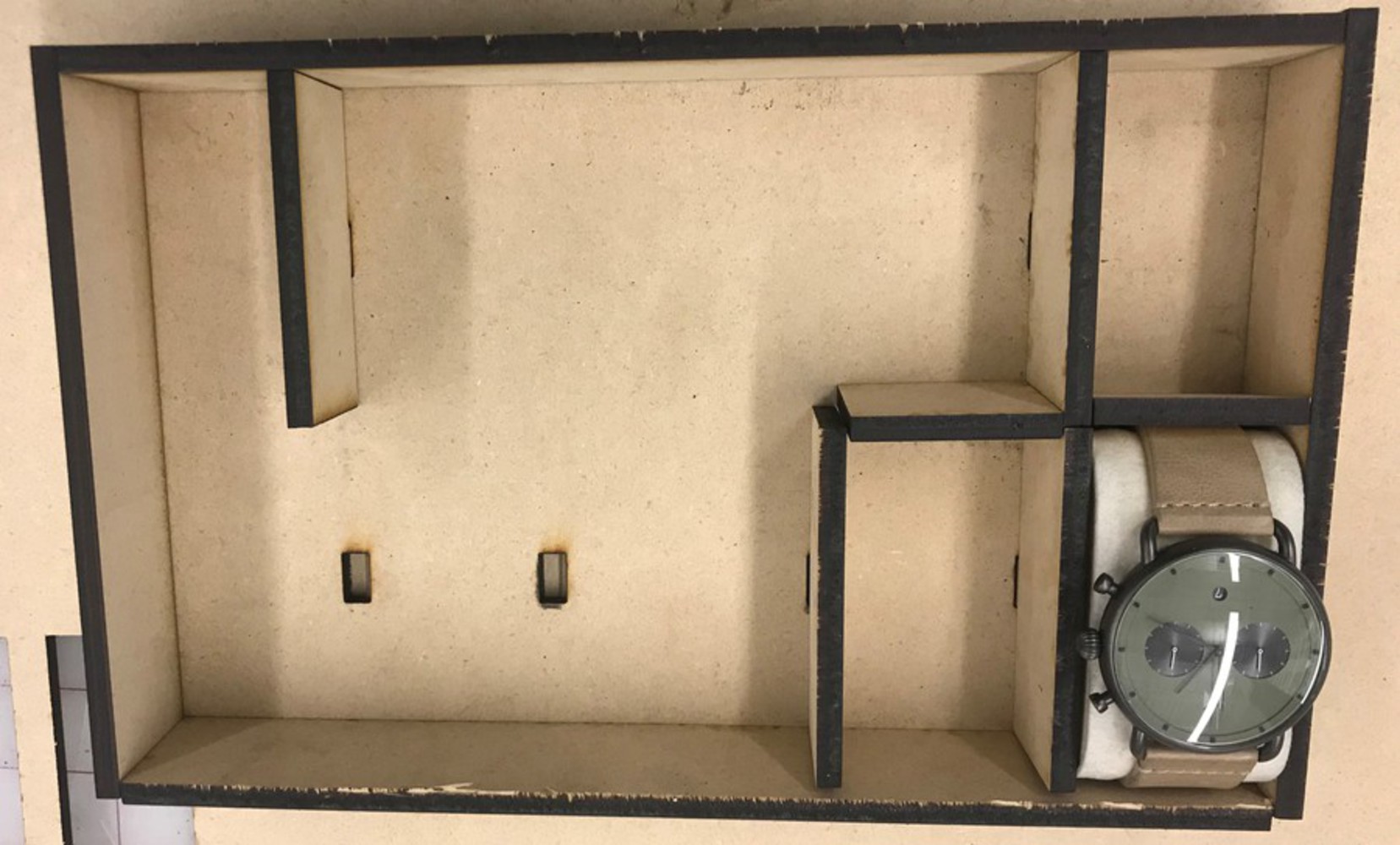

The first step in creating the watchbox was determining the material to use. I chose MDF because of its strength and it was easily cut with the laser cutter. That was key to me as I wanted to use the laser cutter to make sure my pieces were exact.

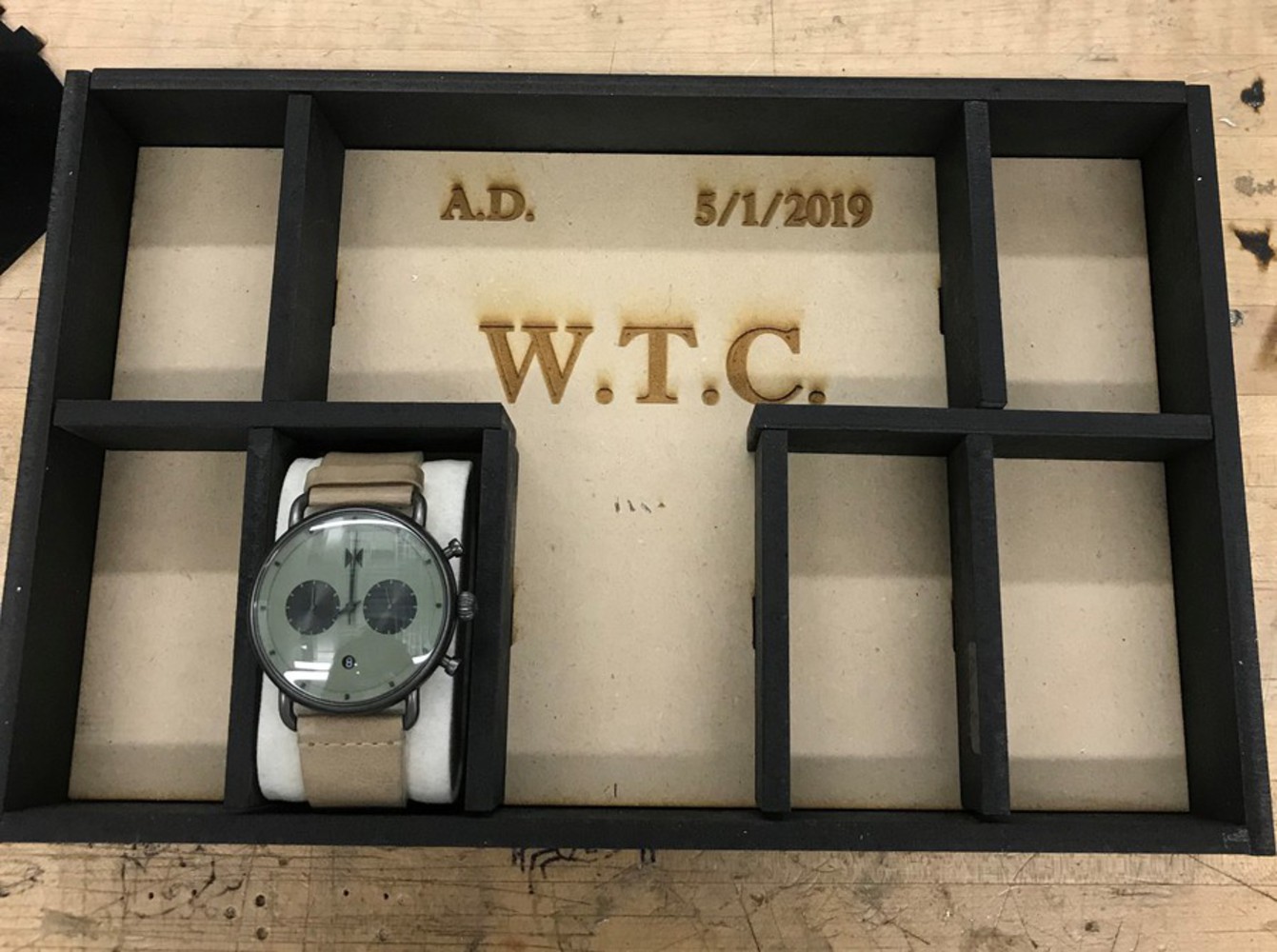

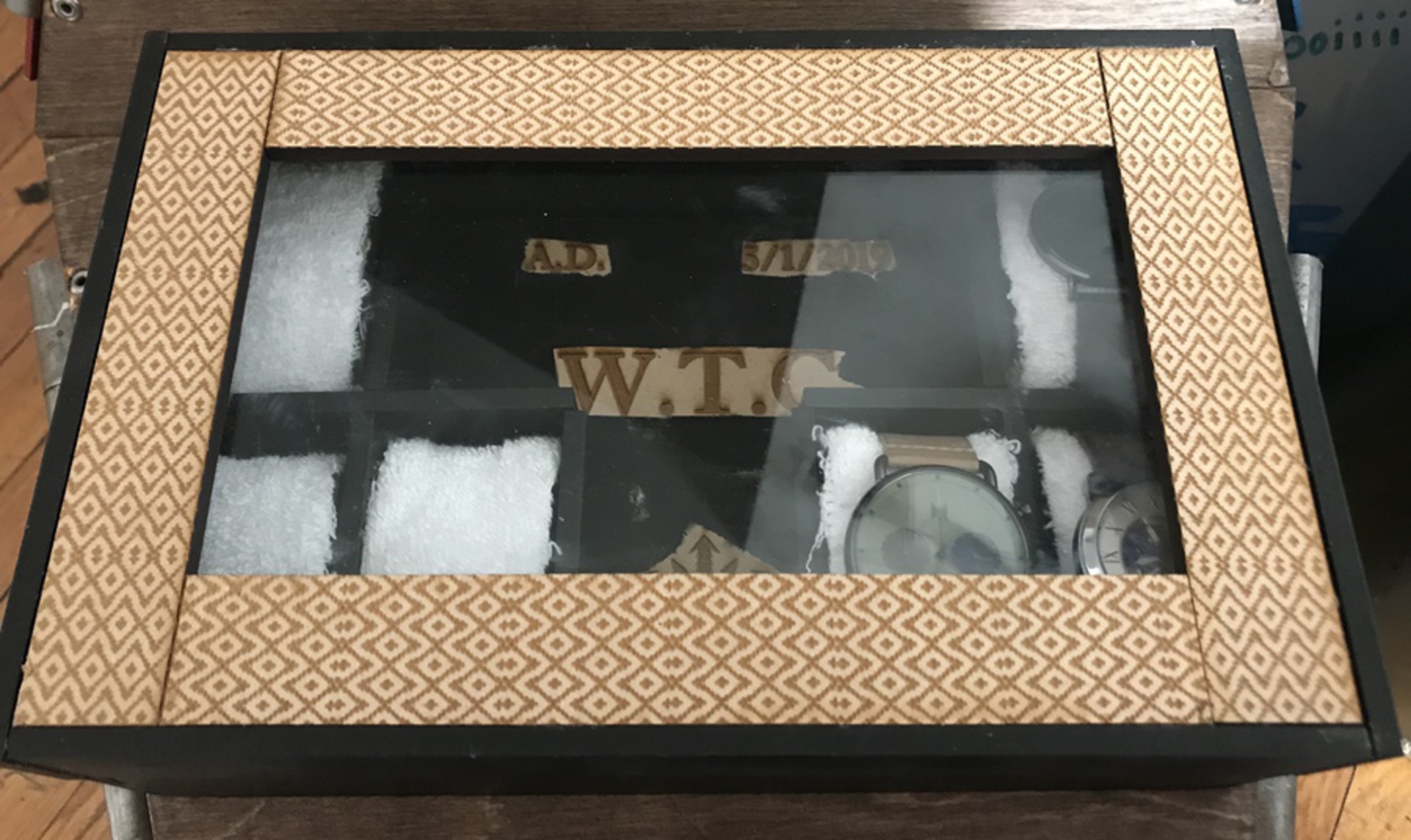

I then designed the box. I looked up current designs for inspiration and really liked the setup of having watches wrapped around pillows that sit in their specific slots in the box. I designed the box with this in mind, but also wanted to add my own touch, so I left the middle open for engraving and space to put things other than watches.