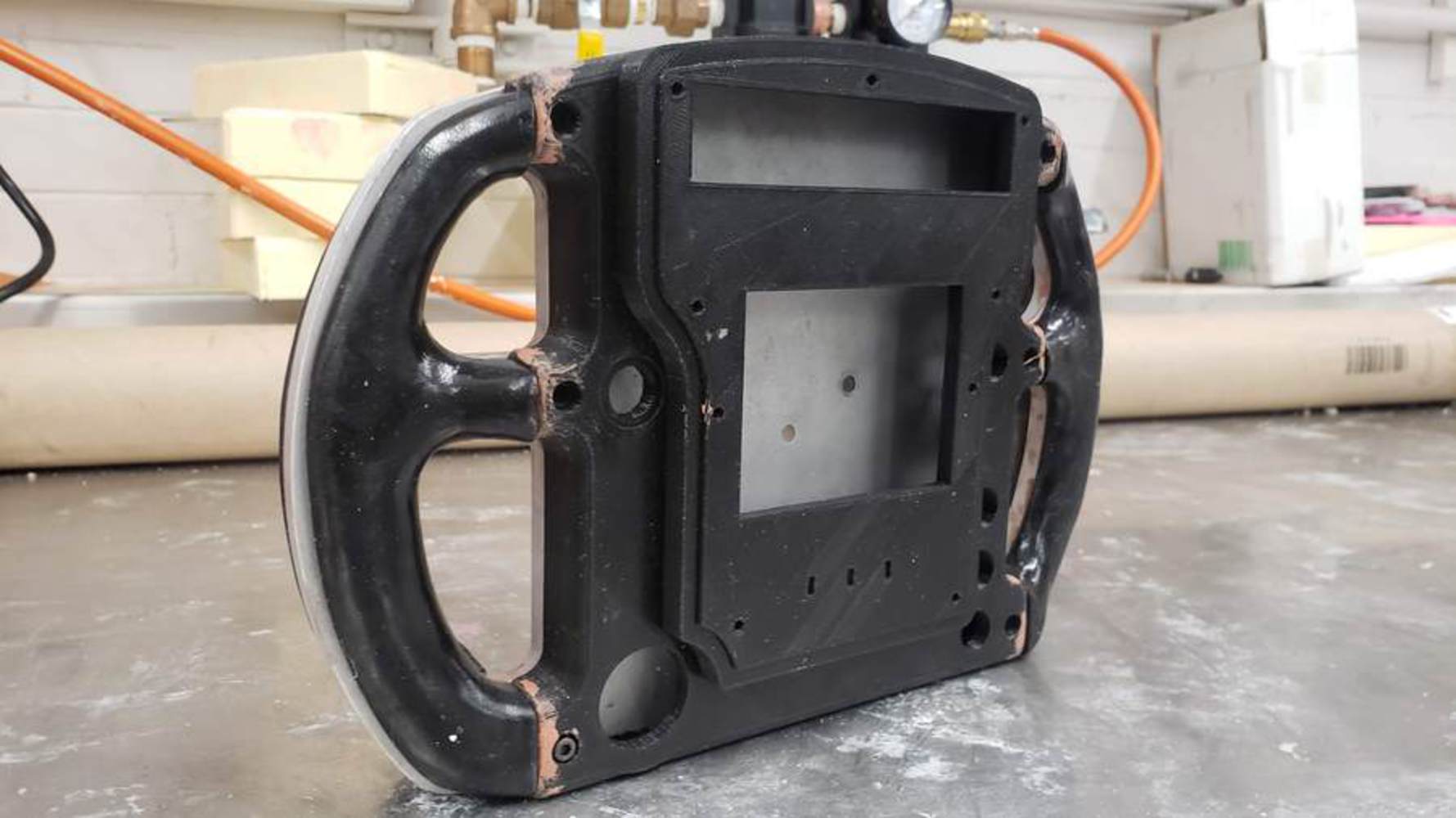

Creating the Mold

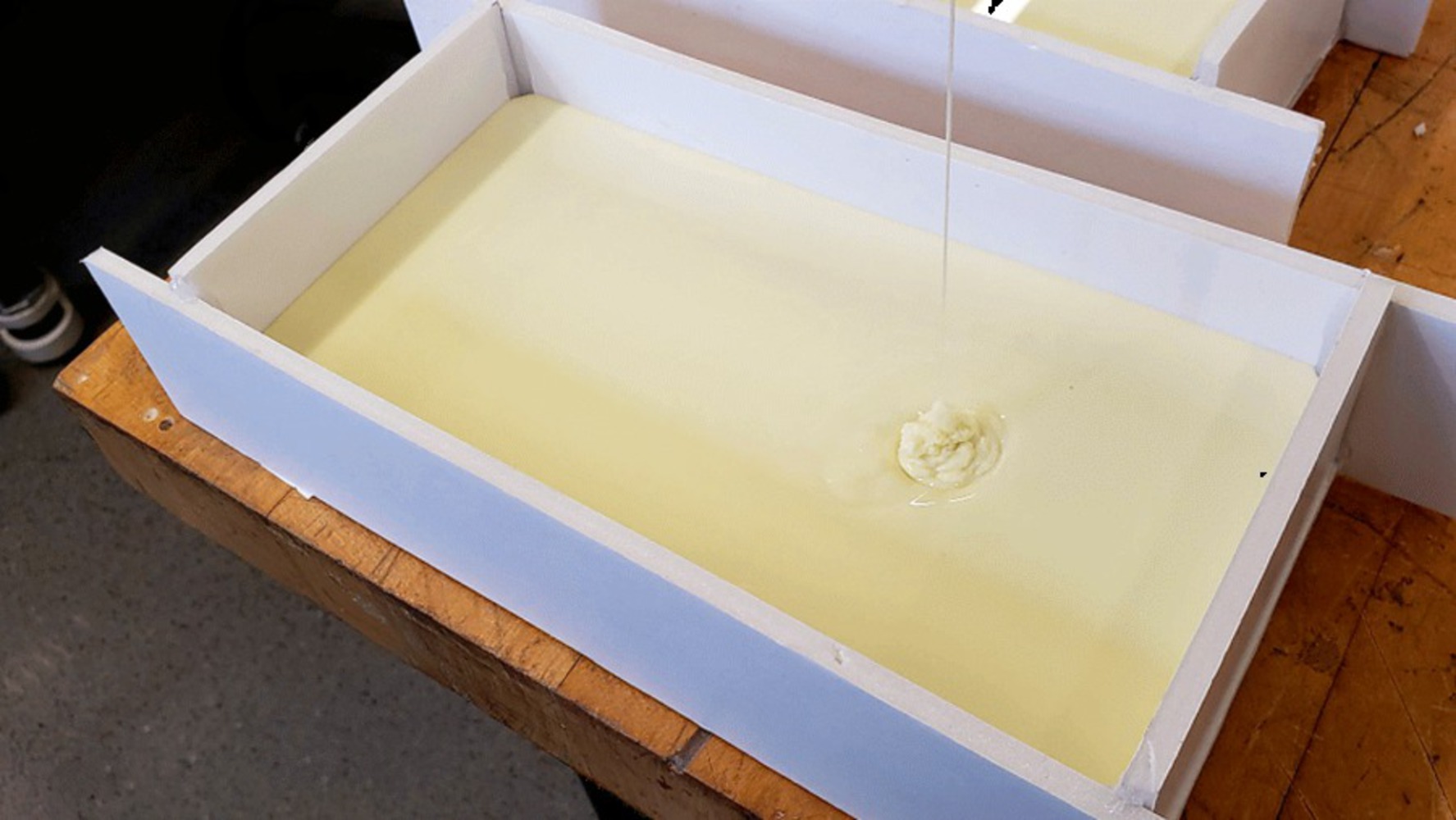

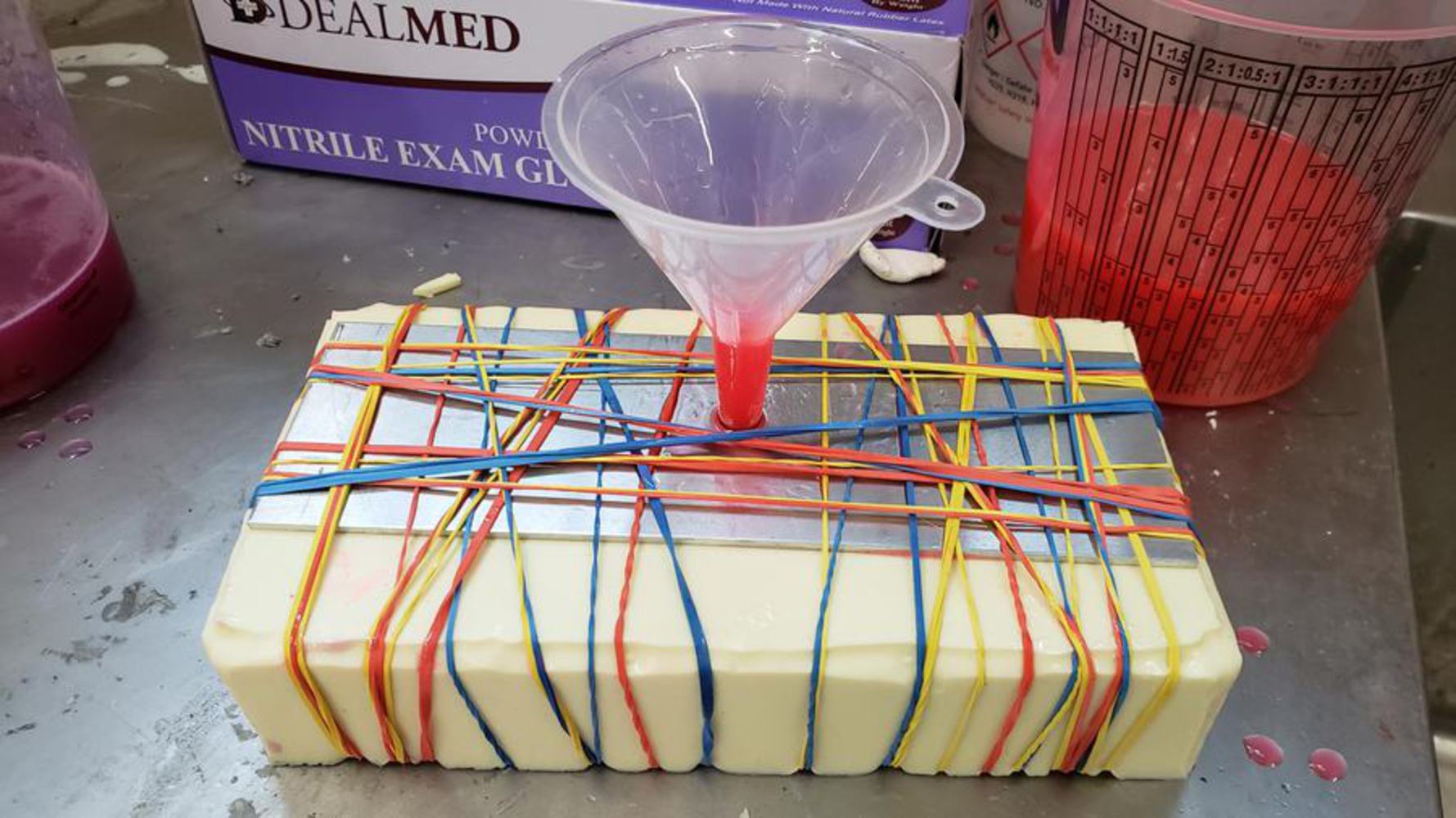

After finishing the clay molding project, the next step was to create a silicone mold of my grips. I made a one part mold for each of the four grips by building foam core walls around five sides and spraying with mold release. After mixing parts A and B of the silicone, I put it into a pressure chamber to get rid of all the bubbles.