Intention

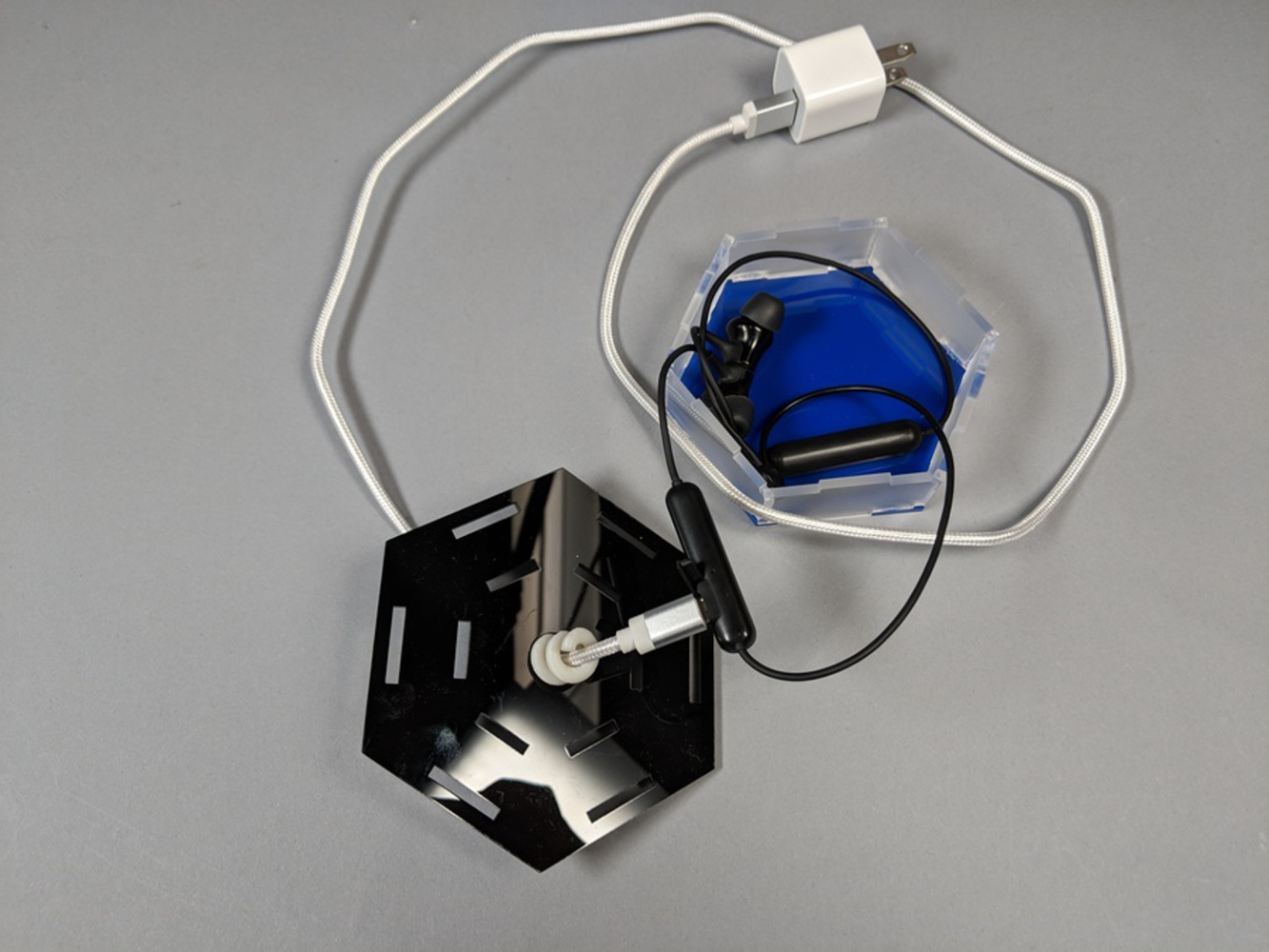

Next to my desk are a bunch of cords belonging to a variety of small devices like external chargers and earbuds of different kinds. It becomes tangled and trying to pull one set of earbuds without unplugging anything else is difficult. It is also hard to manage the cords when going on a trip and making sure to always bring the right one.

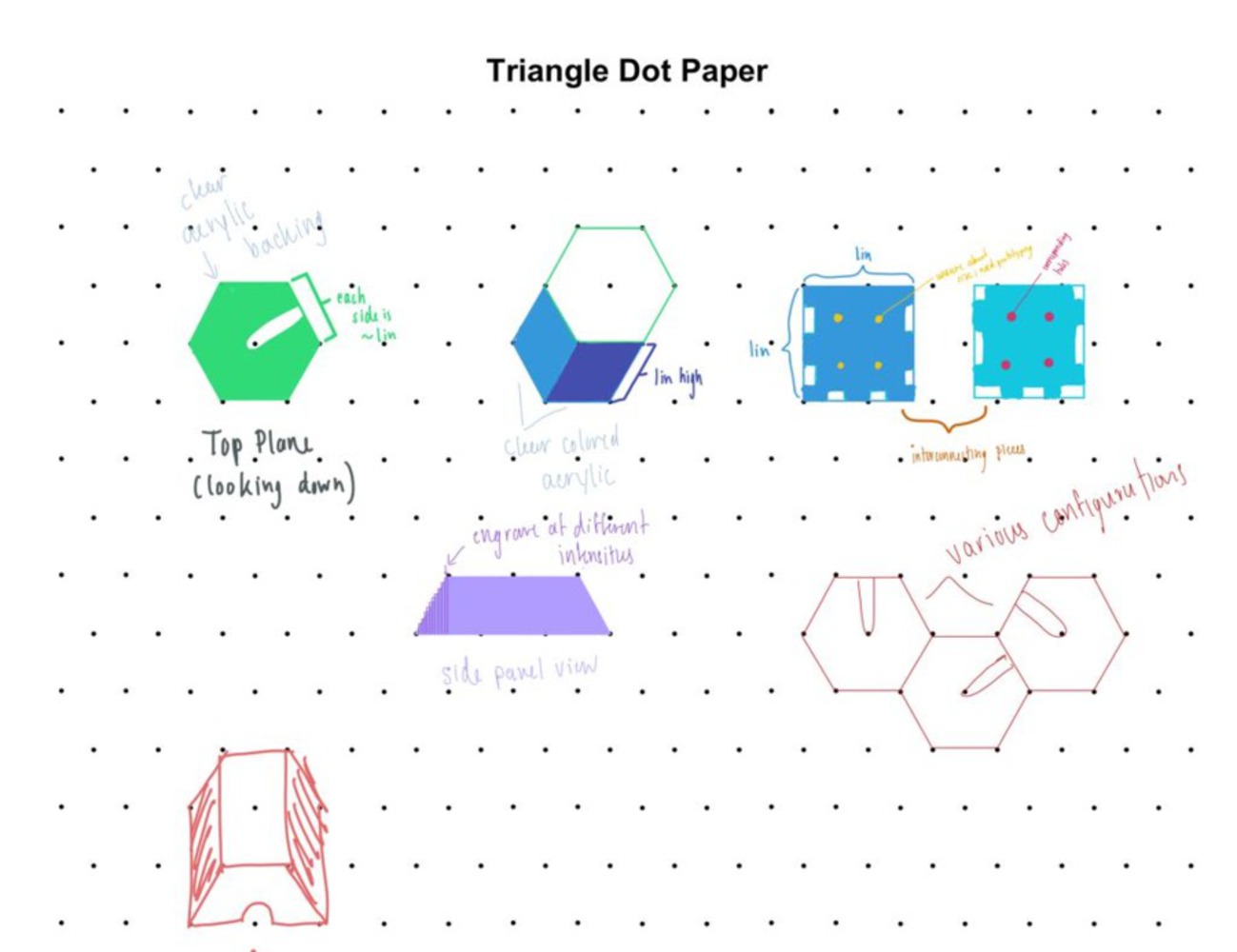

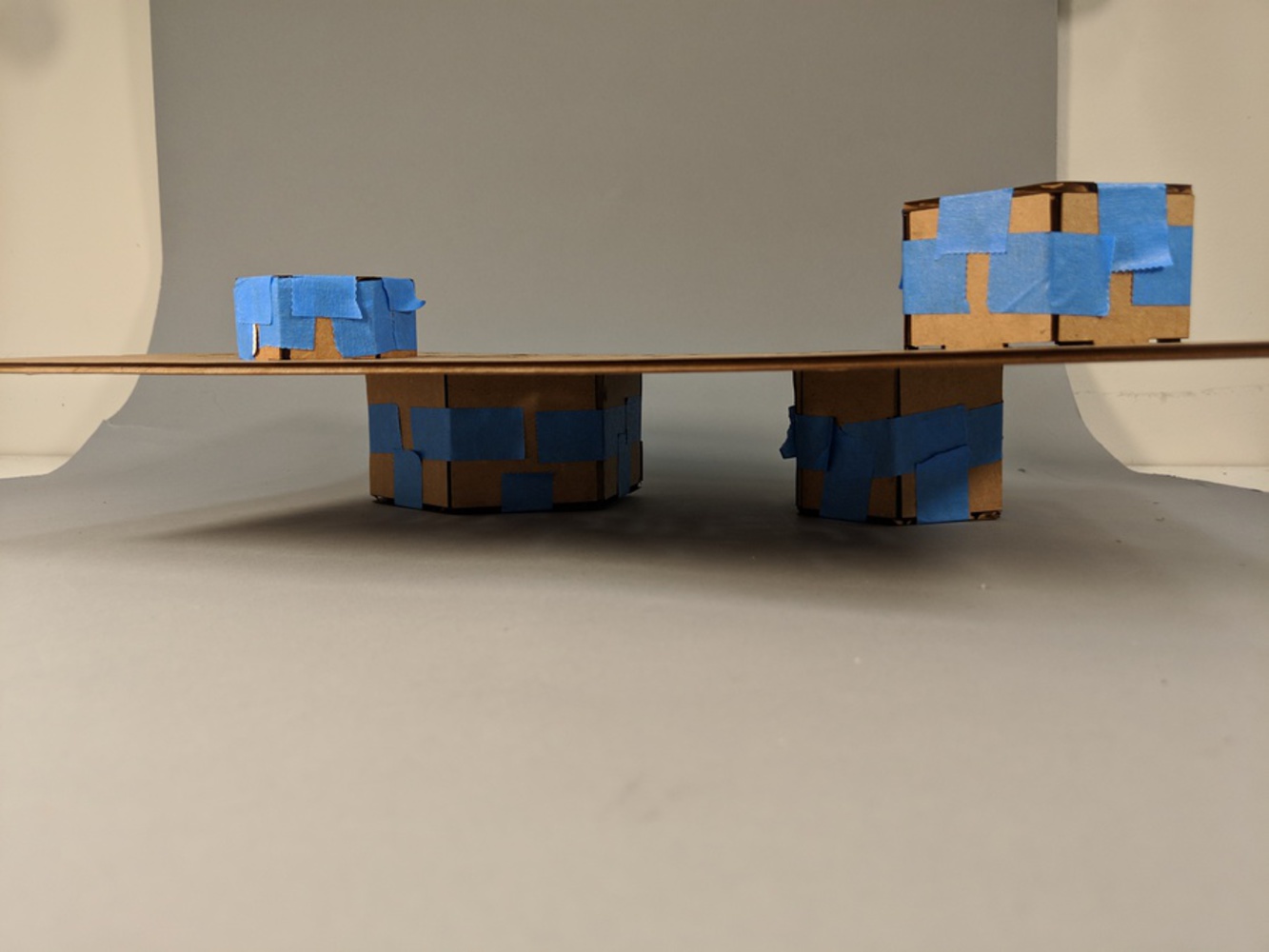

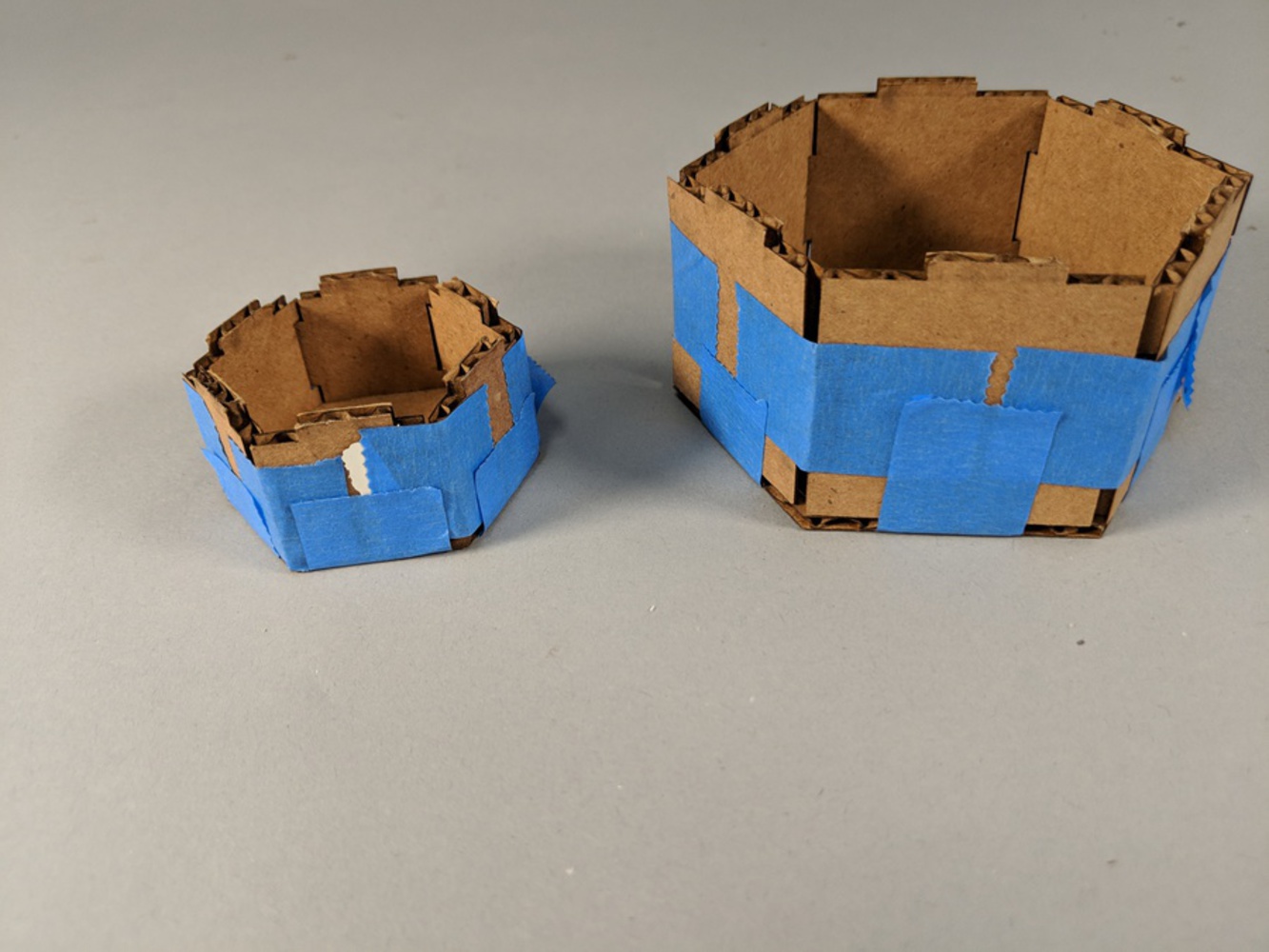

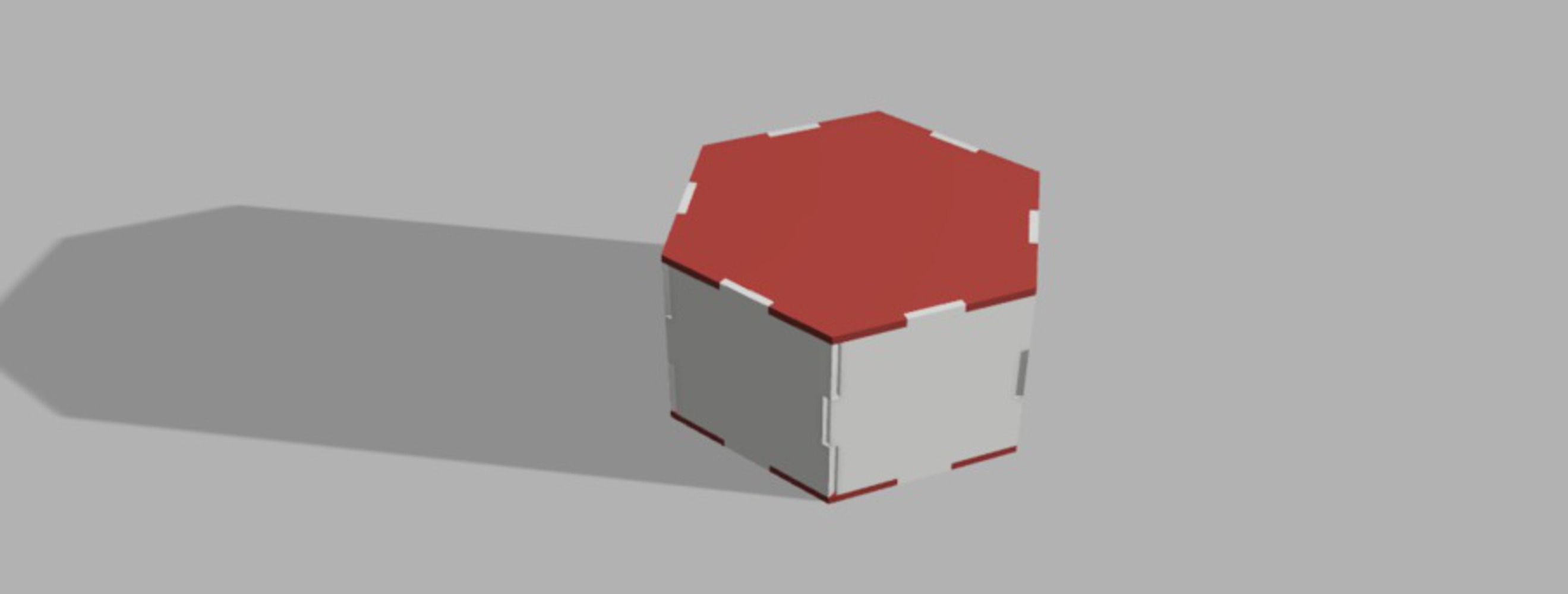

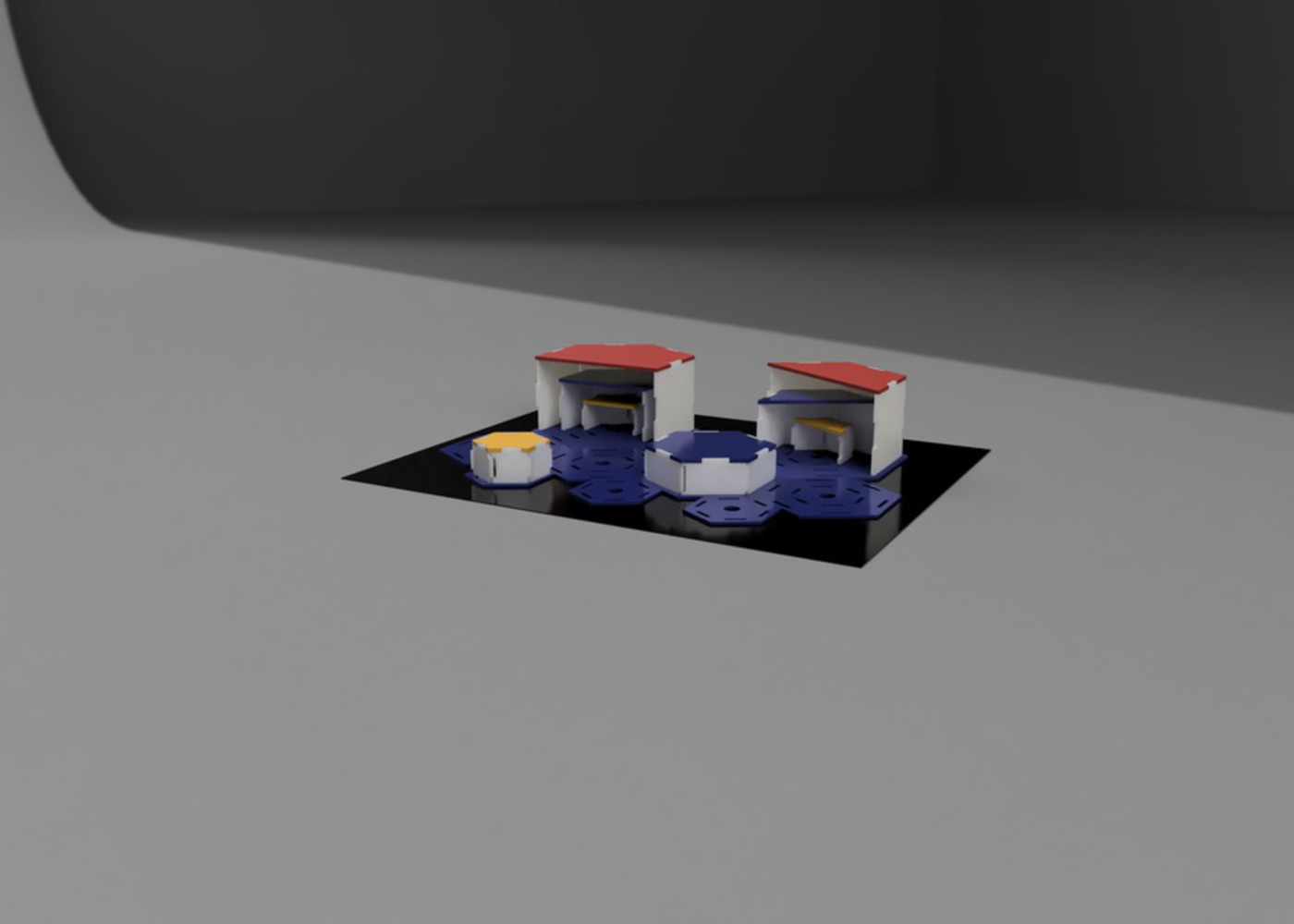

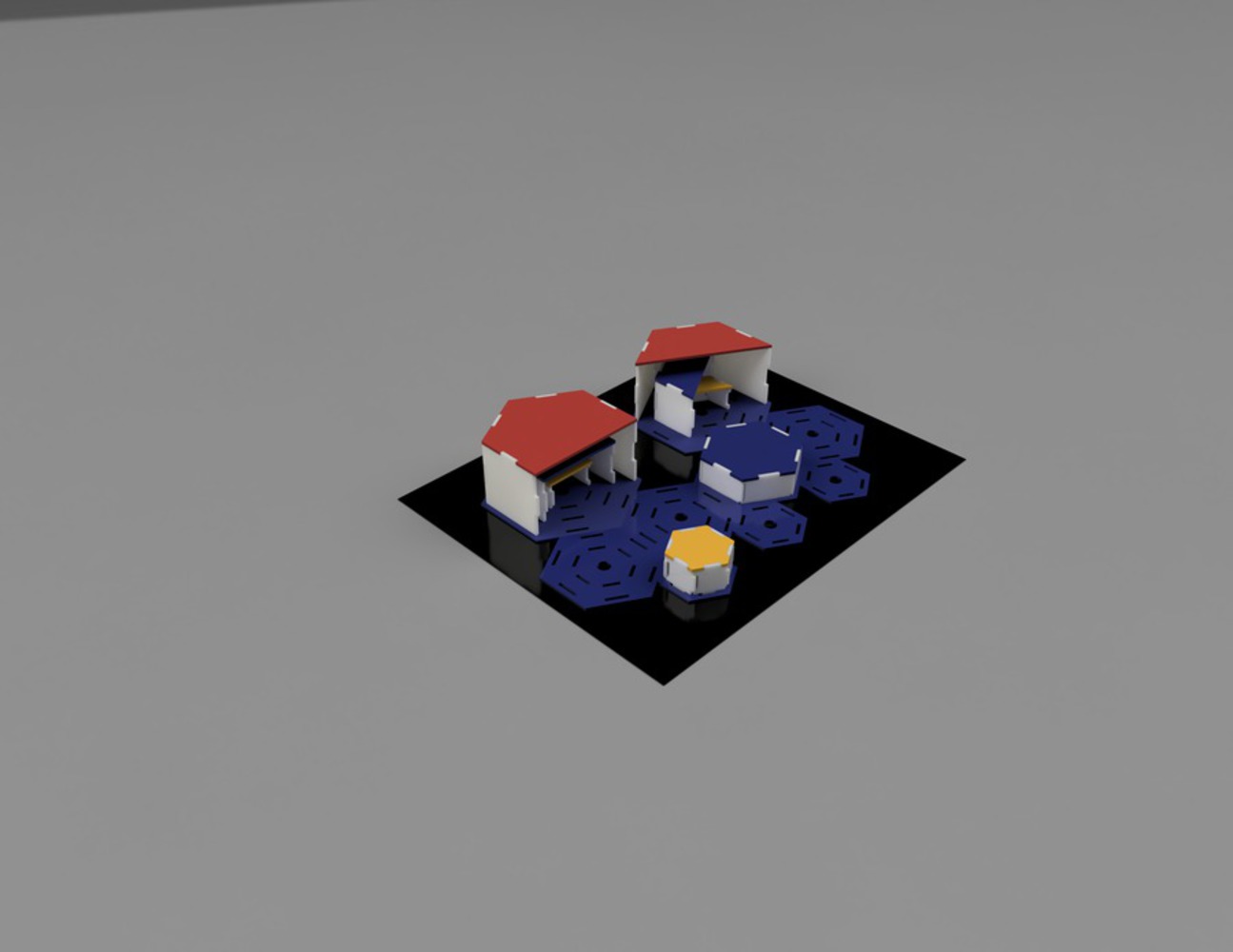

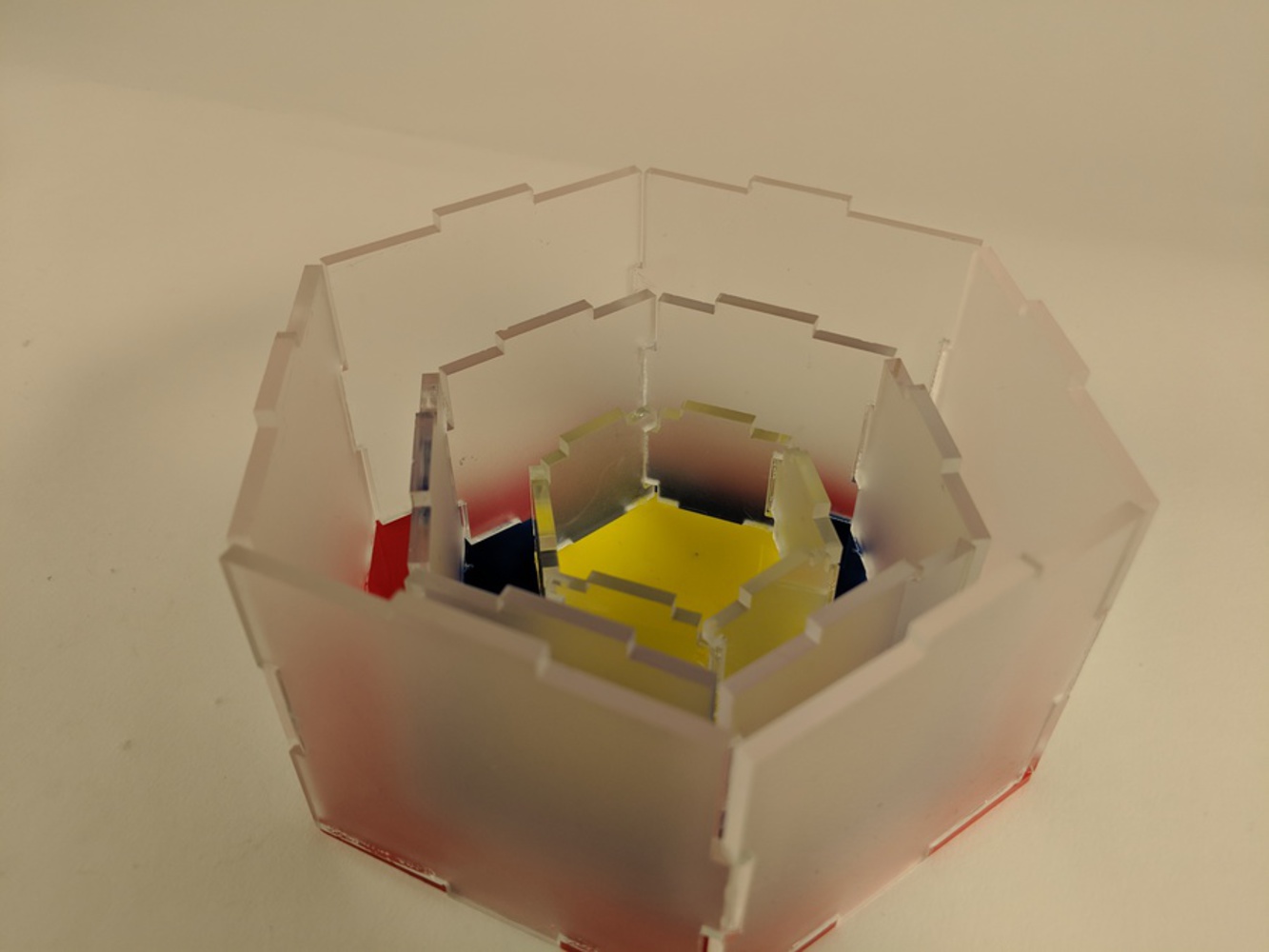

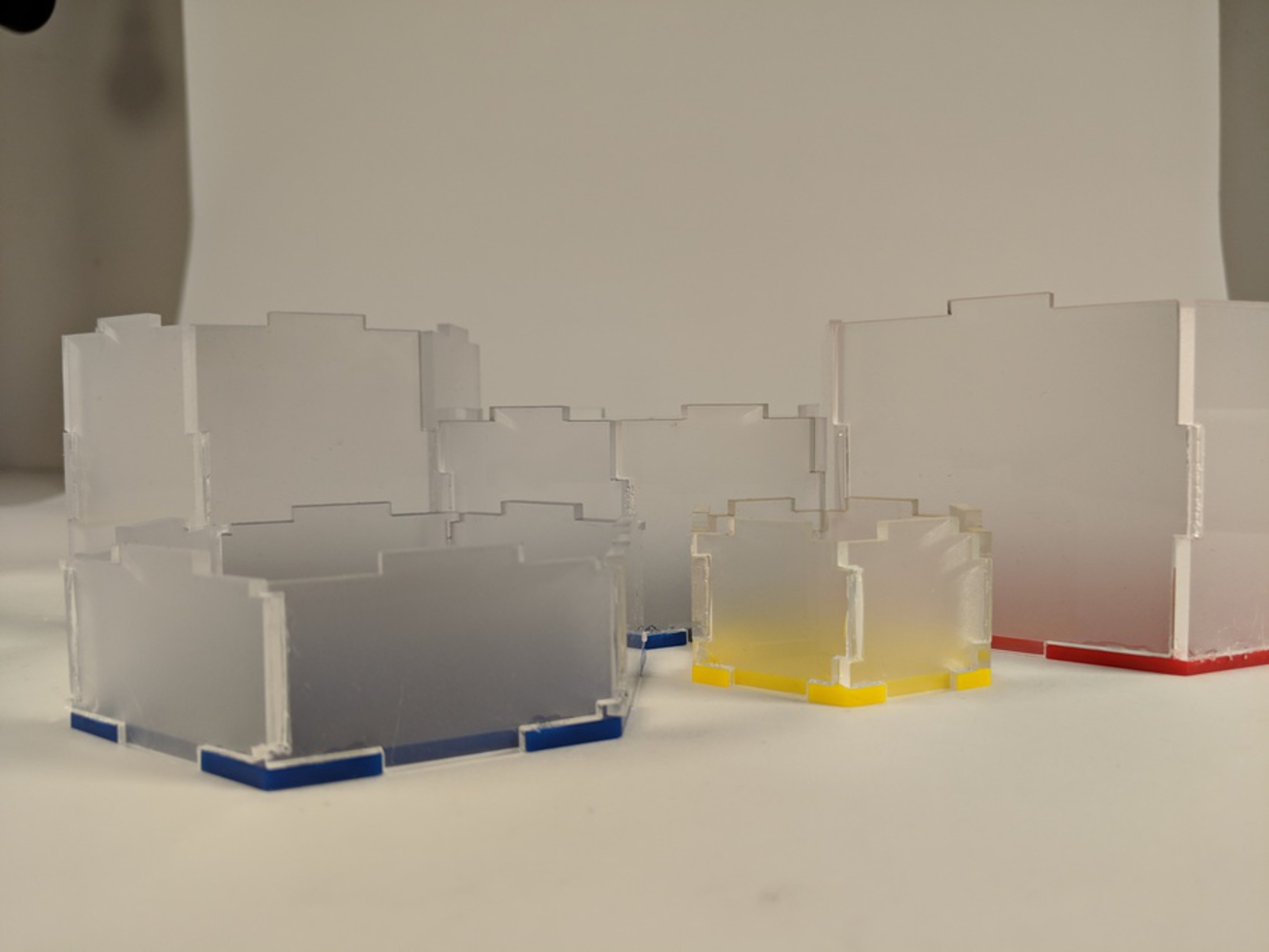

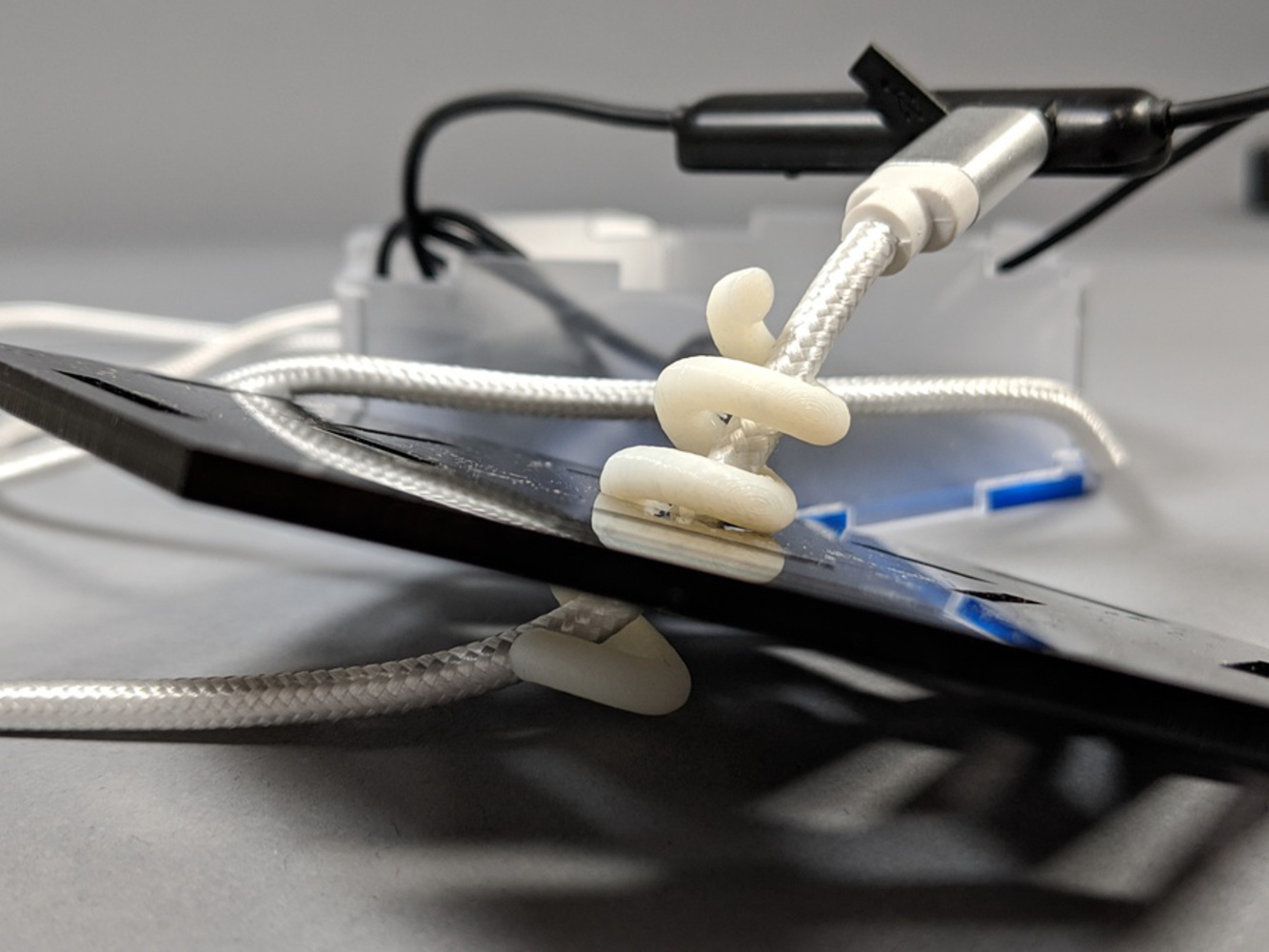

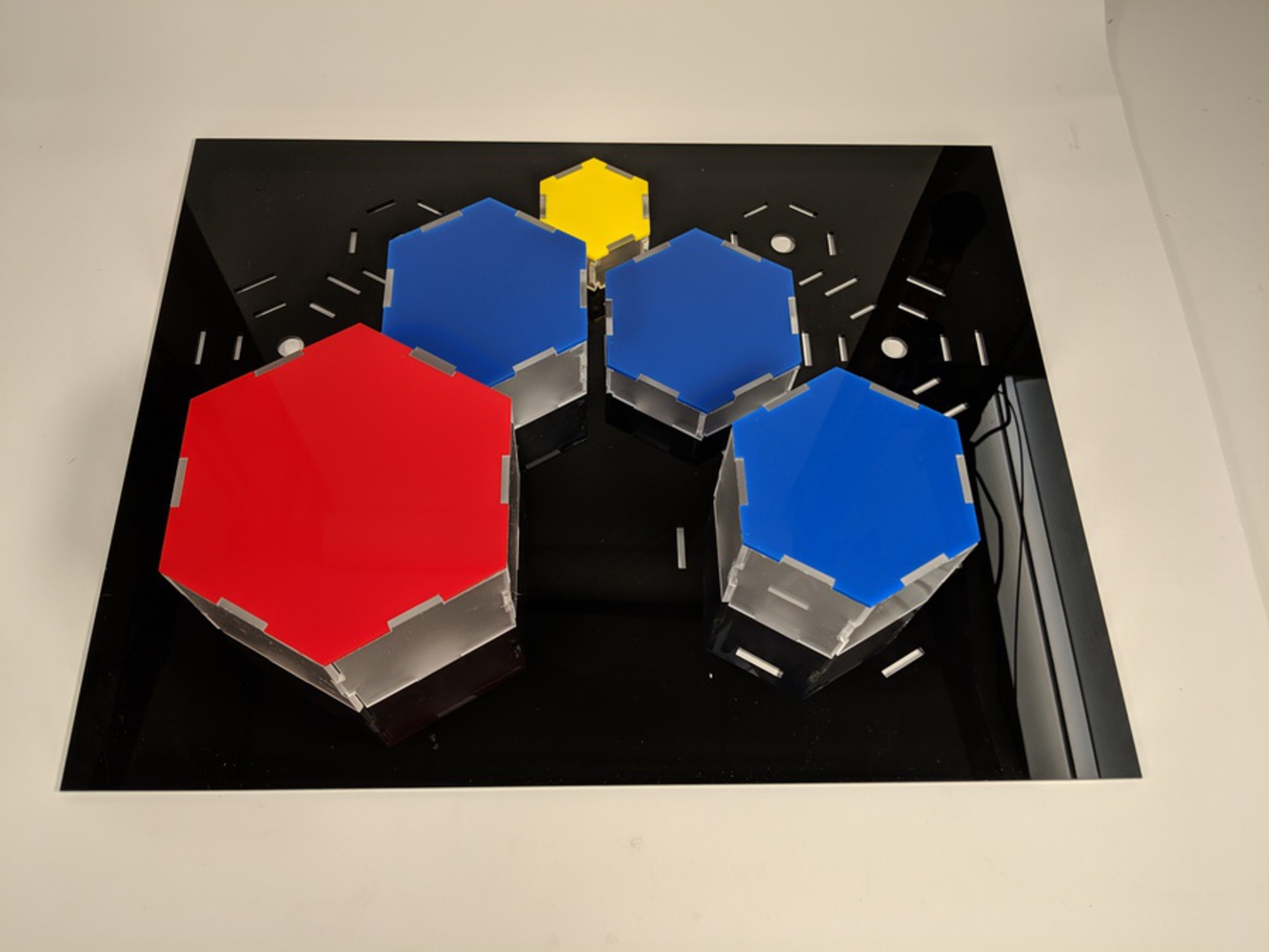

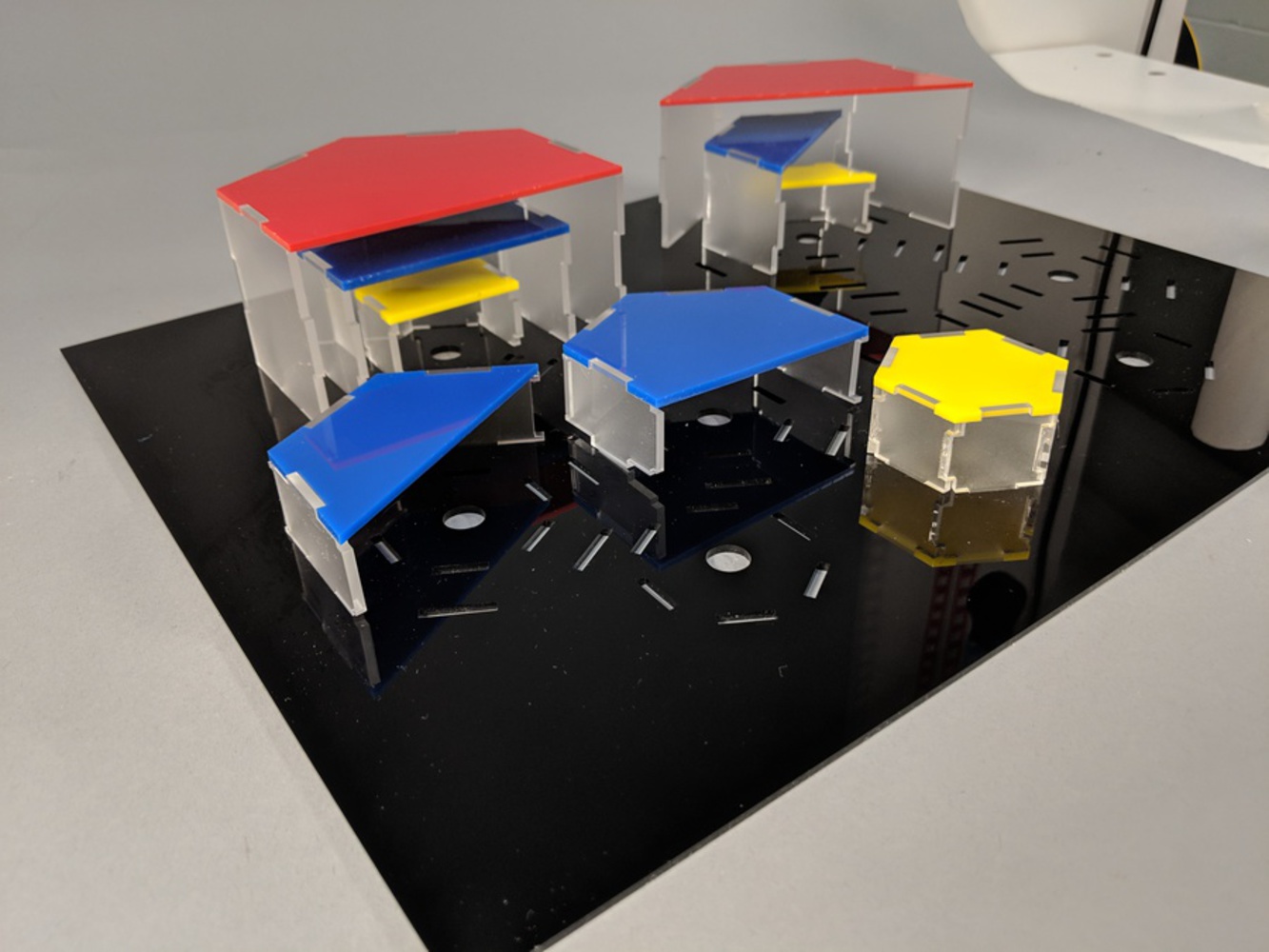

The purpose of the Small Charged Holder is to neatly organize each item into different compartments based on size but could adjust based on what kind of items that I currently own since I go through different earbuds every six months.