Preface

To view my final tri-grip clay model that was used to create my final product, click here: http://ideate.xsead.cmu.edu/gallery/projects/the-tri-grip.

Process

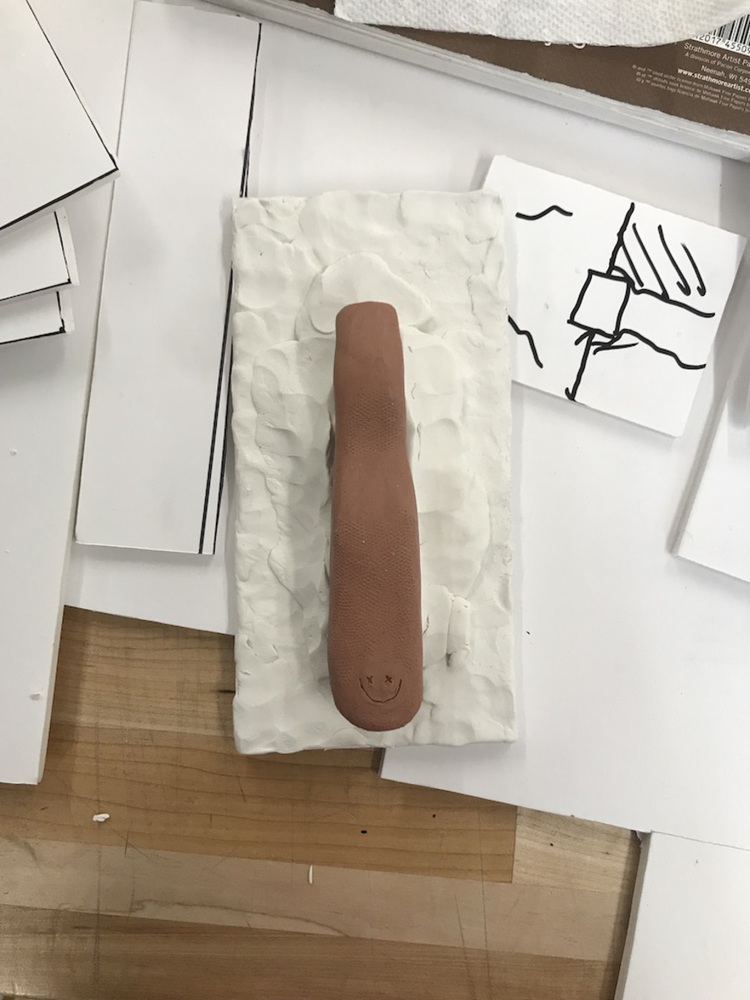

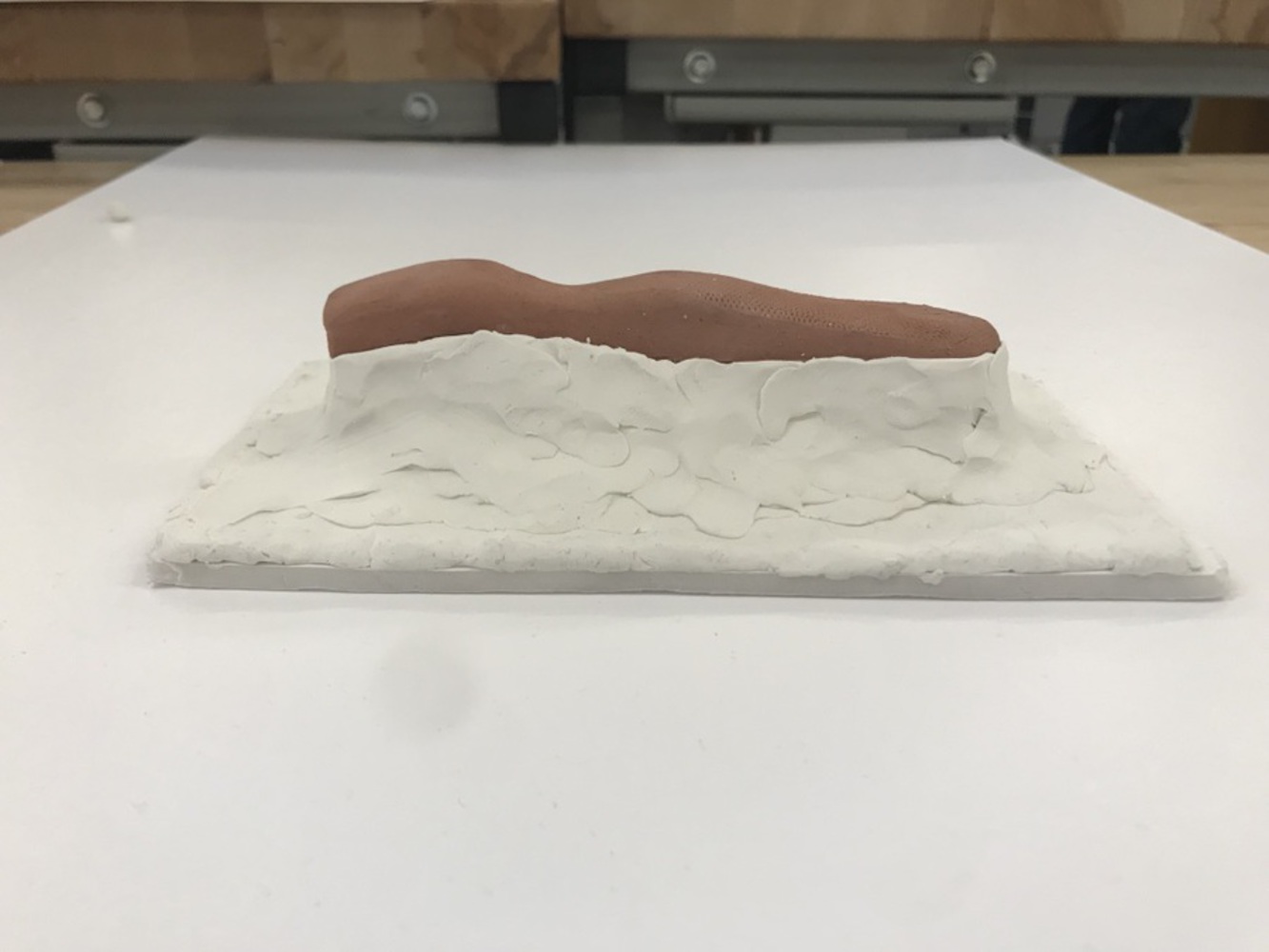

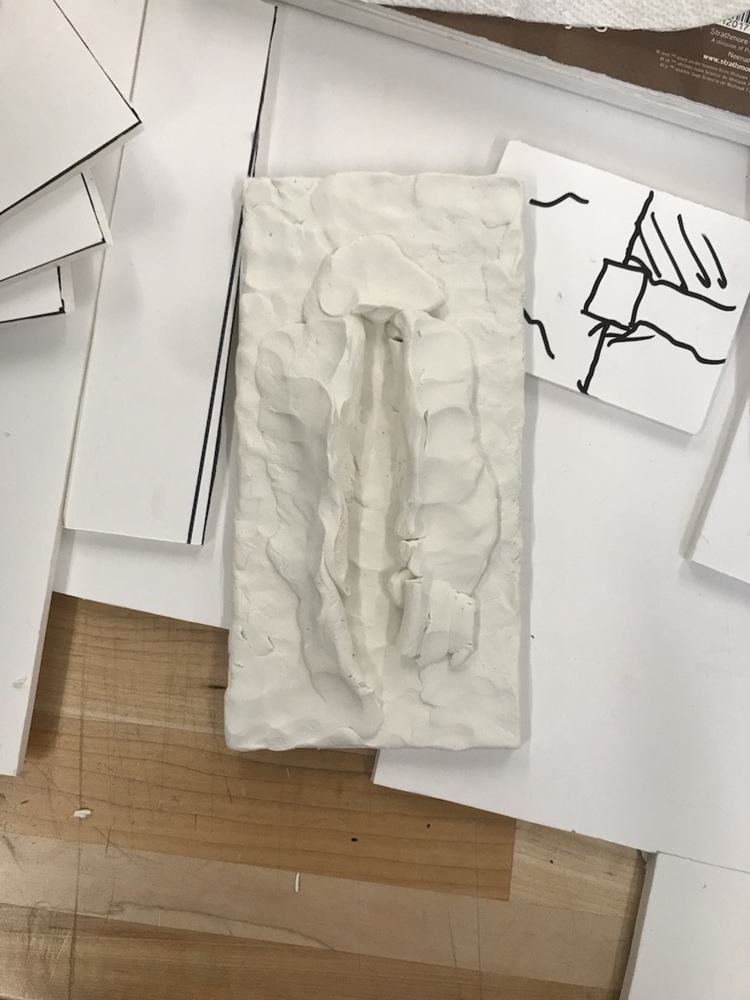

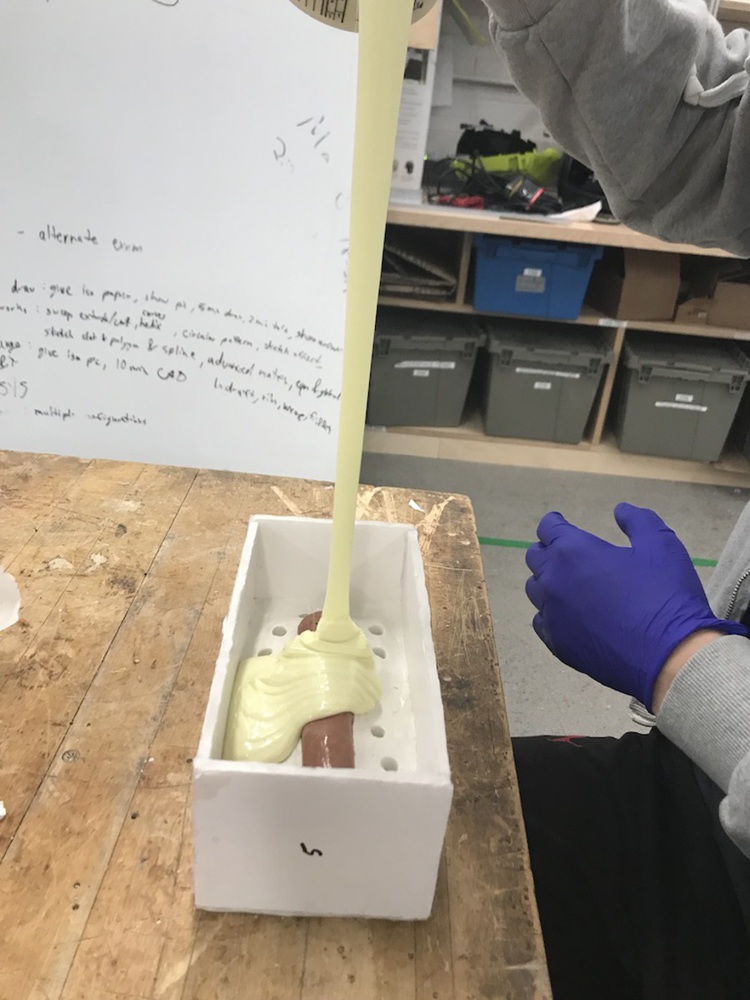

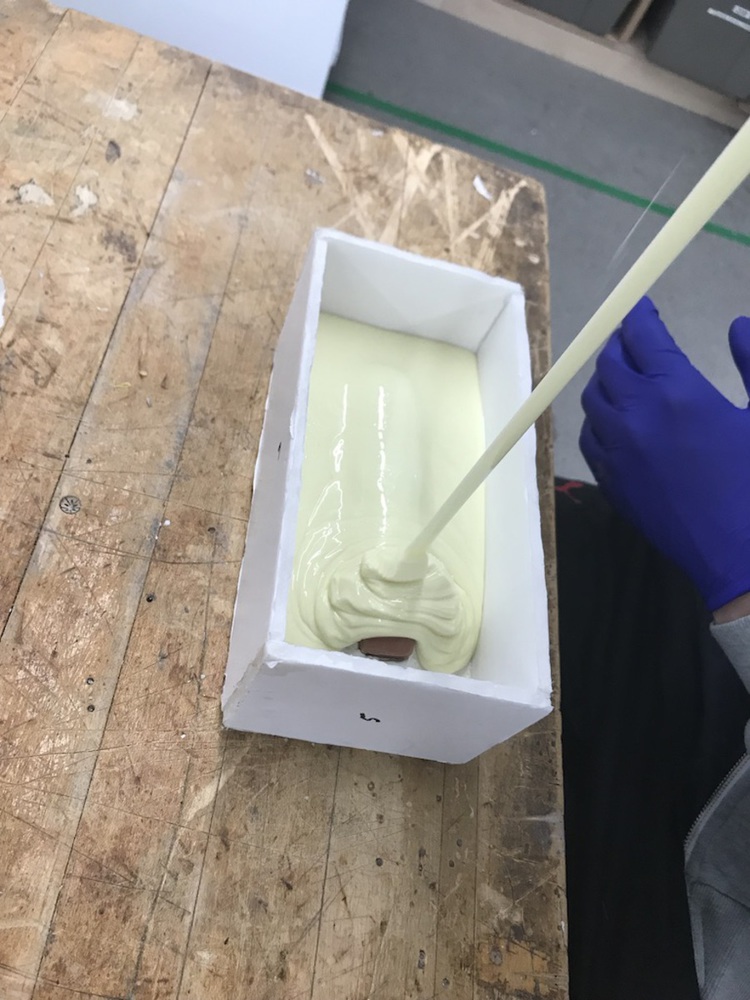

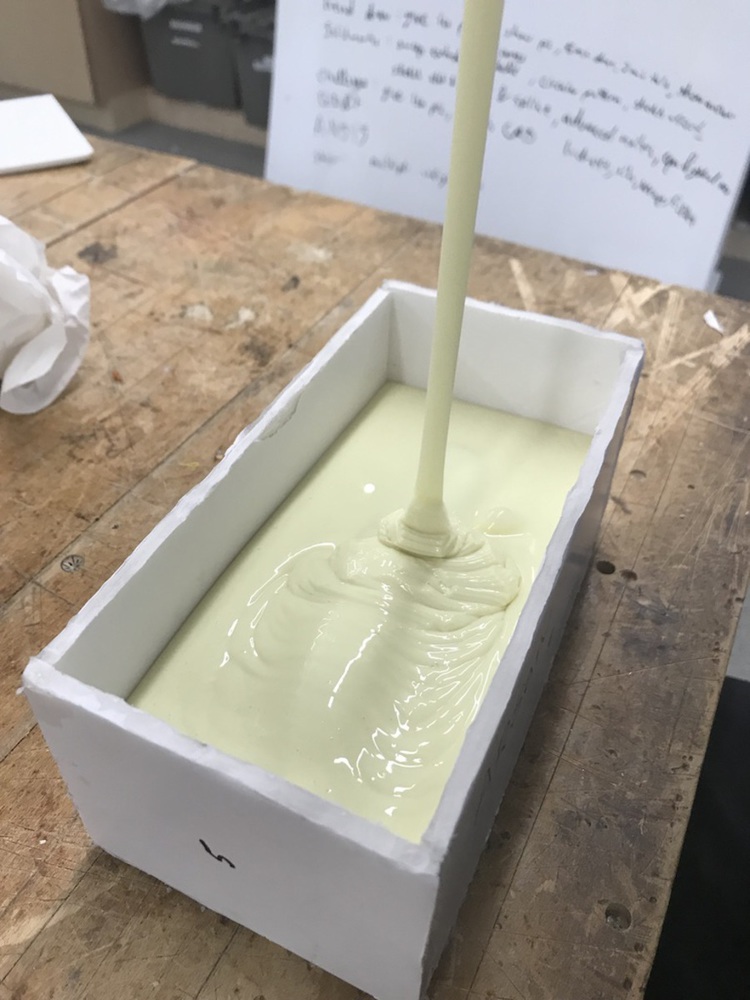

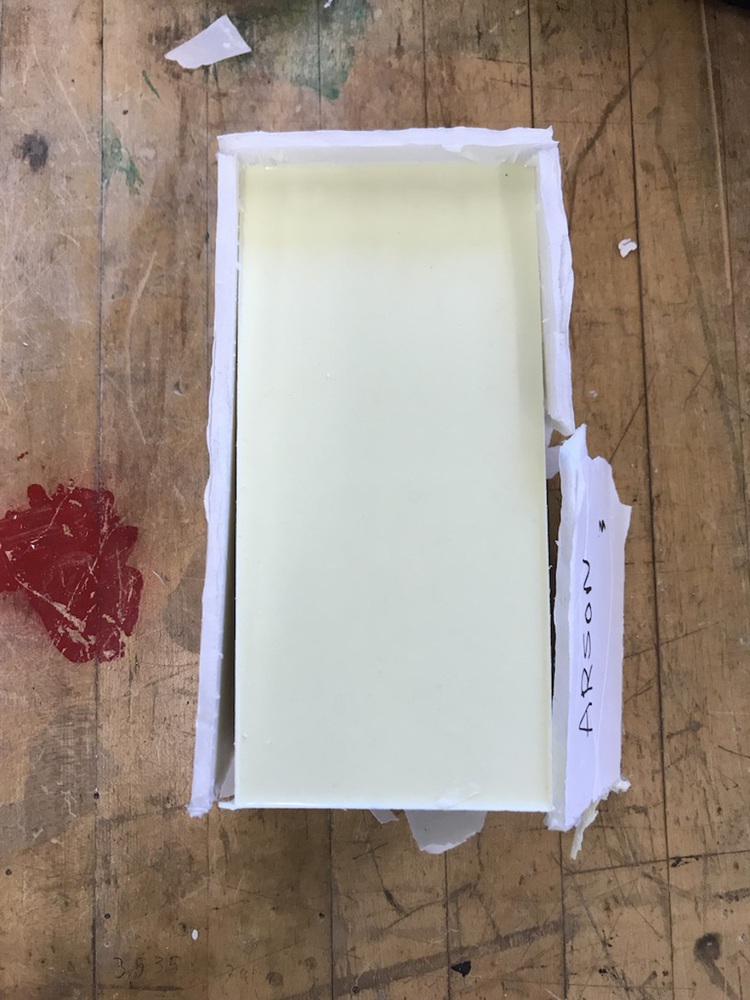

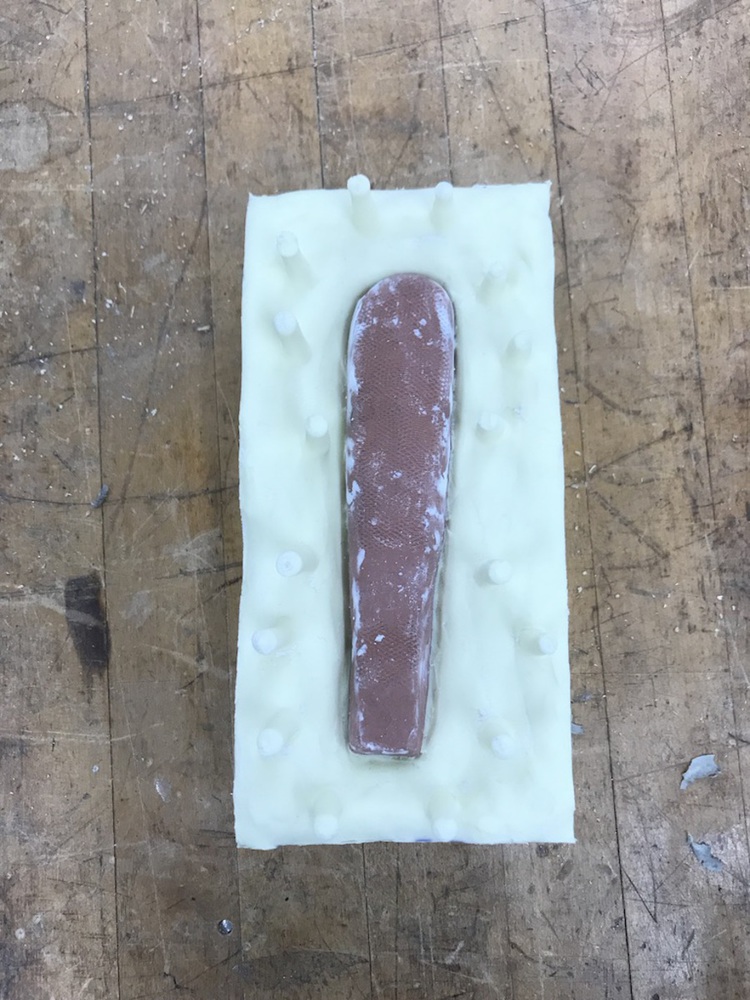

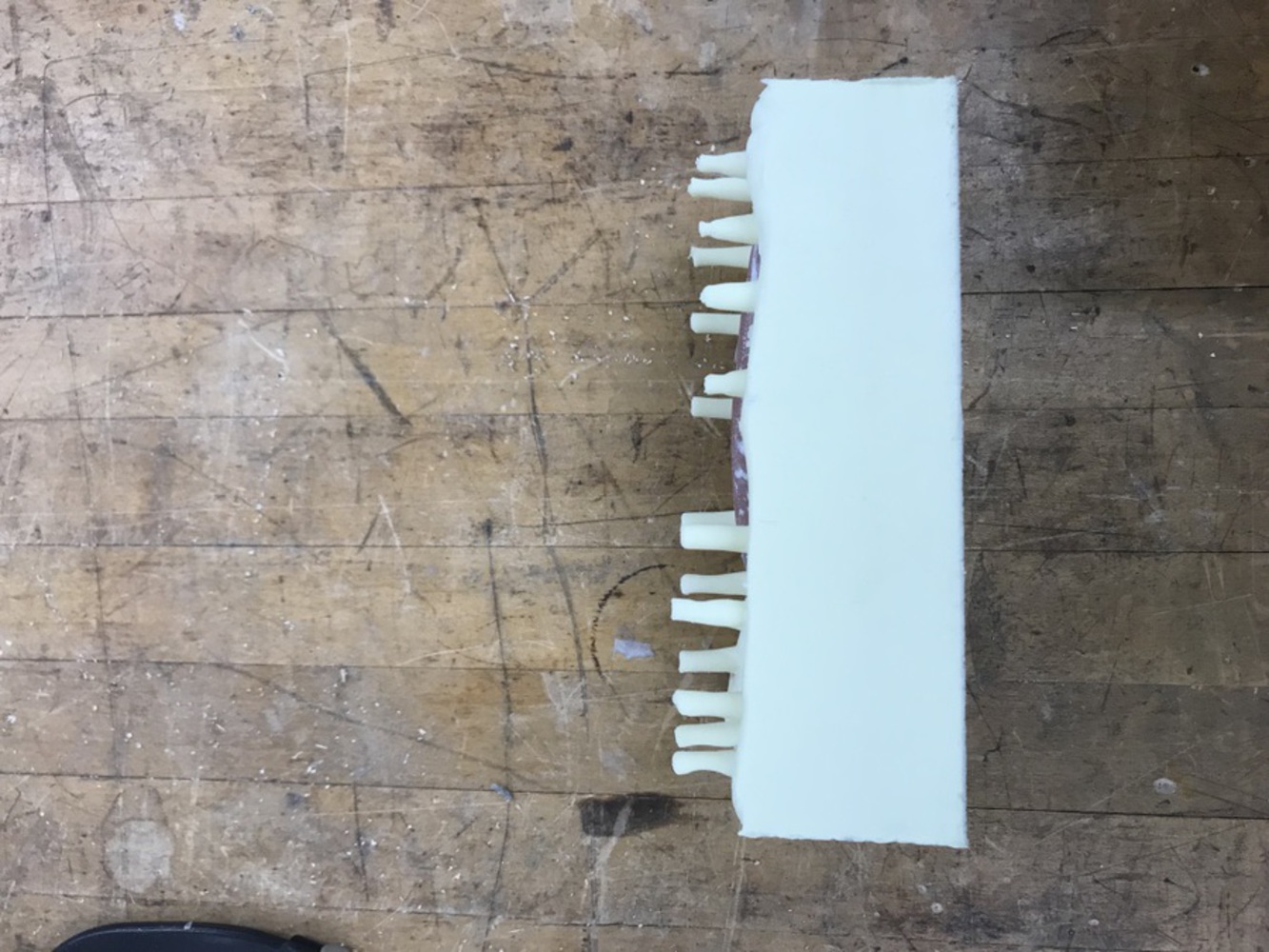

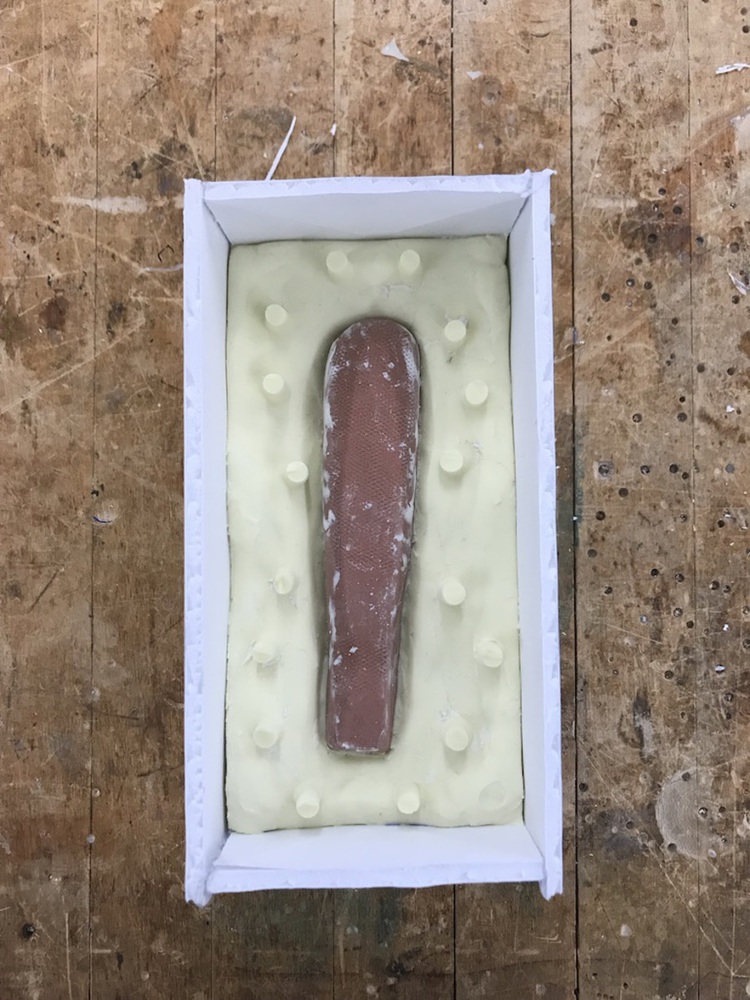

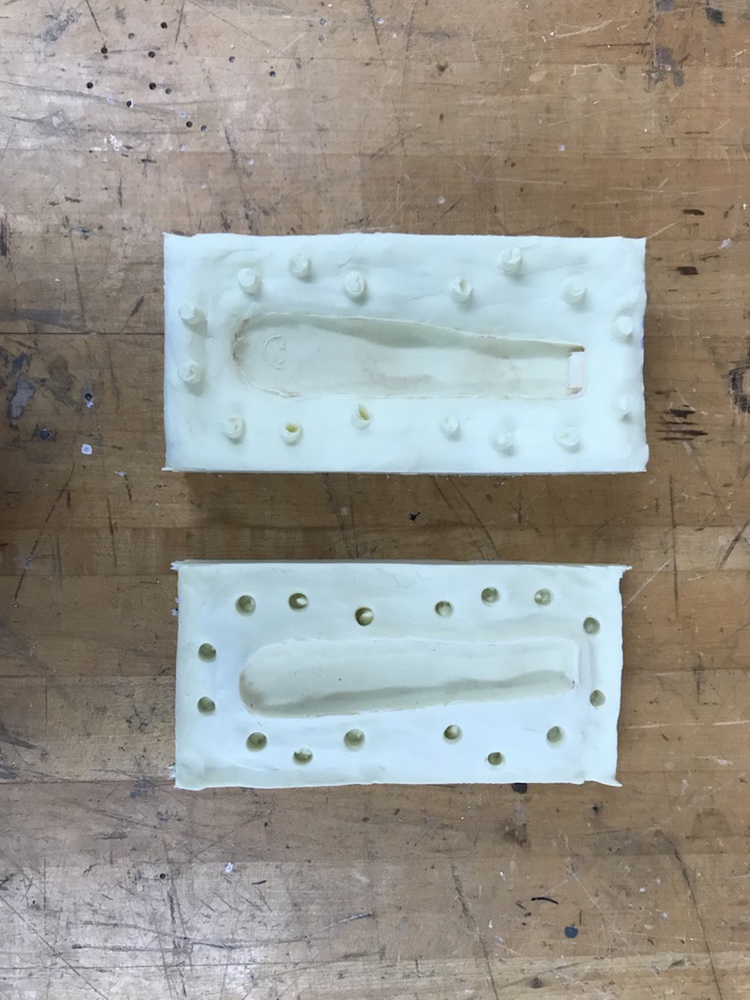

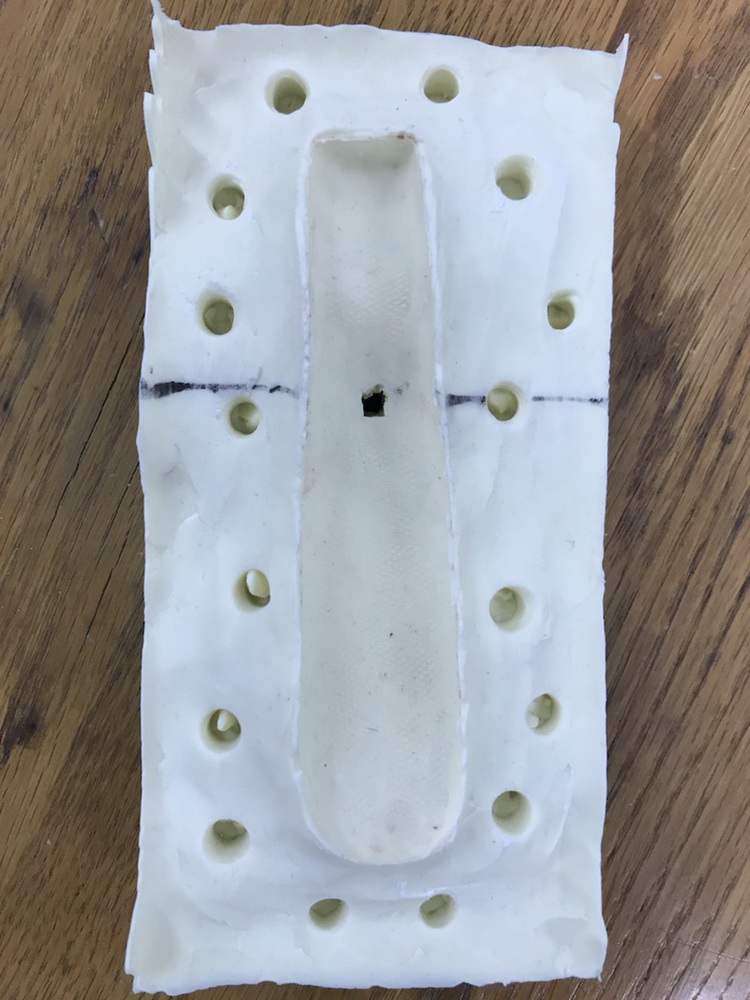

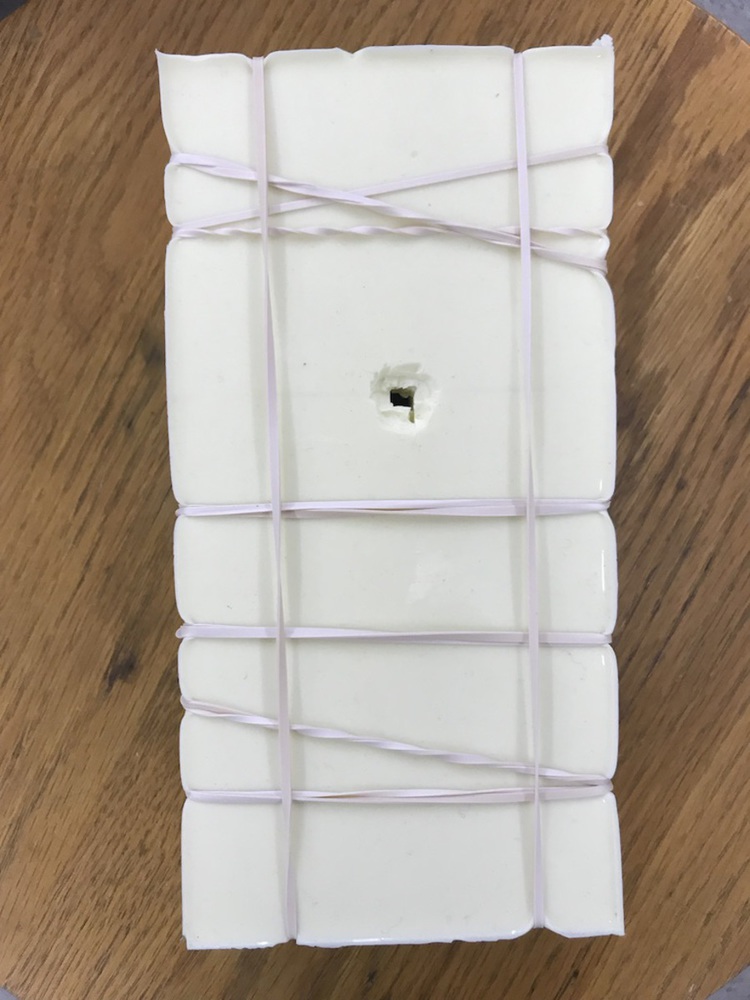

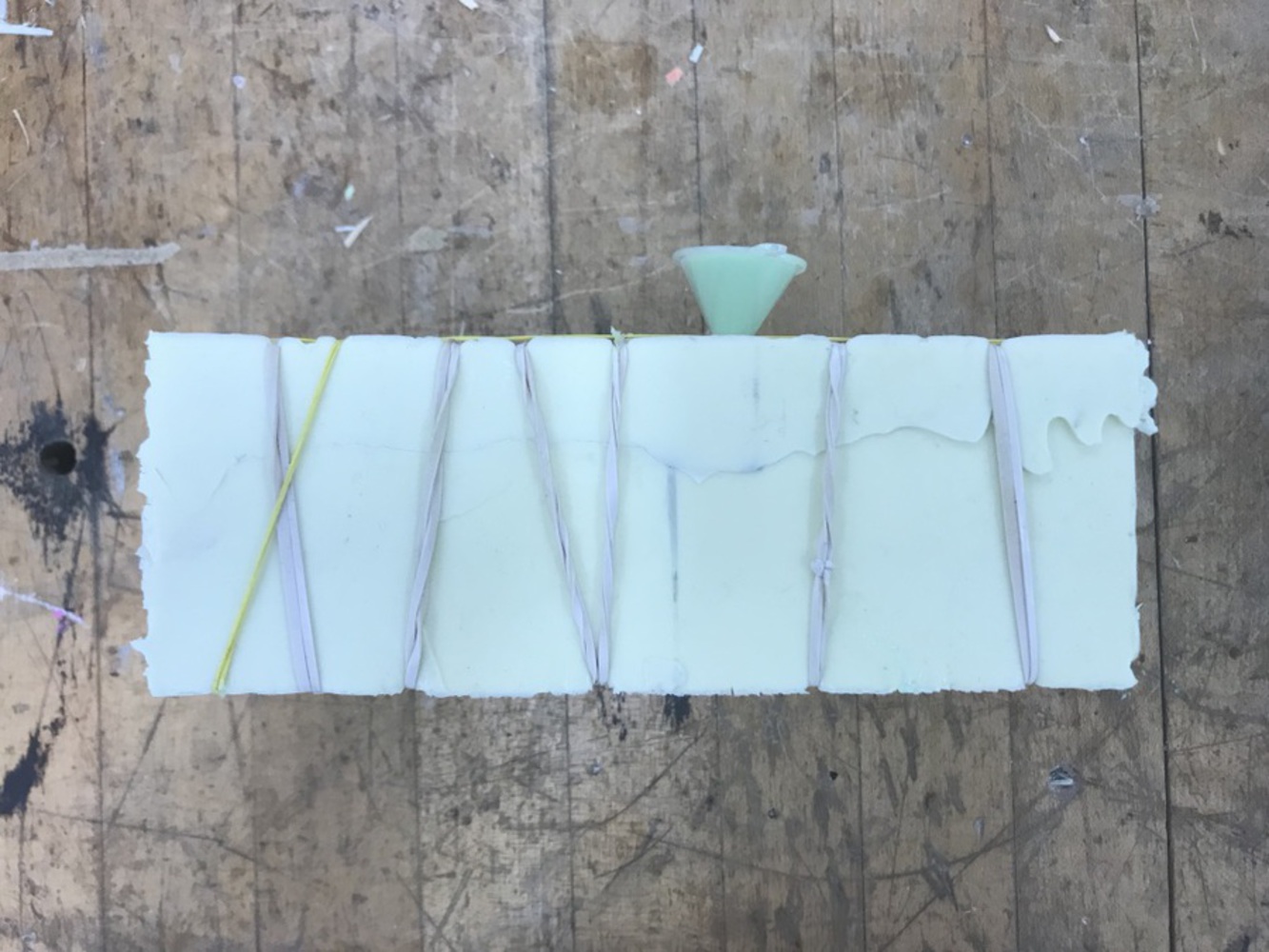

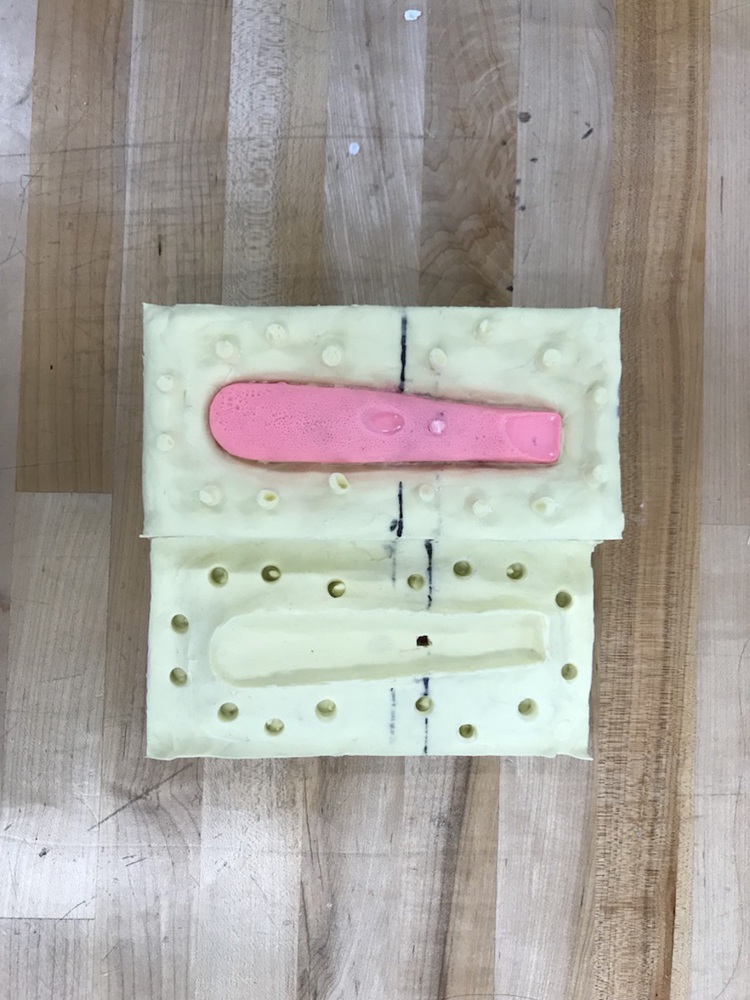

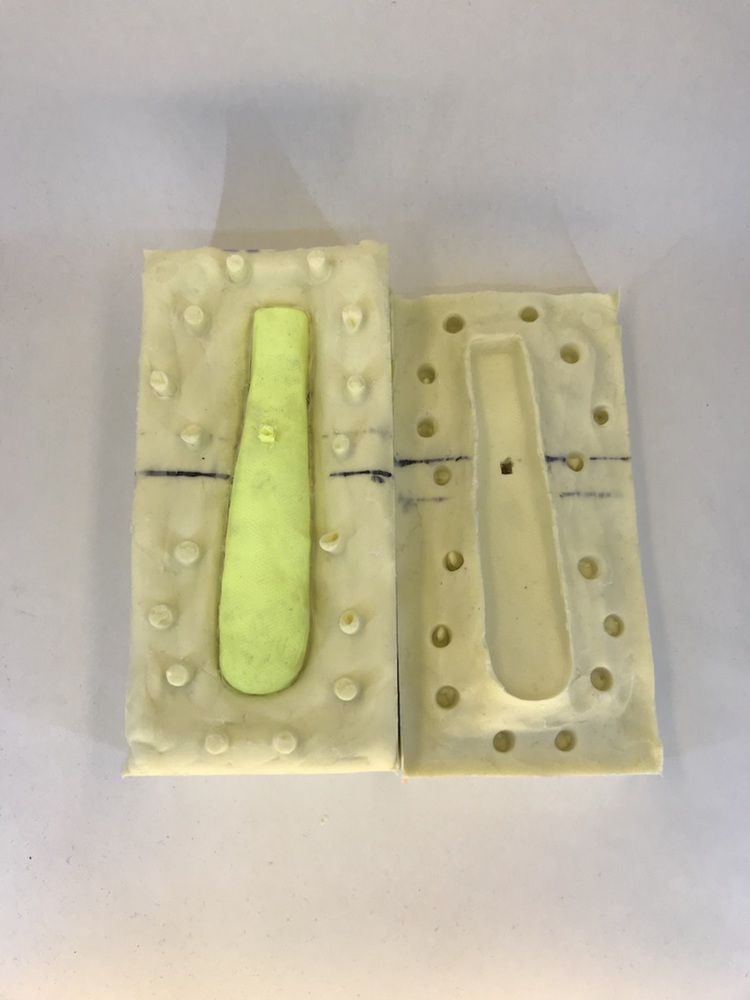

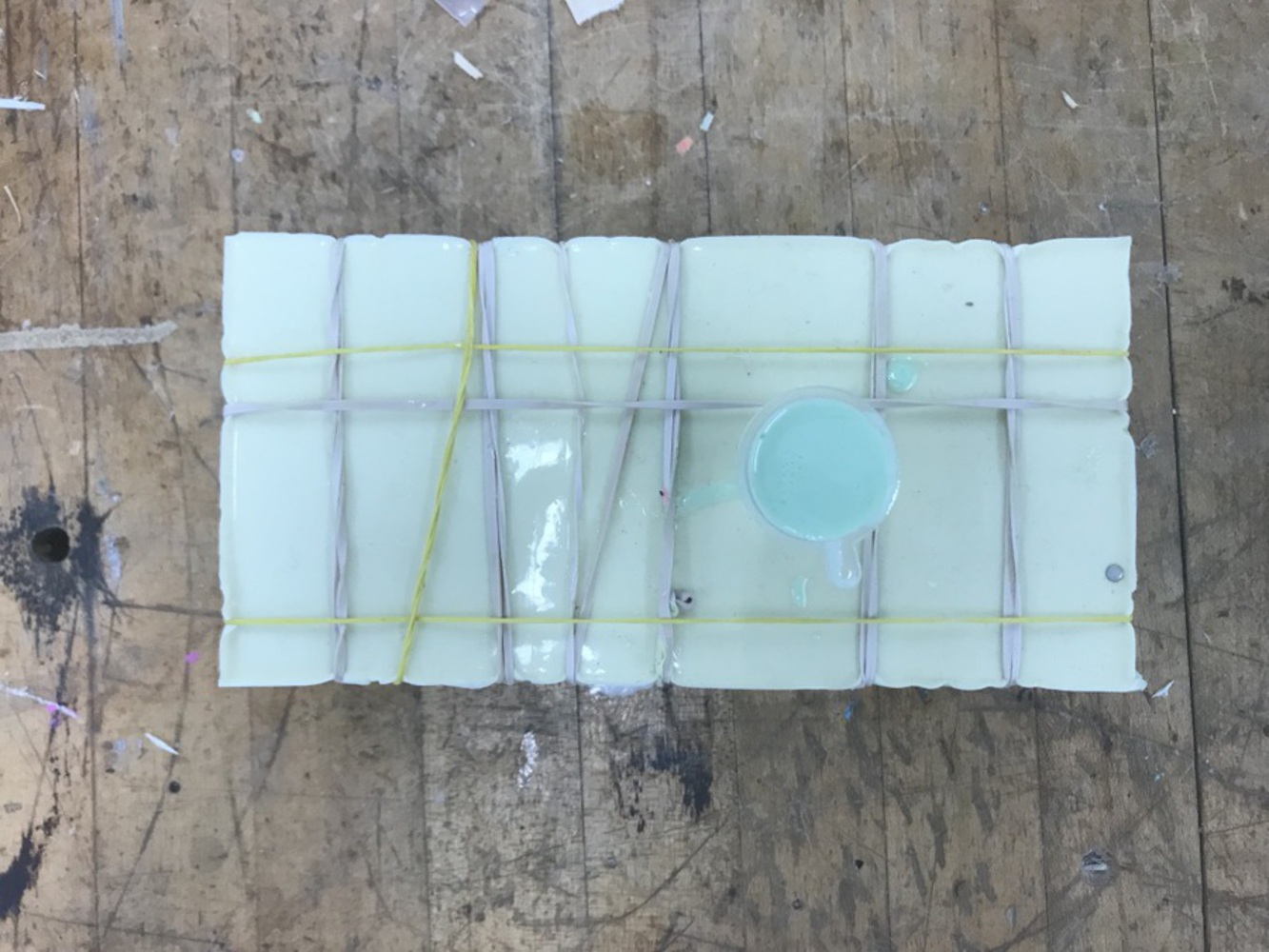

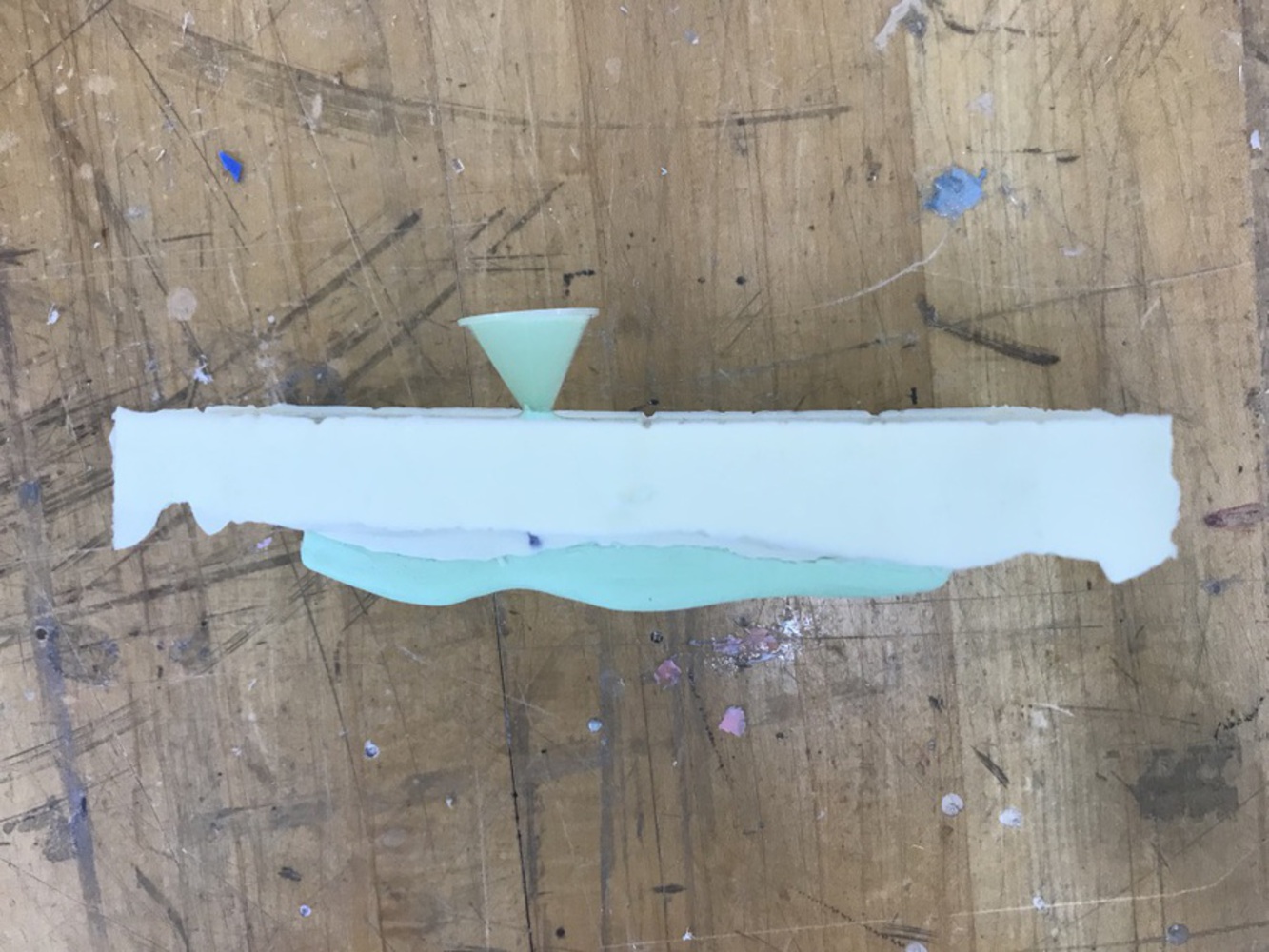

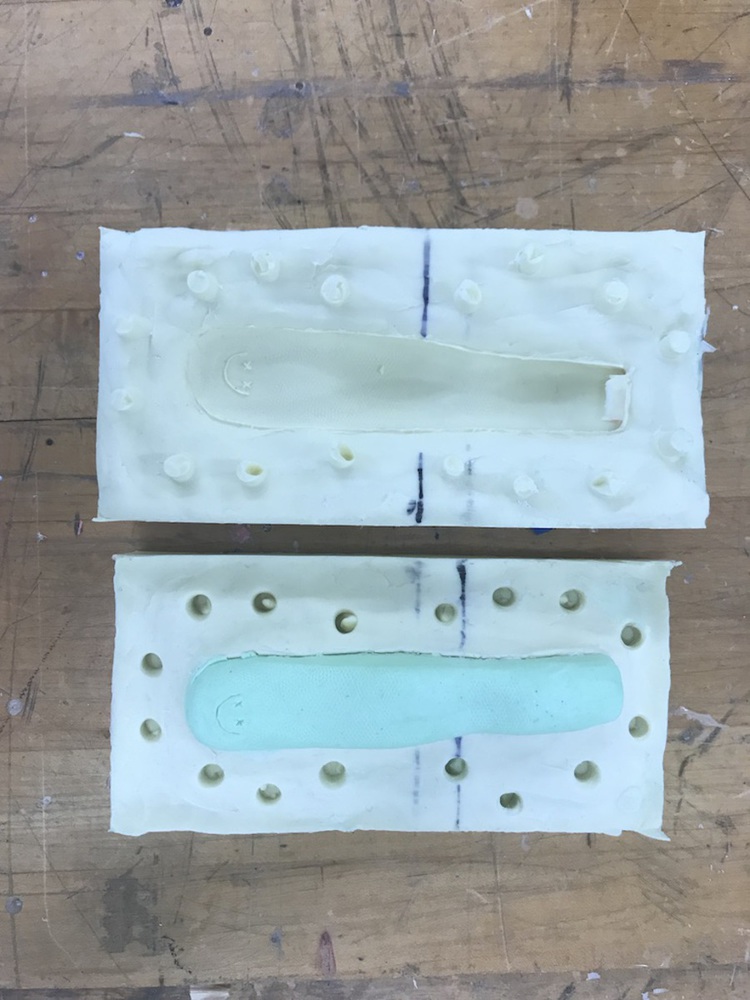

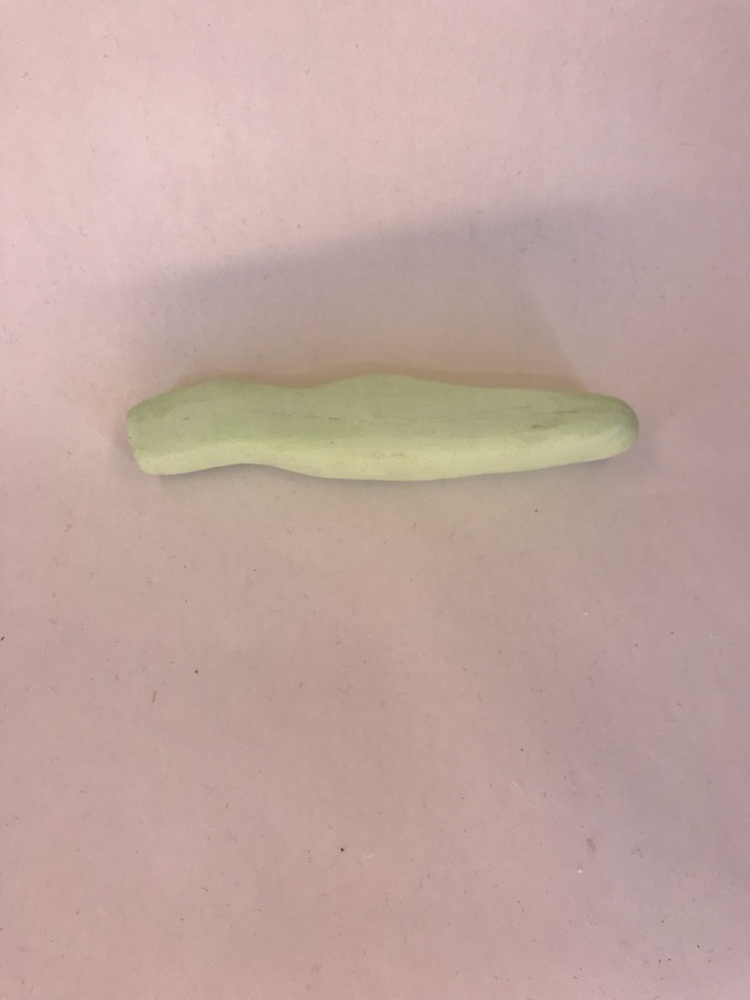

With my existing clay model of the tri-grip, I started by creating a base for my silicon mold using a softer, more malleable clay than the modeling clay used to create the clay model. I packed the white clay around my handle up to the dividing line between the bottom and upper halves so that I could pour the silicon mixture and initially create one half of my silicon mold.