Sample Book

Below are images of all the required samples for this class, which are described below

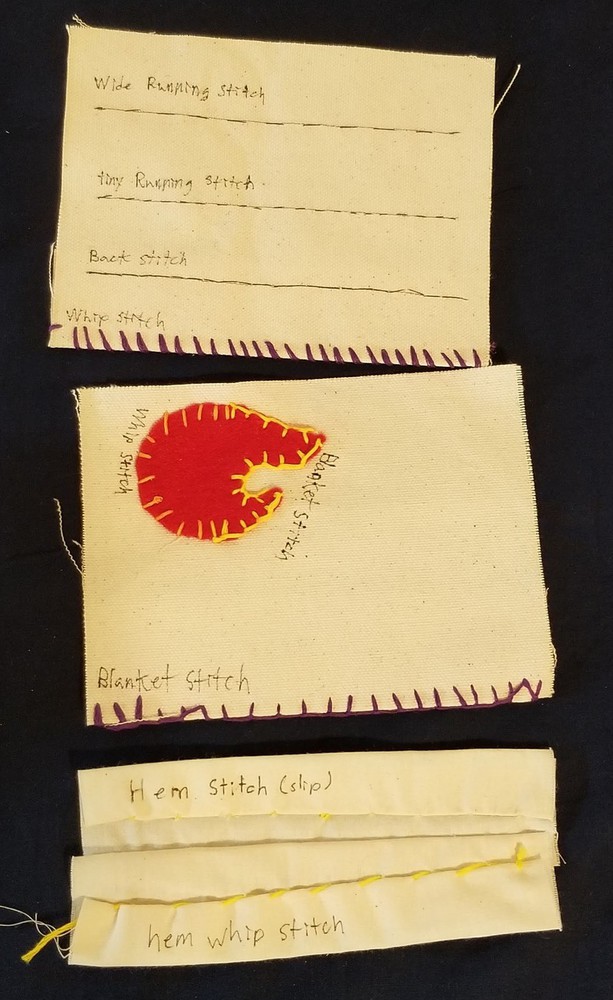

1st Image Running stitch (basting) long and short, backstitch, blanket stitch, overcast stitch, appliqué (half overcast, half blanket). Two fabric pieces sew together with a sewing machine

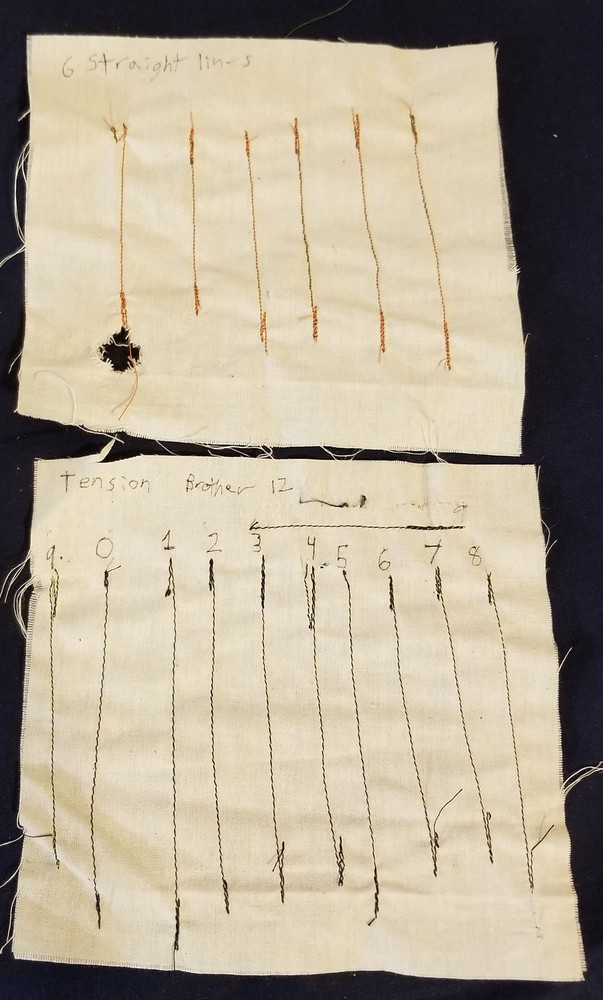

2nd Image 6 straight lines and Tension Sampler

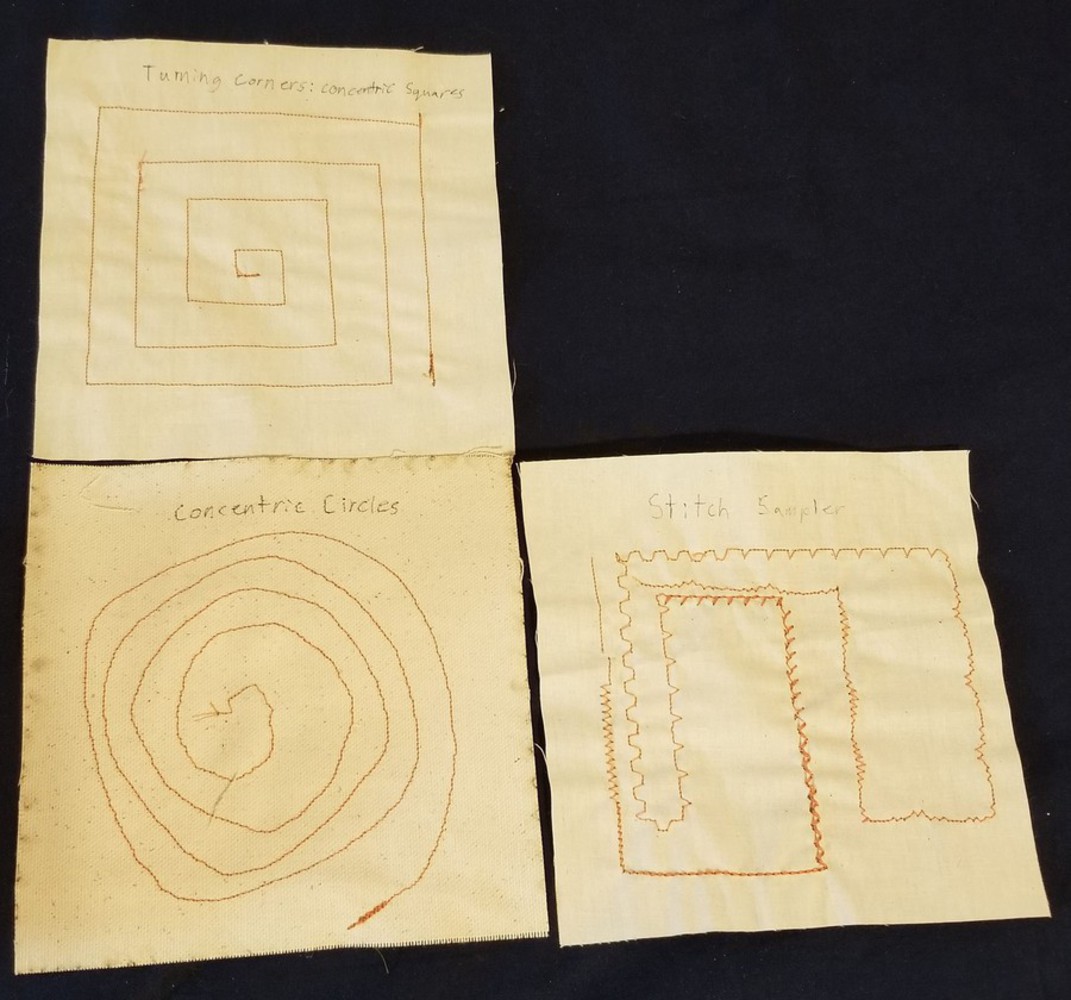

3rd Image square spiral, circular spiral, and doodle with various settings.

4th Image Heart Shaped Form

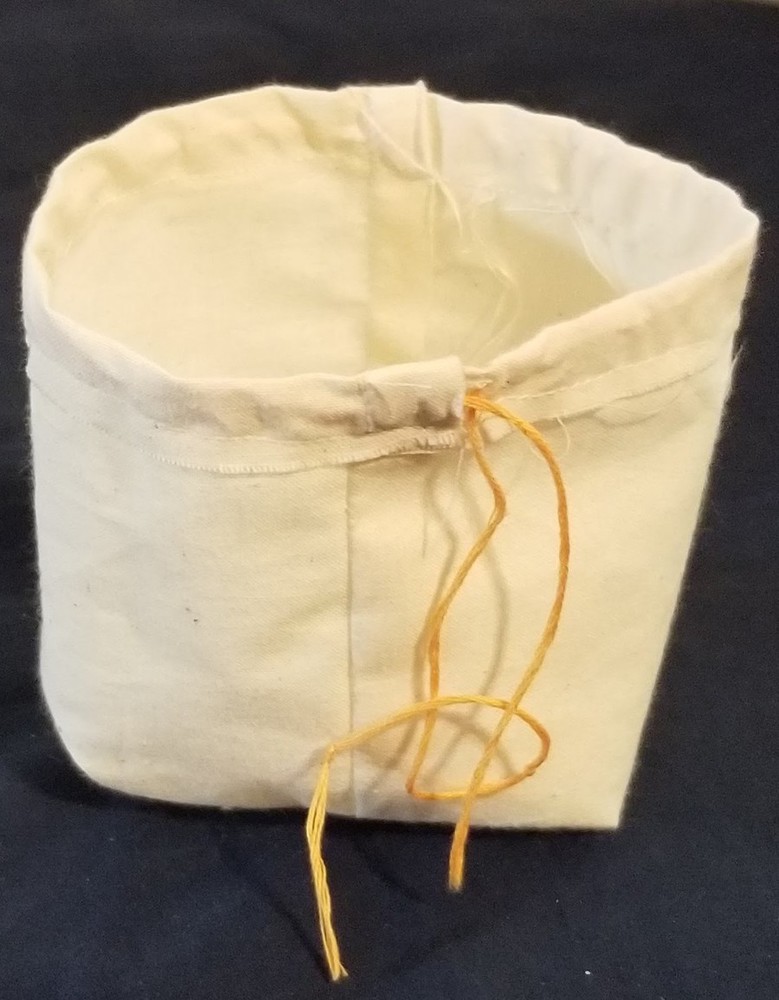

5th and 6th Images Pouch

7th Image Darted circle laser cut

8th Image Darted circle freestyle

9th Image Wet Felted Ball, with a smiley face and hair added by dry felting

10th Image Wet felted sheet, with a face added by dry felting

11th Image Wet felted 3D form

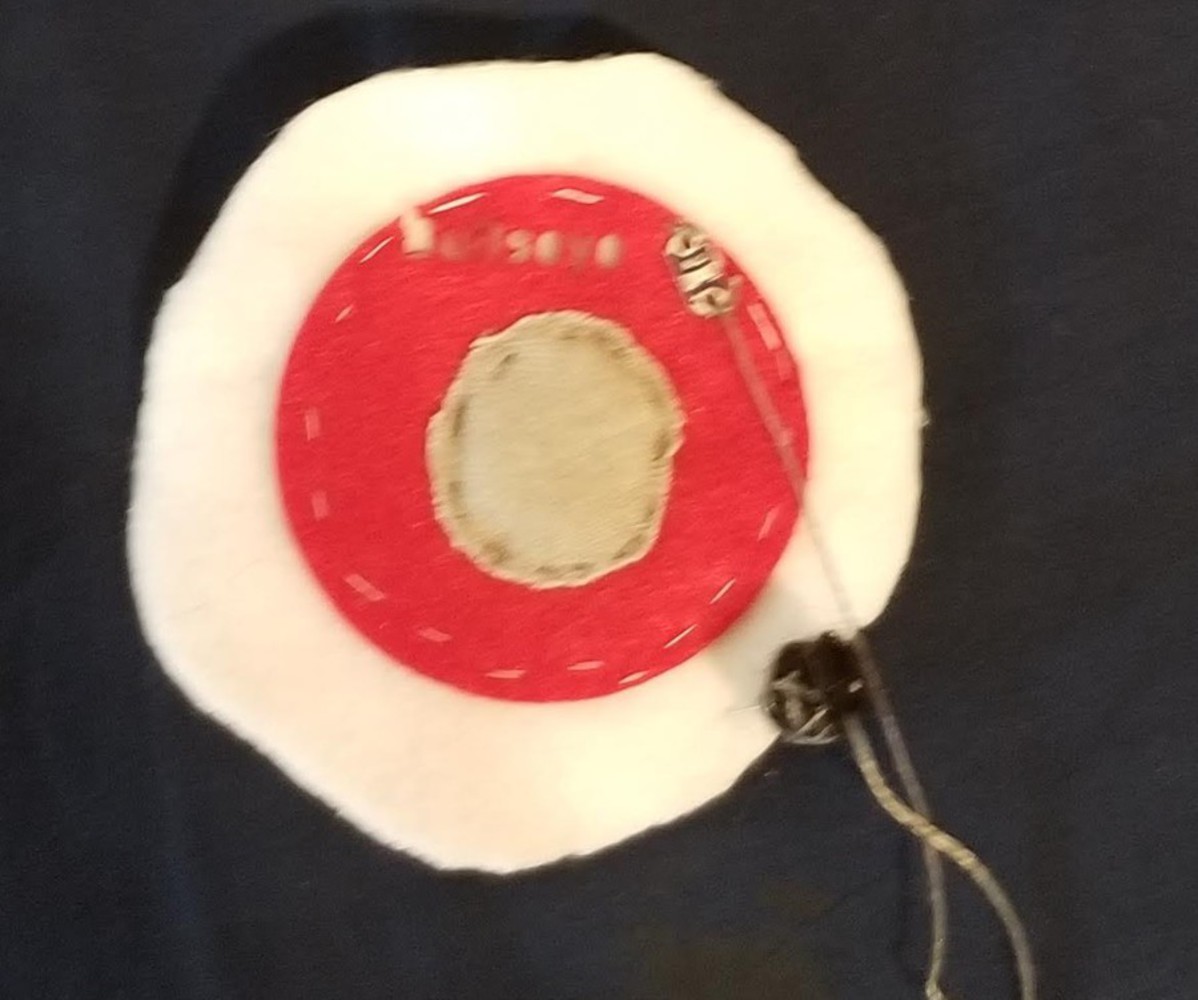

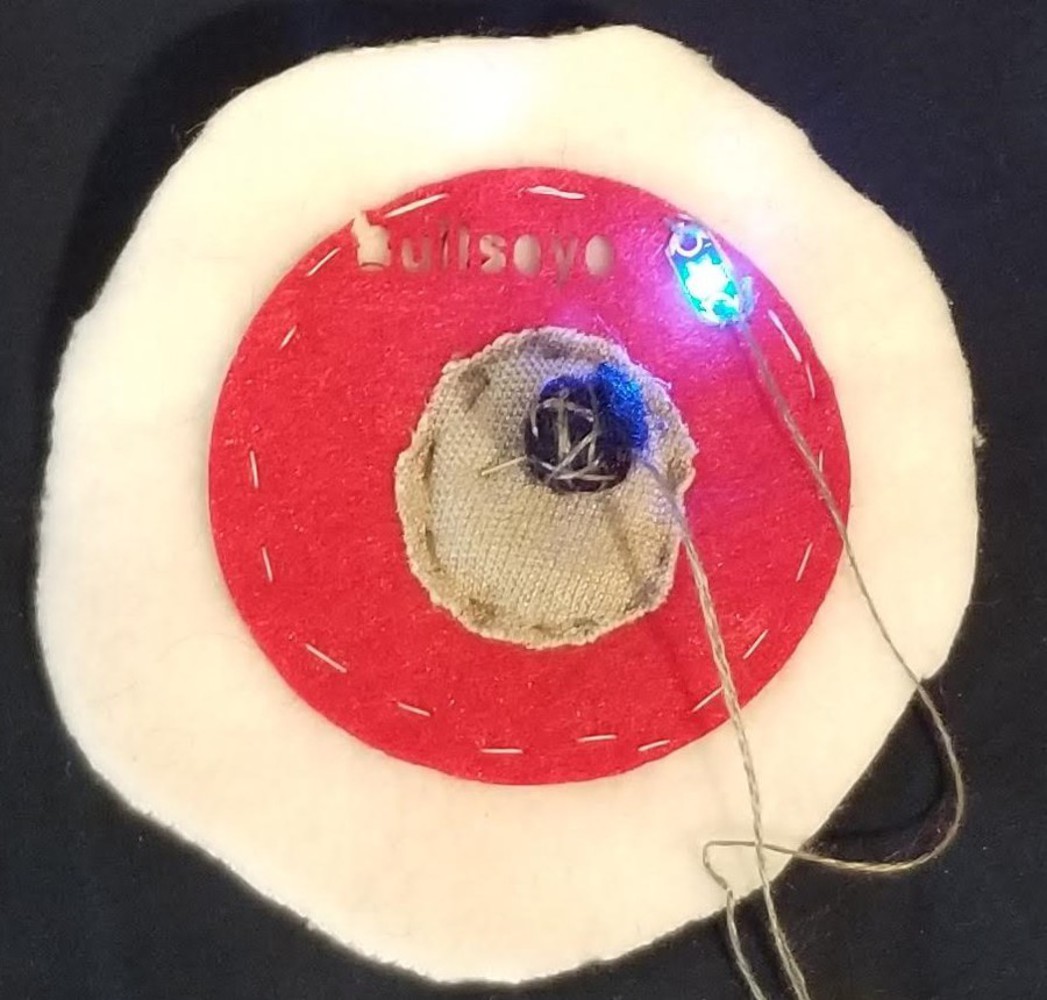

12th and 13th Images Soft circuit "dart board", made with a laser cut red felt piece. Displayed in both the on and off conditions