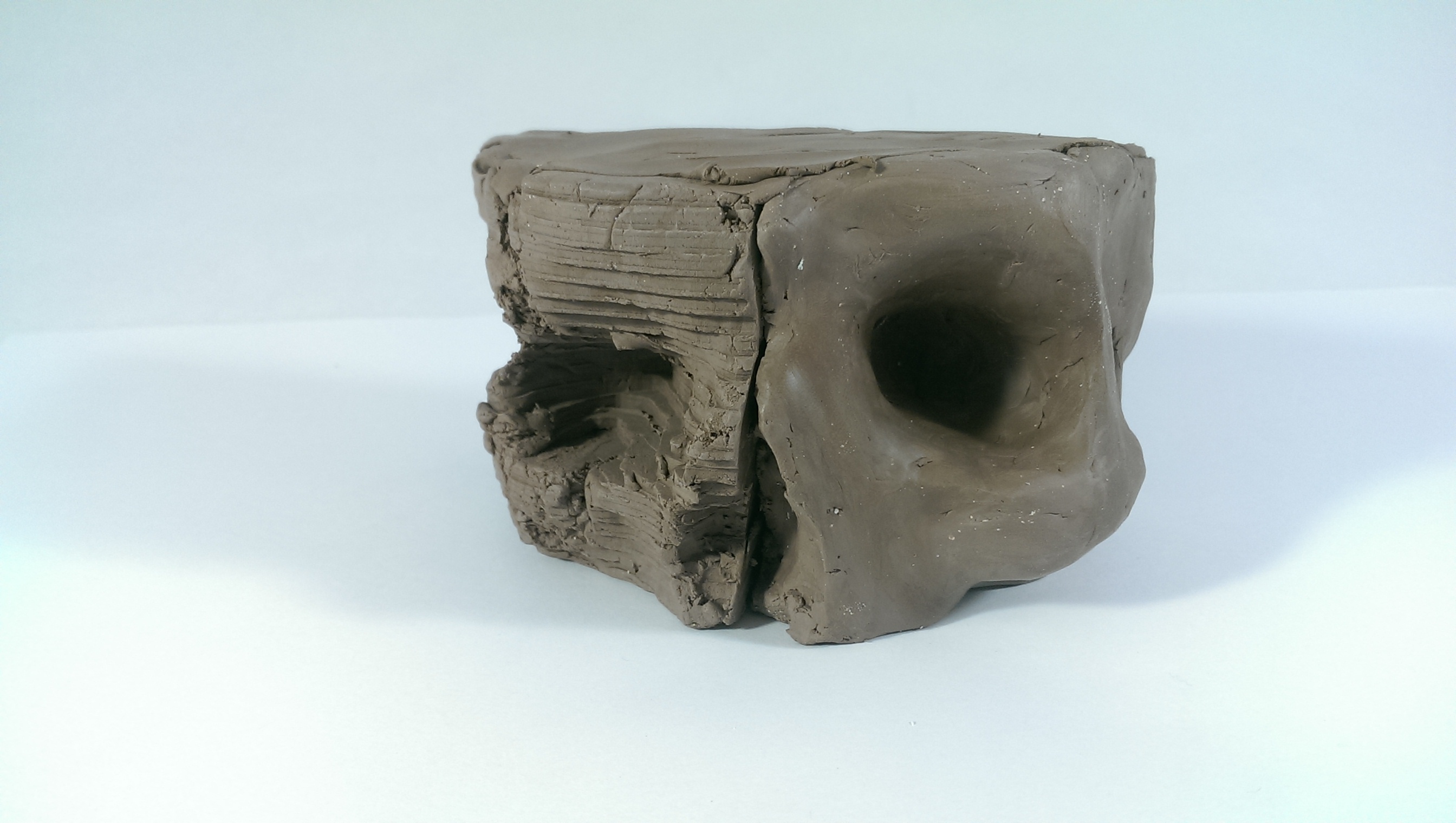

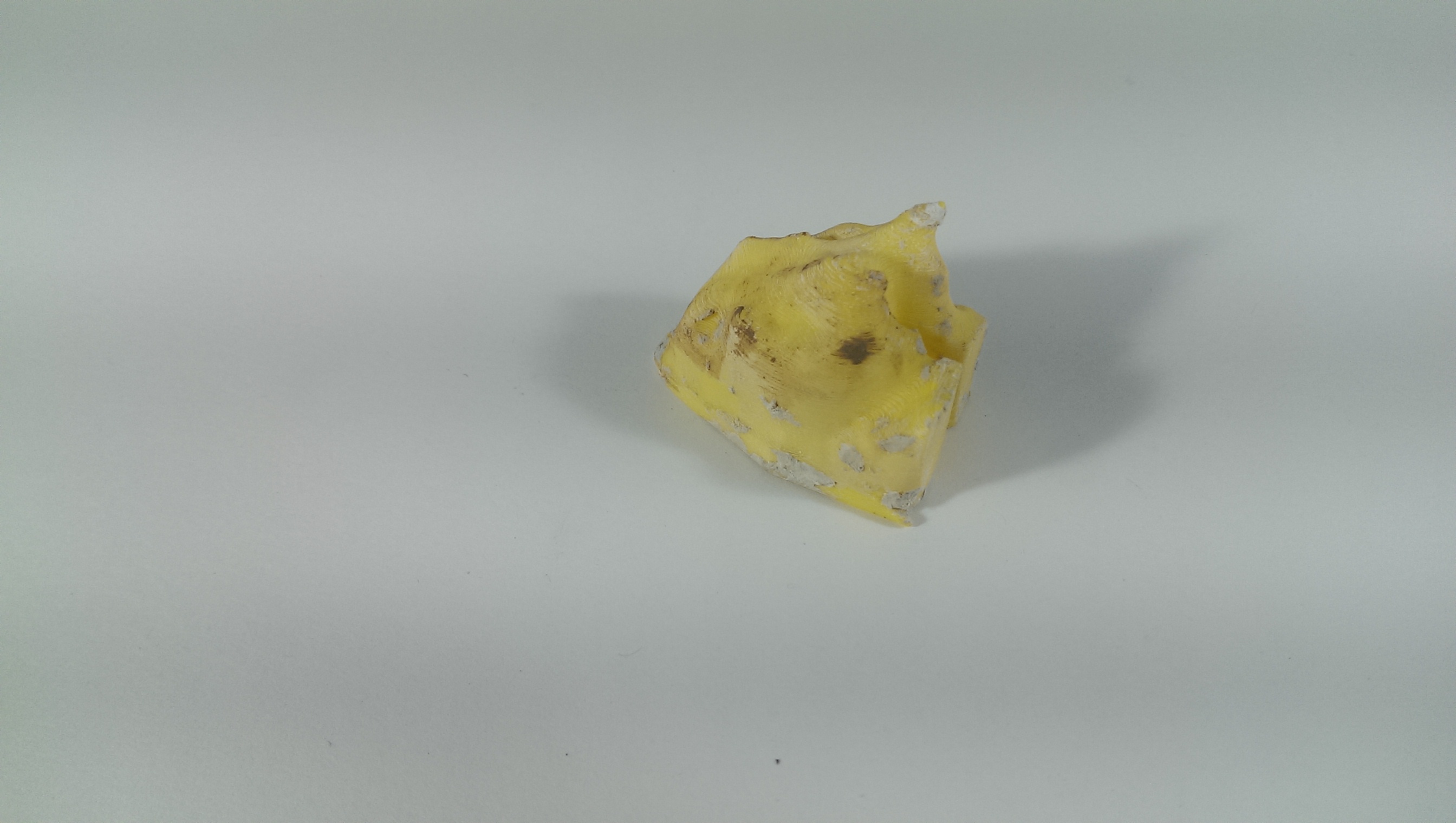

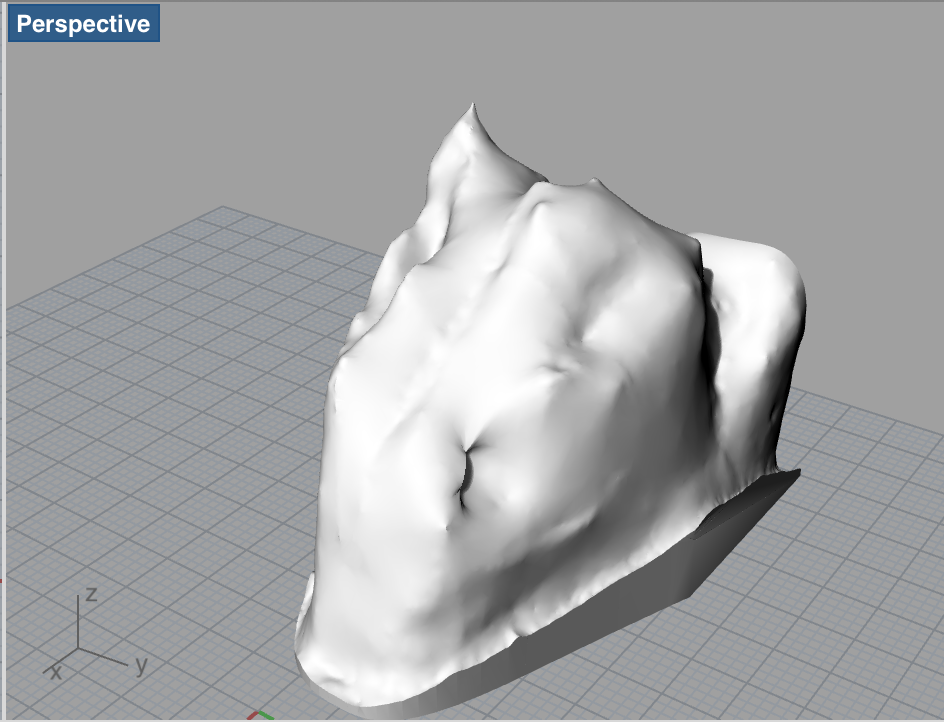

Our final product represents a spectrum of reverse engineering and fabrication processes. Half of the skull is a purely digital, rough reconstruction made by laser cutting contour templates and forming clay inside of them. The other half is a combination of hand work to smooth the molded form and more accurate reconstructions of the eye and nose cavity using custom 3D printed clay tools. We wanted to maintain the interesting geometry of the eye and nose cavity in a way that we couldn't achieve with pure hand work. The 3D printed stamps, based on models captured in 123D Catch, gave us a 3-dimensional base around which to build the refined clay model. The 3D printed stamps are the negatives of the nose and eye cavity. These areas were of specific interest to us because of their detail and refinement: we tried to replicate that with the combination of digital fabrication and traditional skill.