Reflection

Once I realized what I wanted, I selected an awl with a sturdy, wooden handle and a built in bobbin. It came with one straight needle and one curved one. I selected a strap of leather in the hopes of making a dog collar. The stitch was easy enough with the straight needle, but the curved one was far more useful for getting the right tension when pulling the needle out of the leather.

I made two rows of running stitches, one with each needle. I tried to time myself for each to understand efficiency, but as I became more proficient, the difference in efficiency was impossible to measure. I really like the sewing technique of using an awl and will definitely use it for projects in the future.

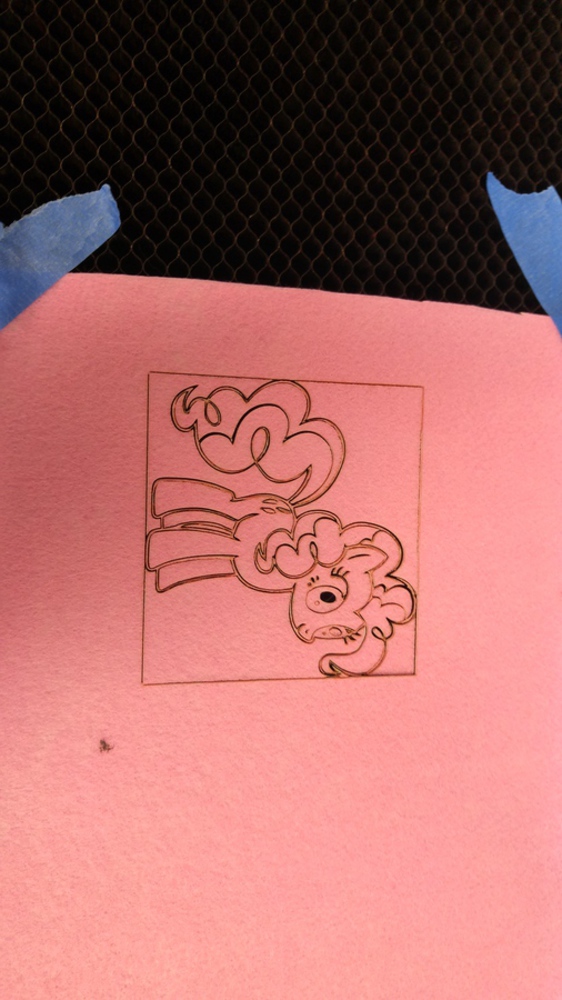

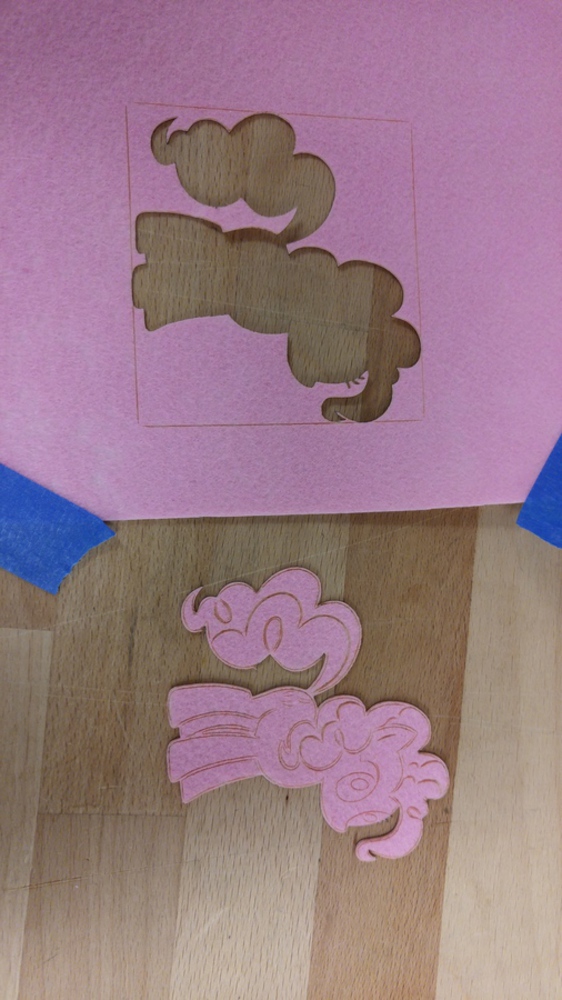

For continuing the project and on all future project, it makes more sense to combine multiple techniques. For example, as sharp and sturdy as the awl needles are, I will laser cut my seam holes so I merely have to insert the needle to make my lock stitch. This ensures straight rows and less damage to equipment and hands.

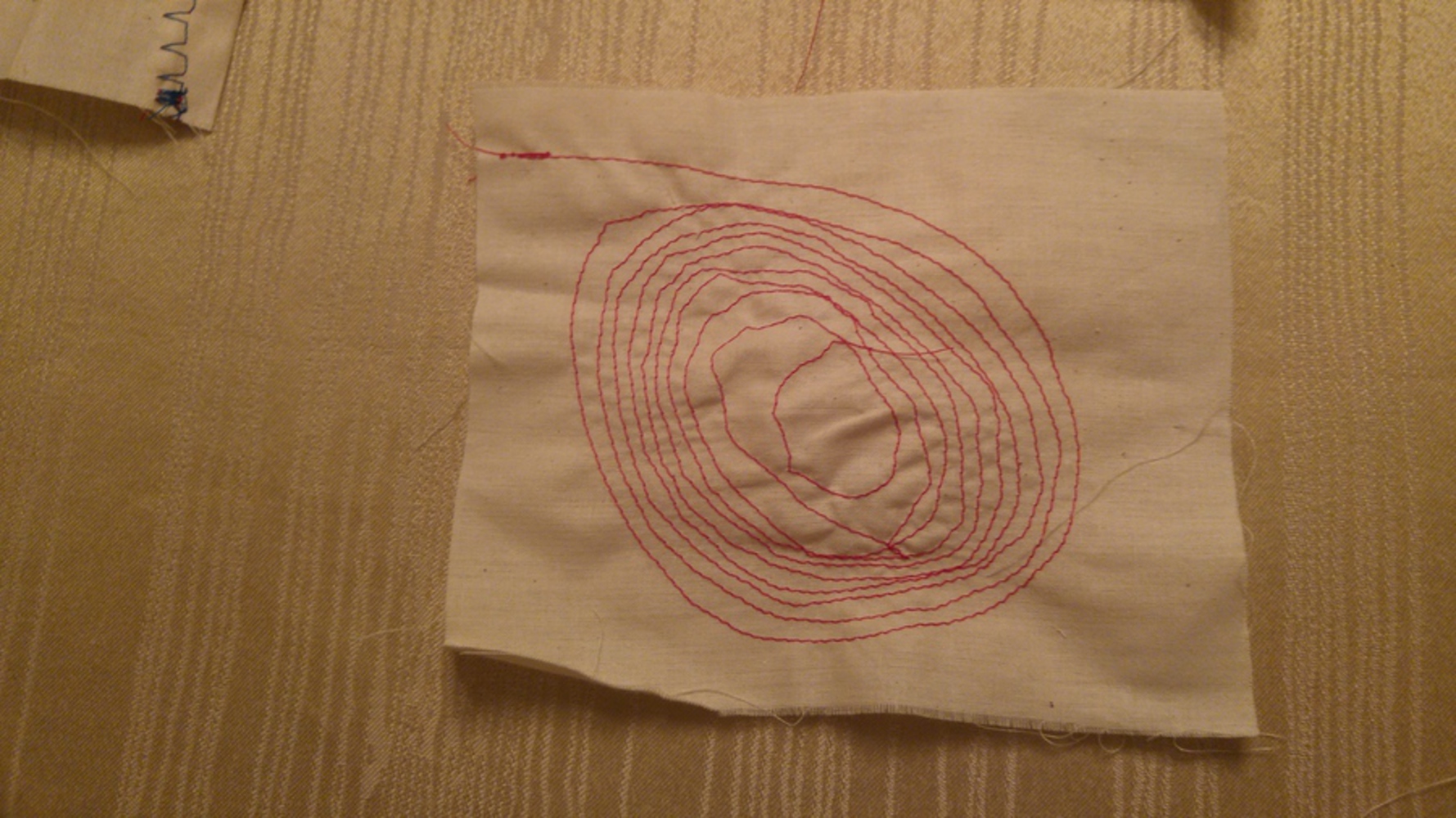

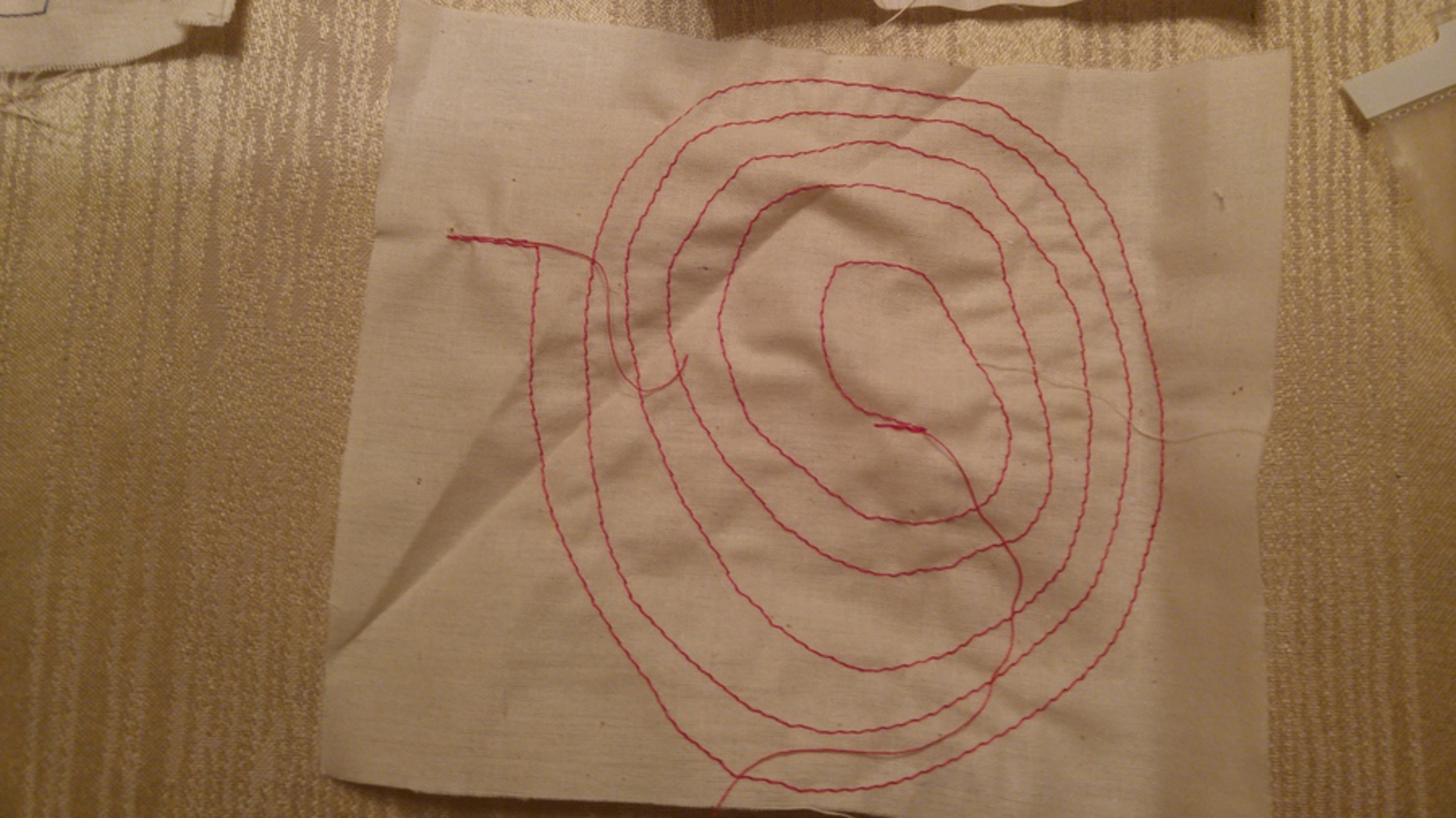

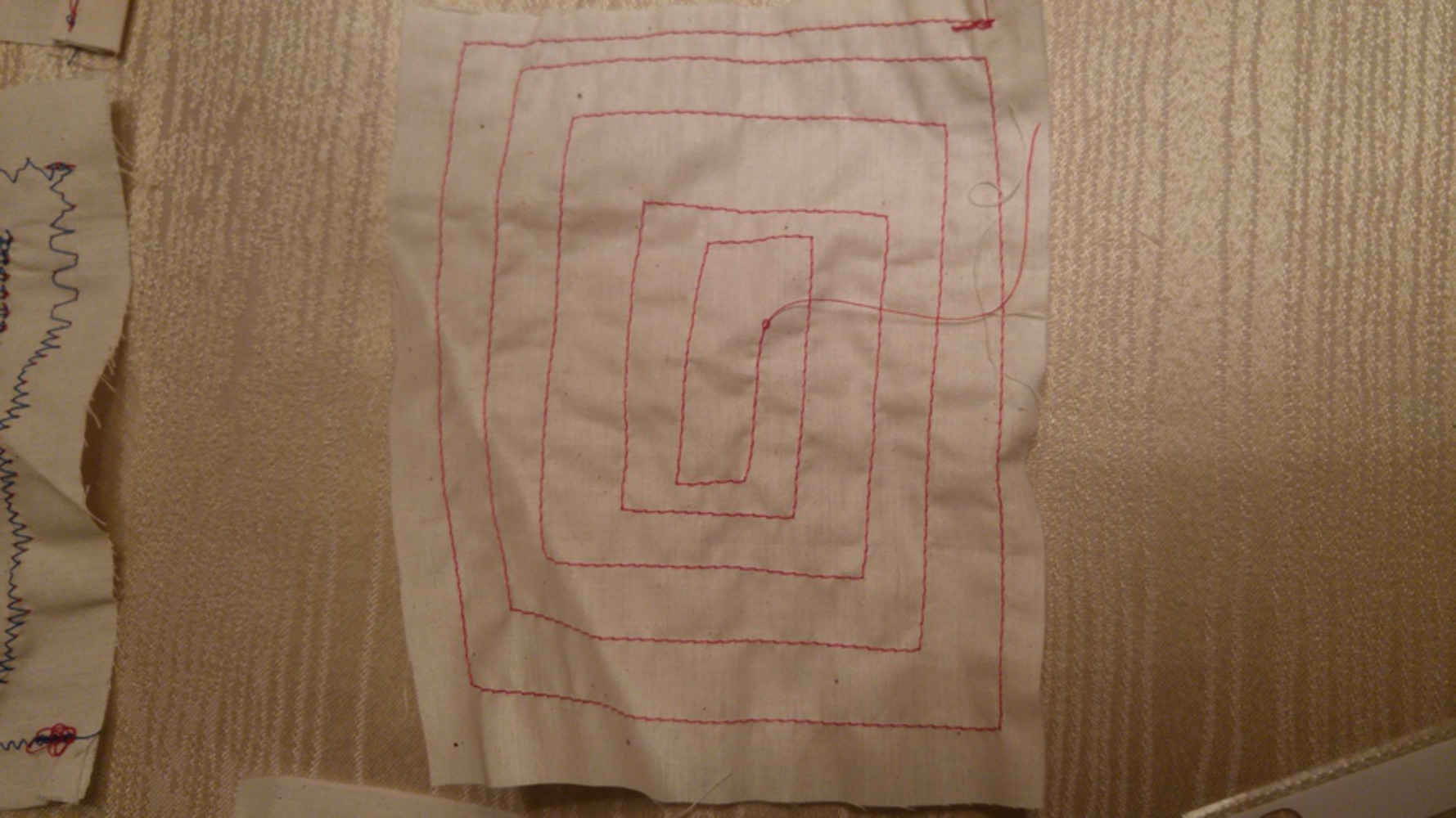

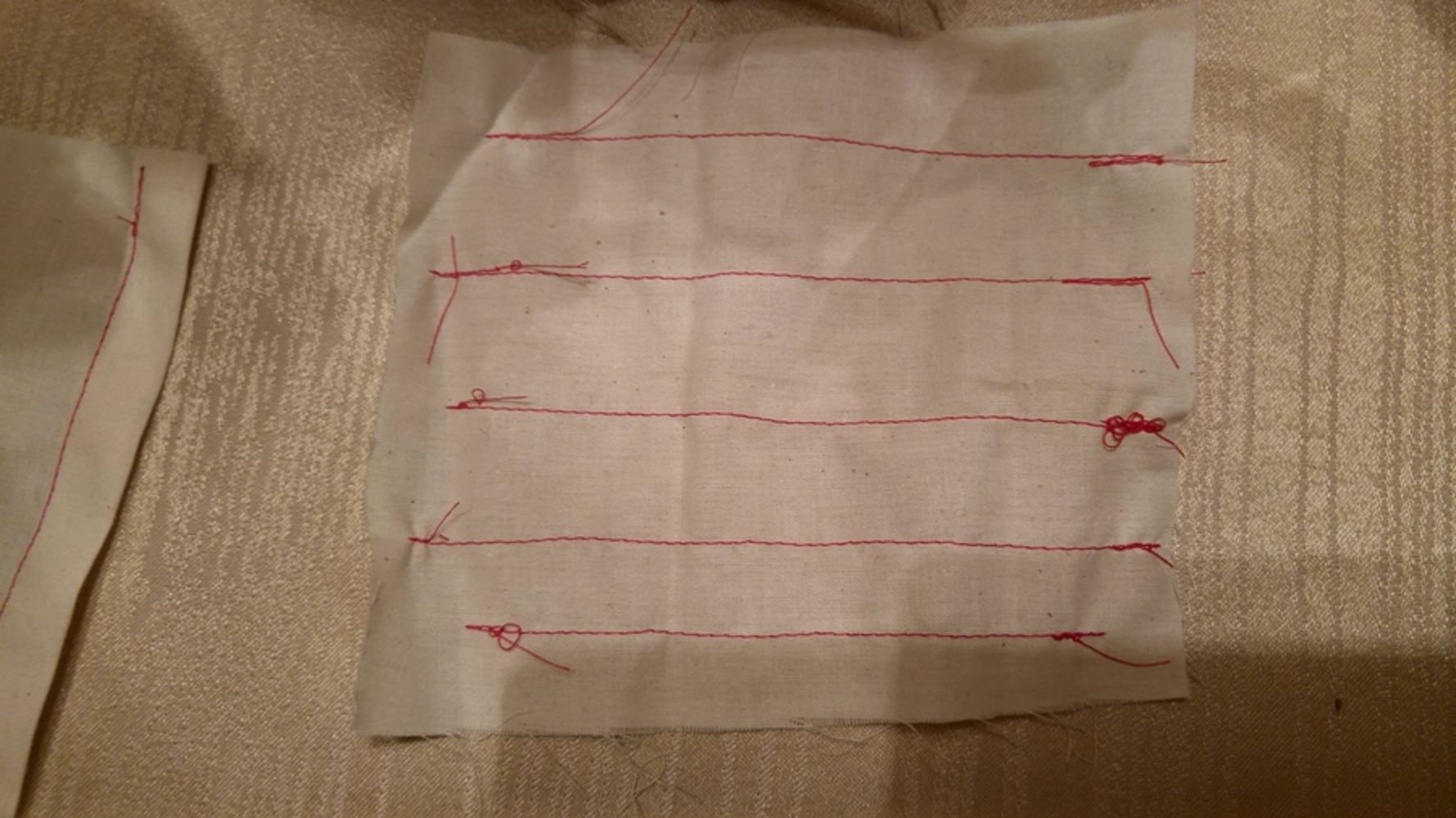

Sample Book:

Below are some of the pieces made during the course, including the sewing awl project.