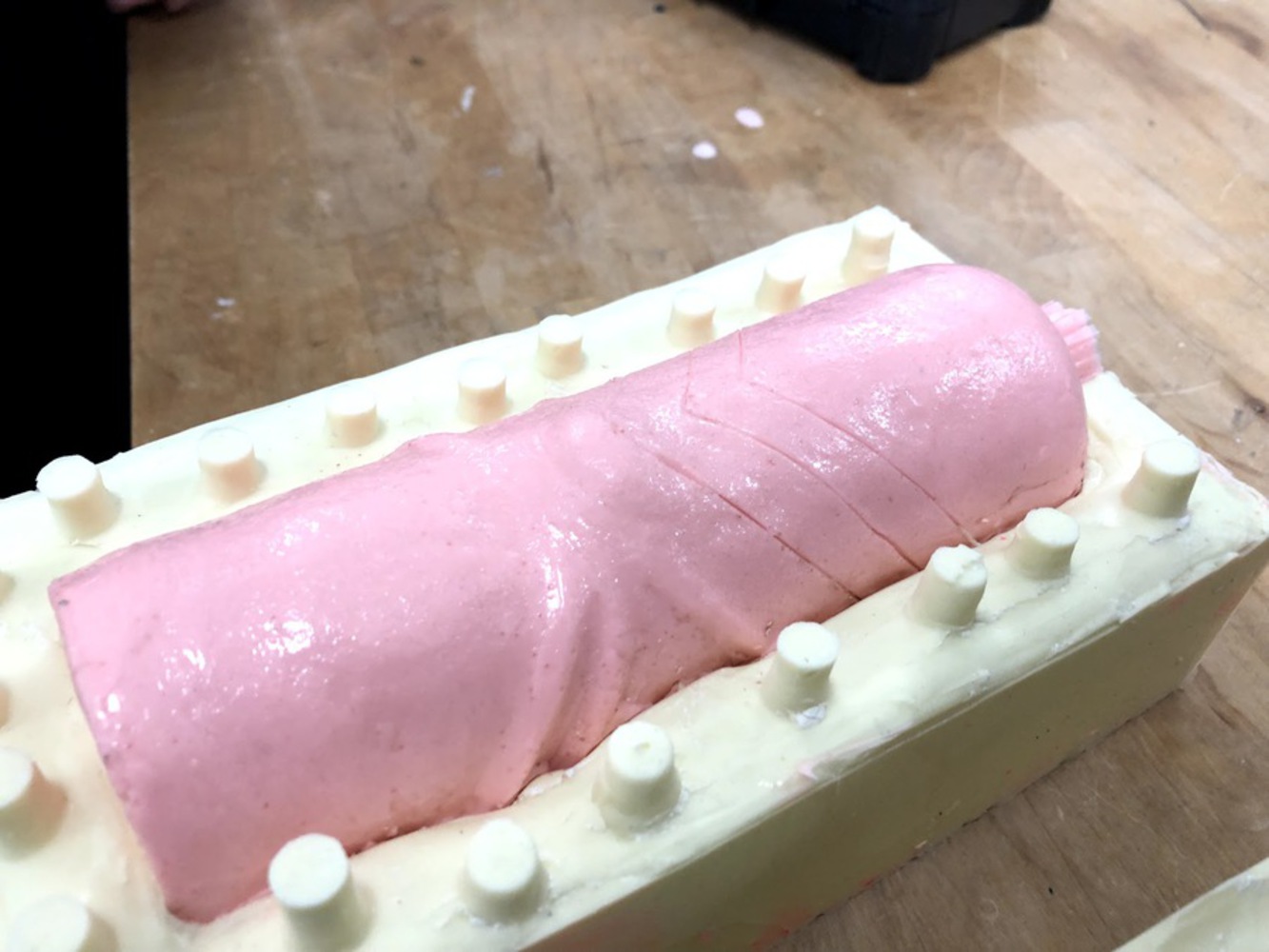

Pulling the box apart was like opening presents on Christmas morning. The first half of my mould was complete. To finish the second, I simply needed to pull the clay off of the silicone, flip it around, and build another box to contain the other half.

The blue flashlight-saber came out of the mould in decent shape. There was quite a bit of mess on the parting line that I needed to sand off. In fact, much of the handle needed to be sanded down. However, due to time constraints I was unable to sand the amount I wanted. I was trying to explore how to depict different textures on the handle using different mounts of sanding; however, I had to continue with my third model.

You can upload files of up to 20MB using this form.