Outcome

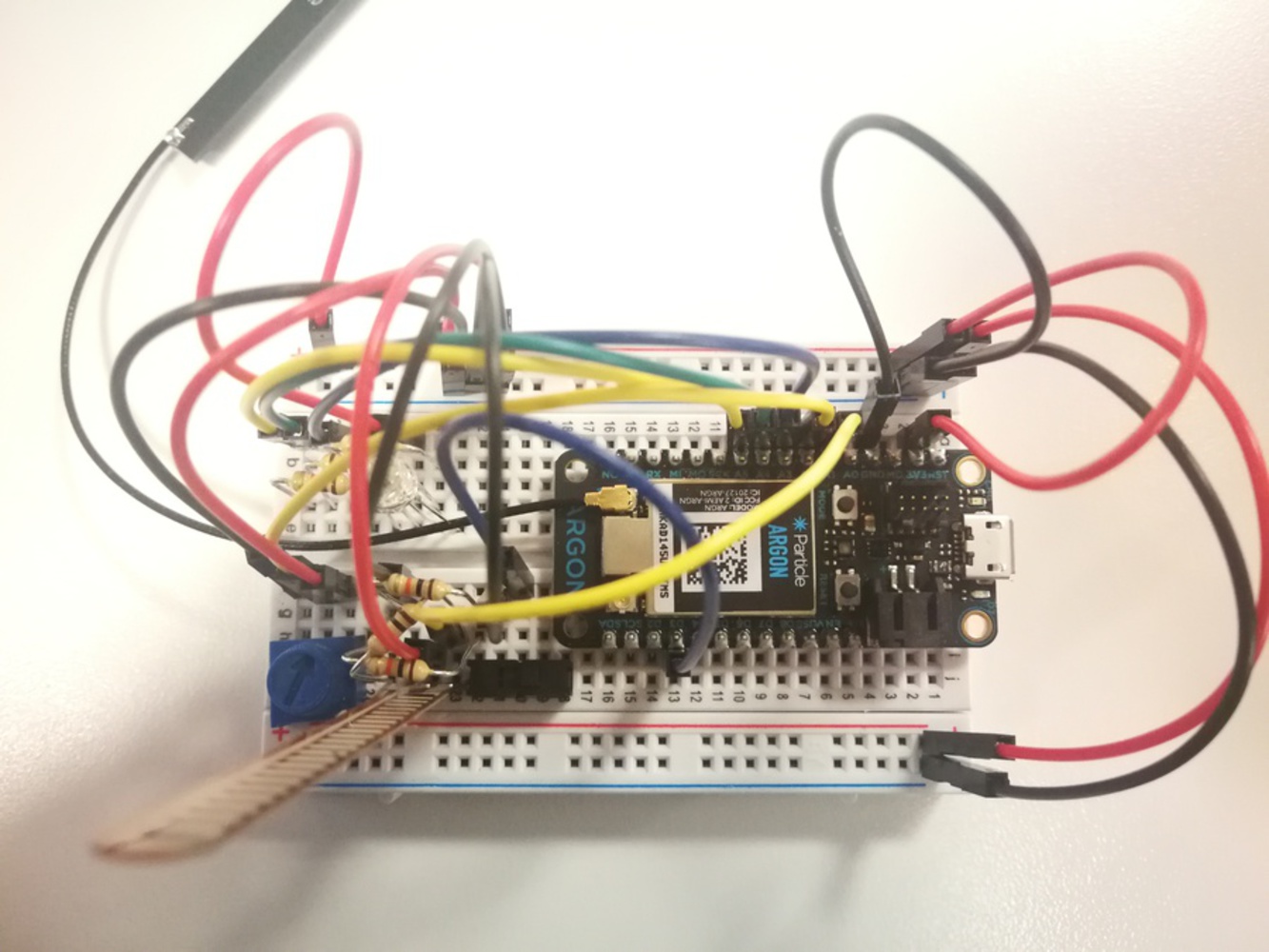

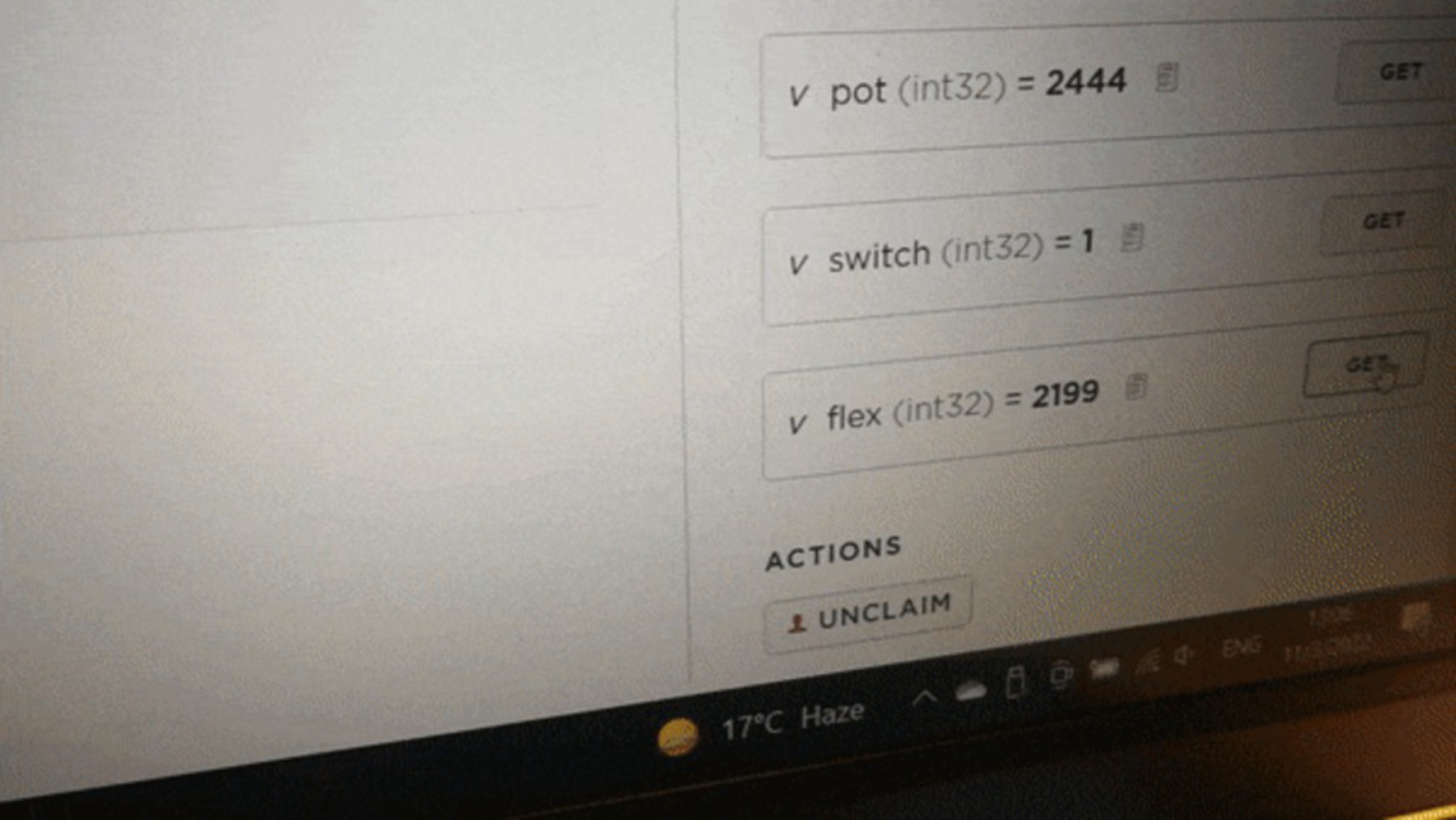

In this project, a switch, flex sensor, and potentiometer were used to control an RGB LED in different ways:

- Turning the potentiometer controlled the intensity of the Red light coming from the LED. Further clockwise = more intensity.

- Bending the flex sensor changed the intensity of the Blue light coming from the LED. More flex = more intensity.

- Flipping the switch causes a digital pin pulled-up to read LO, and turns off the RGB LED no what the values being read from the potentiometer and flex sensor were. Left = OFF, Right = ON.