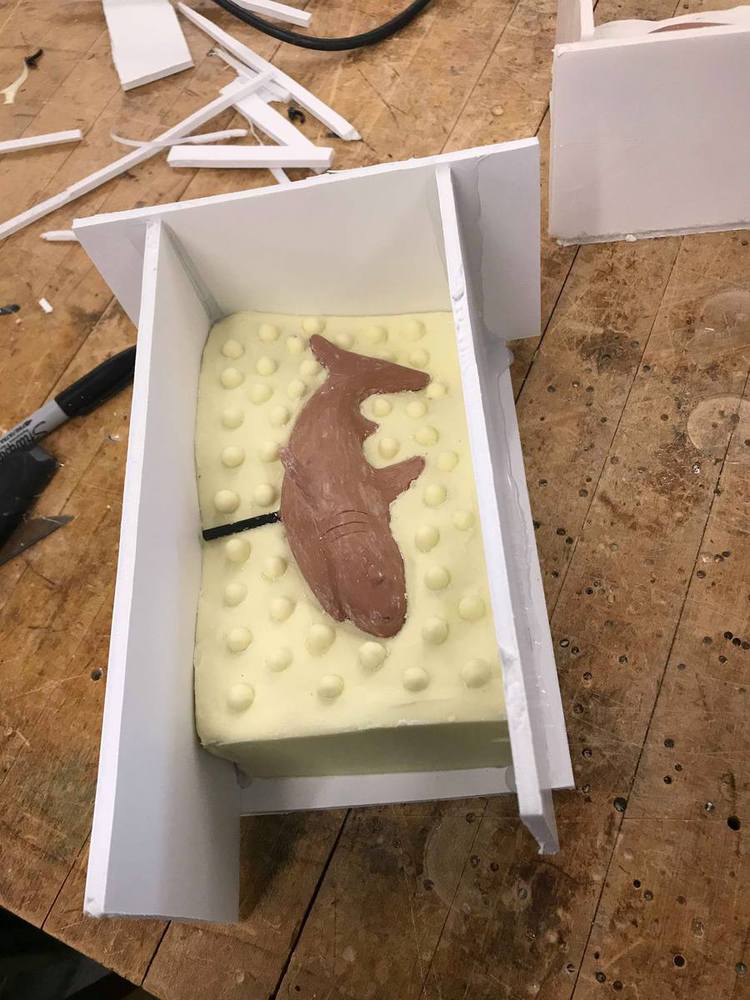

Prior to pouring any silicon for the first part of my mold, I tool my time molding the white clay around my clay shark to minimize any gaps at the parting line and to reduce any leakage.

After the first side was poured, when I was removing the clay I noticed there was some silicon that seeped through around the edges between the white clay and the clay shark. However, it seemed only to be at one point so it didn't effect the outcome of the mold at all and I was able to remove that extra silicon.

Also, when removing the white clay from around the clay shark it was a relatively slow and delicate process because it stuck to the surface of the shark and even pulled on of the fins off.