I LARP. It means I dress up as someone I'm not, in a place I'm not, in a time I'm not in, and run around in the woods hitting other people doing the exact same things with a sword made out of some foam and a golf club. And I enjoy it a lot.

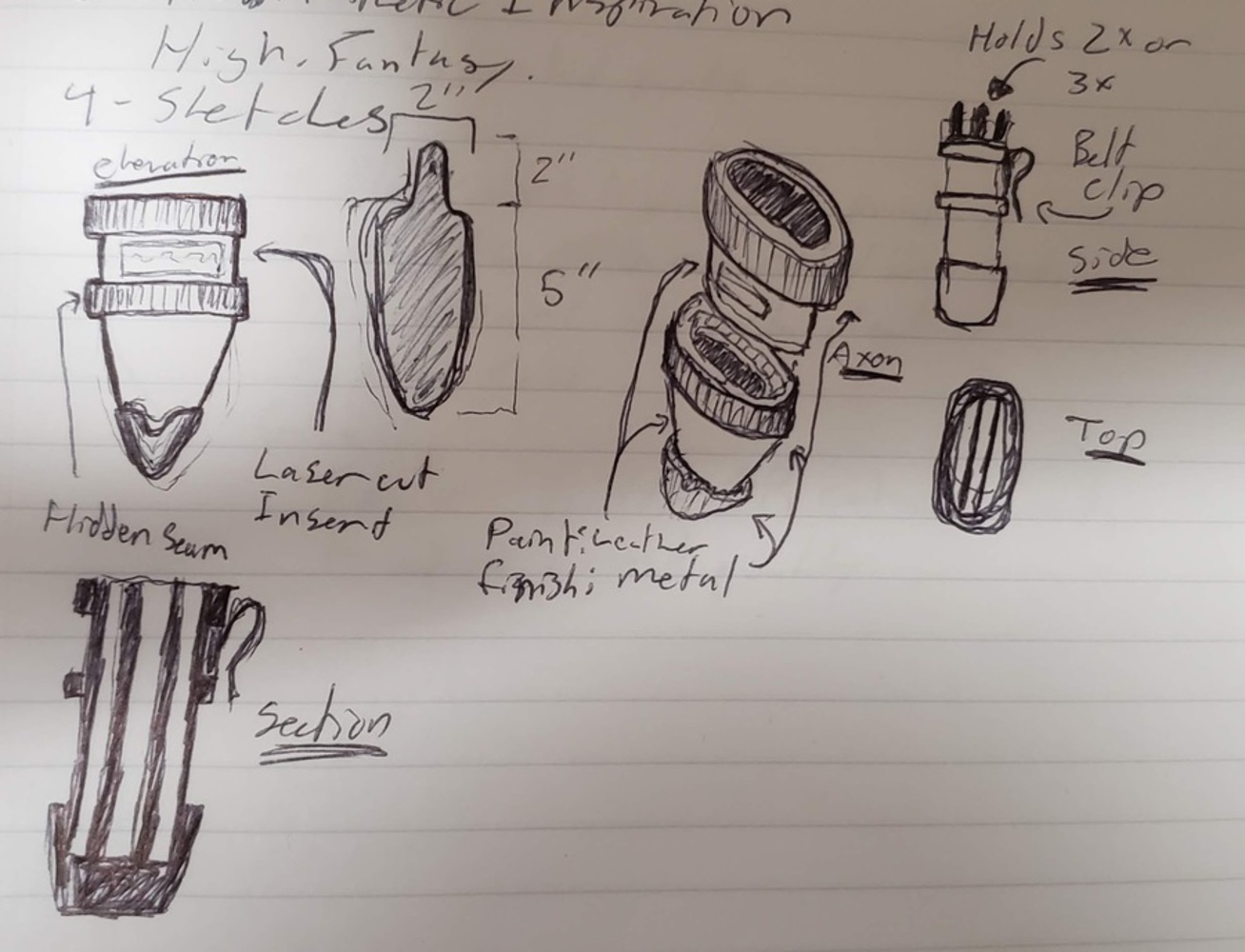

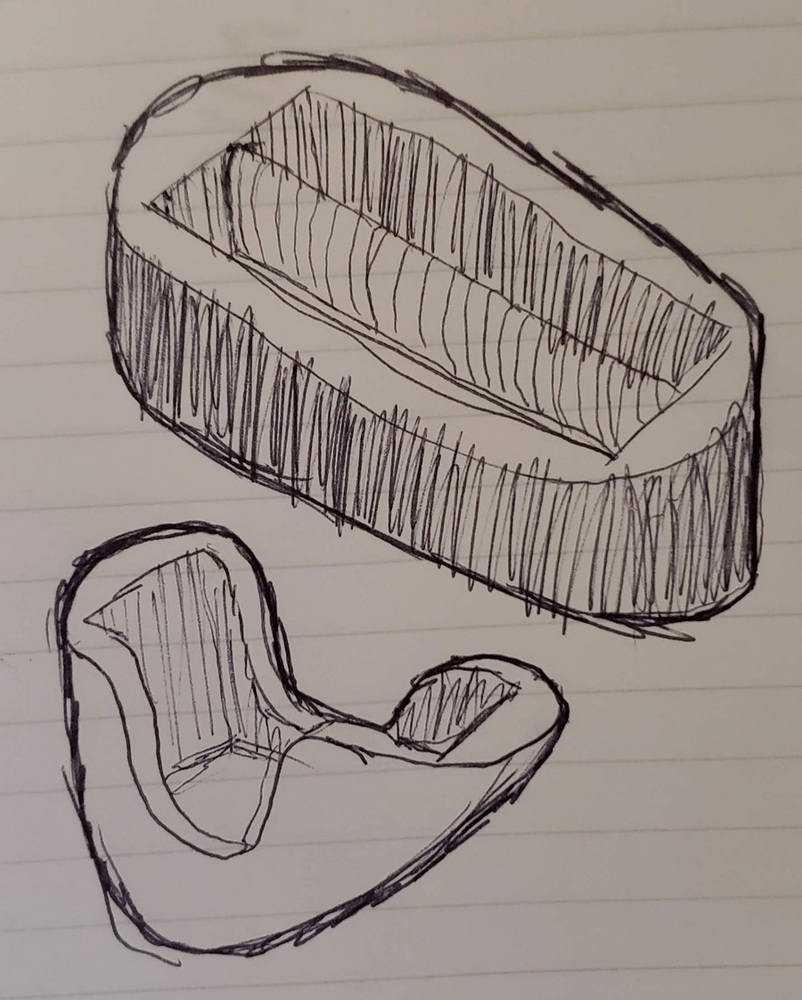

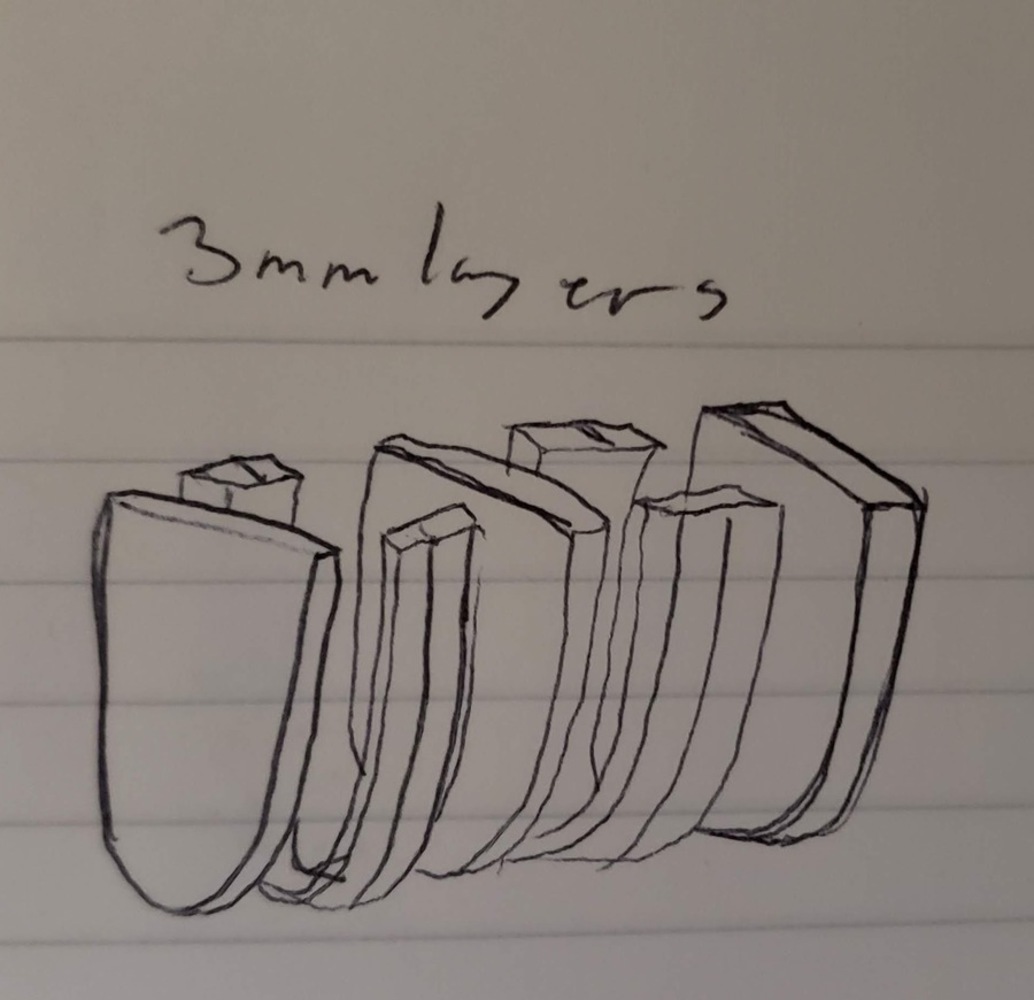

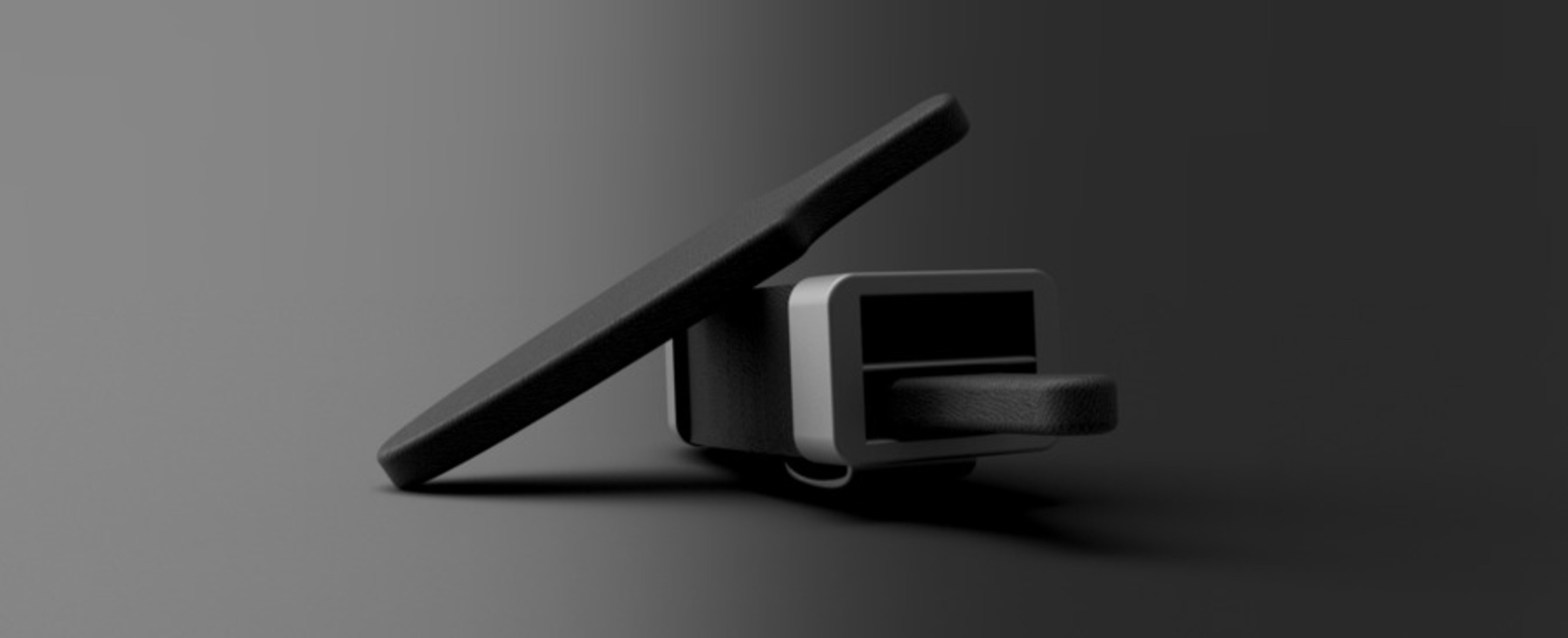

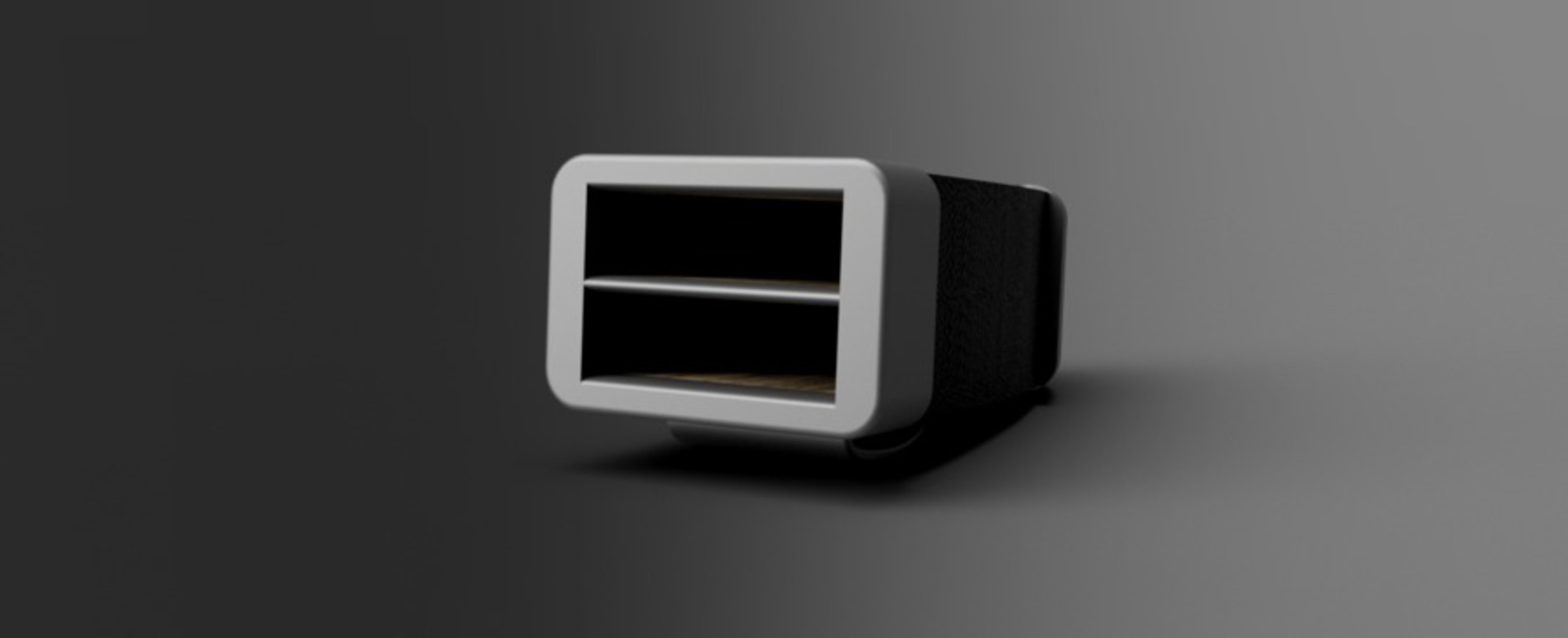

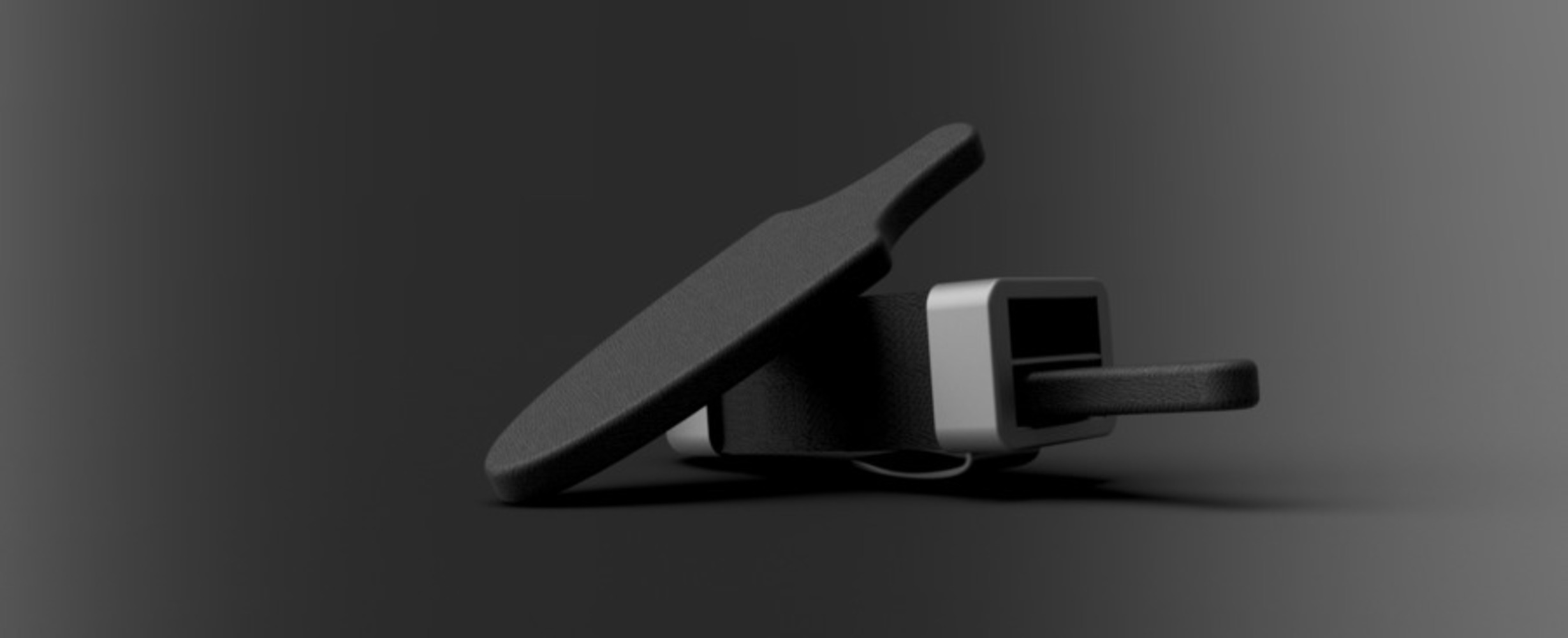

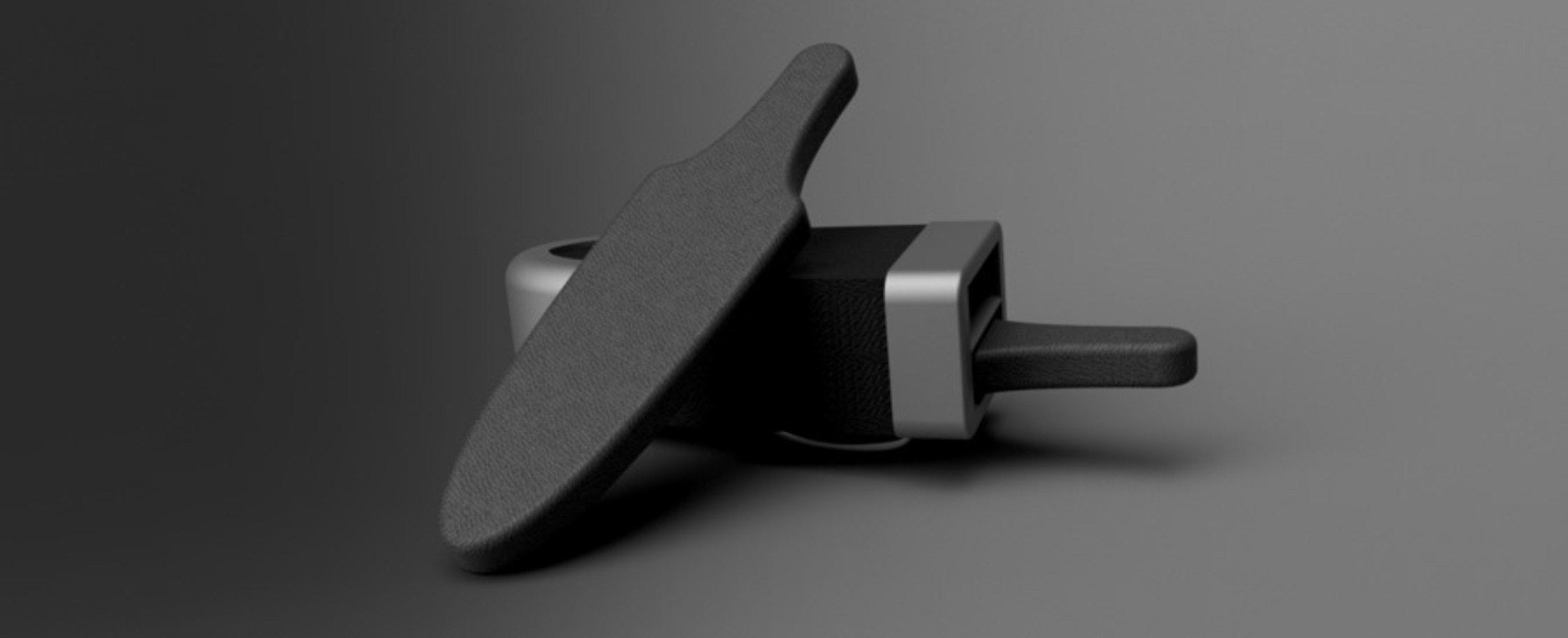

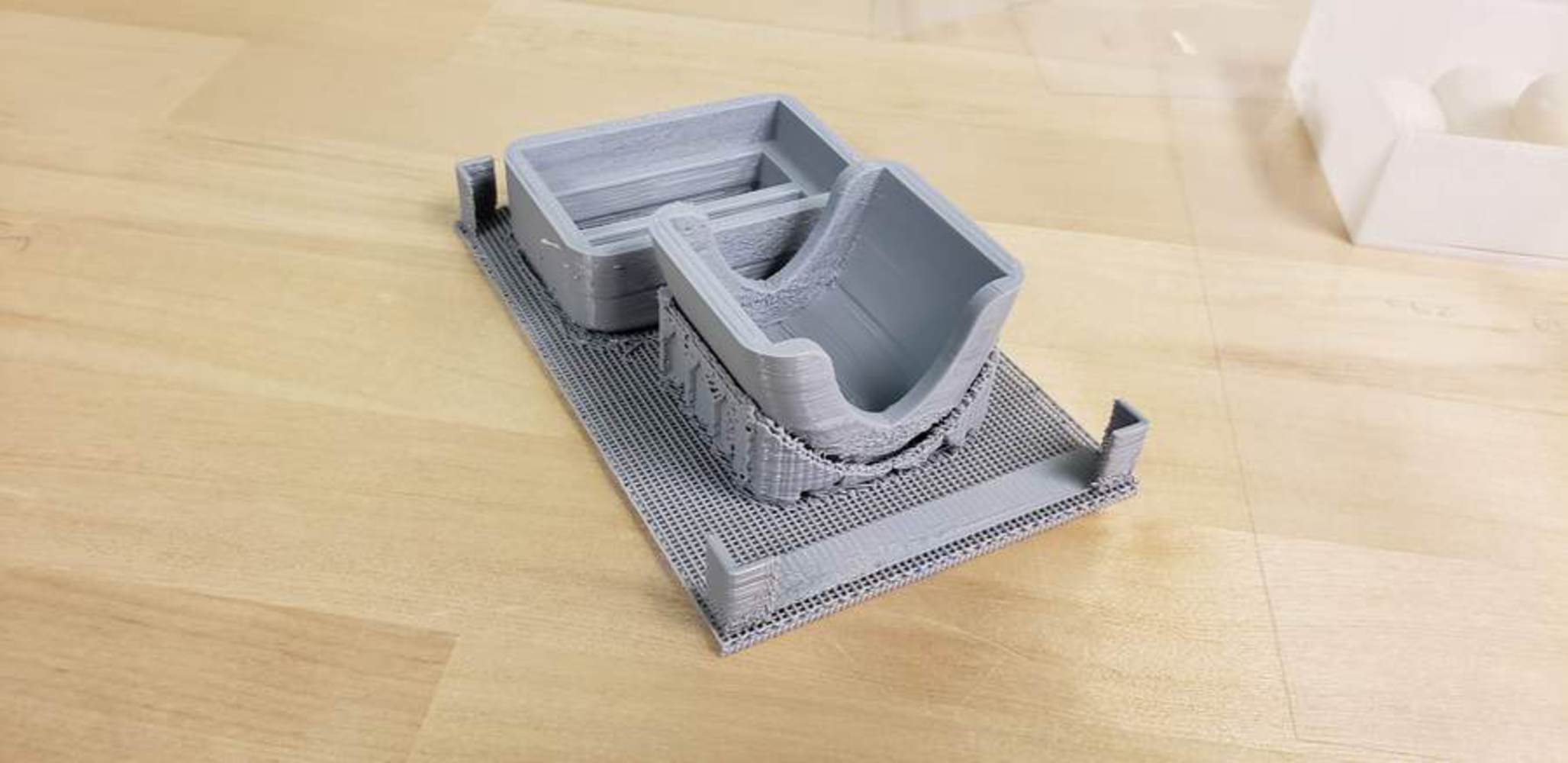

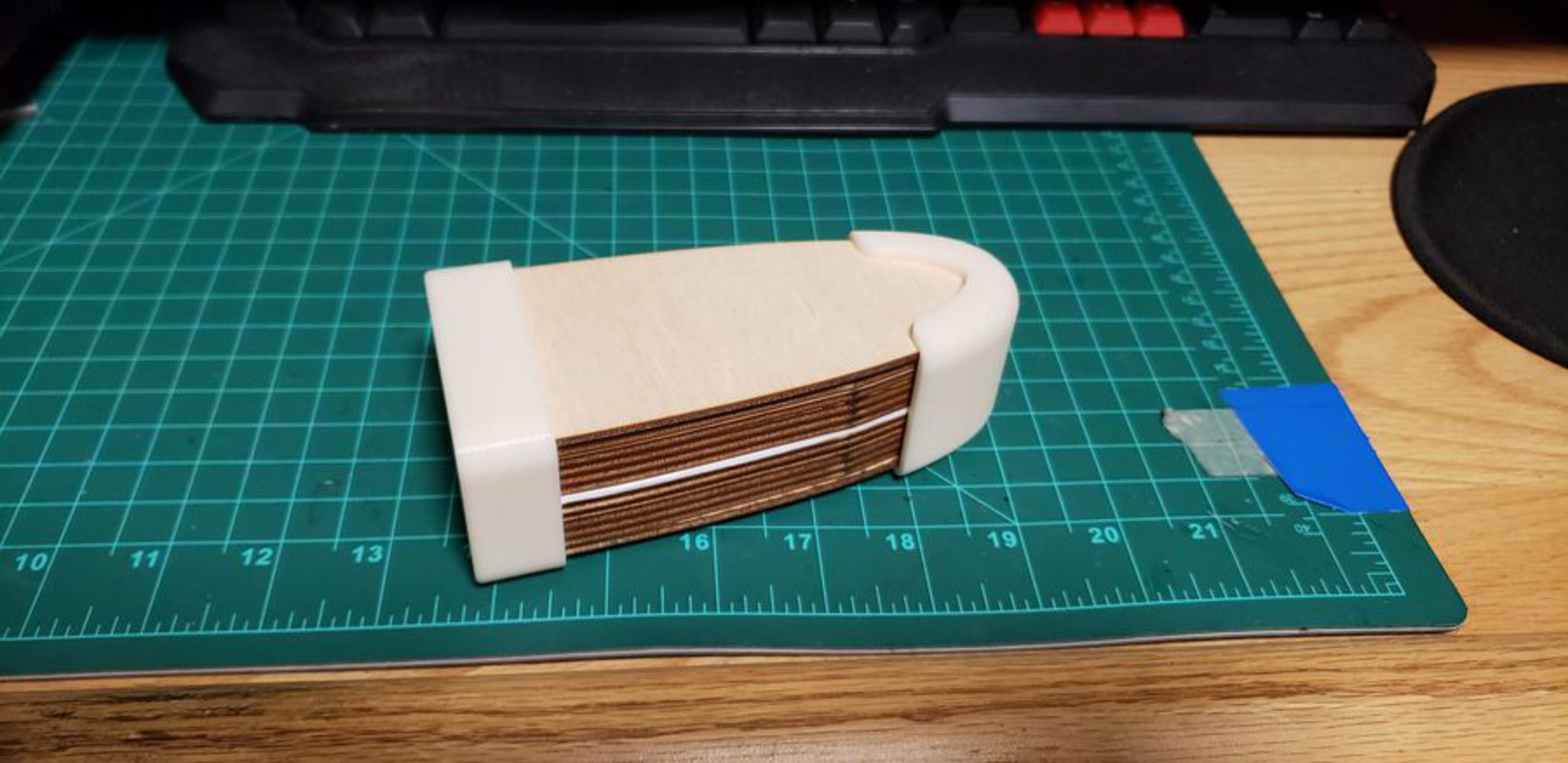

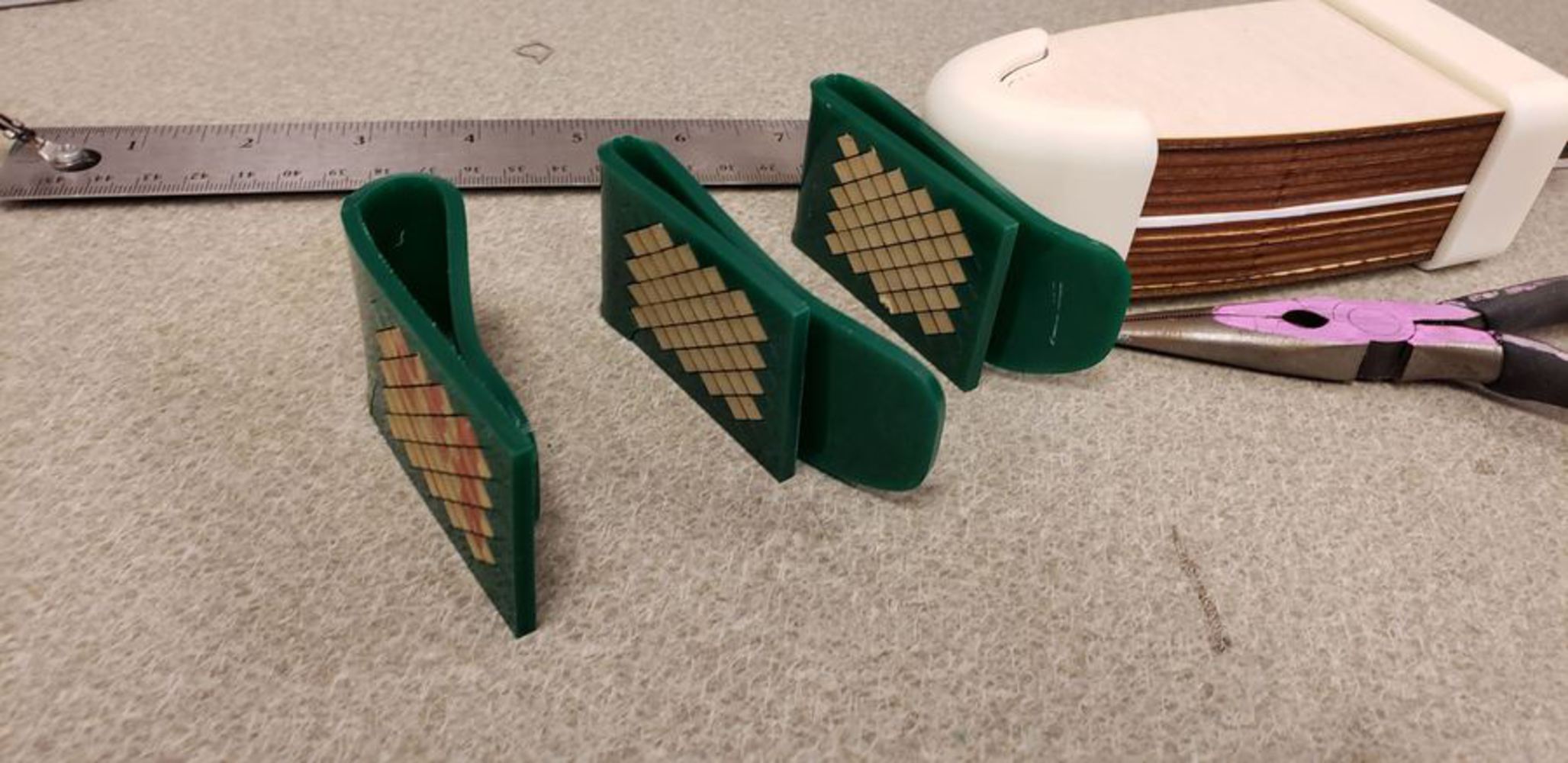

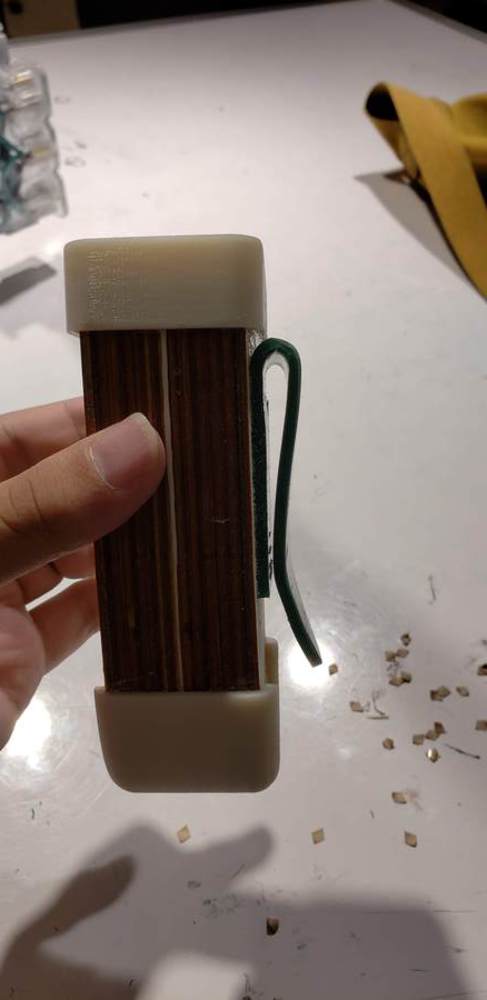

Part of the point of LARP is to have fun. So, I have fun when I can throw these foam throwing daggers, because nobody else does and it's satisfying getting those sneak attacks in. However, I only have built storage that's quick and easy to access, and this holds tow of these guys. It's not that fun when you have to think about picking them up right after you've thrown them.

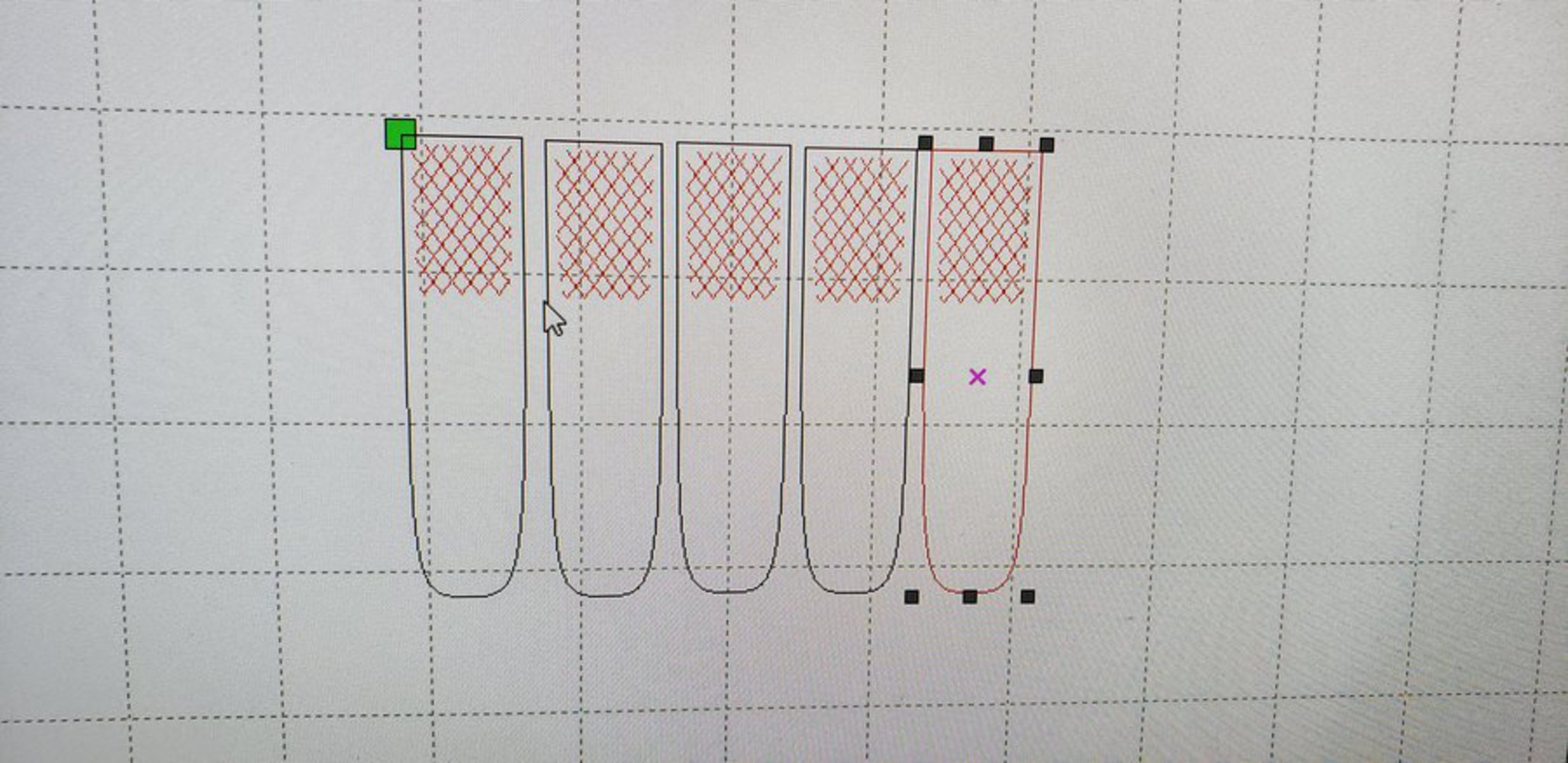

My goal, then , was to be able to hold as many as these guys on me as I possibly could, and I had a lot of empty belt room.