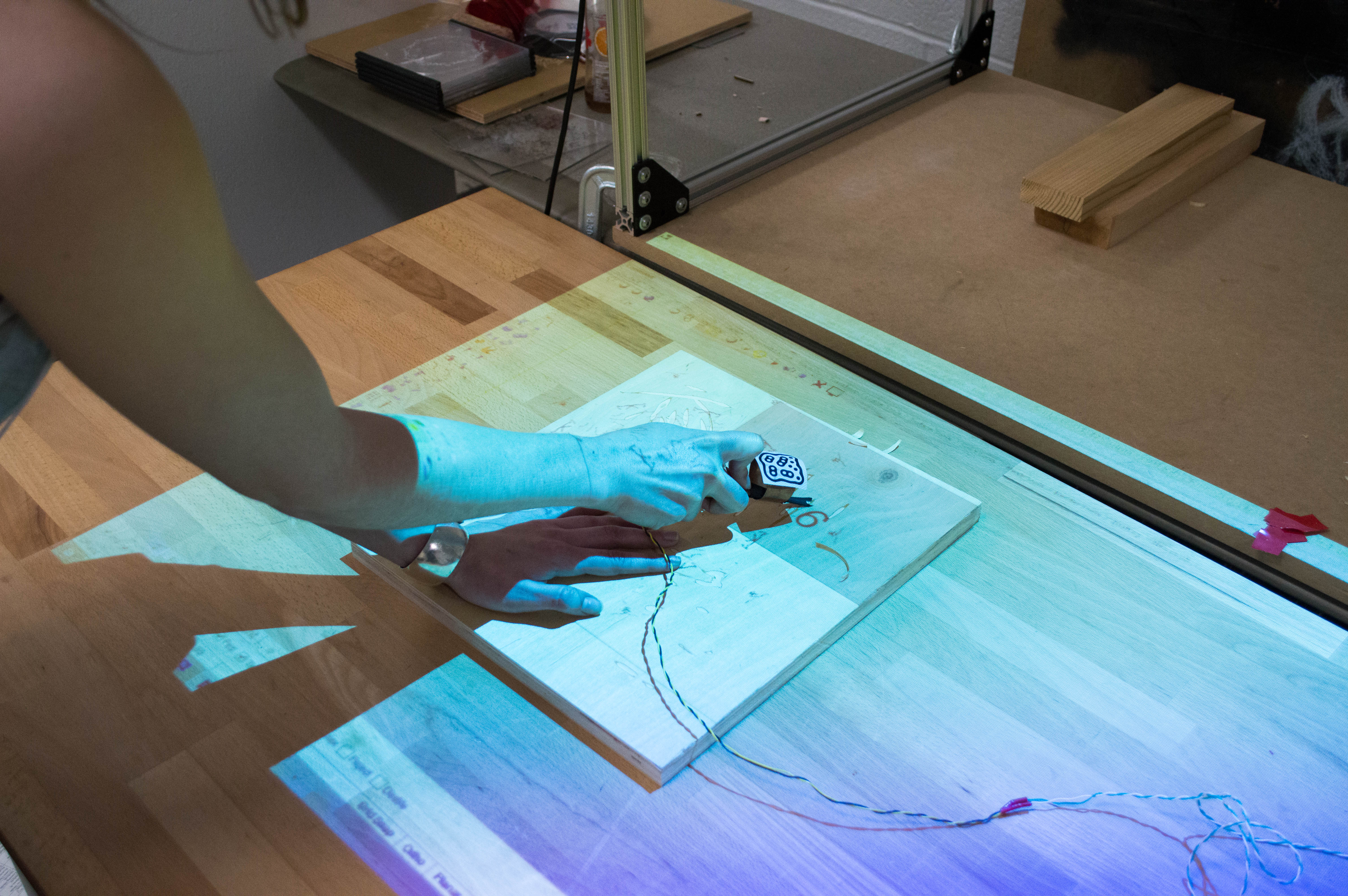

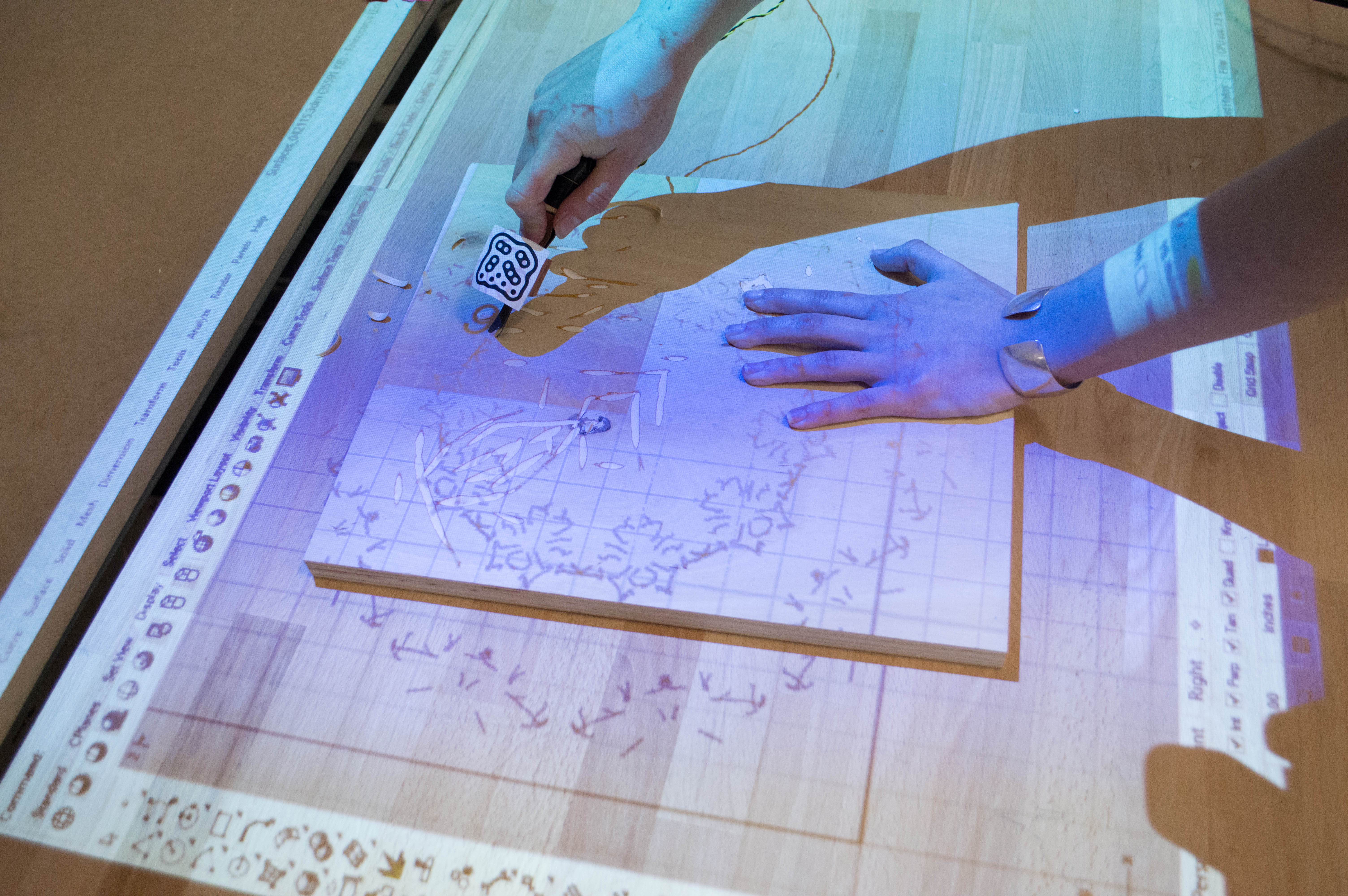

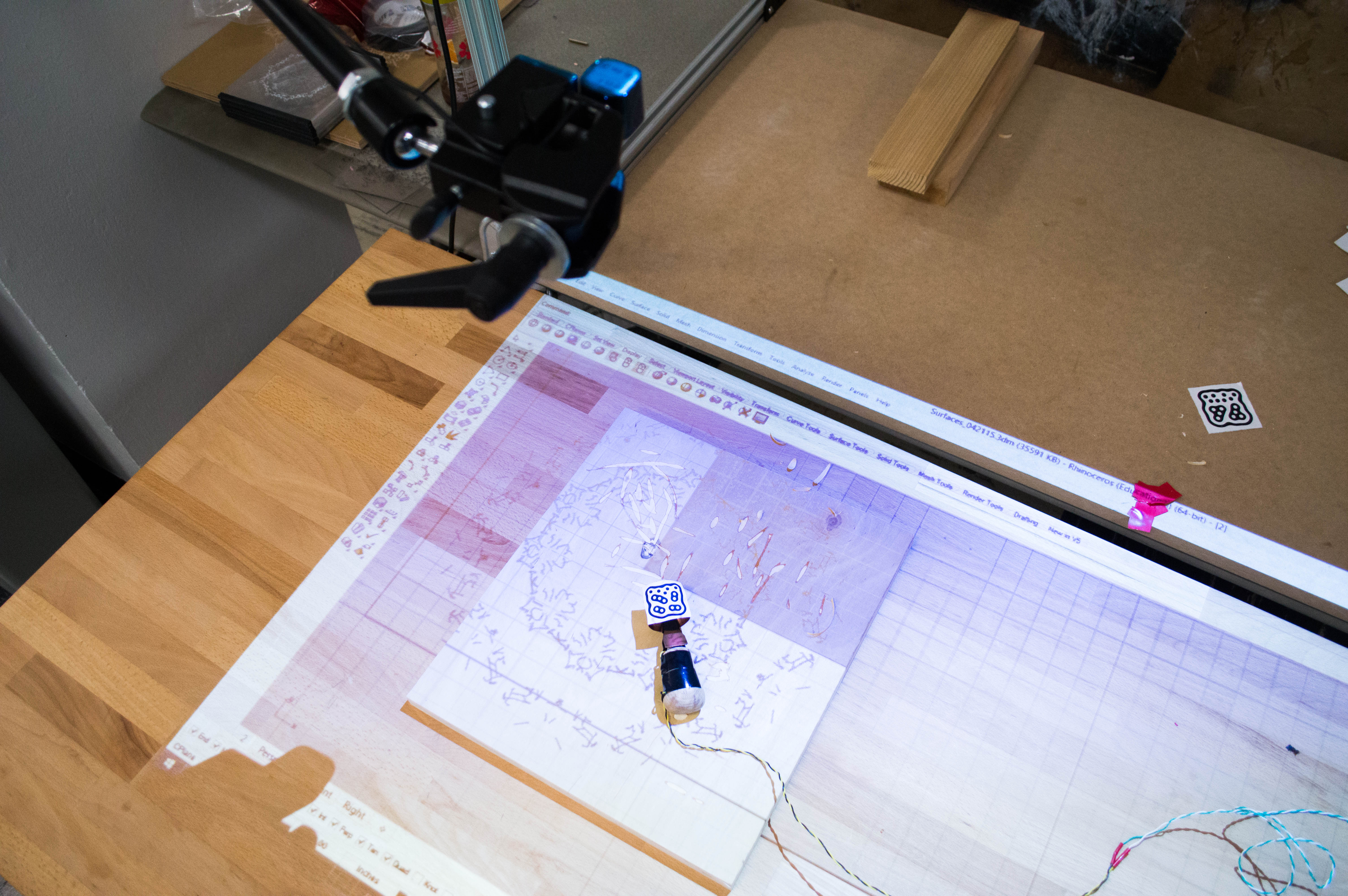

Mandala is a simple way for one to track their movements made when hand carving and then translate those tool paths into complex geometric patterns that mimic the style of mandala paintings. The hope for the project was that the user in the end would be able to take the line work generated by the carving to either use digital technology to reproduce, add to, and fabricate their project -- or they could also use the projection to then hand carve the object out of a wood block.

From the beginning, our group was interested in getting data from hand carved objects. However, we were not exactly sure how. We messed around with a lot of different methods, tracking color, trying to acquire depth data, and hand tracking. They all turned out a bit too complex. What we landed on the idea of using a simple palm chisel with a reactivision tag mounted in close range to a high resolution camera to track the tool. Next, we augmented the tool with the tag and also a button. The button allowed us to know when pressure had been applied to the tool signaling that the user is carving. The signal from the button is connected to Grasshopper through Firefly and Arduino, where it is combined with the reactivision data to create the raw tool path files.