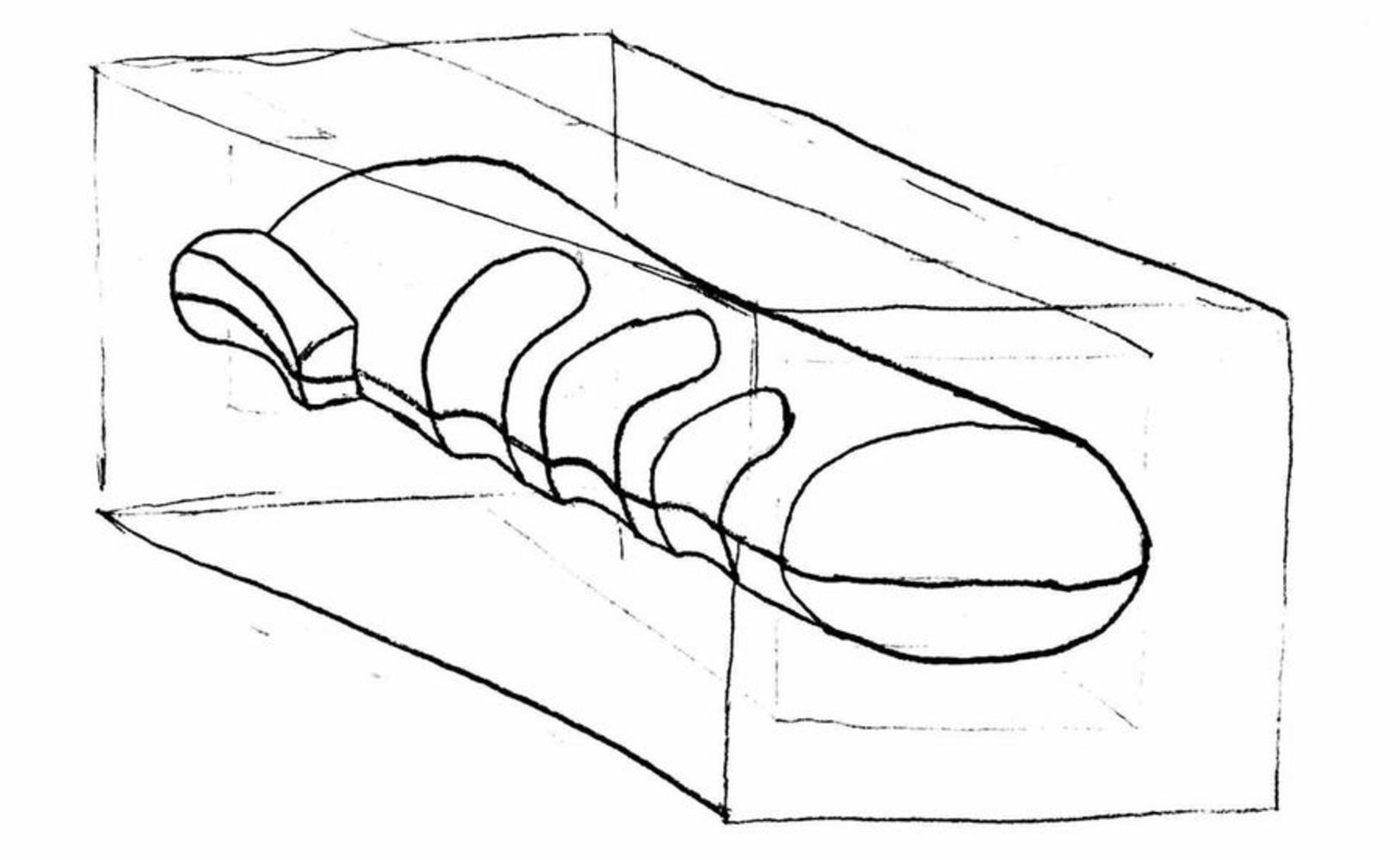

This drawing shows where I planned to put the parting line in the mold.

Outcome

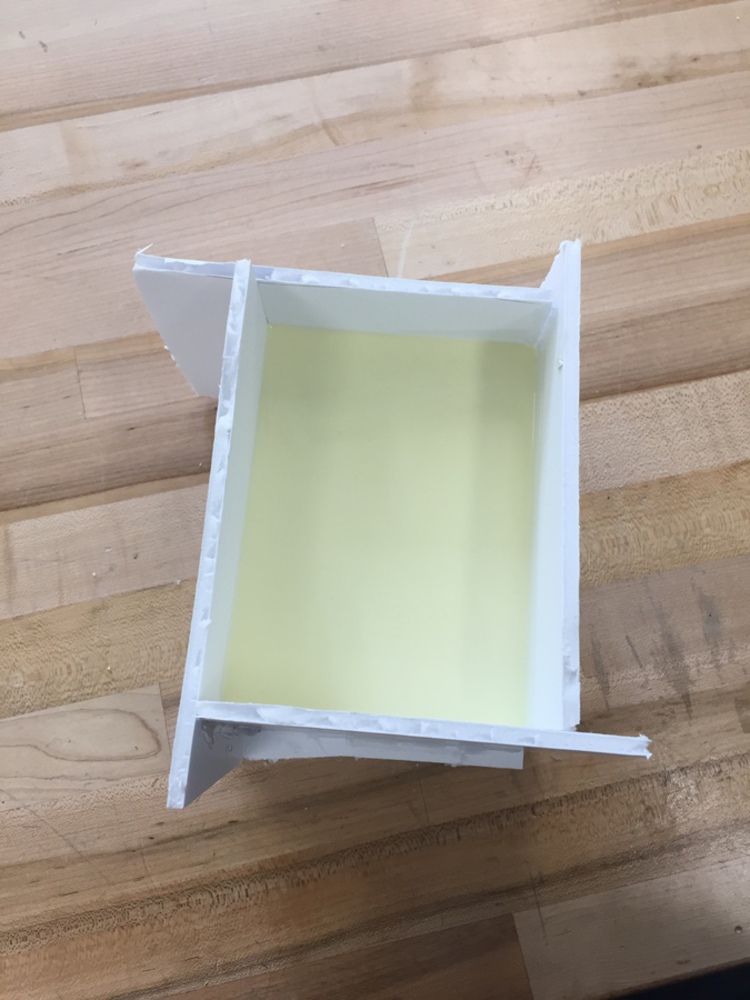

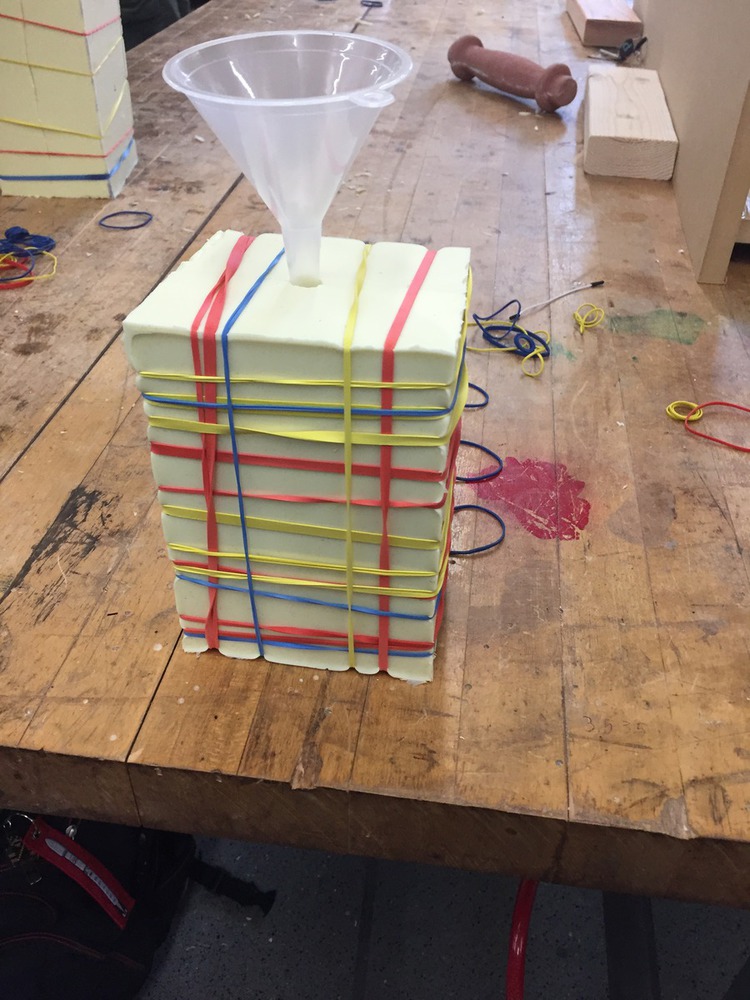

This is the box after pouring silicone. For the second half of the mold, I removed the clay and then built the box around the bottom half of the mold. While removing the clay, I slightly damaged the model of my part. I made the box slightly smaller than the mold in order to compress the silicone and ensure a good seal around the edges of the box and between the mold and the clay part.

I started by cutting off the pour spout and grinding it down with a dremel. The air bubbles are still visible despite the coating of extra resin. If I was making another casting, I would cut a couple vent holes near the pour spout to help air escape. I tried to rotate the mold to help the air escape, but that was clearly not enough.

I then ground off the parting line. I finished the part by sanding with 200 grit and then 1000 grit sandpaper. I discovered that using such a large gap in types of sandpaper isn't a very good idea, since the part still has some visible scratches in it. However, it still feels very smooth.

You can upload files of up to 20MB using this form.