INTENTION

The goal of this project was to create a clock using the laser cutting skills and techniques taught in digiTool. I wanted something clean with high contrast--something that could fit into the decorum of any room.

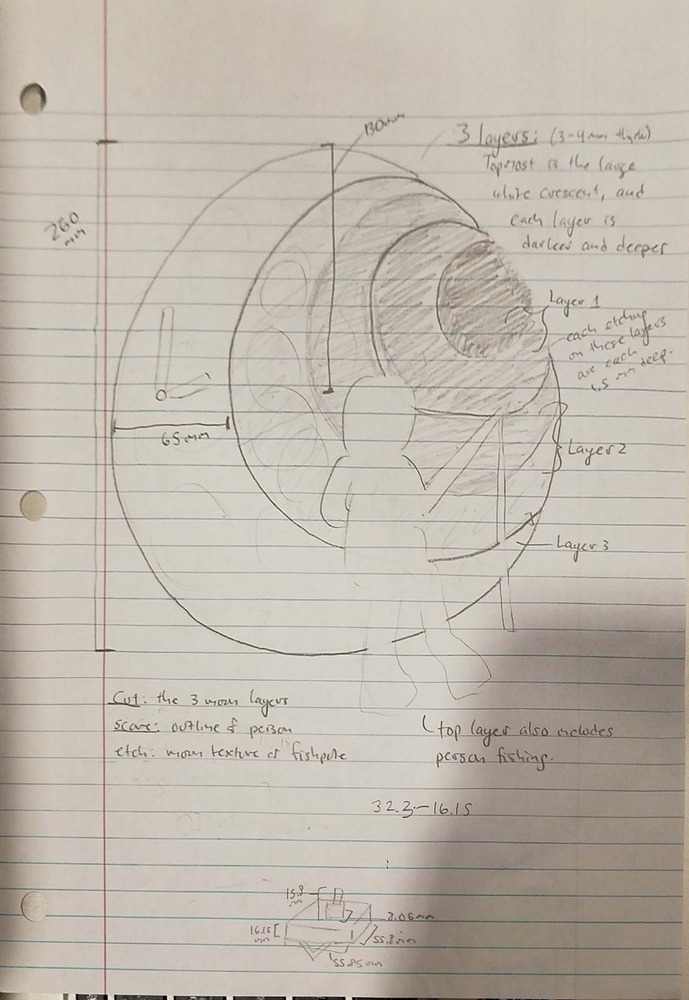

RESEARCH and SKETCH

When I create something, I try to do it from a place of identity. Being of a Muslim background, my go to aesthetic has always been crescent moons. So when the prompt of creating a clock was given, my initial idea was, of course, to create a clock made up of a crescent moon and three small stars. Something like below, which has the clock hands in the middle of the crescent.