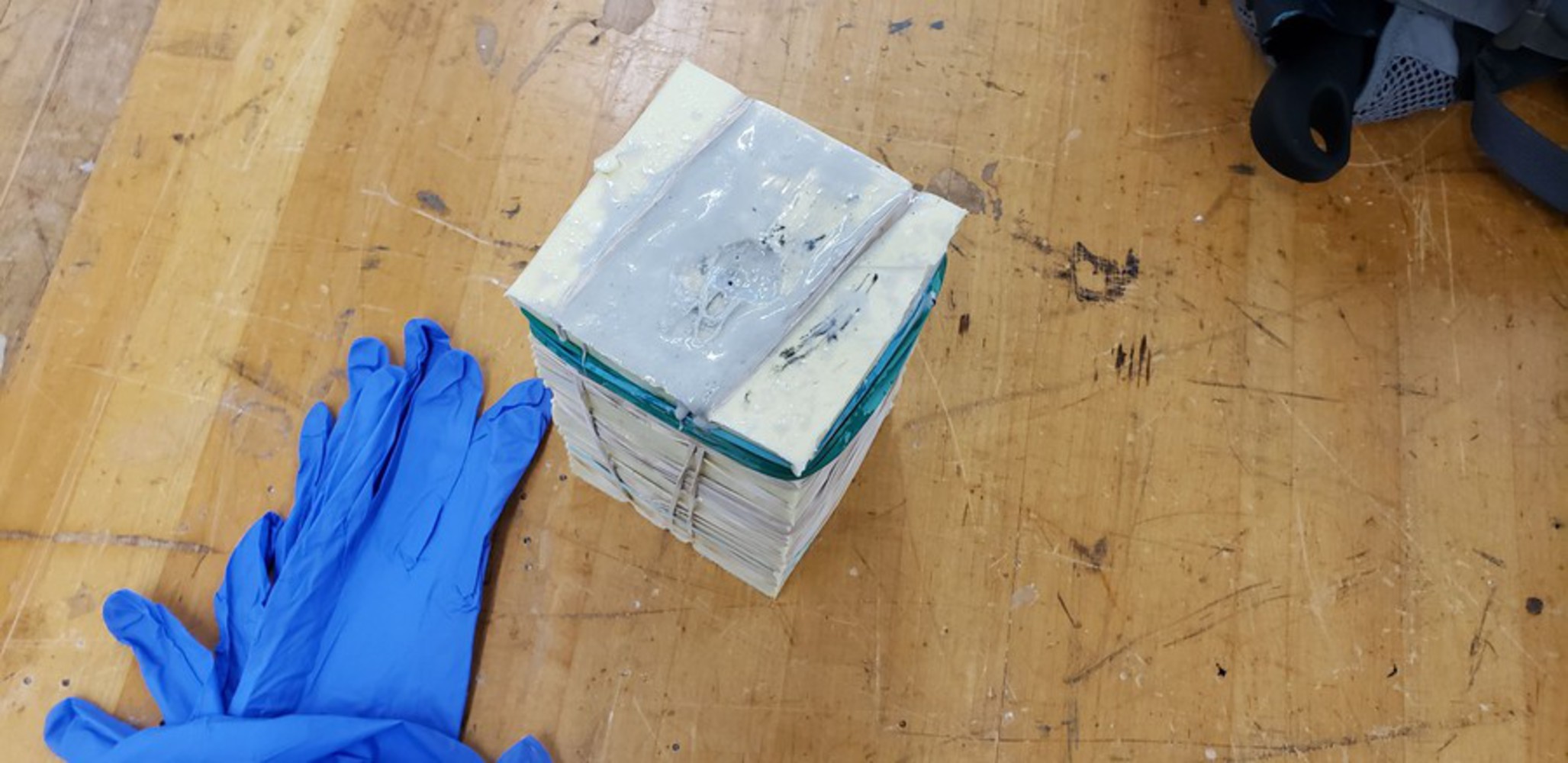

The final products

Outcome

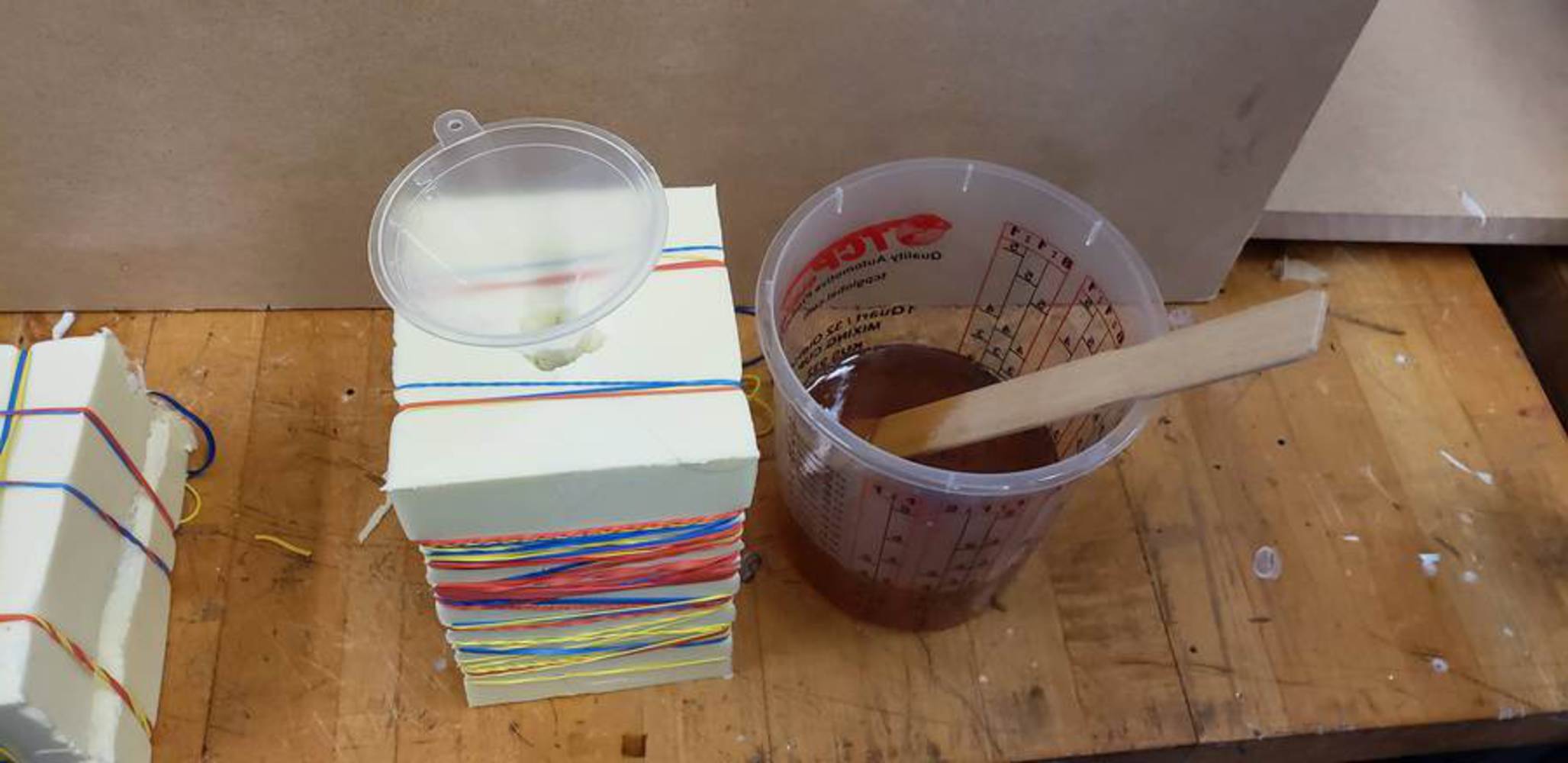

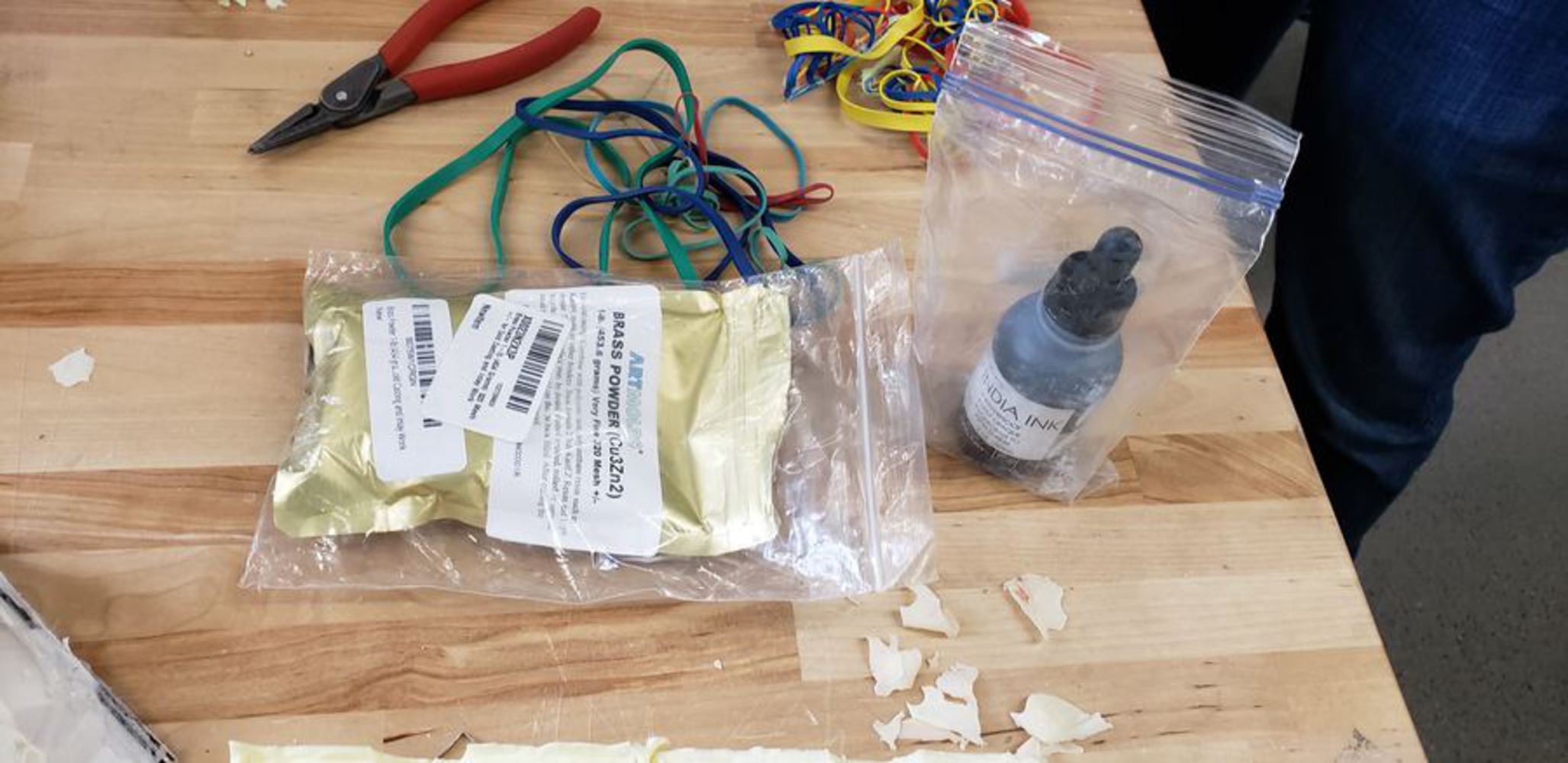

The second pour was another learning oppurtunity. I had picked up brass powder, and was ready to start cold casting, so I dusted the inside of the mold with the powder, and then mixed my resin. I wanted the resin in the back to be black to add to the overall sheen, so I used what I had, India Ink. This was a regrettable choice, as it made the resin bubble. A lot.

However, it actually cured! The cold cast was actually one of the better ones of the project, and it weighed only 50 grams, which is light, since the bubbles were left in the center. To be honest, I might use it in the future if I ever want something lightweight, but it does very little to dye the resin. It also painted up well, and became one of my final pieces.

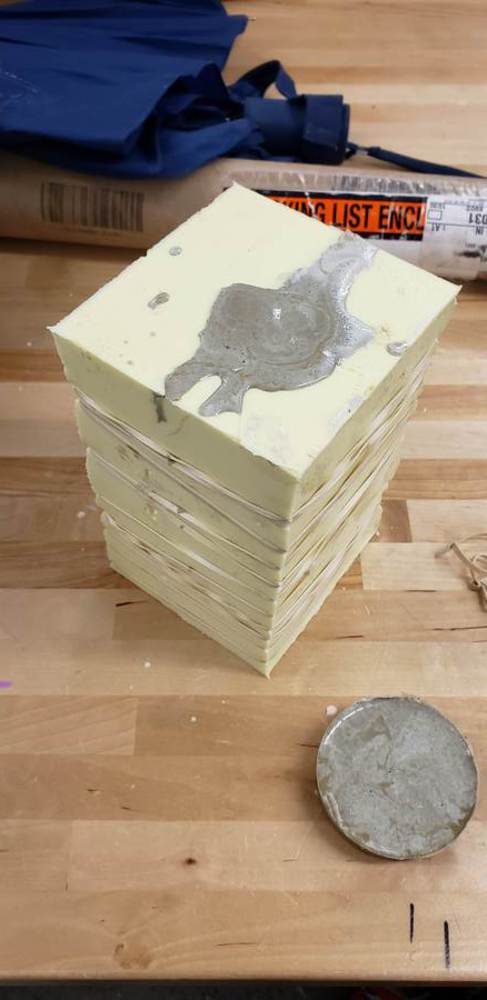

The next 3 casts were uneventful. I mixed the resin, and added brass powder to the resin 1:1 by weight. The brass powder settled a bit during the casting process, meaning that the underside of any raised surfaces didn't have brass powder on the surface. Shaking and tapping the mold didn't help all that much during this process, although they weigned in the neighborhood of 105 grams, almost exactly double the weight of the bubbly cast.

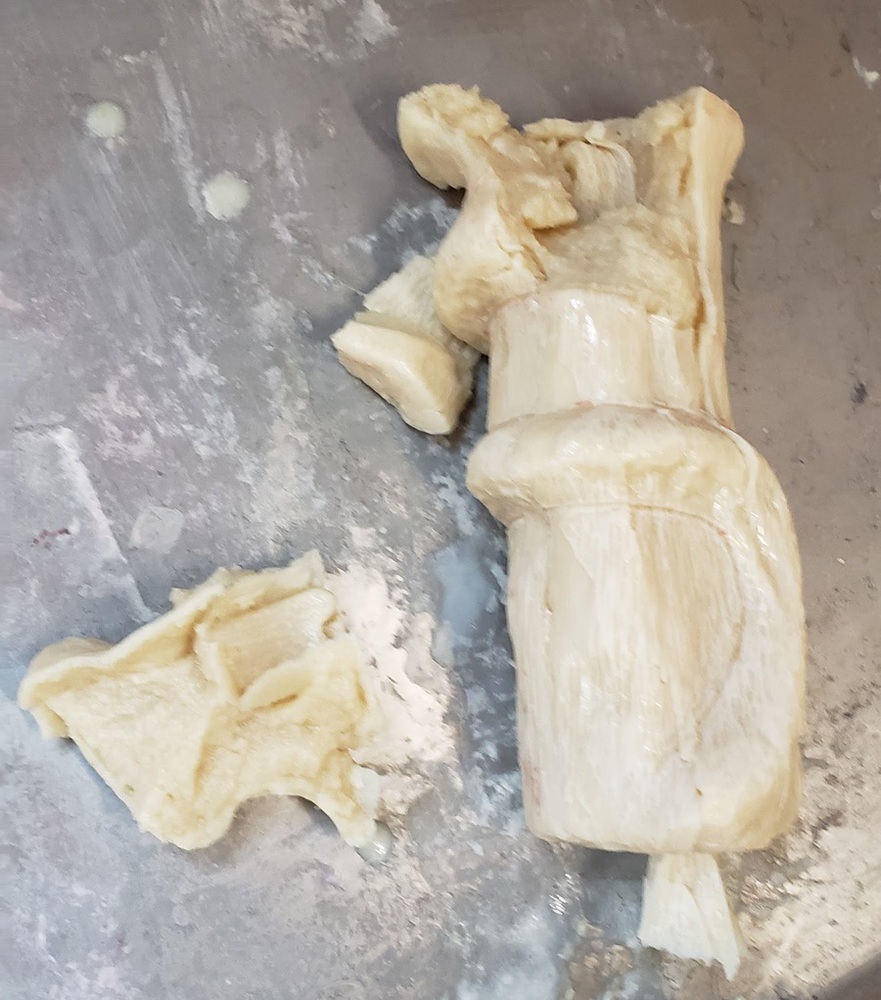

At one point I managed to underpour the resin, which resulted in this monster. Having a spare, I decided to do some science, and by science, I mean I chucked it at the concrete floor by Wean, to see what it would take to break it. It only left some scratches, and I concluded that these could probably be used to break through glass, if needed.

You can upload files of up to 20MB using this form.