Outcome

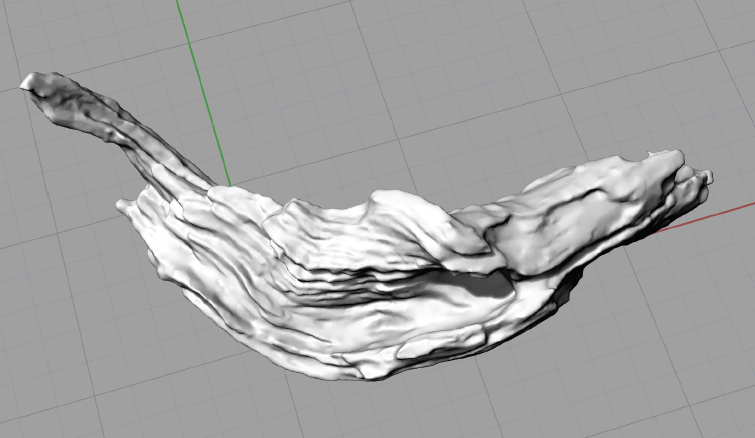

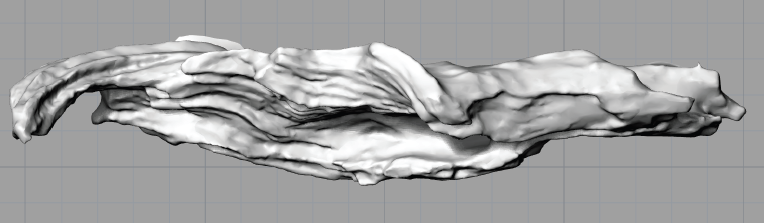

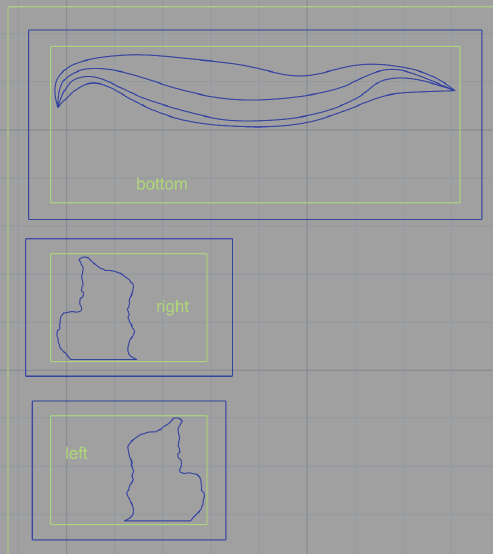

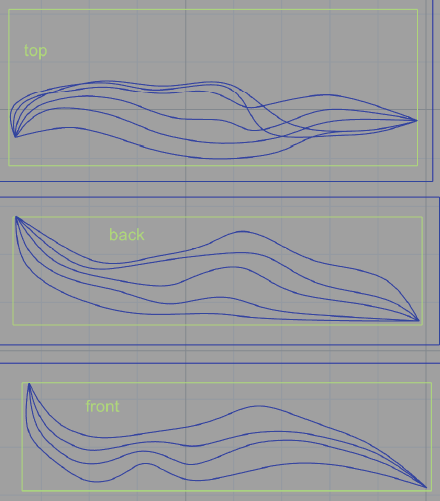

Using two of the cross contours, we traced the shape of the wood onto a small block of basswood, and using the hand chisels attempted to loft a 3D form between the two.

We used the initial photographs of the wood as well as the rendering to help inform the texture that was created with the chisel.

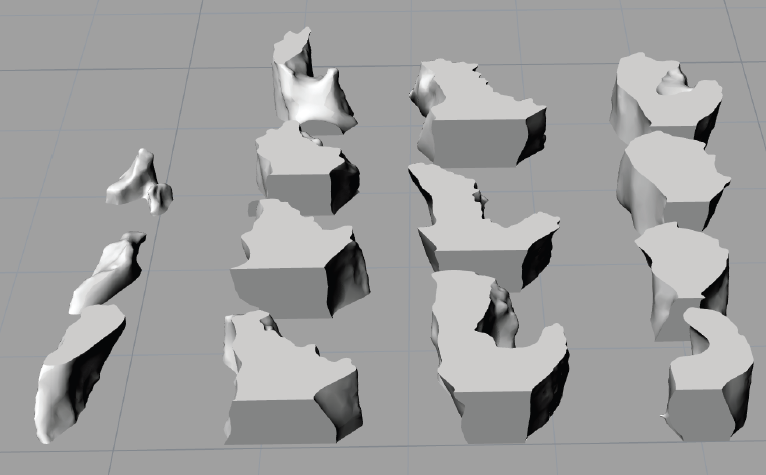

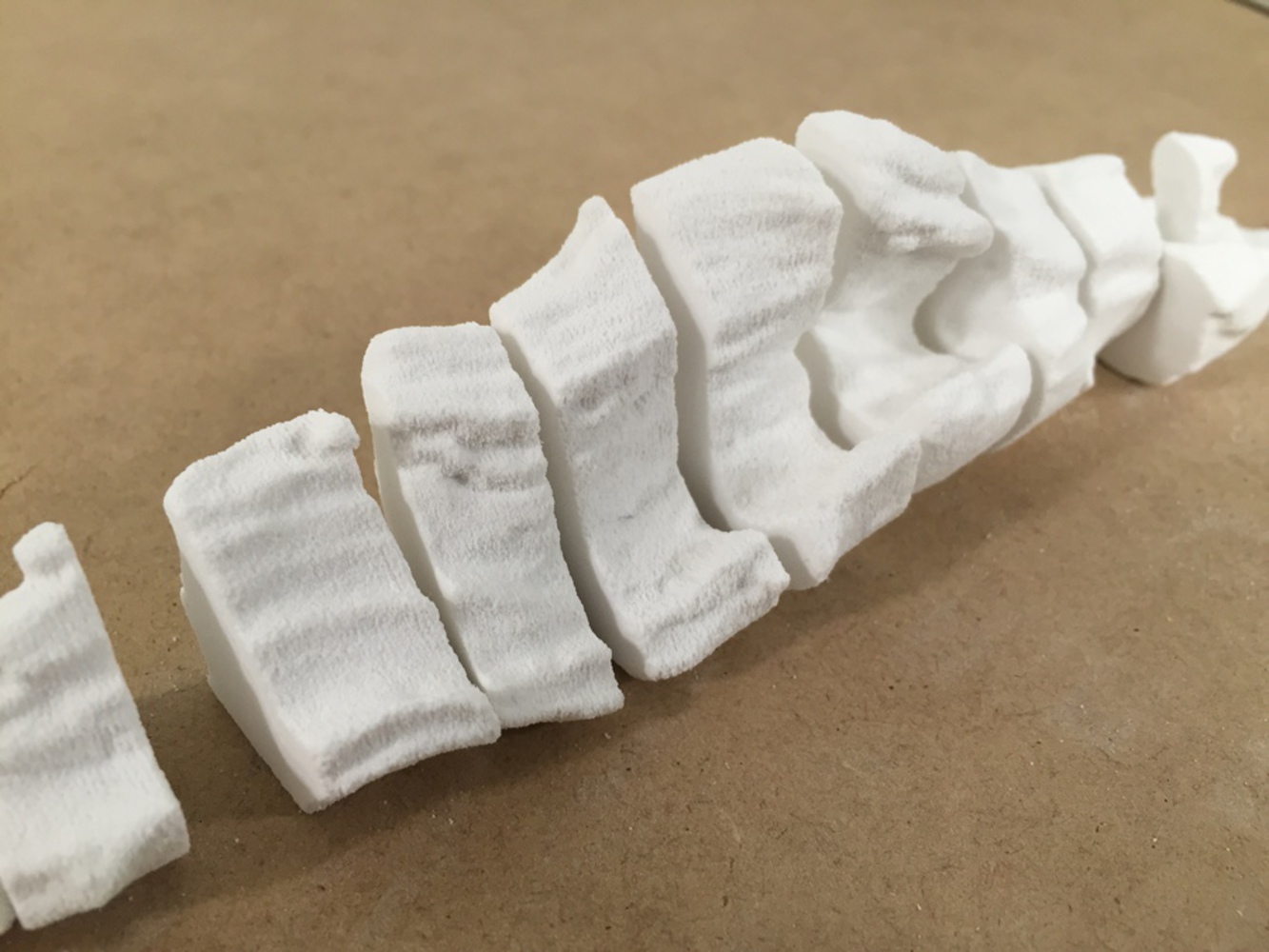

For the next hand-tooled object, the templates were placed on the wood block, and the object was hand chiseled to re flect those markings. The pencil lines representing the grain of the wood in each of the orthographic views were left raised, thereby recreating a grain similar to the original artifact.

In an additional iteration, the templates were again traced onto a block of wood. The outlines of the traced shapes were used as guides to cut out a rough form on the bandsaw. The resulting shape was gestural and refl ective of the grain of the original wood, but very square. The laser cut templates were again traced onto the sides of the wood form, and as in the previous object, served as guides for hand-chiseling. Leaving the markings as raised areas we were able to reproduce the direction and ow of grain as true to the original object.

You can upload files of up to 20MB using this form.